Академический Документы

Профессиональный Документы

Культура Документы

Rexnord Correntes Agricultura

Загружено:

William BorgesИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Rexnord Correntes Agricultura

Загружено:

William BorgesАвторское право:

Доступные форматы

. . .

MOVING AHEAD

Rexnord Chains

Quality

for Agricultural

Machines

Think like partners

act like partners

Speed

Consulting

The speed with which modern technologies

change our world is breathtaking.

Our application engineers concentrate on the

customers interests.

For us two aims are certain:

We concentrate on the individual wishes

and needs of the customer when calculating

and identifying the correct chain drive.

We are determined, with our products for our

customers, to occupy a leading position as

regards technology.

We want, together with our customers, to

achieve quality and sales growth.

Together with our customers, we find solutions, which optimize the factors of safety,

service life and price.

Partnership

We know what the customer needs in his

market for his product in the future.

We listen to you and observe driving and conveying world-wide. We carry out analyses on

the customer's premises and apply practicable solutions. So that you remain competitive.

Service

We are only satisfied when you are.

INTRODUCTION

We have created the conditions for this by

means of intensive consulting, partnership

and our own sales activities. Thus there is

a combination of our market know-how, technical competence, customer service and the

satisfaction of our customers.

Roller chains

Product range

Leaf chains

Competence

As the manufacturer of one of the most extensive chain ranges for drives and conveying we

are an established partner of leading companies. Our 5,000 chain variants provide an

impressively large number of solutions and

flexibility.

Sprockets

Innovation

The secret lies in the production methods and

the material.

Several thousand tools developed by ourselves rotate in the flow of production.

650 special tools were constructed by us for

the manufacture of special chains.

30 special steels, alloyed, stainless, patented,

are processed.

Moreover, we offer many different lubrications.

Through our customers we have become a

specialist in surface refinement and the heat

treatment of steel.

Quality

INTRODUCTION

EINLEITUNG

For Rexnord means that the customer

comes back and not the chain.

Rexnord Methods of Production

Towards Optimizing Quality

High Case Hardness

The pins and bushes that constitute the

chain bearing area are furnished with an

optimally deep hardness layer. This stratum

contributes essentially to the life span.

Surface hardness is approximately 60 HRc.

Ball-Drifting

High Case and

Depth Hardness.

Ball-Drifting.

Ball-drifting of the plate bores serves to

achieve strain-hardening of the material.

All punching flutes and sharp edges are

simultaneously removed. Press fits and

fatigue strength are so optimally improved.

Shot Peening

Shot Peening.

All plates, bushes and rollers are shot

peened for further improving fatigue

resistance. This effective cold processing

moreover consolidates the surfaces and

increases their load-bearing properties.

Such parts have a built-in tension and therefore higher resistance against loading.

Shock-Resistant Rollers

Rexnord Rollers are produced to high

precision, of a uniform wall thickness and

absolutely free from any taper. An optimal

seating and smooth running is so warranted.

The Rollers are shot-peened and posses

a high fatigue strength for resisting runningin impacts.

Shock-Resistant

Rollers.

Pre-Loading

Rexnord Roller Chains are pre-run-in under

high load. Customary chain run-in elongation

is thereby minimized and expensive tensioning in application avoided. All Chains are

subjected to a severe length control. High

pre-loading enhances their load-bearing

property and reliability.

INTRODUCTION

Uniform Quality

The uniform quality of Rexnord chains is not

merely ensured by initial and final inspections, but far more, also by in-process

routine testing of the individual elements.

Pre-Loading.

Uniform Quality.

Advantages of Rexnord Chains

Contrary to widespread opinion, the

breaking load of a chain is not an indicator

of resistance to fatigue and long wear life.

Therefore, chains manufactured to specified standards, and with equal breaking

loads, differ in quality from manufacturer to

manufacturer.

Important for quality are fatigue strength

and wear resistance.

Special manufacturing techniques developed by Rexnord formulate such factors as

fatigue resistance, wear resistance and

tensile strength to provide their optimum

combination.

This jig boring machine plays a large role in the

precision of the Rexnord chain tools.

For the testing of fatigue strength, we use, among

others, this designed according to the latest

technological knowledge high frequency fatigue

testing machine.

Quality Management System

Contents:

Rexnord Kette GmbH employs a quality

management system which is reflected in

the special commitments to our customers.

This handbook contains an all-round binding description, which is written in 20 elements and according to the internationally

known DIN EN ISO 9001.

The quality management handbook

contains the quality management system

from Rexnord Kette GmbH.

The fruits of this policy are shown by the

certification awarded according to

DIN EN ISO 9001, DIN EN ISO 14001 and

API Spec Q1 and Spec 7F

through American Petroleum Institute

Therefore, the colleagues involved have

access to process details, working details

and testing methods as well as all-round

processing practices.

Thereby all our customers have access to

the information how Rexnord realises and

guarantees its products.

Furthermore, we are constantly improving

our products and organisation. Part of this

improvement involves following up internal

and external developments with positive

interest and constant evaluation of our market.

We wish to provide all our colleagues with

some helpful guidelines, which will help to

support and motivate them in their endeavours to work with quality consciousness.

ISO

9001

Application

Consultation

Dispatch

ISO

9001

ISO

9001

ISO

9001

ISO

9001

ISO

9001

ISO

9001

CUSTOMER

ISO

9001

ISO

9001

Production

Buying

ISO

9001

Development

ISO

9001

INTRODUCTION

ISO

9001

Sales

a1

b2

b1

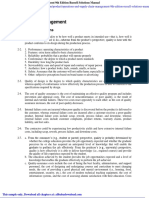

Agricultural Roller Chains

d1

d2

Roller

Link

Pin

Link

Connection link

single wire

Connection link

double cotter

Industry Standard

Chain

Description

Pitch

Roller

Width

Roller

Pin

Diameter Diameter

Inner

Width

d1 max. d2 max. b2 max.

mm

mm

mm

Linkplate

Height

Pin

Width

Overall

Width

Bearing

Area

Ultimate

Strength

Weight

A

cm2

FB

N

q

kg/m

2.1

45 000

2.45

p

new

inch

mm

b1 min.

mm

SK 627

30-1 BG GL

1.18

30.0

19.05

RL 726

S 52 BK

1.50

38.1

16.0

15.24

5.72

21.9

17.0

30.5

33.8

1.2

28 000

1.42

RL 738 1)

38.4 W GL 1)

1.50

38.4

19.05

15.88

6.92

23.9

17.0

33.7

37.55

1.67

31 500

1.68

SK 717 1)

38.4 H GL 1)

1.50

38.4

19.05

15.88

8.27

25.45

20.1

35.6

39.75

2.1

45 000

2.10

RL 753

S 55 SK8 H

1.63

41.4

20.5

15.88

7.97

27.0

20.0

37.2

41.6

2.15

42 500

1.75

RL 764

S 55 H

1.63

41.4

22.23

17.9

8.26

29.23

20.5

39.3

42.8

2.36

47 500

2.04

RL 766 1)

S 55 SK2 GL 1)

1.63

41.4

22.23

15.88

8.26

28.03

20.5

39.3

44.6

2.56

60 000

2.20

RL 774 1)

S 55 SK6 GL 1)

1.63

41.4

19.81

16.87

7.19

25.45

19.0

35.6

39.7

1.86

47 500

1.95

SK 838

216 B SK1 GR

2.00

50.8

19.0

19.05

9.53

27.4

26.0

40.0

44.0

2.62

85 000

2.62

old

AGRICULTURAL ROLLER CHAINS

) Chains with straight link plates

15.88

8.27

25.45

g max.

mm

20.5

a1 max. a3 max.

mm

mm

Loose Parts

35.6

39.0

a3

Offset link

single

Offset link

double

Bushing

Pin

Thermoplastic bearing

Roller Chains

with Thermoplastic Bearings

ISO 487/DIN 8189

Pitch

Roller

Width

Roller

Pin

Diameter Diameter

Inner

Width

d1 max. d2 max. b2 max.

mm

mm

mm

Linkplate

Height

Pin

Width

Overall

Width

Bearing

Area

Ultimate

Strength

Weight

A

cm2

FB

N

q

kg/m

p

old

new

inch

mm

b1 min.

mm

g max.

mm

a1 max. a3 max.

mm

mm

Loose Parts

C

RL 640

S 32 W

1.15

29.21

15.88

11.43

4.47

20.19

13.5

26.7

29.6

0.90

20 000

0.76

RL 670

S 42 W

1.375

34.93

19.05

14.27

7.0

25.4

19.6

34.25

36.7

1.78

27 000

1.49

SK 742

S 45 W

1.63

41.4

22.23

15.24

5.74

28.58

17.2

38.1

40.6

1.63

25 000

1.46

RL 741

S 52 W

1.50

38.1

22.23

15.24

5.74

28.58

17.3

38.1

40.6

1.63

25 000

1.56

SK 744

S 55 W

1.63

41.4

22.23

17.78

5.74

28.58

17.3

38.1

40.6

1.63

25 000

1.65

RL 747

S 62 W

1.65

41.91

25.4

19.05

5.72

30.6

17.0

40.5

42.6

1.82

28 000

1.95

RL 942

S 77

2.30

58.34

22.23

18.26

8.92

30.9

24.6

43.8

49.2

2.77

45 000

2.35

RL 1042

S 88

2.60

66.27

28.58

22.86

8.92

37.52

24.2

50.2

55.5

3.34

45 000

2.78

Inner

Width

Linkplate

Height

Pin

Width

Overall

Width

Bearing

Area

Ultimate

Strength

Weight

A

cm2

FB

N

q

kg/m

1.66

23 600

1.63

with Thermoplastic Bearings

Chain

Description

Pitch

Roller

Width

Roller

Pin

Diameter Diameter

d1 max. d2 max. b2 max.

mm

mm

mm

p

old

RLK 738 1)

1)

inch

mm

b1 min.

mm

38.4 W GL KL 1) 1.50

38.4

19.05

new

Chains with straight link plates

15.88

6.93

24.2

g max.

mm

17.0

a1 max. a3 max.

mm

mm

32.8

30.5

Loose Parts

AGRICULTURAL ROLLER CHAINS

Chain

Description

Agricultural Roller Chains

s

H

Bent Attachment Plates Standard Type

K-1

A

B

A-1

ISO 487/DIN 8189

Chain

Description

old

Bent Attachment

Plate No.

Exterior

Angle

new

Interior

Angle

Pitch

Roller

Width

Roller

Diameter

p

mm

b1 min.

mm

d1 max.

mm

A

mm

B max.

mm

H

mm

C

mm

D min.

mm

K min.

mm

s

mm

RL 640

S 32 W

W 590

29.21

15.88

11.43

21.5

30.8

8.6

14.0

5.3

8.0

1.75

SK 742

S 45 W

W 720

W 723

41.4

22.23

15.24

27.0

37.1

11.4

20.0

8.3

11.5

2.6

RL 741

S 52 W

W 644

W 645

38.1

22.23

15.24

29.4

39.0

11.5

20.0

8.4

10.0

2.6

SK 744

S 55 W

W 720

W 723

41.4

22.23

17.78

27.0

37.1

11.5

20.0

8.3

11.5

2.6

RL 747

S 62 W

W 796

W 797

41.91

25.4

19.05

33.4

47.7

11.4

22.0

8.3

8.3

2.5

RL 942

S 77

W 870

W 873

58.34

22.23

18.26

38.1

50.8

20.8

26.0

8.6

12.5

4.0

RL 1042

S 88

W 930

W 933

66.27

28.58

22.86

48.4

59.7

20.8

32.0

8.6

11.2

4.0

Pitch

Roller

Width

Roller

Diameter

p

mm

b1 min.

mm

d1 max.

mm

A

mm

B max.

mm

H

mm

C

mm

D min.

mm

K min.

mm

s

mm

38.4

19.05

15.88

28.5

40.25

15.4

20.0

8.4

2.4

41.4

20.5

15.88

28.0

43.75

13.0

40.0

8.5

2.9

41.4

22.23

17.78

27.0

37.25

13.2

20.0

8.5

2.9

41.4

20.0

16.0

27.0

37.25

13.2

20.0

8.5

2.9

41.4

19.81

16.87

27.0

36.0

12.7

20.0

8.5

2.6

Industry Standard

Chain

Description

old

RL 738 1)

38.4 W GL 1)

RL 753

S 55 SK8 H

W 810

RL 764

S 55 H

W 804

RL 765

S 55 SK7

AGRICULTURAL ROLLER CHAINS

Exterior

Angle

new

RL 774 1

1)

Bent Attachment

Plate No.

Interior

Angle

W 682

W 804

1

S 55 SK6 GL )

W 900

Chains with straight link plates

A-1

K-1

A-1

K-1

A-1

K-1

1A

1G

Pin Link

Roller Link

Connection link single wire

Agricultural Roller Chains

Front Bent Attachment Standard Type

B

A

h

H

A

B

F-1

ISO 487/DIN 8189

Chain

Description

old

Front Bent

Attachment

No.

new

Pitch

Roller

Width

Roller

Diameter

p

mm

b1 min.

mm

d1 max.

mm

A

mm

B max.

mm

H

mm

h

mm

D min.

mm

K min.

mm

s

mm

U

mm

SK 742

S 45 W

F 722

41.4

22.23

15.24

29.0

41.2

33.7

21.0

6.6

6.6

2.5

28.6

RL 741

S 52 W

F 668

38.1

22.23

15.24

31.0

42.0

29.0

20.0

6.4

6.4

2.5

19.0

SK 744

S 55 W

F 722

41.4

22.23

17.78

29.0

41.2

33.7

21.0

6.6

6.6

2.5

28.6

Pitch

Roller

Width

Roller

Diameter

p

mm

b1 min.

mm

d1 max.

mm

A

mm

B max.

mm

H

mm

h

mm

D min.

mm

K min.

mm

s

mm

U

mm

38.1

15.88

15.24

27.3

38.3

29.0

20.0

6.4

6.4

2.5

19.0

Industry Standard

Chain

Description

old

new

RL 726

S 52 BK

1

F 668

RL 738 )

38.4 W GL )

F 648

38.4

19.05

15.88

26.0

36.0

33.0

24.0

8.6

8.6

2.4

37.4

SK 717 1)

38.4 H GL 1)

F 616

38.4

19.0

15.88

26.0

36.0

36.75

24.0

8.4

8.4

2.9

38.7

RL 753

S 55 SK8 H

F 758

41.4

20.5

15.88

27.5

38.7

29.5

20.0

6.6

9.8

2.9

54.3

Chains with straight link plates

F-1

F-1

1A

1G

Pin Link

Connection link single wire

AGRICULTURAL ROLLER CHAINS

1)

Front Bent

Attachment

No.

Agricultural Roller Chains

with Special Attachments

Chain Description (old) SK742, SK744

H

Chain Description (new) S45W, S55W

Pitch

W 702

Dimensions in mm

A

28.0 37.3 20.0 10.0

11.5

2.6

41.4

Special

Attachment

No.

Chain Description (old) RL 741

H

Chain Description (new) S52W

Pitch

D

K

W 670

Dimensions in mm

A

29.4 38.8 20.0

6.5

11.5

8.2

2.6

2.6

38.1

Special

Attachment

No.

Chain Description (old) SK 742, SK 744

H

Chain Description (new) S45W, S55W

Pitch

10

41.4

W 844

27.5 37.2 20.0

8.5

41.4

W 845 1) 27.5 37.2 20.0

8.3

11.4 14.5

2.6

Chain Description (old) RL 726

H

Chain Description (new) S 52 BK

Pitch

D

K

38.1

B

Dimensions in mm

SPECIAL ATTACHMENTS

Special

Attachment

No.

Special

Attachment

No.

W 644

Dimensions in mm

A

25.0 37.0 20.0

1

8.4

11.5 10.0

s

2.6

38.1

W 645 ) 25.0 37.0 20.0

8.4

11.5 10.0

2.6

38.1

W 670

6.6

11.5

2.6

) interior angle

29.4 38.3 20.0

8.2

Chain Description (old) RL764, RL765

H

Chain Description (new) S 55 H, S 55 SK7

Pitch

W 816

Dimensions in mm

A

27.0 42.5 40.0

8.6

14.8

2.9

41.4

Special

Attachment

No.

Chain Description (old) RL738

H

Chain Description (new) 38.4 W GL

Pitch

Special

Attachment

No.

Dimensions in mm

A

38.4

W 652

28.5 38.0 40.0

8.6

13.0

2.4

38.4

W 908

28.5 42.0 40.0 10.5

16.0

2.4

14.0

2.9

14.8

2.9

Chain Description (old) SK717

C

Chain Description (new) 38.4 H GL

38.4

W 824

28.5 43.0 40.0 10.5

Chain Description (old) RL766

Chain Description (new) S 55 SK2 GL

41.4

28.2 38.7 40.0

8.6

Chain Description (old) RL738

H

W 816

Chain Description (new) 38.4 W GL

Pitch

Special

Attachment

No.

Dimensions in mm

A

38.4

W 672

28.5 37.0 20.0

8.6

11.0

2.4

38.4

W 680

28.5 37.0 20.0

6.4

11.0

2.4

Chain Description (old) RL753

H

Chain Description (new) S 55 SK8 H

p

41.4

Special

Attachment

No.

W 776

Dimensions in mm

A

26.5 35.5 25.4

6.2

18.0

12.8

2.9

SPECIAL ATTACHMENTS

Pitch

11

Chain Description (old) RL753

H

Chain Description (new) S 55 SK8 H

Pitch

W 780

Dimensions in mm

A

30.0 42.5 41.3

8.5

15.0

2.9

41.4

Special

Attachment

No.

Chain Description (old) RL753

H

10

Chain Description (new) S 55 SK8 H

Pitch

D

K

W 770

Dimensions in mm

A

27.5 39.5 22.0

6.8

15.0 10.0

2.9

41.4

Special

Attachment

No.

Chain Description (old) RL753

11

Chain Description (new) S 55 SK8 H

Pitch

W 812

Dimensions in mm

A

55.0 70.0 40.0 11.2

15.0 20.2

s

2.9

41.4

Special

Attachment

No.

12

Chain Description (old) RL738

Chain Description (new) 38.4 W GL

Pitch

p

U

38.4

SPECIAL ATTACHMENTS

h

H

B

A

12

Special

Attachment

No.

F 688

Dimensions in mm

A

30.0 38.0

6.4

24.0 33.0 35.6

s

2.4

13

Chain Description (old) SK 742, SK 744

Chain Description (new) S45W, S55W

Pitch

p

U

h

H

B

A

Special

Attachment

No.

Dimensions in mm

A

41.4

F 728

30.65 41.25

8.4

16.5 25.0

28.6

2.6

41.4

F 738

29.0 39.3

6.0

5.5

16.0 25.0

28.6

2.6

Chain Description (old) RL738

H

14

Chain Description (new) 38.4 W GL

p

Pitch

Dimensions in mm

B

8.2

17.2

20.0

2.9

Special

Attachment

No.

38.4

F 696

37.3 48.35

15

Chain Description (old) RL738

U

C

Chain Description (new) 38.4 W GL

Pitch

F 850

Dimensions in mm

A

31.3 66.8 27.0

6.8

25.0

12.7

2.4

38.4

Special

Attachment

No.

Chain Description (old) RL764, RL765

U

C

Chain Description (new) S 55 H, S 55 SK 7

Pitch

41.4

Special

Attachment

No.

F 888

Dimensions in mm

A

32.0 74.0 30.0

6.5

30.0

13.5

2.9

SPECIAL ATTACHMENTS

16

13

17

Chain Description (old) RL738, RLK 738

Chain Description (new) 38.4 W GL, 38.4 W GL KL

s

Pitch

p

38.4

Dimensions in mm

Special

Attachment

No.

M 820

24.0

37.5

75.0

2.5

18

Chain Description (old) SK627

Chain Description (new) 30-1 BG GL

Pitch

p

H

30.0

Special

Attachment

No.

U 698

K 328

Dimensions in mm

A

14.0

63.0 22.5

19

Chain Description (old) RL766

Chain Description (new) S 55 SK2 GL

Pitch

p

U 173

55.0 37

s

3.0

41.4

Dimensions in mm

Special

Attachment

No.

20

Chain Description (old) RL764, RL765

Chain Description (new) S 55 H, S 55 SK7

Pitch

s

p

41.4

14

H

p

SPECIAL ATTACHMENTS

Dimensions in mm

Special

Attachment

No.

U 924

63.0 22.5 3.0

15

SPECIAL ATTACHMENTS

Вам также может понравиться

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreОт EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreРейтинг: 4.5 из 5 звезд4.5/5 (11)

- Small Block Chevrolet: Stock and High-Performance RebuildsОт EverandSmall Block Chevrolet: Stock and High-Performance RebuildsРейтинг: 4 из 5 звезд4/5 (6)

- Integrated Logistics Support Plan TemplateДокумент16 страницIntegrated Logistics Support Plan TemplateAshwin Hemant Lawanghare100% (1)

- Bridon Wire Rope CatalogueДокумент66 страницBridon Wire Rope Cataloguetunggularif0% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Operations and Supply Chain Management 9th Edition Russell Solutions ManualДокумент21 страницаOperations and Supply Chain Management 9th Edition Russell Solutions ManualD LoОценок пока нет

- SMATH311LC InventoryPart1Документ8 страницSMATH311LC InventoryPart1Ping Ping0% (1)

- Shaft CouplingsДокумент20 страницShaft CouplingsLuis MenaОценок пока нет

- REXNORD Link Belt CatalogoДокумент51 страницаREXNORD Link Belt CatalogoALEXANDER FERREIRA ARENASОценок пока нет

- RUD Lifting Lashing SystemДокумент56 страницRUD Lifting Lashing SystemkazdanoОценок пока нет

- Jungbluth Main Catalogue-LanacДокумент60 страницJungbluth Main Catalogue-LanacMilenkoBogdanovicОценок пока нет

- Company Profile: Office: 141/9 DDM School Road, Tulshi Nagar Ward No. 2 Korba, Chattishgarh - 495677Документ6 страницCompany Profile: Office: 141/9 DDM School Road, Tulshi Nagar Ward No. 2 Korba, Chattishgarh - 495677SITARAM GANESHMALLОценок пока нет

- 5510 Rexnord Bucket Elevators CatalogДокумент12 страниц5510 Rexnord Bucket Elevators CatalogAwir Strange ManОценок пока нет

- Suruburi Cu Bile PDFДокумент0 страницSuruburi Cu Bile PDFFlorin MaricaОценок пока нет

- Engineered Steel ChainsДокумент140 страницEngineered Steel ChainsCarlos Castañeda HernándezОценок пока нет

- Mill ProductsДокумент8 страницMill Productsvegamarco80Оценок пока нет

- Heat Treatment of SSДокумент20 страницHeat Treatment of SSNamye YelusОценок пока нет

- ISC2 Series Broch A4Документ6 страницISC2 Series Broch A4isosicaОценок пока нет

- Catalog BoltДокумент61 страницаCatalog BoltJulius AdomėnasОценок пока нет

- Sajjan Precision BrochureДокумент24 страницыSajjan Precision Brochuremiguel angel sebastianОценок пока нет

- High Performance Bucket Elevator CatalogДокумент12 страницHigh Performance Bucket Elevator CatalogcachorrexОценок пока нет

- James Walker O RingsДокумент30 страницJames Walker O RingsBu Lang NiОценок пока нет

- Hydraulic Cylinders DesignДокумент20 страницHydraulic Cylinders Designyatin88860% (5)

- Slewing Bearings by Liebherr: Application-Optimised, Reliable and RobustДокумент24 страницыSlewing Bearings by Liebherr: Application-Optimised, Reliable and Robustrobson2015Оценок пока нет

- Viking Johnson ProductsДокумент31 страницаViking Johnson ProductsAlvin MiraОценок пока нет

- JafcoДокумент17 страницJafcokhan4luvОценок пока нет

- Norris Pro-Rod Coiled RodДокумент8 страницNorris Pro-Rod Coiled RodMohamed GhareebОценок пока нет

- 05 37 Degree Flare Tube FittingsДокумент24 страницы05 37 Degree Flare Tube FittingsUzair AnsariОценок пока нет

- Power Transformers: Your Partner in Energy SolutionsДокумент24 страницыPower Transformers: Your Partner in Energy SolutionsHamayoun MurtazaОценок пока нет

- Bushan Power Steel PipeДокумент16 страницBushan Power Steel PipeKarthikeyan VisvakОценок пока нет

- Timken Cylindrical Roller BearingДокумент108 страницTimken Cylindrical Roller Bearingbambamtdoy100% (1)

- CatalogДокумент8 страницCatalogBarry KnightingОценок пока нет

- InternshipДокумент27 страницInternshipBhagyashree C KОценок пока нет

- Capabilities Brochure S J Smith CoДокумент24 страницыCapabilities Brochure S J Smith CoAmplified LocalОценок пока нет

- Mechanical Seals - MICRO SEALSДокумент26 страницMechanical Seals - MICRO SEALSMICRO SEALSОценок пока нет

- Cooper Bearing Catalog RudUK5Kv4Документ74 страницыCooper Bearing Catalog RudUK5Kv4a04204100% (2)

- Catalogue-Myonic English 2012Документ76 страницCatalogue-Myonic English 2012jose cuervoОценок пока нет

- SKF Magnetic Bearings - BrochureДокумент8 страницSKF Magnetic Bearings - BrochureJurun_BidanshiОценок пока нет

- SEMPERIT Belt PDFДокумент92 страницыSEMPERIT Belt PDFJaya Kumaar100% (2)

- Gunneboindustries Sheaves 20180919Документ12 страницGunneboindustries Sheaves 20180919Cao Long NhậtОценок пока нет

- Kova BrochureДокумент12 страницKova BrochureRishabgupta12Оценок пока нет

- Marbett Component Solutions For BeverageДокумент48 страницMarbett Component Solutions For Beverageabsalon_jarvОценок пока нет

- Hemco Catalog PDFДокумент27 страницHemco Catalog PDFdiegomilitojОценок пока нет

- Sandvik Seamless Heat Exhanger Tubings 154 Eng.03.2008Документ20 страницSandvik Seamless Heat Exhanger Tubings 154 Eng.03.2008Anghelo AlcaldeОценок пока нет

- CES Business PresentationДокумент50 страницCES Business PresentationGary David CrowhurstОценок пока нет

- Ring Type Joint Brochure 2016Документ16 страницRing Type Joint Brochure 2016perrychemОценок пока нет

- SBN Corp Profile - 2 PDFДокумент33 страницыSBN Corp Profile - 2 PDFSyafiq KamaluddinОценок пока нет

- FAG-Gearboxes Need Rolling BearingsДокумент10 страницFAG-Gearboxes Need Rolling BearingsUMAMAHESWARAN03Оценок пока нет

- Mineralguss enДокумент8 страницMineralguss enNebojša ObradovićОценок пока нет

- Seamless Stainless Tubes For Hydraulic and Instrumentation SystemsДокумент10 страницSeamless Stainless Tubes For Hydraulic and Instrumentation Systemsfezzeh kabiri kenariОценок пока нет

- 2010 Center Face Driver CatalogДокумент68 страниц2010 Center Face Driver CatalogmachineCanОценок пока нет

- Powertech TransformersДокумент12 страницPowertech TransformersXando FredericoОценок пока нет

- Gunnebo Lifting ClassicДокумент20 страницGunnebo Lifting ClassicYosses Sang NahkodaОценок пока нет

- Catalogs Tab POWERMARK y BRK GE PDFДокумент58 страницCatalogs Tab POWERMARK y BRK GE PDFAntonio JaénОценок пока нет

- Catalog For Bearing DesignДокумент70 страницCatalog For Bearing DesignHameer ReddyОценок пока нет

- Corrotherm International Brochure 2019Документ8 страницCorrotherm International Brochure 2019colourhutОценок пока нет

- John Crane Engineered Bearings Service Solutions: Get The Engineering Edge For Your TurbomachineryДокумент8 страницJohn Crane Engineered Bearings Service Solutions: Get The Engineering Edge For Your TurbomachineryAmet koko TaroОценок пока нет

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosОт EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosОценок пока нет

- Grinding Overview: Machinist Grinder Interview Questions and AnswersОт EverandGrinding Overview: Machinist Grinder Interview Questions and AnswersОценок пока нет

- Bim Adoption and Implementation For Engineering and Construction Industry Practices EnglishДокумент44 страницыBim Adoption and Implementation For Engineering and Construction Industry Practices EnglishAde Bdg ChakraОценок пока нет

- Managing Quality in Decentralised ManufacturingДокумент17 страницManaging Quality in Decentralised ManufacturingManish GuptaОценок пока нет

- Environmental Health and Vessel Sanitation Preventive Procedure Instruction #11Документ1 страницаEnvironmental Health and Vessel Sanitation Preventive Procedure Instruction #11VizitiuAnisoaraОценок пока нет

- Bme 3 and 4Документ11 страницBme 3 and 4Unnecessary BuyingОценок пока нет

- MCQs On QC & QAДокумент5 страницMCQs On QC & QAMAHESHWAR S MAREGOUDRUОценок пока нет

- Cost AccountingДокумент128 страницCost AccountingCarl Adrian Valdez50% (2)

- Design For AssemblyДокумент16 страницDesign For AssemblyOmkar Pradeep KhanvilkarОценок пока нет

- Pdyck 06Документ7 страницPdyck 06changumanguОценок пока нет

- Joseph Coffman ResumeДокумент5 страницJoseph Coffman Resumeashish198425Оценок пока нет

- Supplier Assesment MaxionДокумент23 страницыSupplier Assesment Maxionesivaks2000Оценок пока нет

- Schedule Machine Installation FP 3Документ14 страницSchedule Machine Installation FP 3hardidwiОценок пока нет

- Eco Project FinalДокумент36 страницEco Project FinalSakshamОценок пока нет

- Steels For Quenching and TemperingДокумент39 страницSteels For Quenching and Temperingjmwalker90Оценок пока нет

- Cost of ProductionДокумент22 страницыCost of ProductionNourin TasnimОценок пока нет

- 10 603173 0000100201 Mah QMN RPT 000001 - 01Документ98 страниц10 603173 0000100201 Mah QMN RPT 000001 - 01Alaa MohamedОценок пока нет

- EsterlineДокумент10 страницEsterlinesubhasis mahapatraОценок пока нет

- Chapter 4 2020Документ17 страницChapter 4 2020JAEHYUK YOONОценок пока нет

- HPДокумент5 страницHPSEMILLEROS FUSMОценок пока нет

- Pengaruh Lingkungan Terhadap BisnisДокумент27 страницPengaruh Lingkungan Terhadap BisnisharioОценок пока нет

- International Quality Standards: Group 2Документ30 страницInternational Quality Standards: Group 2Venn Bacus RabadonОценок пока нет

- Batching Job Shop BuffersДокумент2 страницыBatching Job Shop BuffersSaad AliKhanОценок пока нет

- Unit 3: Theory of ProductionДокумент40 страницUnit 3: Theory of ProductionJaveria MalikОценок пока нет

- Production: Dr. Jofrey R. CamposДокумент24 страницыProduction: Dr. Jofrey R. Camposfull sunОценок пока нет

- Plant Layout Quiz 3 AnswersДокумент4 страницыPlant Layout Quiz 3 Answersssanthosh073100% (1)

- 3 SME4833 ch4 New OcwДокумент56 страниц3 SME4833 ch4 New OcwMohamed MansourОценок пока нет

- Applied Economics Long Exams 2019-20 1ST SemДокумент1 страницаApplied Economics Long Exams 2019-20 1ST SemDerek AsejoОценок пока нет

- EY Re Engineering The Supply Chain For The Omni Channel of TomorrowДокумент39 страницEY Re Engineering The Supply Chain For The Omni Channel of Tomorrowtluo001Оценок пока нет