Академический Документы

Профессиональный Документы

Культура Документы

SI 6VJRA 001 00 Eng - v1 - m56577569830769083

Загружено:

chandlerОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SI 6VJRA 001 00 Eng - v1 - m56577569830769083

Загружено:

chandlerАвторское право:

Доступные форматы

SI-6VJRA-001-00

General Safety Information

Specifications

Shifting lever

WARNING

Maintenance interval depends on the usage and riding circumstances. Clean regularly the

chain with an appropriate chaincleaner. Never use alkali based or acid based solvents such as

rust cleaners. If those solvent be used chain might break and cause serious injury.

Use the reinforced connecting pin only for connecting the narrow type of chain.

There are two different types of reinforced connecting pins available. Be sure to check the table below before selecting

which pin to use. If connecting pins other than reinforced connecting pins are used, or if a reinforced connecting pin or tool

which is not suitable for the type of chain is used, sufficient connection force may not be obtained, which could cause the

chain to break or fall off.

Chain

9-speed super narrow chain

such as

CN-7701 / CN-HG93

8- / 7- / 6-speed narrow

chain such as

CN-HG50 / CN-HG40

Cable securing and stroke adjustment

Reinforced

connecting pin

Model number

SL-RS36-7

Gears

SIS 7-gears

Silver

TL-CN32 / TL-CN27

Black

TL-CN32 / TL-CN27

SIS 6-gears

RD-TX75

RD-TX55

RD-TX35

RD-TZ50

Type

SGS

SGS

SGS

GS

GS

SS

GS

SS

Gears

7/6

7/6

7/6

RD-TY21

RD-TY18

43T

43T

43T

34T

34T

28T

34T

28T

28-34T

28-34T

28-34T

28T

28T

28T

28T

28T

Rear smallest sprocket

11T

11T

11T

14T

14T

14T

14T

14T

Front chainwheel tooth difference

20T

20T

20T

20T

20T

13T

20T

13T

Rear largest sprocket

Reinforced Connecting Pin

If it is necessary to adjust the length of the chain due to a change in the number of sprocket

teeth, make the cut at some other place than the place where the chain has been joined

using a reinforced connecting pin or an end pin. The chain will be damaged if it is cut at a

place where it has been joined with a reinforced connecting pin or an end pin.

Check that the tension of the chain is correct and that the chain is not damaged. If the

End Pin

Link Pin

tension is too weak or the chain is damaged, the chain should be replaced. If this is not

done, the chain may break and cause serious injury.

Check that the wheels are fastened securely before riding the bicycle. If the wheels are loose in any way, they may come

off the bicycle and serious injury may result.

Obtain and read the service instructions carefully prior to installing the parts. Loose, worn or damaged parts may cause

the bicycle to fall over and serious injury may occur as a result. We strongly recommend only using genuine Shimano

replacement parts.

Obtain and read the service instructions carefully prior to installing the parts. If adjustments are not carried out

correctly, the chain may come off and this may cause you to fall off the bicycle which could result in serious injury.

Read these Technical Service Instructions carefully, and keep them in a safe place for later reference.

Tooth combination (MF)

Tooth combination

(CS-HG20-7)

14, 16, 18, 20, 22, 24, 34T

14, 16, 18, 20, 22, 24, 28T

14, 16, 18, 21, 24, 34T

14, 16, 18, 21, 24, 28T

bp

12, 14, 16, 18, 21, 26, 32T

bm

12, 14, 16, 18, 21, 24, 28T

Gear shifting operation

Install the brake lever in a position where it will not obstruct brake

operation. Do not use in a combination which causes brake

operation to be obstructed.

Pedaling becomes

lighter

1

RD-TY21

4. How to use the B-tension adjustment screw

< RD-TX75 / RD-TX55 / RD-TX35 >

If routing the casing downward:

(The chain should be on the largest chainring and on the largest

sprocket.)

Set the length of the outer casing so that it describes a smooth

arc, and so that the link stops in a position where there is a small

gap between the link and the link stop.

max.

angle

Link

The reinforced connecting pins cannot be used with the UG chain, otherwise the connections will not move properly and

noise will occur.

If gear shifting operations do not feel smooth, wash the derailleur and lubricate all moving parts.

If the amount of looseness in the links is so great that adjustment is not possible, you should replace the derailleur.

You should periodically clean the derailleur and lubricate all moving parts (mechanism and pulleys).

If gear shifting adjustment cannot be carried out, check the degree of parallelism at the rear end of the bicycle. Also check

if the cable is lubricated and if the outer casing is too long or too short.

If you hear abnormal noise as a result of looseness in a pulley, you should replace the pulley.

If the wheel becomes stiff and difficult to turn, you should lubricate it with grease.

Do not apply any oil to the inside of the hub, otherwise the grease will come out.

You should periodically wash the sprockets in a neutral detergent and then lubricate them again. In addition, cleaning the

chain with neutral detergent and lubricating it can be a effective way of extending the useful life of the sprockets and the

chain.

If the chain keeps coming off the sprockets during use, replace the sprockets and the chain.

Use an outer casing which still has some length to spare even when the handlebars are turned all the way to both sides.

Furthermore, check that the shifting lever does not touch the bicycle frame when the handlebars are turned all the way.

Grease the inner cable and the inside of the outer casing before use to ensure that they slide properly.

Use a frame with internal cable routing is strongly discouraged as it has tendencies to impair the SIS shifting function due

to its high cable resistance.

Operation of the levers related to gear shifting should be made only when the front chainwheel is turning.

For smooth operation, use the specified outer casing and bottom bracket cable guide.

To ensure the best performance, be sure to use only the specified type of chain. The wide type chain cannot be used.

For maximum performance we highly recommend Shimano lubricants and maintenance products.

Parts are not guaranteed against natural wear or deterioration resulting from normal use.

For any questions regarding methods of installation, adjustment, maintenance or operation, please contact a professional

bicycle dealer.

Low adjustment

screw

RD-TX75 / TX55 / TX35

Largest

chainring

Chain position

Note

Outer casing

holder

Link

Mounting the shifting lever

max.

angle

Largest

sprocket

Gears

Guide pulley

RD-TZ50

If routing the casing upward:

(The chain should be on the largest chainring and

on the largest sprocket.)

Add 10 mm to the length of the outer casing from

the end that is inserted into the outer casing holder

to the end which is inserted into the link.

Chain position

Sprocket tooth configurations

RD-TY18

Largest

sprocket

Set the outer casing (RD-TX75/RD-TX55) so that its length is as

follows.

6.5mm

7.1mm

While turning the front chainwheel, operate the lever to shift to the lowest gear.

Turn the low adjustment screw so that the guide pulley moves to a position directly below

the largest sprocket.

Place the outer casing so that it does not touch the basket and

mudguard, otherwise it may cause a problem with the performance

of the derailleur.

Rear derailleur

Model number

Total capacity

Chain tool

< RD-TX75 / RD-TX55 >

SL-RS36-6

3. Low adjustment

Largest

sprocket

Largest

chainring

Largest sprocket

Smallest sprocket

Mount the chain on the smallest chainring and the

largest sprocket, and turn the crank arm backward.

Then turn the B-tension adjustment screw to adjust

the guide pulley as close to the sprocket as

possible but not so close that it touches. Next, set

the chain to the smallest sprocket and repeat the

above to make sure that the chain tension is

correct.

B-tension

adjustment screw

< RD-TZ50 >

In order to obtain suitable gear shifting

performance, set the chain onto the smallest

chainring and the largest sprocket. Then turn the B-tension adjustment screw to adjust so

that the distance between the tip of the freewheel and the tip of the guide pulley is about

10 mm. Next, set the chain onto the smallest sprocket and repeat the above to make sure

that the chain tension is correct.

Link stop

SIS Adjustment

Half grip

Operate the shifting lever several times to move the chain to the 2nd

sprocket. Then, while pressing the lever just enough to take up the

play in the lever, turn the crank arm.

Handlebar

Connect the inner cable to the

derailleur as shown in the illustration.

Pedaling becomes

heavier

Leave a gap of 0.5 mm between

the Revo-shift lever and the half grip.

Tightening torque:

2.6 Nm {23 in. lbs.}

3 mm Allen Key

Play

When shifting to 3rd

When no sound at all is

heard

adjustment

barrel

adjustment

barrel

Inner cable

Installation of the rear derailleur

Direct-mount type

Bracket type

Bracket nut

1. Top adjustment

Frame

5 mm Allen Key

Push in and tighten

Tightening torque:

8 - 10 Nm

{70 - 86 in. lbs.}

RD-TX75/55

RD-TX75/55

Turn the top adjustment screw to adjust so that the guide pulley is

below the outer line of the smallest sprocket when looking from the

rear. After this, install the chain.

Tightening torque:

3 - 4 Nm

{26 - 34 in. lbs.}

Bracket bolt

RD-TX35/TZ50/TY21

Outer line of

smallest sprocket

Bracket

RD-TY18

Do not use RD-TZ50-GS for bicycles with small wheels having a diameter of 20 inches or less, otherwise the rear

derailleur may touch the wheel or the road surface.

RD-TX35/TZ50/TY21

Tighten the outer cable adjusting barrel

until the chain returns to the 2nd sprocket.

(clockwise)

Loosen the outer casing adjustment barrel

until the chain touches the 3rd sprocket

and makes noise. (counter clockwise)

Top adjustment

screw

Guide pulley

RD-TZ50

Installation of the freewheel

Technical Service Instructions

SI-6VJRA-001

< MF >

For installation of the HG

sprockets, use the special tool

(TL-LR15 / LR10) to tighten the

lock ring.

Freewheel removal tool

TL-FW30

Rear Drive System

To disassemble

Assembly

Gears

Shifting lever (Right)

Tourney (MEGARANGE)

7-gears

6-gears

7-gears

6-gears

SL-RS36-7R

SL-RS36-6R

SL-RS36-7R

SL-RS36-6R

RD-TX75/

RD-TX55/

RD-TX35

RD-TX75/

RD-TX55/

RD-TX35

RD-TX75/

RD-TX55/

RD-TX35

MF-TZ31/

MF-TZ31-CP

MF-TZ30/

MF-TZ30-CP

MF-HG37/MF-TZ21/

MF-TZ21-CP/

CS-HG20-7

Outer casing

Rear derailleur

Freewheel

Chain

Bottom bracket cable guide

TL-LR15 / LR10

Tightening torque:

30 - 50 Nm {261 - 434 in. lbs.}

Tourney (SIS)

OT-SIS40

OT-SIS40

RD-TX75/RD-TX55/

RD-TX35/RD-TZ50/

RD-TY21/RD-TY18

MF-TZ20/

MF-TZ20-CP

CN-UG51 / CN-HG40

CN-UG51 / CN-HG40

SM-SP18

SM-SP18

For each sprocket, the surface that

has the group mark should face

outward and be positioned so that

the triangle (U) mark on each

sprocket and the A part (where the

groove width is wide) of the

freewheel body are aligned.

A

* Return the lever to its original position (the position where the lever is at

the 2nd sprocket setting and it has been released) and then turn the

crank arm clockwise. If the chain is touching the 3rd sprocket and making

noise, turn the outer casing adjustment barrel clockwise slightly to tighten

it until the noise stops and the chain runs smoothly.

RD-TX75 / TX55 / TX35

2. Connection and securing of cable

Connect the cable to the rear derailleur and, after taking up the initial

slack in the cable, reattach to the rear derailleur as shown in the

illustration.

Secure the cable by pulling it with pliers with a force of 5 - 10 kg.

Tightening torque:

30 Nm {260 in. lbs.}

In order to realize the best performance, we recommend that the following combination be used.

Series

The best setting is when the shifting lever is operated just enough to take

up the play and the chain touches the 3rd sprocket and makes noise.

RD-TY21

To install

Tightening torque:

5 - 7 Nm {44 - 60 in. lbs.}

< CS-HG20-7 >

To replace the HG sprockets, use

the special tool (TL-LR15 / LR10)

and TL-SR21 to remove the lock

ring.

Best setting

Operate lever to change gears, and check that no noise occurs in any of the gear

positions.

For the best SIS performance, periodically lubricate all power-transmission parts.

Note:

Be sure that the cable is

securely in the groove.

Replacing the inner cable

Pull

1. Operate the shifter to set it to the top position. Loosen

Groove

the screws at point A and B with a screw driver in order

to remove the cover.

1

The groove is wide at one place

only.

ac -14T

2. Replace the inner cable by carrying out steps 1 to 3 as

Lock ring

shown in the illustrations.

Inserting the inner cable

U mark

TL-LR15 / LR10

Tool

(TL-SR21)

Disassembly

Insert the inner cable into the outer casing from the end with the

marking on it. Apply grease from the

end with the marking in order to

maintain cable operating efficiency.

Marking

This service instruction explains how to use and maintain the Shimano bicycle parts which have been used on your new

bicycle. For any questions regarding your bicycle or other matters which are not related to Shimano parts, please contact

the place of purchase or the bicycle manufacturer.

Cutting the outer casing

Chain length

< GS, SGS >

Largest

sprocket

Largest

chainring

< SS >

Smallest

sprocket

Add 2 links (with the chain on

both the largest sprocket and

the largest chainring)

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222

3-77 Oimatsu-cho, Sakai-ku, Sakai-shi, Osaka 590-8577, Japan

Please note: specifications are subject to change for improvement without notice. (English) Jul. 2011 by Shimano Inc. XBC IZM Printed in Singapore.

When cutting the outer casing, cut the opposite

end to the end with the marking. After cutting the

outer casing, make the end round so that the

inside of the hole has a uniform diameter.

3

Chain

Guide pulley

* Service Instructions in further languages are available at : http://techdocs.shimano.com

Largest

chainring

Chain

Tension pulley

90

Right angle to the ground

Attach the same outer end

cap to the cut end of the

outer casing.

Outer end cap

Вам также может понравиться

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsОт EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsРейтинг: 5 из 5 звезд5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- rd-m592 2Документ1 страницаrd-m592 2faizgpОценок пока нет

- Shimano XTДокумент1 страницаShimano XTVennia PapadipoulouОценок пока нет

- Shimano Tourney Rear and Knob AdjustmentДокумент1 страницаShimano Tourney Rear and Knob AdjustmentNiraj SuroopjeetОценок пока нет

- SI 5VV0B en v1 m56577569830604982Документ1 страницаSI 5VV0B en v1 m56577569830604982iodinОценок пока нет

- Shimano 105 5700 Rear Derailleur Installation ManualДокумент2 страницыShimano 105 5700 Rear Derailleur Installation ManualjjjОценок пока нет

- SI-5TK0D-En v1 m56577569830603908Документ1 страницаSI-5TK0D-En v1 m56577569830603908dcduquОценок пока нет

- DL RD m760 2 PDFДокумент1 страницаDL RD m760 2 PDFtudor-72Оценок пока нет

- Manuale Cambio ShimanoДокумент1 страницаManuale Cambio ShimanoPaola CapassoОценок пока нет

- Alivio Front Drive SI-6KFFA - v1 - m56577569830565035Документ1 страницаAlivio Front Drive SI-6KFFA - v1 - m56577569830565035setze16setze16Оценок пока нет

- SI 6PZRA 003 ENG - v1 - m56577569830677284Документ1 страницаSI 6PZRA 003 ENG - v1 - m56577569830677284lirch5Оценок пока нет

- Shimano AlivioДокумент1 страницаShimano AlivioBrent MitchellОценок пока нет

- For Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire LeverДокумент3 страницыFor Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire Leverlirch5Оценок пока нет

- ShimanoДокумент1 страницаShimanoProto Popescu VictorОценок пока нет

- Shimano XTR M980 Shift Lever Set ManualДокумент4 страницыShimano XTR M980 Shift Lever Set ManualNick SpeisОценок пока нет

- SH Cset m151 Front Chainwheel FC-M151Документ2 страницыSH Cset m151 Front Chainwheel FC-M151Ingrid VantaОценок пока нет

- Si F570CДокумент1 страницаSi F570CmegclayОценок пока нет

- SI-0087A-001-ENG - v1 - m56577569830657743 Technical Service InstructionsДокумент1 страницаSI-0087A-001-ENG - v1 - m56577569830657743 Technical Service InstructionsIngrid VantaОценок пока нет

- SI F920A ShimanoДокумент7 страницSI F920A ShimanoolligesОценок пока нет

- Disc BrakeДокумент1 страницаDisc BrakepahelwanОценок пока нет

- Shimano Ultegra 6700 Shifters Double Owners ManualДокумент2 страницыShimano Ultegra 6700 Shifters Double Owners ManualTimОценок пока нет

- MTB Technology: FRONT CHAINWHEEL: InstallationДокумент4 страницыMTB Technology: FRONT CHAINWHEEL: InstallationRoy Chung Qi Huan100% (1)

- Inter BrakeДокумент1 страницаInter BrakedovlikusОценок пока нет

- CB E110 enДокумент1 страницаCB E110 enandОценок пока нет

- DM FD0001 00 EngДокумент29 страницDM FD0001 00 EngpietouОценок пока нет

- Maintenance Troubleshooting GuideДокумент28 страницMaintenance Troubleshooting Guidenordsmendoza100% (1)

- 6jr0a enДокумент0 страниц6jr0a enBilly GeorgiouОценок пока нет

- Shimano Bottom Bracket SM-BB6700Документ1 страницаShimano Bottom Bracket SM-BB6700tspinner19Оценок пока нет

- Bike Service PresentationДокумент14 страницBike Service PresentationOnkar RathodОценок пока нет

- Martin Maintenance Anf Troubleshooting GuideДокумент28 страницMartin Maintenance Anf Troubleshooting GuidesuperalitosОценок пока нет

- Shimano Inter-M BR-IM31-R Brakes Service InstructionsДокумент1 страницаShimano Inter-M BR-IM31-R Brakes Service InstructionsJon_Bramley_3524Оценок пока нет

- DM Cn0001 00 Eng (Cadena)Документ8 страницDM Cn0001 00 Eng (Cadena)Mauricio Isaias LargaespadaОценок пока нет

- Cassette Sprocket: Dealer's ManualДокумент15 страницCassette Sprocket: Dealer's ManualrajaОценок пока нет

- Manutenzione CatenaДокумент22 страницыManutenzione CatenaRosa TorreОценок пока нет

- DM FC0003 03 EngДокумент15 страницDM FC0003 03 EngJosko SpehОценок пока нет

- Startrac Spinner Chain MaintenanceДокумент5 страницStartrac Spinner Chain Maintenanceu795992Оценок пока нет

- Shimano MTB Rear Deraileur Dealer Manual PDFДокумент24 страницыShimano MTB Rear Deraileur Dealer Manual PDFJose Luis GutierrezОценок пока нет

- Shimano WH R 600Документ1 страницаShimano WH R 600AHSetiawanОценок пока нет

- Bicycle Engine Kit Installation Guide - Raw 80ccДокумент9 страницBicycle Engine Kit Installation Guide - Raw 80ccSokitome0% (1)

- Tensioner Training PresentationДокумент29 страницTensioner Training Presentationaravindan476Оценок пока нет

- DiaTech Hombre Rear U-Brake InstallДокумент3 страницыDiaTech Hombre Rear U-Brake InstallfgfgjlfnglkОценок пока нет

- SI 3TF0A 001 00 Eng - v1 - m56577569830732611Документ1 страницаSI 3TF0A 001 00 Eng - v1 - m56577569830732611Yutt WattОценок пока нет

- Steering Axle: Safety Precautions Maintenance and RepairДокумент9 страницSteering Axle: Safety Precautions Maintenance and RepairPhilip Peter HanssenОценок пока нет

- Rear Derailleur: Dealer's ManualДокумент41 страницаRear Derailleur: Dealer's ManualNicky KiloОценок пока нет

- If-Nt: General Safety InformationДокумент1 страницаIf-Nt: General Safety InformationJackson MeloОценок пока нет

- Maintenance ScheduleДокумент16 страницMaintenance ScheduleSiska0806Оценок пока нет

- V - Belt BandoДокумент12 страницV - Belt BandoEko Wibowo100% (1)

- 01 Rock Shox Judy Owners ManualДокумент7 страниц01 Rock Shox Judy Owners ManualakjasonОценок пока нет

- Chain Installation and Maintenance Instructions: Cutting & Riveting Instructions For D.I.D KM500R and KM501E ToolsДокумент4 страницыChain Installation and Maintenance Instructions: Cutting & Riveting Instructions For D.I.D KM500R and KM501E ToolsKonstantinosTavernierОценок пока нет

- V-Belt and Timing Belt Installation and Maintenance: SERVICE EXPRESS 1-800-829-6612Документ11 страницV-Belt and Timing Belt Installation and Maintenance: SERVICE EXPRESS 1-800-829-6612yeop03100% (1)

- SR Suntour XC Pro Forks Instructions ManualДокумент8 страницSR Suntour XC Pro Forks Instructions Manual110972ryanОценок пока нет

- Traxxas Revo Slipper RebuildДокумент1 страницаTraxxas Revo Slipper RebuildbernadysroseОценок пока нет

- Bike Service Present-2Документ11 страницBike Service Present-2Onkar RathodОценок пока нет

- Track Chain Removal and AssemblyДокумент12 страницTrack Chain Removal and AssemblyAaron MulengaОценок пока нет

- Avid User Manual Bb7Документ2 страницыAvid User Manual Bb7Elizabeth Soares BourneОценок пока нет

- Motokolo Manual001 Rev AДокумент18 страницMotokolo Manual001 Rev AViktor BurkertОценок пока нет

- Owners Manual Judy 2000Документ6 страницOwners Manual Judy 2000groening1993Оценок пока нет

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingОт EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingРейтинг: 4.5 из 5 звезд4.5/5 (9)

- T Mu Am 02002 Ti - 3Документ42 страницыT Mu Am 02002 Ti - 3jesus_yustasОценок пока нет

- Abs Electrical PDFДокумент361 страницаAbs Electrical PDFCharles SteblinaОценок пока нет

- Desert Bus Iveco Eurocargo Deniz ModelДокумент1 страницаDesert Bus Iveco Eurocargo Deniz ModelkamilОценок пока нет

- Bliss Hair and BeautyДокумент1 страницаBliss Hair and BeautyDigital MediaОценок пока нет

- Bristol Airport, Stop 22 - Bus and Coach Park 20:05 DepartureДокумент4 страницыBristol Airport, Stop 22 - Bus and Coach Park 20:05 DepartureAidaОценок пока нет

- Converter Lining CatalogДокумент76 страницConverter Lining CatalogMarianoОценок пока нет

- 2014-02 PP Transport Heavyweights North America enДокумент36 страниц2014-02 PP Transport Heavyweights North America enTh NattapongОценок пока нет

- Unit 8 - ListeningДокумент9 страницUnit 8 - ListeningPD Hoàng0% (4)

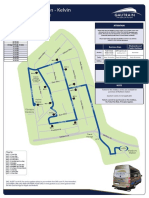

- Marlboro Station - Kelvin Midibus Service: R10 Per TripДокумент1 страницаMarlboro Station - Kelvin Midibus Service: R10 Per TripRudy PentyОценок пока нет

- Introduction To ITS: Prof. Omer MaaitahДокумент49 страницIntroduction To ITS: Prof. Omer Maaitahrio_harcanОценок пока нет

- 199995Документ359 страниц199995Elieser SinagaОценок пока нет

- Oman Roads and Bridges Project Snapshot: Batinah Coastal Road - Phase 2Документ4 страницыOman Roads and Bridges Project Snapshot: Batinah Coastal Road - Phase 2ScribdInOmanОценок пока нет

- Cycling MapДокумент2 страницыCycling MapMarek E. LewandowskiОценок пока нет

- Dvsa Drivers Record PDFДокумент7 страницDvsa Drivers Record PDFunjohОценок пока нет

- Rticulated UMP Ruck: Net HorsepowerДокумент12 страницRticulated UMP Ruck: Net HorsepowerOnar BagusОценок пока нет

- Lab 3 Road Skid ResistanceДокумент9 страницLab 3 Road Skid ResistanceAmar AizadОценок пока нет

- CMLP Land Use Policy DocumentДокумент201 страницаCMLP Land Use Policy DocumentLuke PsailaОценок пока нет

- Eagle Army Air Field (1942)Документ15 страницEagle Army Air Field (1942)CAP History LibraryОценок пока нет

- Sweet Bird SouthДокумент43 страницыSweet Bird SouthNone None None100% (2)

- Thesis FinalДокумент37 страницThesis FinalCharles LacreemaОценок пока нет

- Chapter 3 Elements of Cross-Section Lecture2 PDFДокумент19 страницChapter 3 Elements of Cross-Section Lecture2 PDFRabin DhakalОценок пока нет

- CJP & PJP WeldsДокумент3 страницыCJP & PJP WeldsL095244Оценок пока нет

- ARMP Manual 2017Документ42 страницыARMP Manual 2017Ram NepaliОценок пока нет

- BCE 412 LAYUPAN Transportation EvaluationДокумент2 страницыBCE 412 LAYUPAN Transportation EvaluationChristopher Toff LayupanОценок пока нет

- VilniusДокумент100 страницVilniusPedro José Soto AledoОценок пока нет

- Basic Security Duties and ReponsibilitiesДокумент10 страницBasic Security Duties and ReponsibilitiesFerdinand Camilo Carnaje Kimura100% (7)

- Pneumatic Speed Breaker With Day Night Control (PSB)Документ40 страницPneumatic Speed Breaker With Day Night Control (PSB)Giri TharanОценок пока нет

- NTDP Executive Summary PDFДокумент13 страницNTDP Executive Summary PDFBlincentОценок пока нет

- Delhi Road Transport Taxi FareДокумент3 страницыDelhi Road Transport Taxi FareKutuk TimmiОценок пока нет