Академический Документы

Профессиональный Документы

Культура Документы

GTU MECHATRONICS SYLLABUS

Загружено:

pmagrawalОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GTU MECHATRONICS SYLLABUS

Загружено:

pmagrawalАвторское право:

Доступные форматы

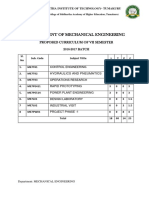

GUJARAT TECHNOLOGICAL UNIVERSITY

MECHANICAL (CAD/CAM) (08)/ MECHANICAL (MACHINE

DESIGN) (09)

MECHATRONICS

SUBJECT CODE: 2710809

M.E. 1st SEMESTER

Type of course: Engineering Science

Prerequisite: Zeal to learn the subject

Rationale: This syllabus is formed to create knowledge in Mechatronic systems and impart the

source of concepts and techniques, which have recently been applied in practical situation. It gives a

framework of knowledge that allows engineers and technicians to develop an interdisciplinary

understanding and integrated approach to engineering

Teaching and Examination Scheme:

Teaching Scheme

L

T

P

Content:

Sr.

No.

1

Credits

C

Theory Marks

ESE PA (M)

(E)

70

30

Examination Marks

Practical Marks

PA (V)

PA (I)

ESE

OEP

PA

RP

20

10

20

0

Topics

Introduction:

Introduction to Mechatronics, need and applications, elements of mechatronic

systems, role of mechatronics in automation, manufacturing and product

development.

Sensors and Feedback Devices:

Importance of sensors in Mechatronics, Static and Dynamic characteristics of

sensors, errors and output impedance of sensors, transducers for measurement

of displacement, strain, position, velocity, noise, flow, pressure, temperature,

humidity, vibration, liquid level, vision sensors.

Control Elements and Actuators:

On/off push buttons, control relays, thermal over load relays, contactors,

selector switches, solid state switches. Mechanical actuators types of motion,

gear trains, belt and chain drives, screw rods, Electrical actuators, solenoids,

DC drives and AC variable frequency drives, AC and DC motors,

servomotors, stepper motors, linear motors. Hydraulic and Pneumatic controls,

functional diagram - control valves, cylinders and hydro motors.

Computational Elements and Controllers:

Basic concepts of control systems open loop, closed loop, semi closed loop

control system, block and functional diagrams controllers for robotics and

CNC, linear and rotary encoders, timers, counters, microprocessors and

microcontrollers: architecture and pin details, introduction to PLC, simple

programs for process control application based on relay ladder logicSupervisory Control and Data Acquisition Systems (SCADA) and Human

Machine Interface (HMI).

Interfacing System:

Introduction to interfacing of different hard wares in industry, need for

Total

Marks

150

Teaching

Hrs.

Module

Weightage

10

12

20

12

20

12

20

06

15

networks in industrial plants, hierarchy and structure of networking, RS 232

based network, Ethernet, TCP/IP, MAP/TOP.

Applications of Mechatronic Systems:

Introduction to factory automation and integration, design of simple

Mechatronics systems, Case studies based on the application of mechatronics

like Pick and place Robot, Conveyor based material handling system,

Mechatronics Control in automated Manufacturing, Data Acquisition,

autotronics, bionics and avionics.

07

15

Reference Books:

1.

2.

3.

4.

5.

6.

7.

8.

Introduction to Mechatronics Appu Kuttan K.K.Oxford University Press

Mechatronics: Integrated Mechanical Electronic Systems Ramchandran K P, Vijayaraghavan G K,

Balasundaram, M S.Wiley India.

Measurement Systems Design and applications Doeblin E.O., McGraw Hill

Mechatronics : Principle, Concepts and Applications Mahalik N.P. McGraw Hill.

Fundamentals of Programmable Logic Controllers, Sensors and Communications Jon Stenersons Prentice Hall,

2004.

Mechatronics Bolton W. Pearson Education.

Computer Control of Manufacturing Systems Yorem Koren McGraw Hill.

Introduction to Mechatronic Design J E Carryer, R M Ohline and T W Kenny Pearson

List of Experiments:

Experiments should be designed to include the contents of the syllabus. The experiments may also include simulation

using Matlab or equivalent platform.

1.

2.

3.

4.

5.

6.

7.

Control the single acting and double acting cylinders using pilot valves.

Continuous reciprocating of single acting and double acting cylinder using pilot valves.

Design a pneumatic circuit for sequencing.

Actuation of single acting cylinder using ON and OFF delay timer.

Servo motor control using open loop and close loop system.

Run the stepper motor at different speed and different direction.

PLC control of sequencing circuit using PLC ladder diagram.

Open Ended Problems:

1. Design and Simulate Hydraulic circuit for Excavator (3 - Cylinders).

2. Design Circuit for LIFT using PLC.

3. Control the rotational movement of Windmill using stepper motor

Course Outcome:

After learning the course the students should be able to

1. Students would understand be able to apply fundamentals of mechatronics for various mechanical systems.

2. Students would be able to use various types of sensors and controllers.

3. Students would be able to analyse hydraulic and pneumatic systems.

Вам также может понравиться

- Allen Bradley Power Monitor 3000 Manual PDFДокумент356 страницAllen Bradley Power Monitor 3000 Manual PDFAndrewcaesar100% (1)

- Citric Acid Passivation of Stainless SteelДокумент41 страницаCitric Acid Passivation of Stainless Steelnqh2009100% (2)

- Syllabus of Automotive Electronics CourseДокумент2 страницыSyllabus of Automotive Electronics Coursemtechsurendra100% (2)

- P3 Past Papers Model AnswersДокумент211 страницP3 Past Papers Model AnswersEyad UsamaОценок пока нет

- Regenerative Medicine Manual ISSCA 2020 EnglishДокумент21 страницаRegenerative Medicine Manual ISSCA 2020 EnglishDana MihutОценок пока нет

- GTU Automation Engineering Course OverviewДокумент3 страницыGTU Automation Engineering Course OverviewIndrajit SodhaОценок пока нет

- MCT Lab ManualДокумент75 страницMCT Lab ManualManeeshОценок пока нет

- MECHATRONICS LABORATORY MODULE 1Документ104 страницыMECHATRONICS LABORATORY MODULE 1Nandha KumarОценок пока нет

- Bill No. 1 - General Items PreliminariesДокумент24 страницыBill No. 1 - General Items PreliminariesNorazreen NorAzharОценок пока нет

- BE Mechanical Syllabus FinalДокумент2 страницыBE Mechanical Syllabus FinalsabnisnileshОценок пока нет

- Mechatronics ME5007Документ5 страницMechatronics ME5007Kalum ChandraОценок пока нет

- ME8791 SyllabusДокумент2 страницыME8791 SyllabusAnonymous mRBbdopMKfОценок пока нет

- Mechatronics Course Code 13ME1140Документ3 страницыMechatronics Course Code 13ME1140Amr IbrahimОценок пока нет

- Be Electrical Engg 2008 SyllabusДокумент40 страницBe Electrical Engg 2008 SyllabusGaurav sОценок пока нет

- 2171103Документ4 страницы2171103narayanОценок пока нет

- Industrial AutomationДокумент4 страницыIndustrial AutomationmeghasugauliОценок пока нет

- Module Information Module Title Electric Drives and Control Module Code MMD2511Документ4 страницыModule Information Module Title Electric Drives and Control Module Code MMD2511Ashley KaОценок пока нет

- Course Objectives:: Me3254: MechatronicsДокумент7 страницCourse Objectives:: Me3254: Mechatronicsgiriaj kokareОценок пока нет

- 29 MT242 ElectroHydraulic and ElectroPneumatic SystemsДокумент2 страницы29 MT242 ElectroHydraulic and ElectroPneumatic SystemsLeonidas PerezОценок пока нет

- Teaching Model-Based Design and Rapid Prototyping To Undergraduate StudentsДокумент6 страницTeaching Model-Based Design and Rapid Prototyping To Undergraduate StudentsMKTR_AHMETОценок пока нет

- PLC and SCADA ApplicationsДокумент4 страницыPLC and SCADA ApplicationsShreemanti RokadeОценок пока нет

- 2171103Документ4 страницы2171103snehalОценок пока нет

- Electro-Hydraulic Systems. Development of Circuits For Industrial,-/automationДокумент3 страницыElectro-Hydraulic Systems. Development of Circuits For Industrial,-/automationAmeya GanpatyeОценок пока нет

- CDM ME 407 Mechatronics - 2021Документ15 страницCDM ME 407 Mechatronics - 2021Tony K PaulОценок пока нет

- 1.unit 1 MechatronicsДокумент63 страницы1.unit 1 MechatronicsSolcastic SoulОценок пока нет

- Industrial Instrumentation and AutomationДокумент3 страницыIndustrial Instrumentation and AutomationArya RahulОценок пока нет

- ME8791 SyllabusДокумент2 страницыME8791 SyllabusMr.G.Chandrasekar mechanicalstaffОценок пока нет

- Anna Univ Syllabus For EIE 3rd To 8th Sem Syllabus - WWW - Annaunivedu.infoДокумент58 страницAnna Univ Syllabus For EIE 3rd To 8th Sem Syllabus - WWW - Annaunivedu.infosudentsideaОценок пока нет

- Pias 2020-18earc302Документ23 страницыPias 2020-18earc302Deepak KumarОценок пока нет

- Industrial AutomationДокумент2 страницыIndustrial AutomationmaheshОценок пока нет

- ASEE2010 PendulumДокумент9 страницASEE2010 Pendulumpatmos666Оценок пока нет

- Saya Suka AwakДокумент6 страницSaya Suka AwakNazif JaafarОценок пока нет

- A New Undergraduate Course in Electromechanical Systems For Industrial Engineering TechnologyДокумент13 страницA New Undergraduate Course in Electromechanical Systems For Industrial Engineering TechnologyMesafint kassieОценок пока нет

- 1Документ2 страницы1DollaRaiОценок пока нет

- Me2401 MechatronicsДокумент3 страницыMe2401 MechatronicsJaya Om100% (1)

- Mechatronics 1Документ2 страницыMechatronics 1arpitsinghai109Оценок пока нет

- UG Mechatronics Course Combines Mechanics & ElectronicsДокумент3 страницыUG Mechatronics Course Combines Mechanics & ElectronicsAshutosh KumarОценок пока нет

- Final BTech MechanicalДокумент31 страницаFinal BTech MechanicalAniket GaikwadОценок пока нет

- ME407 MechatronicsДокумент2 страницыME407 MechatronicsVivek SivaramanОценок пока нет

- ME401 Design of Machine Elements - I.image - MarkedДокумент2 страницыME401 Design of Machine Elements - I.image - MarkedShino BabuОценок пока нет

- HIT PLC Programming Course Covers Control, NetworksДокумент7 страницHIT PLC Programming Course Covers Control, NetworksTanaka dzapasi100% (1)

- MechatronicsДокумент8 страницMechatronicsJeslet JoyОценок пока нет

- Gujarat Technological University: Control Engineering Subject B.E. 5 SemesterДокумент3 страницыGujarat Technological University: Control Engineering Subject B.E. 5 Semesterishan shahОценок пока нет

- MT221 Control Engineering Course OverviewДокумент2 страницыMT221 Control Engineering Course OverviewHanover PedroОценок пока нет

- Riya Katiyar 1712910Документ131 страницаRiya Katiyar 1712910Ram SinghОценок пока нет

- Mechatronics Systems DesignДокумент1 страницаMechatronics Systems DesignKannan MuthusamyОценок пока нет

- Third Year Sem A Sem B UpdatedДокумент40 страницThird Year Sem A Sem B UpdatedArpitОценок пока нет

- Fifth Semester EeeДокумент19 страницFifth Semester EeeIronthroneОценок пока нет

- Mechatronics & AutomationДокумент9 страницMechatronics & AutomationAnandababuОценок пока нет

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2151908Документ3 страницыGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2151908Mulu GirmayОценок пока нет

- Software For Embedded SystemДокумент39 страницSoftware For Embedded Systemjani28cseОценок пока нет

- 2018 Syllabus 7th SEMДокумент25 страниц2018 Syllabus 7th SEM18ME045Оценок пока нет

- I M C T P L C C: Ntegration OF Otion Ontrol Echnologies Into A Rogrammable Ogic Ontrols OurseДокумент5 страницI M C T P L C C: Ntegration OF Otion Ontrol Echnologies Into A Rogrammable Ogic Ontrols OurseGoran MiljkovicОценок пока нет

- VI TH Sem MechanicalДокумент15 страницVI TH Sem MechanicalNabeel KhanОценок пока нет

- Study & Evaluation Scheme Three Year Diploma Course in Instrumentation and Control Engineering (2014 Scheme) Semester - VДокумент15 страницStudy & Evaluation Scheme Three Year Diploma Course in Instrumentation and Control Engineering (2014 Scheme) Semester - VVarun RanaОценок пока нет

- PLC Training Module on Programmable Logic ControllersДокумент69 страницPLC Training Module on Programmable Logic ControllersMebreОценок пока нет

- R18 B.Tech Eie Iii YearДокумент37 страницR18 B.Tech Eie Iii YearkailashjkОценок пока нет

- Form 1 Course OutlineДокумент5 страницForm 1 Course OutlineMuhammad SumeetОценок пока нет

- SEC Mechatronics Lab Manual R2013 Shan PDFДокумент93 страницыSEC Mechatronics Lab Manual R2013 Shan PDFMonish KumarОценок пока нет

- Jntu Citd M.tech Mechatronics SyllabusДокумент24 страницыJntu Citd M.tech Mechatronics SyllabusSai KiranОценок пока нет

- VTU-Bosch Rexroth Centre of Competence in Automation Technology TrainingДокумент10 страницVTU-Bosch Rexroth Centre of Competence in Automation Technology TrainingeskayОценок пока нет

- Mechatronics Lab Manual Module 1: Introduction to Mechatronics and CNC MachinesДокумент105 страницMechatronics Lab Manual Module 1: Introduction to Mechatronics and CNC Machineskbmn2Оценок пока нет

- Course Code Course Name L-T-P-Credits Year of Introduction ME407 Mechatronics 3-0-0-3 2016 Prerequisite: Nil Course ObjectivesДокумент2 страницыCourse Code Course Name L-T-P-Credits Year of Introduction ME407 Mechatronics 3-0-0-3 2016 Prerequisite: Nil Course ObjectivesAnirudh Madhav KakkadОценок пока нет

- Practical Control of Electric Machines: Model-Based Design and SimulationОт EverandPractical Control of Electric Machines: Model-Based Design and SimulationОценок пока нет

- 1 BmeДокумент44 страницы1 BmepmagrawalОценок пока нет

- Evs MCQ 1Документ1 страницаEvs MCQ 1pmagrawalОценок пока нет

- Fanuc G M CodesДокумент2 страницыFanuc G M CodespmagrawalОценок пока нет

- PT 1Документ2 страницыPT 1pmagrawal0% (1)

- Manufacturing ProcessesДокумент2 страницыManufacturing ProcessespmagrawalОценок пока нет

- Creo SuppliersДокумент1 страницаCreo SupplierspmagrawalОценок пока нет

- Pom IeДокумент5 страницPom IepmagrawalОценок пока нет

- Mechanics of SolidsДокумент2 страницыMechanics of SolidspmagrawalОценок пока нет

- Unit No. Topics Teaching HoursДокумент1 страницаUnit No. Topics Teaching HourspmagrawalОценок пока нет

- Aadhaar Data Update FormДокумент1 страницаAadhaar Data Update FormAbhishek Kumar100% (2)

- Methods DynamicДокумент6 страницMethods DynamicpmagrawalОценок пока нет

- Greek Alphabet Chart with Capital & Lowercase LettersДокумент1 страницаGreek Alphabet Chart with Capital & Lowercase LetterspmagrawalОценок пока нет

- Unit No. Topics Teaching HoursДокумент1 страницаUnit No. Topics Teaching HourspmagrawalОценок пока нет

- Commonly Used For:: CartesianДокумент9 страницCommonly Used For:: CartesianpmagrawalОценок пока нет

- Unit No. Topics Teaching HoursДокумент1 страницаUnit No. Topics Teaching HourspmagrawalОценок пока нет

- Define The TermДокумент1 страницаDefine The TermpmagrawalОценок пока нет

- Manual Process PlanningДокумент1 страницаManual Process PlanningpmagrawalОценок пока нет

- Chemistry Project ReportДокумент13 страницChemistry Project ReportpmagrawalОценок пока нет

- VITEEE2017 ChemistryДокумент2 страницыVITEEE2017 ChemistryReddy GmdОценок пока нет

- 3D Geometry ExplainedДокумент3 страницы3D Geometry ExplainedpmagrawalОценок пока нет

- Commonly Used For:: CartesianДокумент9 страницCommonly Used For:: CartesianpmagrawalОценок пока нет

- 2181911Документ3 страницы2181911pmagrawalОценок пока нет

- Asrs - FMSДокумент2 страницыAsrs - FMSpmagrawalОценок пока нет

- 3D GeometryДокумент3 страницы3D GeometrypmagrawalОценок пока нет

- FEM Shape Functions & Isoparametric ElementsДокумент1 страницаFEM Shape Functions & Isoparametric ElementspmagrawalОценок пока нет

- Why sensors are important for robot motion and object identificationДокумент1 страницаWhy sensors are important for robot motion and object identificationpmagrawalОценок пока нет

- Vibration AnalysisДокумент17 страницVibration AnalysispmagrawalОценок пока нет

- Standard Error of The EstimateДокумент3 страницыStandard Error of The EstimatepmagrawalОценок пока нет

- Identification of Cations and Anions Present in ToothpasteДокумент4 страницыIdentification of Cations and Anions Present in ToothpastepmagrawalОценок пока нет

- Ma 2264 NM Eee Q.BДокумент26 страницMa 2264 NM Eee Q.BpmagrawalОценок пока нет

- Spin - 2021Документ60 страницSpin - 2021Tanel LaanemägiОценок пока нет

- Whatever Happens, Happens For Something Good by MR SmileyДокумент133 страницыWhatever Happens, Happens For Something Good by MR SmileyPrateek100% (3)

- The Grey Nomads Guide To AustraliaДокумент3 страницыThe Grey Nomads Guide To AustraliaFreerangecamping60% (5)

- Heradesign Brochure 2008Документ72 страницыHeradesign Brochure 2008Surinder SinghОценок пока нет

- 6b530300 04f6 40b9 989e Fd39aaa6293aДокумент1 страница6b530300 04f6 40b9 989e Fd39aaa6293attariq_jjavedОценок пока нет

- 44 Sounds Aus EnglishДокумент2 страницы44 Sounds Aus EnglishAlfie Arabejo Masong LaperaОценок пока нет

- Project Data Collection & Risk ReportingДокумент2 страницыProject Data Collection & Risk Reportinggambler yeagerОценок пока нет

- Instruction Manual: E2M40 and E2M80 Rotary Vacuum PumpsДокумент46 страницInstruction Manual: E2M40 and E2M80 Rotary Vacuum PumpsVicki NugrohoОценок пока нет

- Basler Electric 87T - Great InfoДокумент3 страницыBasler Electric 87T - Great InfoMrОценок пока нет

- Lab Manual Cape Bio Unit 1 2023Документ37 страницLab Manual Cape Bio Unit 1 2023drug123addict25Оценок пока нет

- Standardization Parameters For Production of Tofu Using WSD-Y-1 MachineДокумент6 страницStandardization Parameters For Production of Tofu Using WSD-Y-1 MachineAdjengIkaWulandariОценок пока нет

- Ninoy Aquino Parks and Wildlife CenterДокумент7 страницNinoy Aquino Parks and Wildlife CenterNinia Richelle Angela AgaОценок пока нет

- Typhoon Ulysses Philippines Deadly StormДокумент2 страницыTyphoon Ulysses Philippines Deadly Stormjai mansosОценок пока нет

- GE - Oil Sheen Detection, An Alternative To On-Line PPM AnalyzersДокумент2 страницыGE - Oil Sheen Detection, An Alternative To On-Line PPM AnalyzersjorgegppОценок пока нет

- Hedging Techniques in Academic WritingДокумент11 страницHedging Techniques in Academic WritingÛbř ÖňОценок пока нет

- IotДокумент88 страницIotLalithyaОценок пока нет

- Sundar KandvalmikiДокумент98 страницSundar Kandvalmikifactree09Оценок пока нет

- Etoh Membrane Seperation I&ec - 49-p12067 - 2010 - HuangДокумент7 страницEtoh Membrane Seperation I&ec - 49-p12067 - 2010 - HuangHITESHОценок пока нет

- Fendering For Tugs: Mike Harrison, Trelleborg Marine Systems, UKДокумент5 страницFendering For Tugs: Mike Harrison, Trelleborg Marine Systems, UKRizal RachmanОценок пока нет

- Company Profile 2Документ7 страницCompany Profile 2R Saravana KumarОценок пока нет

- Overlord - Volume 01 - The Undead KingДокумент223 страницыOverlord - Volume 01 - The Undead KingPaulo FordheinzОценок пока нет

- Lect 17 Amp Freq RespДокумент22 страницыLect 17 Amp Freq RespBent777Оценок пока нет

- Kuffner Final PresentationДокумент16 страницKuffner Final PresentationSamaa GamalОценок пока нет

- Workload Assessment in Railway ControlДокумент8 страницWorkload Assessment in Railway ControlbbeeОценок пока нет

- 60 GHZДокумент9 страниц60 GHZjackofmanytradesОценок пока нет