Академический Документы

Профессиональный Документы

Культура Документы

Sizing Gensets For Motor Starting

Загружено:

Qatada1Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sizing Gensets For Motor Starting

Загружено:

Qatada1Авторское право:

Доступные форматы

Power Systems

POWER SYSTEMS TOPICS 103

Sizing gensets for motor starting

A practical guide to understanding how motor-starting loads affect genset performance

By:

Dan Krueger

Senior Field

Applications Engineer

Kohler Power

Systems-Americas

Rick Van Maaren

Senior Staff Engineer

Kohler Power

Systems-Americas

Todays standby power loads are

more complex than ever before. In

many industrial and commercial

applications, standby gensets must

supply power to a mixture of linear

and nonlinear loads in addition to

large motor loads that cycle on and

off. Of all the diverse loads a standby

genset must supply, applications with

motors present the most sizing issues.

The dynamic interactions of motors

and gensets along with the impact

of motor starters, system inertia,

motor loading, frequency dip, genset

preload and nonlinear loading make

manual genset sizing difcult, if

not impossible.

Not only is sizing an application

with large motors complex, but

different genset manufacturers have

different approaches for specifying

a standby power system that

will function reliably. Each major

genset manufacturer has created

genset-sizing software to help

with this complex task, but due to

manufacturers differing approaches

to motor starting, this software

can yield quite different results

sometimes specifying a larger and

more expensive generator or too small

a generator than is necessary for

KohlerPower.com

reliable operation. The purpose

of this article is to explain how

motors affect genset performance

and how sizing software, such as

Kohler Power Systems QuickSize,

deals with motor loads. Armed

with this understanding, power

system speciers will be able to

select the most cost-effective and

reliable genset for motorstarting applications.

BASIC CHARACTERISTICS OF

MOTOR LOADS

Motor loads cause difculty because a

motor draws high current when started

at full voltage. Starting current is typically

six times a motors rated full-load current,

and this inrush current stays high until the

motor reaches about 75 percent of rated

speed. When a motor is started on normal

utility power, the high inrush current will

cause only a small voltage dip because

the utility is a more robust voltage source.

However, when a motor is started on

genset power, the high inrush currents

(measured in kilovolt-amperes or KVAs) can

result in a large voltage dip that can inhibit

the motor from reaching its

operating speed.

The challenge, then, is to size the genset

to handle the motor-starting load, but also

2009

by Kohler Co.

POWER SYSTEMS TOPICS 103

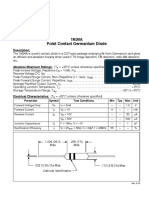

Letter Designation

KVA per Horsepower

with Locked Rotor

0 - 3.14

3.15 - 3.54

3.55 - 3.99

4.0 - 4.49

4.5 - 4.99

5.0 - 5.59

5.6 - 6.29

6.3 - 7.00

7.1 - 7.99

8.0 - 8.99

9.0 - 9.99

10.0 - 11.10

11.2 - 12.49

12.5 - 13.99

14.0 - 15.99

16.0 - 17.99

18.0 - 19.99

20.0 - 22.39

22.4 and up

Manufacturers Association (NEMA) sets design

standards for motors and has established a

NEMA code-letter designation for classifying

motors according to the ratio of locked-rotor

KVAs (LRKVAs) per horsepower. These code

letters range from A to V, covering motors with

an LRKVA-per-horsepower ratio of 3.14 or less

to a ratio of 22.4 LRKVA-per-horsepower or

more. See Figure 1.

For example, a 50 hp Code F motor requires

279.5 LRKVA per horsepower upon starting

(50 hp x 5.59 LRKVA per hp = 279.5 LRKVA/hp).

LRKVA is also known as starting KVA

or SKVA.

Small motors have a higher NEMA code

letter and correspondingly higher LRKVA-perhorsepower requirement than large motors.

Typical motor sizes and codes are shown in

Figure 2.

Figure 1: Locked Rotor Indicating Code Letters

Source: 2006 NEMA

VOLTAGE DIP

to minimize the impact on the other connected

loads that may be affected by voltage dips or

frequency dips.

Therefore, when sizing a genset, it is critical

to accurately predict voltage dips and to

understand how much excess starting capability

is available in the motor and what amount of

voltage dip can be allowed. The most common

methodology for sizing gensets for motor

starting focuses on understanding allowable

instantaneous voltage dips, as the

primary criteria. However, there is

Size

one manufacturer that considers

allowable sustained voltage dips

1 - 2 HP

as the primary criteria for

3 HP

5 HP

motor-load starting.

The motor-starting KVA can

be determined by the motors

nameplate. The National Electrical

KohlerPower.com

p. 2

The KVA requirements of a motor running at

full load and rated speed are normally less than

one KVA per horsepower. With the possible

exception of small motors, it would be overly

conservative to size a genset set simply by

matching the alternators KVA to the motors

KVA. This would typically result in a genset

with more than twice the capacity necessary.

However, due to the dynamic interaction of the

system components, several characteristics

combine to make this approach impractical.

Code

Locked Rotor

KVA/HP

L or M

9 - 11

8- 9

7-8

7.5 - 10 HP

6-7

15 HP and up

5.6 - 6.3

Figure 2: Typical Code Letters for Various HP Motors

Source: 2006 NEMA

Power Systems

POWER SYSTEMS TOPICS 103

HP

E

IN

G

N

E

A

KV

/

P

H

AT

8

0.

PF

F

.4 P

T0

A

A

/KV

HP

E

GIN

EN

Values for motor LRKVA are based on fullvoltage starting. In practice, there is always

a voltage dip when a motor is started on

genset power, and there is even a small dip

when a motor is started on utility power.

When the voltage drops, inrush current is also

proportionally reduced so that starting KVA is

reduced as the square of the voltage dip. A 30

percent voltage dip reduces starting KVA by

about 50 percent (0.7 kilovolts x 0.7

amps = 0.49 KVA).

At least for the rst few cycles, the voltage

AMPS OR KVA

0.4 Power Factor = 50% HP Factor

Figure 3: Engine Power Required for

Low Power-Factor Load

Source: Kohler Power Systems

The rst characteristic is power factor. Threephase genset sets are usually rated in KVA at 0.8

power factor. Starting power factors of motors

vary from 0.3 to 0.5 and increase towards unity

as the motor accelerates and its KVA demand

drops. With a 0.4 power-factor load, a typical

genset is capable of producing nearly twice

its continuous-rated KVA for the time required

to accelerate a motor to the speed at which

its KVA requirement drops sharply. The genset

engine will not stall even though it is being asked

to supply more than its rated KVA, because

low power-factor loads (see Figure 3) do not

require as much horsepower as higher powerfactor loads. This genset characteristic allows

satisfactory motor-starting results with a genset

half the size predicted by the conservative

approach, which matches the genset 0.8 powerfactor KVA rating to the motor-LRKVA rating.

VOLTAGE DIP

The other characteristic that can substantially

reduce the size of the genset needed for a

particular motor-starting load is voltage dip.

KohlerPower.com

p. 3

dip is determined by the size of the load

(i.e., the motors LRKVA) and the reactance of

the alternator which is somewhat proportional

to the total mass of copper and iron present in

the alternator. The issue in sizing a genset is

determining what voltage dip will be acceptable

for a particular load when considering its effect

on all components in the system, some of

which may have unknown transient

acceptance specications.

A voltage dip can affect motors themselves,

in addition to other loads on the system. For

example, excessive voltage dip can cause

control relays or magnetically held motorstarting contactors to drop out, or ultimately,

cause the motor to not start at all. If the relays

or contactors drop out, the load is removed

from the genset, causing voltage to rise and

the cycle to repeat rapidly. This can damage

contactors if allowed to continue. Most control

relays and motor-starting contactors will tolerate

a 35 percent voltage dip. However, there are

exceptions. Some relays or contactors will

start to chatter if subjected to a voltage dip as

little as 20 percent. Likewise, other voltagesensitive loads need to be accounted for

(e.g., UPS systems, medical equipment, HID

lighting) in any genset-sizing exercise. To ensure

satisfactory operation on a given standby power

Power Systems

POWER SYSTEMS TOPICS 103

MOTOR STARTERS CAN REDUCE

VOLTAGE DIP

system, consult the voltage/frequency

limitations of control components from the

manufacturers or suppliers.

The high inrush current and high starting

torque associated with full-voltage starting

of motors on utility power may create

problems with the equipment driven by

the motor, or the voltage dips may raise

objections from the electric utility. To

circumvent these issues, many facilities

use various types of motor starters for their

motors. Some of these devices also benet

motor starting when running on genset

power, often allowing a smaller genset to

be utilized.

Voltage dips also reduce the torque a

motor can supply to its load. A common

NEMA Design B motor will develop 150

percent of rated full-load torque during

starting. Torque is proportional to the KVA

delivered to the motor, so a 30 percent

voltage dip that reduces KVA to 49 percent

also reduces torque to 49 percent of its

rating. If the motor starts unloaded as

most fans, centrifugal pumps and motors

used with elevators do this torque

reduction produces no problem other than

a somewhat longer acceleration time.

Other types of loads, such as positive

displacement pumps, may require more

Closed Transition

Open Transition

4

Line Circuit

4

Line Circuit

Reduced-voltage starters Most

reduced-voltage starters connect the load

to the power source in two or more steps.

The starters may be either open- or

closed-transition starters, but only closedtransition, reduced-voltage starters are

helpful when running on genset power. As

seen in Figure 4, open-transition starters

create an unacceptable spike in KVA

demand when switching between

steps occurs.

Start

Start

2

Run

Run

Time

Time

Figure 4: Closed Transition vs. Open Transition Starters

Source: Kohler Power Systems

torque than the motor can develop at

reduced voltage, which prevents the

motor from reaching full speed. Additional

consequences could include tripping of

breakers or overheating of the motor. To

ensure proper motor starting in these

applications, it is necessary to compare the

torque curves of the pump and the motor at

reduced voltage.

Part-winding starters Part-winding

starters are used with motors that have two

identical windings intended to be connected

in parallel. These windings can be energized

in sequence to provide reduced starting

current and torque. Since part-winding

starters are inherently closed-transition

starters, the maximum inrush current occurs

at the moment the rst winding is energized,

and the maximum inrush KVA load on a

genset set will be reduced to 6070 percent

of normal.

See Figure 5.

Autotransformer starters This type

of starter provides reduced voltage at

KohlerPower.com

p. 4

Power Systems

POWER SYSTEMS TOPICS 103

Solid-state (soft-start) starters This

type of starter is most popular and provides

exceptional operating exibility. It is a form

of reduced-voltage starter that utilizes silicon

controlled rectiers (SCRs) to increase voltage

at a predetermined rate. Limits on the starting

current can also be adjusted to increase system

performance. A note of caution: any performance

prediction made at a specic value will change

when the settings are changed in the eld. Also,

since solid-state starters utilize nonlinear SCRs,

they can cause voltage distortion during motor

starting that must be considered.

LINE CURRENT - % OF FULL LOAD

Wye-delta starters Some motors have six

leads that allow them to be connected in either

600

Full Voltage Starting

Part-Winding Starting

100

33 percent of the delta connected values. Use

only with closed-transition starters, however.

See Figure 7.

FACTORS AFFECTING REAL-WORLD

MOTOR STARTING

Genset frequency dip The gensets engine

cannot be ignored in motor starting due to

the high horsepower demanded when a large

motor is started. When the engine slows under

load, frequency dips; this, in turn, increases

the alternator voltage dip. The amount of

impact on engine RPM during motor starting is

dependent on the performance characteristics

of a given conguration of engine and alternator.

These factors are taken into consideration

when running the sizing software based on a

maximum allowable voltage and frequency dip.

Voltage regulator and excitation system

response time Thorough testing has revealed

that in addition to the transient reactance of the

LINE CURRENT - % OF FULL LOAD

the motor terminals from a tapped 3-phase

autotransformer and generally gives the best

results with gensets. See Figure 6. Taps on

the transformer provide selection of 80, 65 or

50 percent of initial line voltage to the motor

terminals. Starting torque is reduced by the

voltage squared to give 64, 42 or 25 percent

of the full-voltage value, respectively. To avoid

reducing starting torque to unacceptable levels,

use either the 80 or 65 percent taps.

600

Full Voltage Starting

Autotransformer Starting on 65% Tap

100

Full Load Current

0

MOTOR SPEED

Full Load

Speed

Figure 6: Autotransformer Starting

Source: Kohler Power Systems

Full Load Current

MOTOR SPEED

Full Load

Speed

Figure 5: Part-Winding Starting

alternator, voltage regulators and exciters affect

voltage dip and recovery. A fast-responding

excitation system can limit the initial voltage dip

as shown in Figure 8.

Source: Kohler Power Systems

wye or delta congurations. By connecting the

motor winding in the wye conguration and using

a voltage source corresponding to the delta

rating, starting current and torque are reduced to

KohlerPower.com

p. 5

On voltage dips of 35 percent or less, a fastresponding system will start the motor faster.

Power Systems

LINE CURRENT - % OF FULL LOAD

POWER SYSTEMS TOPICS 103

operation of magnetic motor starters and other

equipment running on the genset, never exceed

a 35 percent instantaneous voltage dip.

600

Full Voltage Starting

Wye-Delta Starting

Closed Transition

100

Full Load Current

0

MOTOR SPEED

Full Load

Speed

Figure 7: Wye-Delta Starting

Source: Kohler Power Systems

Preloaded genset The pre-existing load on

the genset can affect both the frequency dip and

voltage dip during motor starting. For example,

a 50 percent preloaded genset may dip an

additional 2 percent compared to the

published gure.

Nonlinear loads Electronic motor starters and

Variable Frequency Drives (VFDs) are nonlinear

loads. VFDs are not actually a motor-starting

problem but a potential harmonic distortion

problem. Check the genset manufacturers sizing

program to see if it predicts the voltage

harmonics present when running nonlinear

loads. This can be very useful for analyzing

harmonic concerns.

Loaded motors These tend to take longer to

accelerate and recover to full voltage, due to the

initial loaded condition of the motor. With loaded

motors, there is a more signicant relationship

between recovery voltage during motor starting

and the gensets ability to accelerate the motor

to full speed and rated voltage. A few examples

of loaded motors include the following:

rock crushers, elevators, conveyors, single/

multicylinder compressors and

submersible pumps.

VOLTAGE RECOVERY VERSUS

VOLTAGE DIP

Genset manufacturers differ on some of the

fundamental criteria for proper genset sizing for

motor starting. Most manufacturers focus on

instantaneous voltage dip as the primary factor

in genset sizing, while at least one manufacturer

stresses voltage recovery during motor starting

Motor Starting

Voltage vs Time

120%

110%

100%

MOTOR LOADING

There are two types of motor loading: highbreakaway-torque loads (i.e., unloaded

motors) and high-inertia loads (i.e.,

loaded motors).

Unloaded motors These tend to reach

operating speed quickly. A few examples

of unloaded motors include the following:

centrifugal blowers, rotary and centrifugal

pumps (starting under low head pressure),

clutched motors and fan motors (starting

with low restriction). To avoid improper

KohlerPower.com

p. 6

90%

80%

70%

Fast Responding

Exciter

Conventional Exciter

60%

50%

40%

30%

20%

10%

0%

0

0.5

1.5

Time

Figure 8: Motor-Starting Voltage vs Time

Source: Kohler Power Systems

Power Systems

POWER SYSTEMS TOPICS 103

VOLTAGE (PERCENT OF RATED)

105

V4

V2

100

+%

-%

V3

95

V1

90

85

80

T0

T1

T2

TIME (SECONDS)

V1 = Voltage dip

T0 = Point at which load is applied

V2 = Maximum transient voltage overshoot

T1 = Time to recover to a specified band

V3 = Recovery voltage

T2 = Time to recover to and remain

V4 = Steady-state regulator

within the specified band

Figure 9 Generator Transient Voltage vs.Time for Sudden Load Change

Source: 2006 NEMA MG1 Part 32

as the primary driver for genset sizing, which

can lead to confusing specications. However,

extensive eld experience indicates that voltage

recovery is more a function of exciter size

than of main alternator size, and not a true

representation of the gensets ability to start

the motor.

While it is necessary to account for the extended

acceleration time of motors starting under

a loaded condition, addressing the required

LRKVA at the maximum instantaneous voltage

dip experienced by all the connected loads

should remain the primary criteria. In lab testing

with actual motors and very high inertia loads,

researchers have found that because of the

dynamics of motor inrush current and power

factor changes, actual motor-starting capability

is more closely correlated with instantaneous

voltage dip than with voltage recovery. Both

NEMA and MIL standards have recognized that

the initial voltage dip is the primary criteria to be

used in genset sizing.

KohlerPower.com

p. 7

FUNDAMENTAL CRITERIA FOR

MOTOR STARTING

Regardless of what sizing method is used or

how manufacturers specify motor-starting

performance, the following fundamental criteria

for motor starting must be accomplished and

in the following sequence to successfully

start a motor:

1. Sufcient LRKVA at the instantaneous

voltage dip for inrush current

The required LRKVA at the maximum

permissible instantaneous voltage dip is

considered to be the rst step for motor starting

by most genset and alternator manufacturers.

Typical motors are designed to sustain a 30 to

35 percent instantaneous voltage dip before

the motor-starting contacts drop out. Many

specifying engineers prefer a maximum 20

percent instantaneous voltage dip limit to

ensure the motor will start and hold in the

starting contacts.

2. Sufcient genset torque and power

Next, the torque available from the genset must

exceed the torque required by the motor load,

or the motor will stall or never start.

3. Sufcient alternator excitation system

strength The genset must have sufcient

excitation system strength and adequate

response to accelerate the motor and return it

to operational voltage and speed. This third and

nal step addresses voltage recovery.

INSTANTANEOUS VERSUS SUSTAINED

VOLTAGE DIP

While most genset manufacturers focus

on instantaneous voltage dip as a primary

criterion for genset sizing, at least one genset

manufacturer writes specications with a

Power Systems

POWER SYSTEMS TOPICS 103

different maximum motor-starting KVA value

that allows the genset voltage to recover to 90

percent of rated voltage. This concept known

as sustained voltage dip maximum KVA

assumes that when the genset can recover to 90

percent of rated voltage, the motor will develop

81 percent rated torque, allowing the motor to

accelerate to full speed in most applications.

Real-world experience reveals that using a 90

percent sustained-voltage motor-starting KVA

value can overstate motor-starting performance

and lead to improper sizing of the genset due to

dynamic conditions during motor starting.

Voltage Dip (%)

Please see the graph below for a

visual explanation.

60.0%

55.0%

50.0%

45.0%

40.0%

35.0%

30.0%

25.0%

20.0%

15.0%

10.0%

5.0%

0.0%

Instantaneous Voltage Dip Rating

at 90% Sustained Voltage Dip

The entire red shaded area is not

available if the motor starting

contacts drop out at a 35% voltage

dip. At a 20% voltage dip

requirement, the area of available

LRKVA is further reduced.

Nameplate

LRKVA

500

1000

1500

2000

2500

3000

3500

Motor Nameplate LRKVA

Figure 10: Motor Nameplate LRKVA vs Voltage Dip

Source: Kohler Power Systems

Caution - Maximum LRKVA based on sustained

voltage of 90 percent can and usually does

show a much larger value, but the voltage dip

is typically greater than 35 percent. The LRKVA

value at 90 percent sustained voltage can be

excessively overstated, as it is of no use once

exceeding either 35 percent instantaneous

voltage dip or less, if required by the motor.

KohlerPower.com

p. 8

CONCLUSION

When using a genset to supply motor-starting

loads, the interactions are dynamic and complex.

For the most reliable and accurate results, the

sizing exercise needs to consider the genset as a

system, including the engine, alternator, voltage

regulator and excitation system, along with motor

starters. Dynamic conditions, such as systems

inertia, motor loading, motor type and genset

preload, are also important. By analyzing this

dynamic system and evaluating the functions

in real-world applications, speciers will have a

better understanding of how to properly predict

motor-starting performance in a more consistent

and reliable way.

Finally, due to the complexity of total system

loads and the dynamics of the genset and

motor-starting applications, its important

to utilize proven genset-sizing software to

ensure performance of the entire system in

its specic application.

QuickSize is Kohlers genset-sizing software;

it includes industry-leading features, such as

the ability to select gensets based on voltage

dip, frequency dip and total harmonic distortion.

These features allow the user to select the genset

set that best ts his or her power requirements.

The user can select different types of linear and

nonlinear loads, including motors, VFDs, UPS

systems, battery chargers, ofce equipment, air

conditioning, miscellaneous loads, lighting and

medical-imaging equipment.

QuickSpec is an industry-leading system

specication writing tool from Kohler that can

output a complete power system specication

for gensets and transfer switches. QuickSpec

outputs the specication into a rich text le that

can be saved in Microsoft Word for easy editing

and customization, allowing the user to integrate

the power system specication into a complete

building specication. To request access to the

QuickSize and QuickSpec programs, contact the

Kohler Power Systems distributor nearest you.

Power Systems

POWER SYSTEMS TOPICS 103

ABOUT THE AUTHORS

Dan Krueger is a Senior Field

Applications Engineer with Kohler Power

Systems-Americas. He has worked

within the power generation industry for

more than 15 years, in manufacturing,

product and business management,

and sales both domestically and

internationally. Krueger joined Kohler in 1998, primarily

working with the engineering community, supporting

system sales and providing training on KOHLER

products and paralleling switchgear systems.

Rick Van Maaren is a Senior Staff

Engineer with Kohler Power SystemsAmericas. He has worked in alternator

development of standby, marine,

residential and mobile generator sets

for more than 25 years. He holds a

BSEE from Michigan Technological

University, is a registered professional engineer in the

State of Wisconsin, a senior member of the IEEE and

a holder of four patents. He has authored an IEEE

IAS paper titled Rotor Lamination Design for Surface

Permanent Retention at High Speeds and a chapter of

the EGSA On-Site Power Generation reference book titled

Permanent Magnet Generators.

Power Systems

To contact us by phone, call +1-920-565-3381

or visit us online at KohlerPower.com

Kohler Power Systems

Kohler, Wisconsin 53044

Printed in U.S.A.

G26-7 KPS 103 6/09

2009 by Kohler Co.

Use of this material for reproduction on the Internet and World Wide

Web is strictly prohibited without written permission from Kohler Co.

Вам также может понравиться

- Sizing Gensets For Motor Starting PDFДокумент9 страницSizing Gensets For Motor Starting PDFQatada1Оценок пока нет

- 54-SMSS-2, Rev. 1Документ9 страниц54-SMSS-2, Rev. 1Qatada1Оценок пока нет

- Numerical Relay S Series Feeder Protection RelayДокумент8 страницNumerical Relay S Series Feeder Protection RelayQatada1Оценок пока нет

- Compact Integrated Distribution Substation (CIDSДокумент12 страницCompact Integrated Distribution Substation (CIDSQatada1Оценок пока нет

- Lucy Aegis Ring Main Unit Technical DatasheetДокумент2 страницыLucy Aegis Ring Main Unit Technical DatasheetQatada1Оценок пока нет

- 37-SDMS-01 Rev. 03 SPECIFICATIONS FOR LOW VOLTAGE MOLDED CASE CIRCUIT BREAKERS FOR SERVICE CONNECTIONSДокумент20 страниц37-SDMS-01 Rev. 03 SPECIFICATIONS FOR LOW VOLTAGE MOLDED CASE CIRCUIT BREAKERS FOR SERVICE CONNECTIONSQatada1Оценок пока нет

- Saso 2203 2015Документ22 страницыSaso 2203 2015Qatada1100% (1)

- SEC Distribution Transformer SpecificationsДокумент22 страницыSEC Distribution Transformer SpecificationsQatada1100% (1)

- Prequalified Manufacturers 20140101Документ26 страницPrequalified Manufacturers 20140101striker190Оценок пока нет

- Neutral Currents in 3 Phase Wye SystemsДокумент10 страницNeutral Currents in 3 Phase Wye SystemsscribdledeeОценок пока нет

- Harmonic CurrentsДокумент14 страницHarmonic Currents(unknown)Оценок пока нет

- Circuit BrakerДокумент62 страницыCircuit BrakerRony SuryatmanОценок пока нет

- Metal Enclosures - Al Fanar CatalogДокумент20 страницMetal Enclosures - Al Fanar CatalogAkhil MohanОценок пока нет

- Current Transformers Selection Guide PDFДокумент20 страницCurrent Transformers Selection Guide PDFsdvijayОценок пока нет

- Tiepco Unit SubstationДокумент1 страницаTiepco Unit SubstationQatada1Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Metal Oxide Varistor 7mm Disc Metal Oxide Varistor 7mm DiscДокумент1 страницаMetal Oxide Varistor 7mm Disc Metal Oxide Varistor 7mm DiscAnca SterianОценок пока нет

- PIMCAT LINEAR FLEX - 25-26 Page PDFДокумент2 страницыPIMCAT LINEAR FLEX - 25-26 Page PDFSarvesh MauryaОценок пока нет

- Transistor de Potencia Mitsubishi m67580Документ2 страницыTransistor de Potencia Mitsubishi m67580Dickens Javier Solarte Bucko50% (2)

- 10 KW GeneratorДокумент4 страницы10 KW GeneratorFadhilah SurotoОценок пока нет

- 1ZBG000482 - en - A - Integrated Measurement Relay - IMRДокумент2 страницы1ZBG000482 - en - A - Integrated Measurement Relay - IMRCristianoGuimaraesОценок пока нет

- 1N34AДокумент1 страница1N34Ayamaha640Оценок пока нет

- 2W PricelistДокумент369 страниц2W PricelistMihir MehraОценок пока нет

- Unijunction TransistorДокумент13 страницUnijunction Transistorraman yarramilliОценок пока нет

- Rave20 Workshop Manual-Service Procedures 5ed NASДокумент1 007 страницRave20 Workshop Manual-Service Procedures 5ed NASzefrench60% (5)

- Trip Circuit - Supervision Relay: Model TCSRДокумент6 страницTrip Circuit - Supervision Relay: Model TCSRMD. AL MUZAHIDОценок пока нет

- Ficha Técnica SUPRESOR DE PICOS 40 2 POLOSДокумент2 страницыFicha Técnica SUPRESOR DE PICOS 40 2 POLOSmanuel montero guerraОценок пока нет

- Lighting - Nuova ASP2014Документ436 страницLighting - Nuova ASP2014giorgis072Оценок пока нет

- NeutraДокумент6 страницNeutraKinga KokovicsОценок пока нет

- Vocabulary Regular - Irregular Verbs PDFДокумент12 страницVocabulary Regular - Irregular Verbs PDFGerardo RiveraОценок пока нет

- 34OJWN3gb Installation and OperatingДокумент16 страниц34OJWN3gb Installation and OperatingluanagueОценок пока нет

- Delfino Service ManualДокумент107 страницDelfino Service ManualDavid BenitoОценок пока нет

- Engine Control System: SectionДокумент1 203 страницыEngine Control System: SectionPercy Aduviri FloresОценок пока нет

- DTC U0028 - 87 (Advanced Keyless Entry and Push Button Start System)Документ2 страницыDTC U0028 - 87 (Advanced Keyless Entry and Push Button Start System)Yousef ShishaniОценок пока нет

- How to Build a Simple 4x6 Hunting Blind for $125-150Документ2 страницыHow to Build a Simple 4x6 Hunting Blind for $125-150Julian WeaverОценок пока нет

- Electrical Thumb Rules - 6Документ6 страницElectrical Thumb Rules - 6Jeya KannanОценок пока нет

- D2 Electrical LibraryДокумент728 страницD2 Electrical Librarydev modemОценок пока нет

- Tonepad SmallcloneДокумент2 страницыTonepad Smallclonehiroyoshi miyachiОценок пока нет

- Connecting an engine control moduleДокумент1 страницаConnecting an engine control moduleOmar Hernández100% (1)

- Vinay Katariya ABCM REPORT 6 PDFДокумент10 страницVinay Katariya ABCM REPORT 6 PDFVinay KatariyaОценок пока нет

- Cessna 172: Abbreviated ChecklistДокумент2 страницыCessna 172: Abbreviated ChecklistGourav DasОценок пока нет

- Tarifa SD MachДокумент28 страницTarifa SD MachBac Viet NguyenОценок пока нет

- AXESNETWORK CABLE AXCAB-0007-02a rev2 specificationsДокумент1 страницаAXESNETWORK CABLE AXCAB-0007-02a rev2 specificationsHarlan TaylorОценок пока нет

- SLD of MDB-3 Last Update For Print-ModelДокумент1 страницаSLD of MDB-3 Last Update For Print-ModelSharif 087Оценок пока нет

- Fire Escape RouteДокумент27 страницFire Escape RouteNitesh SasidharanОценок пока нет

- Vestibule (Architecture) - Wikipedia (Προθάλαμος)Документ3 страницыVestibule (Architecture) - Wikipedia (Προθάλαμος)kepe81Оценок пока нет