Академический Документы

Профессиональный Документы

Культура Документы

Instrumentation

Загружено:

TayebASherifАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Instrumentation

Загружено:

TayebASherifАвторское право:

Доступные форматы

IC | INSTRUMENTATION & CONTROL

IC

01

INSTRUMENT PRE-INSTALLATION & INSTALLATION

GUIDELINES

OBJECTIVE:

Participants will learn about the fundamental techniques and theoretical aspects of

installation and commissioning of instrumentation control systems.

WHO SHOULD ATTEND:

Instrumentation Engineers

Construction/Instrumentation Engineers & Technicians

DURATION:

5 days

TECHNICAL

TOPICS:

84

Introduction to instrument installation

Installation activity cycle:

- Organization

- Planning

- Communication

- Cost control

Equipment & tools

Documentation and forms issuance

Loop checks, commissioning & startup phases

Engineering For The Petroleum And Process Industries

INSTRUMENTATION & CONTROL | IC

IC

02

INSTRUMENTATION IN HAZARDOUS

LOCATIONS

OBJECTIVE:

Participants will learn about the requirements of safe application of instrumentation in

hazardous locations.

WHO SHOULD ATTEND:

Instrumentation Engineers

(With a minimum of 2 Years experience)

DURATION:

5 days

TOPICS:

Engineering For The Petroleum And Process Industries

TECHNICAL

Classification of hazardous locations & apparatus

Overview of protection methods:

- Explosion proof & flame proof

- Purging (or pressurization)

- Encapsulation

- Oil Immersion

- Powder Filling

- Sealing, Limited-breathing & dust proofing

Increased safety

Intrinsic safety

Non-incentive (or simplified protection)

Special protection method

Mixed protection method

85

IC | INSTRUMENTATION & CONTROL

IC

02

INSTRUMENTATION

, IN HAZARDOUS

LOCATIONS (Cont d)

TOPICS: (Cont,d)

Comparison between the widely used protection methods

Explosion proof protection methods - detailed considerations

Intrinsic safety protection methods - detailed considerations

The detailed philosophy of intrinsic safety

Intrinsically safe systems analysis

Installation of intrinsically safe & associated apparatus

Maintenance considerations

Certifications, labels, marks & ratings

Standards & practices

Agencies & testing facilities

TECHNICAL

86

Engineering For The Petroleum And Process Industries

INSTRUMENTATION & CONTROL | IC

IC

03

BASICS OF INSTRUMENTATION & CONTROL

OBJECTIVE:

The basic principles and applied techniques for various process measurements and

controls.

WHO SHOULD ATTEND:

Instrumentation Engineers

DURATION:

5 days

TOPICS:

Engineering For The Petroleum And Process Industries

TECHNICAL

Basic principle of process measurements:

- Flow measurements

- Pressure measurements

- Temperature measurements

- Level measurements

Basic principles of process controls:

- On/off control

- Modulating control

- Open loop control

- Ratio control

- Closed loop control

87

IC | INSTRUMENTATION & CONTROL

IC

04

PROCESS MEASUREMENTS

OBJECTIVE:

Participants will be provided with the basic knowledge and skills utilized in

process plants measurement of the big-four variables: pressure, flow rate, level &

temperature. Selection and application guides will also be tackeled.

WHO SHOULD ATTEND:

Instrumentation Engineers

Operation Engineers

DURATION:

5 days

TECHNICAL

TOPICS:

88

Process measurements & means for plant productivity, product quality & cost

optimization

Applied terminology

The big process measurements:

- Pressure measurement

- Flow measurement

- Level measurement

- Temperature measurement

Engineering For The Petroleum And Process Industries

INSTRUMENTATION & CONTROL | IC

IC

05

FLOW MEASUREMENTS (Basic)

OBJECTIVE:

Participants will be introduced to the main principles and techniques practically

applied in process plants flow rate measurement. Participants will also be introduced

to the theoretical basics, practical sizing equations, selection criteria and application

guidelines.

WHO SHOULD ATTEND:

Instrumentation Engineers

Operation Engineers

DURATION:

5 days

TOPICS:

Volumetric and mass flow units & conversion factors

Pressure, temperature & viscosity corrections of volumetric flow rate

Differential pressure methods

Orifice plates

Venturi tubes

Flow nozzles

Pitot tubes

Differential pressure flow transmitters

Vortex type flow element

Target flowmeter

Magnetic flowmeter

Turbine flowmeter

Positive displacement flowmeters

Ultrasonic flowmeters

Mass flowmeters (coriolis)

Engineering For The Petroleum And Process Industries

TECHNICAL

89

IC | INSTRUMENTATION & CONTROL

IC

06

FLOW MEASUREMENTS (Advanced)

OBJECTIVE:

Throughout this training program, Participants will be provided with the in-dept

knowledge of the process plants measurement tools and techniques. Participants will

also learn about the concepts of the most commonly used systems in various flow

measuring techniques. Participants will also gain understanding of the classification and

the characterization of the approaches, classes, types and the actual devices used in

flow measurements.

WHO SHOULD ATTEND

Senior Instrumentation Engineers

Senior Operation Engineers

DURATION:

5 days

TECHNICAL

TOPICS:

90

Course overview and introduction

Classification of flowmeters

General flow-measurement terminology

Theory of differential pressure flow metering devices

Head-producing flowmeters I (conventional)

Head-producing flowmeters II (special)

Head-producing flowmeters III (open channel)

Pulse producing flowmeters

Powers flowmeters

Special techniques

Mass flow measurement

Flowmeter selection

Engineering For The Petroleum And Process Industries

INSTRUMENTATION & CONTROL | IC

IC

07

BOILER CONTROL

OBJECTIVE:

Participants will learn about the main Principles and methods of design & operation

for boilers control.

WHO SHOULD ATTEND:

Instrumentation Engineers

Operation Engineers

DURATION:

5 days

TOPICS:

Engineering For The Petroleum And Process Industries

TECHNICAL

Introduction to boilers (an overview):

- Principles of steam production

- Functions of boiler systems

Boiler Feed water & steam:

- Corrosion scale on boiler components

- Boiler response to steam demand

- Three basic approaches to freed water control

Boiler controls:

- Boiler startup procedure

- Boiler operators responsibilities

- Boiler shut down procedure

- Abnormal & emergency condition

Boiler design & construction:

- Basic types of boilers

- Functions of water tube boiler components

Boiler fuel & air (controlling for safety & efficiency):

- Three types of boiler fuels

- Factors needed to control combustion

- Combustion control systems

91

IC | INSTRUMENTATION & CONTROL

IC

08

CONTROL VALVE ENGINEERING

OBJECTIVE:

Participants will be provided with the essential knowledge and skills required for sizing,

selection, installation and testing practices of control valves used in process industries.

WHO SHOULD ATTEND:

Instrumentation Engineers

Piping Engineers

DURATION:

5 days

TECHNICAL

TOPICS:

92

Control valve as a control loop element

Control valve as a part of a piping system

Control valve terminology

Control valve components

Control valve body: types & styles

Control valve trim: types & styles

Inherent & installed valve characteristics

Body & trim materials selection guide lines

Valve actuator types & selection guide lines

Factors to consider in valve selection

Sizing data, equations & application

Flashing, cavitations & noise

Control valve installation & commissioning

Sizing & selection examples

Engineering For The Petroleum And Process Industries

INSTRUMENTATION & CONTROL | IC

IC

09

PROCESS CONTROL (Basic)

OBJECTIVE:

Participants will learn about the basics of process control theory and practice in the

field of Oil & Gas.

WHO SHOULD ATTEND:

Instrumentation Engineers

Operation Engineers

Process Engineers

DURATION:

5 days

TOPICS:

Terminology of process control

Review of basic feedback control schemes

Review of PID control algorithms & application criteria

Cascade control

Ratio control

Split range control

Override control

Feed-forward control

The dead time problem & how to deal with it

Controller tuning & calculation of tuning parameters

Application examples

Open discussion on process control

Engineering For The Petroleum And Process Industries

TECHNICAL

93

IC | INSTRUMENTATION & CONTROL

IC

10

PROCESS CONTROL SYSTEMS (Advanced)

OBJECTIVE:

Participants will get acquainted with the advanced methods, techniques and

applications of advanced process control. Participant will learn about system

performance evaluation, automated tuning, optimal state estimators, model predictive

control, fuzzy logic control and neural networks.

WHO SHOULD ATTEND:

Senior Instrumentation Engineers

Senior Process/Operation Engineers

DURATION:

5 days

TECHNICAL

TOPICS:

94

Basic Principles of advanced process control

Evaluating system performance

Process characteristics & automated tuning

Adaptive control

Expert systems

Optimal state estimators

Model predictive control

Fuzzy logic control

Neural network

Engineering For The Petroleum And Process Industries

INSTRUMENTATION & CONTROL | IC

IC

11

PROGRAMMABLE LOGIC CONTROLLERS (PLC)

(Basic)

OBJECTIVE:

Participants will be introduced to the main concepts, components, architecture

practices and guidelines of Programmable Logic Controllers (PLC) Systems.

WHO SHOULD ATTEND:

Instrumentation/Electrical Engineers (minimum 2 years experience in process plants)

DURATION:

5 days

TOPICS:

Engineering For The Petroleum And Process Industries

TECHNICAL

Conceptual review:

- Sequence Control

- Process & Equipment Alarms & Alarm Levels

- Process Shutdown Requirements

- Emergency Shutdown Requirements

- The need for event monitoring & recording

Basic components & functions of PLCs

Triple Modular Redundant PLCs (TMR)

Logic diagrams/overview:

- Cause & effect diagrams

- Functional logic

- Ladder logic

- Ladder logic functional diagrams

Programming languages

Review of IEC 1131 - 3 as a standard programming resource

95

IC | INSTRUMENTATION & CONTROL

IC

11

PROGRAMMABLE

LOGIC CONTROLLERS (PLC)

,

(Basic) (Cont d)

TOPICS: (Cont,d)

PLCs & hybrid control (PIDs & logic control)

Design basis & selection guidelines

FAT & SAT guidelines

PLC installation guidelines

Preventive maintenance guidelines

Corrective maintenance & spare parts management

TECHNICAL

96

Engineering For The Petroleum And Process Industries

INSTRUMENTATION & CONTROL | IC

IC

12

PROGRAMMABLE LOGIC CONTROLLERS (PLC)

(Advanced)

OBJECTIVE:

Participants will be introduced to Programmable Logic Controllers (PLC) including:

binary logic fundamentals, input & output systems and advanced ladder programming.

Participants will also learn about the advanced data communication system.

WHO SHOULD ATTEND:

Senior Instrumentation Engineers

Senior Electrical Engineers

DURATION:

5 days

TOPICS:

Introduction to programmable controllers

Binary logic fundamentals

Input/output systems

Memory & addressing

Ladder diagram programming

Advanced ladder programming

Standard PLC programming languages

Functional block diagram programming

Data communication systems

Engineering For The Petroleum And Process Industries

TECHNICAL

97

IC | INSTRUMENTATION & CONTROL

IC

13

SUPERVISORY CONTROL & DATA ACQUISITION SYSTEM

(SCADA)

OBJECTIVE:

Participants will learn about the main concepts, components and architecture practices

and guidelines of Supervisory Control & Data Acquisition System (SCADA)

WHO SHOULD ATTEND:

Instrumentation Engineers

Electrical Engineers

(Familiar with the concepts associated with microprocessors & digital systems)

DURATION:

5 days

TECHNICAL

TOPICS:

98

Basic Concepts & Features

Basic architecture of a SCADA system

Basic hardware components

Communications systems overview

Transmission media

Remote Terminal Unit (R.T.U)

Master Terminal Unit (M.T.U)

Operator interface

System security requirements and concepts

Selection of a SCADA system

Pre-installation site planning

Installation requirements and considerations

Preventive maintenance guidelines

Engineering For The Petroleum And Process Industries

INSTRUMENTATION & CONTROL | IC

IC

13

SUPERVISORY CONTROL&

DATA ACQUISITION SYSTEM

,

(SCADA) (Cont d)

TOPICS: (Cont,d)

Corrective maintenance & spare parts management

Software upgrades & support

Training considerations

FAT & SAT guidelines

TECHNICAL

Engineering For The Petroleum And Process Industries

99

IC | INSTRUMENTATION & CONTROL

IC

14

DISTRIBUTED CONTROL SYSTEMS (DCS)

OBJECTIVE:

Participants will learn about the basic concepts, components & architecture practices &

guidelines for the Distributed Control System (DCS).

WHO SHOULD ATTEND:

Instrumentation Engineers

Process Engineers

(Five Years experience in process plants)

DURATION:

5 days

TECHNICAL

TOPICS:

100

Introduction & historical background

Basic architecture of DCS

Basic hardware components

Communications systems overview

System security requirements & concepts

Implementation of project-specific applications

DCS graphics & displays philosophy & guide lines

Windows-based displays & operator interactions

What does open architecture mean?

Pre-installation site planning

Preventive maintenance guidelines

Corrective maintenance & spare parts management

Software upgrades & support

Training considerations

FAT & SAT guidelines

Engineering For The Petroleum And Process Industries

INSTRUMENTATION & CONTROL | IC

IC

15

ADVANCED DCS & SIS CONTROL PHILOSOPHY

OBJECTIVE:

Participants will learn the most recently applied trends in control systems with due

emphasis on the advanced DCS. Participants will further understand the system main

components, architecture & design, configuration & interface with process. Participants

will also get acquainted with system safety and control philosophy.

WHO SHOULD ATTEND:

Instrumentation Engineers

Process Engineers

DURATION:

5 days

TOPICS:

Recent trends for digital control systems

Main benefits of advanced DCS

Basic components - structure of advanced DCS

System architecture simplified design

Distributed control system configuration

System interface with process

Openness & integration with PLC,s

System maintenance

How to evaluate a DCS system

Plant safety & control standards

Engineering For The Petroleum And Process Industries

TECHNICAL

101

IC | INSTRUMENTATION & CONTROL

IC

16

FIELD BUS FOUNDATION

OBJECTIVE:

This course aims at providing participants with a comprehensive overview of Emerson

data communicator,s fundamental, operation principles and guidelines. Participants

will have a comprehensive hands-on training on field bus foundation, maintenance

and troubleshooting.

WHO SHOULD ATTEND:

Instrumentation Engineers/Technicians

Operators & Maintenance Staff

DURATION:

5 days

TECHNICAL

TOPICS:

102

Introduction to foundation field bus (FF) benefits, components & terminology

FF technology (hardware & software)

Overview of field bus communications fundamentals

Field bus blocks

Field bus engineering

Segment design

Field bus interoperability

Reliability & redundancy

Field bus intrinsically safe

Field bus commissioning

Field bus diagnostic

Installation, operation, maintenance & troubleshooting

Engineering For The Petroleum And Process Industries

INSTRUMENTATION & CONTROL | IC

IC

17

ON-LINE ANALYZERS & VIBRATION MEASUREMENTS

OBJECTIVE:

Participants will gain knowledge of modern applied techniques for online measurement

of chemical composition and properties of liquid and gas streams. Participants will also

be introduced to vibration measurement modern techniques and applications.

WHO SHOULD ATTEND:

Instrumentation Engineers

Operation/Mechanical Engineers

DURATION:

5 days

TOPICS:

On-line analysis

Infrared absorption

Thermal conductivity

O2 analysis

Chromatography

Dew point analysis

Density meters

Reid vapor pressure analyzer

What is vibration?

Amplitude, velocity, acceleration measurement

Phase measurement

Time plots

X-Y plots

Vector notion & balancing application

Fundamentals of magnetic bearings

Engineering For The Petroleum And Process Industries

TECHNICAL

103

IC | INSTRUMENTATION & CONTROL

IC

18

HYDRAULIC/PNEUMATIC CONTROL TECHNOLOGY

OBJECTIVE:

Participants will be introduced to the basic concepts, components, practices and

application of hydraulic/pneumatic control technology. Participants will learn about

the main techniques & equipment of hydraulic/pneumatic control such as hydraulic

fluids, pumps, motors, rotary actuators, accumulators.... etc.

WHO SHOULD ATTEND:

Instrumentation Engineers

Operation/Mechanical Engineers

DURATION:

5 days

TECHNICAL

TOPICS:

104

Basic principles of hydraulic/pneumatic control system

Standard symbols

Hydraulic fluids

Hydraulic pumps & motors

Hydraulic axial piston units

Hydraulic cylinders

Rotary actuators

Accumulators

Non-return & directional valves

Pressure & flow control valves

Filter & other accessories

Pneumatic devices installations, operation concepts

Engineering For The Petroleum And Process Industries

INSTRUMENTATION & CONTROL | IC

IC

18

,

HYDRAULIC/PNEUMATIC CONTROL TECHNOLOGY (Cont d)

TOPICS: (Cont,d)

Hydraulic power units

Example application of: detailed design of shutdown, well head control panels, line

break detection systems

TECHNICAL

Engineering For The Petroleum And Process Industries

105

IC | INSTRUMENTATION & CONTROL

IC

19

EMERGENCY SHUTDOWN SYSTEM (ESDS)

OBJECTIVE:

Participants will be introduced to the basic concepts of process safe guarding systems.

Participants will learn about the basic concepts of safety automation systems along

with the main safeguarding system components.

WHO SHOULD ATTEND:

Instrumentation Engineers with automatic control theory background

Process & Operation Engineers

DURATION:

5 days

TECHNICAL

TOPICS:

106

Basic definitions of safety terms

Safety Standards

Safety Considerations

Principle Functions

Availability & Reliability Issues

System architecture & components

Examples of ESD systems applied in the Oil & Gas Industry

HIPPS System

Engineering For The Petroleum And Process Industries

INSTRUMENTATION & CONTROL | IC

IC

20

DISTILLATION COLUMN CONTROL

OBJECTIVE:

Participants will learn about the main principles and methods of design and operation

for distillation column control.

WHO SHOULD ATTEND:

Instrumentation Engineers

Operation Engineers

DURATION:

5 days

TOPICS:

Engineering For The Petroleum And Process Industries

TECHNICAL

Basic operation in distillation:

- Function of components

- Maintaining product composition

- Vapor pressure in components

- Controlling pressure & temperature

Reflux stream:

- Features of reflux stream

- Controlling reflux stream & bottoms

Controlling heat in the system:

- Temperature control in reboiler

- Pressure control

- Working of column feed control

- Control of column bottoms

- Control of column temperature

Controlling transport of condensate:

- Flow of condensate

- Control of reflux rate

107

CE | CIVIL ENGINEERING

CE

01

REPAIR & STRENGTHENING OF CONCRETE STRUCTURE

OBJECTIVE:

Participants will learn about the main causes of defects in structures and how to

evaluate and avoid them each type with suggested remedies.

WHO SHOULD ATTEND:

Structural Engineers

Civil Engineers

DURATION:

3 days

TECHNICAL

TOPICS:

108

Reasons of defects

Types of cracks

Corrosion cause and effect

Evaluation of defects

Testing methods

Methods of repairing and strengthening

Repair of cracks

Provision to protect against repair of corrosion

Materials used for repair

Repair and strengthening of columns, beams, slabs and footings

Engineering For The Petroleum And Process Industries

Вам также может понравиться

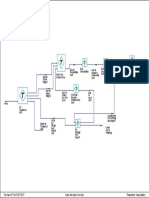

- Workbook: Vent Gas Recover Compression Unit (TPL2) : StreamsДокумент3 страницыWorkbook: Vent Gas Recover Compression Unit (TPL2) : StreamsTayebASherifОценок пока нет

- Flash Gas Compression: Tue Nov 07 19:07:07 2017 Case: The Last R & M.HSC Flowsheet: Case (Main)Документ1 страницаFlash Gas Compression: Tue Nov 07 19:07:07 2017 Case: The Last R & M.HSC Flowsheet: Case (Main)TayebASherifОценок пока нет

- Strategic Account Plan e BookДокумент22 страницыStrategic Account Plan e BookTayebASherif100% (1)

- Trouble Shooting CourseДокумент4 страницыTrouble Shooting CourseTayebASherifОценок пока нет

- LLEXДокумент1 страницаLLEXTayebASherifОценок пока нет

- HYSYS Petroleum Refining Ops-V9Документ822 страницыHYSYS Petroleum Refining Ops-V9TayebASherif50% (2)

- DRW 1Документ3 страницыDRW 1TayebASherifОценок пока нет

- Introductory Session To Process Engineering in The Oil & GasДокумент1 страницаIntroductory Session To Process Engineering in The Oil & GasTayebASherifОценок пока нет

- Sr. Process Engineer CVДокумент6 страницSr. Process Engineer CVTayebASherif50% (2)

- Introduction To Electrical EngineeringДокумент2 страницыIntroduction To Electrical EngineeringTayebASherif100% (1)

- Electrical Materials Sizing CalculationДокумент3 страницыElectrical Materials Sizing CalculationTayebASherifОценок пока нет

- Oil & Gas Technologies Overview CVДокумент2 страницыOil & Gas Technologies Overview CVTayebASherifОценок пока нет

- Tanks CalculationsДокумент102 страницыTanks CalculationsTayebASherifОценок пока нет

- Expanding The Column Overhead System: Instructor: Eng. Ahmed Deyab Fares Mobile: 0127549943Документ14 страницExpanding The Column Overhead System: Instructor: Eng. Ahmed Deyab Fares Mobile: 0127549943TayebASherifОценок пока нет

- Instrumetation Report ClarificationДокумент10 страницInstrumetation Report ClarificationTayebASherifОценок пока нет

- KaibelДокумент2 страницыKaibelTayebASherifОценок пока нет

- Control Valves FekerДокумент180 страницControl Valves FekerTayebASherifОценок пока нет

- Cover Letter: Jerry VargheseДокумент1 страницаCover Letter: Jerry VargheseTayebASherifОценок пока нет

- Nfpa 58 2011 Compliance PackageДокумент29 страницNfpa 58 2011 Compliance PackageTayebASherifОценок пока нет

- STF Kemim ValveДокумент3 страницыSTF Kemim ValveTayebASherifОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Guide Book Fatek Vol.1Документ62 страницыGuide Book Fatek Vol.1PutraHarizalОценок пока нет

- Boiler Automation PDFДокумент5 страницBoiler Automation PDFHarshada DeokateОценок пока нет

- Priyan Mendis Et Al - Recent Advances in Security Technology 2007Документ399 страницPriyan Mendis Et Al - Recent Advances in Security Technology 2007YamveaОценок пока нет

- Oring PerformanceДокумент66 страницOring Performancefake fОценок пока нет

- CGD IntroductionДокумент48 страницCGD IntroductionManav Modi0% (1)

- Installation Manual - SMD V3Документ35 страницInstallation Manual - SMD V3FelipeOliveiraОценок пока нет

- A30 1 PDFДокумент2 страницыA30 1 PDFscribdkhatnОценок пока нет

- Training CoursesДокумент16 страницTraining CoursesFeroz KhanОценок пока нет

- 7SJ80 Katalog EnglДокумент23 страницы7SJ80 Katalog EngleliahudОценок пока нет

- PLC TrainingДокумент4 страницыPLC Trainingshaleenm_2Оценок пока нет

- C264 BrochureДокумент8 страницC264 Brochurechaima haddoudiОценок пока нет

- State Board of Technical Education and Training, Tamil Nadu Syllabus For Diploma in Electrical and Electronics Engineering L-SchemeДокумент6 страницState Board of Technical Education and Training, Tamil Nadu Syllabus For Diploma in Electrical and Electronics Engineering L-SchemeRoshindas Pudhiya PurayilОценок пока нет

- WWW Control Com Thread 1026194428Документ23 страницыWWW Control Com Thread 1026194428skyline1122Оценок пока нет

- SCADA Functional Design DocumentДокумент130 страницSCADA Functional Design DocumentFIRMANSYAH100% (1)

- DELTA IA-SI DIAView C EN 20190517 web-SCADAДокумент20 страницDELTA IA-SI DIAView C EN 20190517 web-SCADAchandra mouliОценок пока нет

- Scada ReportДокумент29 страницScada Reportkiswah computersОценок пока нет

- Ikeydiag Manual PDFДокумент18 страницIkeydiag Manual PDFjucegarciaОценок пока нет

- An Introduction To MOP 21 - Automation of Wastewater Treatment FacilitiesДокумент5 страницAn Introduction To MOP 21 - Automation of Wastewater Treatment FacilitiesSugrit BuddhirakkulОценок пока нет

- 2016 US UTC Meet The TeamДокумент3 страницы2016 US UTC Meet The Teamapic20Оценок пока нет

- Amalmathew CURRICULUM VITAEДокумент3 страницыAmalmathew CURRICULUM VITAEahmadОценок пока нет

- SQ-402 SCADA Add-In User GuideДокумент23 страницыSQ-402 SCADA Add-In User Guidemojsic6313100% (1)

- Essay Examples About LifeДокумент7 страницEssay Examples About Lifeyeuroqaeg100% (2)

- Wellwatcher Instruct: Multiwell Acquisition UnitДокумент2 страницыWellwatcher Instruct: Multiwell Acquisition UnitRRAОценок пока нет

- TLC For Your PlcsДокумент5 страницTLC For Your Plcsdavev2005Оценок пока нет

- Industrial Automation Using PLC and Scada: Presented byДокумент27 страницIndustrial Automation Using PLC and Scada: Presented bycaddcentre gtiОценок пока нет

- Sigma Load ControlДокумент3 страницыSigma Load ControlTanmoy AcharyaОценок пока нет

- Design SCADA Remote Supervision Operation Wind Power Plants PDFДокумент72 страницыDesign SCADA Remote Supervision Operation Wind Power Plants PDFwilliamОценок пока нет

- CH 3. Four Pillars of IoTДокумент15 страницCH 3. Four Pillars of IoTKarthik Sara MОценок пока нет

- Remote Terminal Unit (RTU) Hardware Design PDFДокумент4 страницыRemote Terminal Unit (RTU) Hardware Design PDFMootez MnassriОценок пока нет

- Are Va TrainingДокумент620 страницAre Va TrainingFLAMMMMME100% (4)