Академический Документы

Профессиональный Документы

Культура Документы

Side Stand Filter Technical Spec

Загружено:

sunitkumarbhaumikАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Side Stand Filter Technical Spec

Загружено:

sunitkumarbhaumikАвторское право:

Доступные форматы

Side Stream Filters (SMS Division)

SKB/SSF/14-15/08/REV-00

Multigrade Filter or Dual Media Filter for Side Stream Filters For SMS Division.

30 M3/Hr Multi Grade Filter or Dual Media Filter for Side Stream Filter shall be designed for an operating pressure of 3.5 kg/cm (g). MGF/DMF will be used

to reduce the turbidity and total suspended solids of the cooling water to the required level. Free board of at least 50% shall be left over the filtering

media to facilitate backwash. The filter shall be provided with the necessary nozzles including water inlet, water outlet, back wash, air scour and air

release nozzles. The filter shall be complete with necessary filtering medium. Scope of supply shall include backwash system. Raw water shall be used

for back washing of MGF/DMF.

Vessel design standard

Type

Capacity of each filter

Design Pressure

IS 2825 or ASME Sec. VIII Div.1

:

Multigrade filter

/ Dual Media Filter

To be sized for output required for both

3.5 kg/cm (g)

Design Temperature

Normal flow velocity

Filtering medium

Minimum bed depth

Minimum shell thickness

Dish end thickness

:

:

:

:

50C

18 m/hr

Vendor to specify

Vendor to specify

:

5 mm Minimum

:

6 mm Minimum

Free board

Material of construction

50%

As per IS 2062

Corrosion Allowance

:

1.5 mm

Effluent Quality

:

Turbidity not to exceed 5.00 NTU

Internal coating

:

Two coats of epoxy

External coating

:

As per painting spec

Dished end

:

Semi ellipsoidal

Inlet and out Parameters as mentioned in Annexure.

MATERIAL OF CONSTRUCTION

For all Vessels and Tanks

All vessels and tanks shall be vertical shell type with dished ends the material of construction shall be carbon steel conforming to IS : 2062 unless

specified otherwise.

For Pipes and Fittings

All internal pipes and header shall conform to IS : 1239 Part 1 up to 150 mm NB and IS: 3589 Class 3 above 150 mm NB.

Piping up to MGF : IS 1239 (Medium)

For Flanges

Flanges up to 20 mm thick shall conform to IS : 6392 and above 20 mm thick shall conform to IS: 2062.

For Gaskets

Gaskets shall be compressed asbestos fibre with nitrlle rubber binder conforming to IS: 2712.

Fasteners

Fasteners shall be of ASTM A 307 Gr. B carbon steel.

Valves for Corrosive Water/Acid/Alkali

Valves for corrosive water/acid/alkali shall be diaphragm type with cast iron rubber lined body and neoprene diaphragm.

Internal and external painting

Two coats of internal painting and two coats of external painting wherever required shall be done. For unlined vessels, the internal painting shall be with

two coats of primer and two coats of epoxy. For lined vessel, internal painting shall be with two coats of primer. External painting shall be with two coats

of primer and two coats of enamel as mentioned in Annexure.

GENERAL

The design of vessels and tanks shall be as per IS 2825.

All tanks shall be provided with vent & drain facility.

All flanges at the terminal point and within the battery limit shall be only as per ASME B 16.5.

All pipes within the battery limit including that required for backwash and regeneration shall be included in the scope.

All pipe supports and auxiliary steel structure required for supporting pipe shall be included in the scope as per the battery limits

Operational convenience design shall be done.

If after performance test, the treated water quality does not meet the stipulated quality requirement, BIDDER shall take necessary action to rectify or

replace the system without any extra cost.

All pressure tapings shall be provided with one root valve.

All pumps shall be provided with suction strainers with perforated plates and strainer element made of stainless steel.

All valve material shall be compatible to the pipe material, wherever they are used.

1 of 3

Side Stream Filters (SMS Division)

SKB/SSF/14-15/08/REV-00

SCOPE OF SUPPLY

Design, engineering, manufacture, supply, supervision erection & commissioning and performance testing of One (1) nos. of multi grade Filters/DMF

complete with filter media & its accessories.

THE DETAILED SCOPE OF SIDE STAND FILTER IS AS FOLLOWS:

Interconnecting pipe work complete with valves fittings, supports and accessories including

Piping required for the back wash and regeneration of the vessels

Instrumentation as per requirement

OTHER ITEMS INCLUDE

Common base frame with foundation bolts and nuts required for grouting all equipment (piping and supports) within terminal points shall be included in

the scope of supply.

Special tools and tackles and Commissioning spares.

Final painting.

O & M manuals for the complete system with necessary drawings, catalogues and other information pamphlets for all the equipment covered in the

scope.

Furnishing load data for all equipment foundations with civil drawings for all RCC structures.

First fill of required for equipment, interval of topping up, quantity required per annum with the name of the Indian suppliers.

All consumable items, chemicals, spares, etc. sufficient for 3 months operation.

OTHER ACCESSORIES

All frontal piping / all interconnecting piping / recirculation piping / valves/ fittings / fasteners / pipe supports and accessories integral to the MGF/DMF. All

piping shall be pre-fabricated as per the layout so that they shall be erected directly.

The filter shall be with the filtering material and all internals.

All terminal points shall be provided with suitable dummy flanges.

Foundation bolts with base plates.

2 year operational spares list

SCOPE OF SERVICES

Process engineering, basic engineering and design engineering of the MGF/DMF.

Survision Erection of the MGF/DMF

Supervision of Testing and Commissioning of the MGF/DMF.

Pre commissioning, testing, start up and run tests, load test, performance tests

QA/AC plan, inspection and testing of equipment at works, submission of test certificates. Trial operation for a minimum period of one week from the

date of successful commissioning and achieving the rated output and parameters

Analyzing the Input water and treated water during the PG test.

EXCLUSIONS

All civil works.

Electrical works

Piping work as per the Battery limits

BATTERY LIMITS

Raw water

Effluent water

Drains & Wash lines

:

:

:

At the inlet of MGF/DMF

At the outlet of MGF/DMF

At the discharge trench

SUB - VENDOR LIST

Diaphragm valve : Procon Valves Ltd, Alfa Laval, Avcon

Butterfly valve

: Intervalve Ltd, Hawa Valves Ltd, Crane Process, Alfa Laval

Ball valve

: Hawa, Karan, Norflow Controls Ltd, Audco Valves Airmax

Needle valve

: Hawa, Norflow Controls Ltd

Solenoid valves : Rotex, Airmax, Jenatics

Note:-

Bidder will quote In Bifurcate manner (Technical cum Commercial)

For any Deviation in Vendor/Sub-vender list, approval from Real Ispat & Power Ltd. must before quote.

2 of 3

Side Stream Filters (SMS Division)

S.No

SKB/SSF/14-15/08/REV-00

TECHNICAL DETAILS FOR SIDE STREAM FILTERS FOR SMS DIVISION

Description

Units

GENERAL

IS2825 / ASME SEC VIII Div.I

Design code

2

3

Design Pressure of all vessels

Test pressure

Corrossion allowance for unLined vessels, pipes, etc

5

6

7

8

9

10

11

All Flange dimensions (without hub) as per

Bolts & nuts with 2 washers

All pipes

Valves 80NB & above for DMF

Valves lesser than 80NB for DMF

V-Notch shall be provided for all vessels

Internal Painting (wherever applicable)

12

External Painting

13

Finishing Painting

14

All terminal points with mating flanges, gaskets & fasteners

Required

15

The mentioned flow rate is Net output. Vendor shall design

the system considering the back wash & regeneration

Required

S.No

A

1

2

B

1

2

S.No

C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Parameters

3.5 kg/cm2g

1.5times of design pressure

1.5mm

ANSI B16.5, SORF

IS1363

MS ERW - medium duty

Butterfly

Diaphragm

Provided

2 coats

2 coats of Red oxide primer - Total 110

DFT

2 coats of Enamel / Epoxy - Total 110

DFT

Description

Multigrade Filter

Total suspended solids

Turbidity

Multigrade Filter

Total suspended solids

Turbidity

Description

MGF/DMF

Diameter

HOS

Free board

Service Flow Rate

Service Hours

Material of Construction

Shell Thickness

Dish end thickness

Velocity

Media Used

Media depth

Inlet Distribution system / MOC

Under bed Collection system / MOC

Flow direction during operation

Flow direction during backwash

Back wash duration

Annexure ((to be filled by vendor))

Units

Inlet

PPM

NTU

Parameters

Inlet Parameters

PPM

NTU

Units

1

mm

mm

<5

<5

50

50

TREATED WATER

QUALITY

Parameters

m / hr

22 hrs

mm

mm

m3/hr/m2

m

min

3 of 3

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Site Specific Safety PlanДокумент12 страницSite Specific Safety PlanMatthew OdoОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Panasonic Dmc-Fs35eb Service ManualДокумент68 страницPanasonic Dmc-Fs35eb Service ManualABUTALEB_535364936Оценок пока нет

- Job Description - Mechanical Integrity - Project Engineer (1713975)Документ3 страницыJob Description - Mechanical Integrity - Project Engineer (1713975)Bil KaОценок пока нет

- Vinoth CVДокумент5 страницVinoth CVNikhatRizaviОценок пока нет

- RecoverPoint For Virtual Machines 4.3 Installation and Deployment GuideДокумент29 страницRecoverPoint For Virtual Machines 4.3 Installation and Deployment GuideBilal AkerОценок пока нет

- Subclassing in MFCДокумент3 страницыSubclassing in MFCPiscesvenОценок пока нет

- Env 1996-1-1-1996Документ129 страницEnv 1996-1-1-1996nvh202148Оценок пока нет

- Circuit Breaker Technical SpecificationsДокумент24 страницыCircuit Breaker Technical SpecificationssanjayОценок пока нет

- Boiler Efficiency CalculationДокумент4 страницыBoiler Efficiency CalculationAhmad RahanОценок пока нет

- Royal Mail International Claims FormДокумент2 страницыRoyal Mail International Claims FormLeslie PerkinsОценок пока нет

- Pressure GaugeДокумент4 страницыPressure GaugesunitkumarbhaumikОценок пока нет

- Drum LevelДокумент2 страницыDrum LevelsunitbhaumikОценок пока нет

- CondensateДокумент1 страницаCondensatesunitkumarbhaumikОценок пока нет

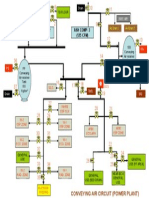

- Conveying AirДокумент1 страницаConveying AirsunitkumarbhaumikОценок пока нет

- Wind Speed Map IndiaДокумент12 страницWind Speed Map IndiaAn1rudh_Sharma100% (1)

- NGN Module 2 PDFДокумент19 страницNGN Module 2 PDFkikinjoОценок пока нет

- Kershaw CatalogДокумент68 страницKershaw CatalogjoeОценок пока нет

- SFVL & DSVL Data Sheet RD7FE102 PDFДокумент8 страницSFVL & DSVL Data Sheet RD7FE102 PDFLuciano CaireОценок пока нет

- IBIA Guidance On Best Practice For Fuel Oil SuppliersДокумент18 страницIBIA Guidance On Best Practice For Fuel Oil SuppliersAnonh AdikoОценок пока нет

- 160513071421Документ5 страниц160513071421VJ ChaudharyОценок пока нет

- ENISA Controls Meta FrameworkДокумент9 страницENISA Controls Meta FrameworkducuhОценок пока нет

- Material Safety Data Sheet: Page 1 of 3 AB-80Документ3 страницыMaterial Safety Data Sheet: Page 1 of 3 AB-80Denise AG100% (1)

- Alfresco Datasheet Records ManagementДокумент3 страницыAlfresco Datasheet Records ManagementJelatang HinaОценок пока нет

- CIS Red Hat Enterprise Linux 7 Benchmark v2.2.0Документ386 страницCIS Red Hat Enterprise Linux 7 Benchmark v2.2.0Sandro MeloОценок пока нет

- System InformationДокумент22 страницыSystem InformationErcan YilmazОценок пока нет

- Flanged Ball Trunnion ValvesДокумент24 страницыFlanged Ball Trunnion ValvesMahdi DalyОценок пока нет

- CCNA Security 640-553 Study NotesДокумент10 страницCCNA Security 640-553 Study NotesHebert MolinaОценок пока нет

- Aks PPT TtsДокумент16 страницAks PPT TtsKavya AmmuОценок пока нет

- Ro-Ro Passenger Ship Safety Regulations ComparedДокумент9 страницRo-Ro Passenger Ship Safety Regulations ComparedRadostin DechevОценок пока нет

- Section 5 - Drawings Design Calculations & Specifications ControlДокумент5 страницSection 5 - Drawings Design Calculations & Specifications ControlYasser Hammad MohamedОценок пока нет

- Future of The BIM CMMДокумент19 страницFuture of The BIM CMMJohnDecaprioОценок пока нет

- InteliCharger 240 24 Reference Guide r2Документ17 страницInteliCharger 240 24 Reference Guide r2Luis MonteagudoОценок пока нет

- Supported Media Formats Guide for BlackBerry DevicesДокумент53 страницыSupported Media Formats Guide for BlackBerry Devices!ofiuco2000Оценок пока нет

- Putty For Windows, Linux and Mac - Install SSH in PuTTYДокумент10 страницPutty For Windows, Linux and Mac - Install SSH in PuTTYRiris Sigit PramonoОценок пока нет

- Method Statement of Overwatervilla and WalkwayДокумент10 страницMethod Statement of Overwatervilla and WalkwayMuhammad Uwais100% (1)