Академический Документы

Профессиональный Документы

Культура Документы

Apresentação Regulus PDF

Загружено:

ricardoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Apresentação Regulus PDF

Загружено:

ricardoАвторское право:

Доступные форматы

Putting You In Control

HeadquartersExport, Pennsylvania, USA

Basingstoke, United Kingdom

Houston, Texas, USA

Jubail, Kingdom of Saudi Arabia

Los Angeles, California, USA

With this easy-to-use, multifaceted system, plant operators

compressor is preferred directly through the DCS, FS-Elliotts

Mangalore, India

are empowered to master one of a facilitys highest operating

team is ready to assist with the integration solution including

Sao Paulo, Brazil

expensesenergy costs. Savings are achieved through the

instrumentation and control logic development. Optional

Shanghai, China

REGULUS operating systems superior pressure control

redundant and fail safe systems can also be incorporated

Taipei, Taiwan

capability, thereby eliminating excessive air blow-offs to

into the REGULUS package for end users preferring these

the atmosphere while efficiently responding to the facilitys

addedfeatures.

changing air demands.

The REGULUS Sequencer is an additional FS-Elliott control

Building on a 50-year tradition of excellence in compressor design and manufacturing,

This proven Programmable Logic Controller (PLC) based

system enhancements for facilities that require multiple

FS-Elliott brings our customers the resources of a global industry leader along with the convenience

system is designed with leading-edge technology processors

unit control and total system administration. This user-

and memory capabilities providing performance, reliability and

friendly system includes advanced energy management

and responsiveness of local sales and service. Thousands of reliable, hard-working FS-Elliott

convenience. At the touch of the Human Machine Interface

capabilities that simultaneously control multiple centrifugal

(HMI), the operator dictates how REGULUS monitors,

air compressors. Supervisory functions include monitoring

controls and manages all of the air compressor systems

numerous system components such as cooling towers, dryers,

needs. Plant operators can perform these functions locally

pumps, motor control centers and other auxiliary equipment.

or from a remote location. The REGULUS information

management function stores operating data that can be used

for analysis and preventative maintenance. This historical

information is a valuable asset, enabling engineers to identify

compressors are installed worldwide.

Whatever the need, FS-Elliotts engineering staff has the

know-how to meet and exceed your requirements with a

REGULUS Control System.

and avert potential problems. A serial port allows interface

communication between the REGULUS Control System and

FS-Elliott Co., LLC

the Users Distributed Control System (DCS). If control of the

5710 Mellon Road

Precise System Control With Energy Savings And Simplicity

Energy Savings

Simplicity

Experience the REGULUS control systems energy

savings features and realize the profitability benefits from

day number one.

Discover the simplicity of the REGULUS control system

together with the outstanding operational benefits it

delivers to your facility.

Precise air system pressure control

All control set points from one interface

Maximizes turndown capability and energy savings

Numerous language display capabilities

Advanced adaptive controller permits protected

operation closer to actual surge resulting in energy

savings

Multiple choices of communication protocols with

interfacing systems

Innovative adjustable inlet guide vane design

maximizes efficiency at off design operations

Suction Throttle and Auto-Dual control modes add

operational flexibility and efficiency

Multiple compressor unit energy management capability

Supervisory capabilities include monitoring the

entire air system from one location

Data storage and trend viewing are instantaneously

available with the touch of the finger

The compressor can virtually run unattended

at optimum efficiency through various plant air

demand conditions

Export, PA 15632-8948

724.387.3200 tel

724.387.3270 fax

info@fs-elliott.com email

Represented by:

www.fs-elliott.com

ISO 9001-certified for the

design and manufacture of

centrifugal compressors.

FS-Elliott Co., LLC reserves the right to modify the

design or construction of the equipment described

in this brochure and to furnish it, as altered,

without further reference to the illustrations or

information contained herein.

Bulletin FSP78-713

FS-Elliott Co., LLC 2013

REGULUS: The Quality is Built-in,

The Performance is Superior

Designed & Built to Exceed Expectations

The REGULUS Control System Series Consists of Four Models: R150, R200, R300 and R400

The REGULUS Control System includes a comprehensive group of standard

features. In addition, FS-Elliott offers an extensive number of hardware

options that enable you to configure the system to accommodate your

specific needs. These features have been pre-engineered to maintain

FS-Elliotts control systems have been a fundamental part of our equipment

standardization and minimize the cost and delivery impact.

packages since the very first compressor was shipped more than half a century

NEMA 4 and NEMA 4X control cabinets are available in carbon and

ago. Thousands of our control systems are operating at high levels of excellence

stainless steel materials of construction.

in facilities located around the globe. It is this incredible depth of experience that

The REGULUS control system is driven by the most current Siemens

has earned FS-Elliott the reputation as the premier provider of reliable control

Control panel cooling modes can be provided with single or dual

and Allen Bradley Programmable Logic Controllers (PLC).

vortex and air conditioning units.

technology for centrifugal compressors. Today, every FS-Elliott air compressor has

Large touch screen HMIs for operator ease-of-use.

at its heart one of our advanced REGULUS Control Systems.

Communication capabilities include Modbus, Profibus, Ethernet and

Teleservice. Remote diagnostics options are also available.

Available heater devices ensure cabinet component reliability in the

harshest environments.

The REGULUS has expansive Input / Output (I/O) module

capabilities. Sensing instrumentation input is processed to provide

precise output signals to control devices located in the main air and

auxiliary systems.

Air system operational information and set point data is easily stored

on a large capacity memory flash card for future reference and

downloading to a computer.

A conveniently located USB port is provided to access the REGULUS

Control System.

Modbus is a registered trademark of Schneider Automation, Inc.

The REGULUS Control System enables operators to

manage air compressor operation with an easy to use yet

powerful interface. FS-Elliott offers training programs

that include compressor functions and settings to obtain

optimum performance.

Innovative Solutions For Todays Applications

Industrial Series

Engineered Series

Typical Industrial Series installations include food and

For those applications requiring customized solutions, the

beverage, automotive manufacturing, pharmaceuticals,

REGULUS Engineered Series is the control system of choice.

electronic component manufacturing, mining, textiles and

Our Engineered Series systems can be found in everyday use

many others. The base model R150 includes a powerful

within world-scale Oil & Gas Production, Refining, Chemical

PLC packaged with control and monitoring features that are

and Petrochemical facilities. The R300 includes additional

Many air compressor operators have specialized needs that require customized solutions. FS-Elliotts staff has the depth and know-

considered optional items on comparable systems. The R150

I/O modules to accommodate installations with increased

how to meet the most challenging control applications. The optional REGULUS is a testimonial to the expertise, flexibility and

also includes a Liquid Crystal Display (LCD) touch screen and

analog and digital input and output requirements. The R300

reliability that is fundamental to our customer focused marketing approach.

multiple language capability. Networking communication

features an easy to operate HMI touch screen with a Thin Film

protocol capabilities include Ethernet and Modbus.

Transistor (TFT) color graphic display.

The R200 features include an enhanced PLC and additional

Simply said, the R400 is adaptable to any compressor

Input/Output (I/O) capacity that increase the base models

system application. In addition to having the most

capabilities and provide for an expanded list of optional items.

powerful processor available, the R400s flexibility easily

The R200s larger memory provides for advanced trending

accommodates the most complex system requirements. The

and diagnostics while still maintaining the cost benefits of a

R400 capabilities include dual redundancy, multiple voting

standardized design.

and custom software development.

REGULUS Sequencer

With the addition of the REGULUS Sequencer package, plant operators have the ability to incorporate the most comprehensive

master controller available for multiple compressors. The REGULUS Sequencers unique control methodology assures that

each compressor in the system shares the load against total system demand in the most energy efficient manner. This exclusive

control scheme provides energy savings by making certain that all of the compressors utilize their full turndown capability before

unloading air to the atmosphere. The capabilities also include time-sharing functions and automatic run time equalization.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- THM07 Module 2 The Tourist Market and SegmentationДокумент14 страницTHM07 Module 2 The Tourist Market and Segmentationjennifer mirandaОценок пока нет

- Café Management System Full and Final ReportДокумент18 страницCafé Management System Full and Final ReportMuhammad Xalman Xhaw100% (3)

- Floating PonttonДокумент9 страницFloating PonttonToniОценок пока нет

- The Nation State and Global Order A Historical Introduction To ContemporaryДокумент195 страницThe Nation State and Global Order A Historical Introduction To Contemporaryrizwan.mughal1997100% (1)

- Back WagesДокумент24 страницыBack WagesfaisalfarizОценок пока нет

- Women in IslamДокумент22 страницыWomen in Islamsayed Tamir janОценок пока нет

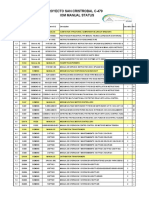

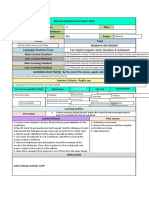

- Proyecto San Cristrobal C-479 Iom Manual StatusДокумент18 страницProyecto San Cristrobal C-479 Iom Manual StatusAllen Marcelo Ballesteros LópezОценок пока нет

- 47 Vocabulary Worksheets, Answers at End - Higher GradesДокумент51 страница47 Vocabulary Worksheets, Answers at End - Higher GradesAya Osman 7KОценок пока нет

- Chapter 2 Demand (ECO415)Документ28 страницChapter 2 Demand (ECO415)hurin inaniОценок пока нет

- 3RD Last RPHДокумент5 страниц3RD Last RPHAdil Mohamad KadriОценок пока нет

- Effect of Perceived Work Environment On Employees' Job Behaviour and Organizational EffectivenessДокумент10 страницEffect of Perceived Work Environment On Employees' Job Behaviour and Organizational EffectivenessTanvee SharmaОценок пока нет

- 08-20-2013 EditionДокумент32 страницы08-20-2013 EditionSan Mateo Daily JournalОценок пока нет

- Independence of Costa RicaДокумент2 страницыIndependence of Costa Ricaangelica ruizОценок пока нет

- Bed BathДокумент6 страницBed BathKristil ChavezОценок пока нет

- PFASДокумент8 страницPFAS王子瑜Оценок пока нет

- Glint 360 Design GuideДокумент2 страницыGlint 360 Design GuidebОценок пока нет

- D3Документ2 страницыD3zyaОценок пока нет

- Ogl 350 Paper 2Документ5 страницOgl 350 Paper 2api-672448292Оценок пока нет

- RS485 Soil 7in1 Sensor ES SOIL 7 in 1 Instruction ManualДокумент15 страницRS485 Soil 7in1 Sensor ES SOIL 7 in 1 Instruction ManualĐoàn NguyễnОценок пока нет

- The Syllable: The Pulse' or Motor' Theory of Syllable Production Proposed by The Psychologist RДокумент6 страницThe Syllable: The Pulse' or Motor' Theory of Syllable Production Proposed by The Psychologist RBianca Ciutea100% (1)

- Kami Export - Tools in Studying Environmental ScienceДокумент63 страницыKami Export - Tools in Studying Environmental ScienceBenBhadzAidaniOmboyОценок пока нет

- Geotagging ManualДокумент93 страницыGeotagging ManualAlthea AcasОценок пока нет

- Campus Design: School of Architecture & Planning at PondicherryДокумент9 страницCampus Design: School of Architecture & Planning at Pondicherrynadhir sulaimanОценок пока нет

- English Unit 7 MarketingДокумент21 страницаEnglish Unit 7 MarketingKobeb EdwardОценок пока нет

- AN6001-G16 Optical Line Terminal Equipment Product Overview Version AДокумент74 страницыAN6001-G16 Optical Line Terminal Equipment Product Overview Version AAdriano CostaОценок пока нет

- English 4 First Mid-Quarter Review TestДокумент24 страницыEnglish 4 First Mid-Quarter Review TestAivy Ylanan100% (1)

- Duck 2019Документ52 страницыDuck 2019Adrian BAGAYANОценок пока нет

- Sociology of Arts & HumanitiesДокумент3 страницыSociology of Arts & Humanitiesgayle gallazaОценок пока нет

- 130004-1991-Maceda v. Energy Regulatory BoardДокумент14 страниц130004-1991-Maceda v. Energy Regulatory BoardChristian VillarОценок пока нет

- Ips Rev 9.8 (Arabic)Документ73 страницыIps Rev 9.8 (Arabic)ahmed morsyОценок пока нет