Академический Документы

Профессиональный Документы

Культура Документы

TBi Infiniturn e

Загружено:

thiagofininhoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TBi Infiniturn e

Загружено:

thiagofininhoАвторское право:

Доступные форматы

RoboMIG TBi Infiniturn

Welding torch system

for hollow wrist robots

Endless rotation

Air and water cooled versions

Reliable and powerful

Technical data

TBi Infiniturn welding torch system

Rating (depends on welding torch used)

max. 400 A / 60% duty cycle

- air cooled

- water cooled

max. 550 A / 100% duty cycle

Blow out function

separate gas line,

max. 10 bar

Total weight

approx. 4.2 kg

Connection

Euro central connector,

other types available

KSC-1 Torch mount with safety-off mechanism

Repeatability

0.1 mm at the TCP of a

standard TBi RoboMIG torch

Max. deflection

Infiniturn media coupling, air and water cooled

IEC

60974-7

4 1.65

4.1.65 TBi Infiniturn

TBi RoboMIG welding torches

The TBi Infiniturn system employs the well proven torch necks of the RM-series.

Therefore different models, air and water cooled with a performance rating of

up to 550 Amps at 100% duty cycle, are available.

Ordering information

For detailed information regarding torches and consumables please see the separate

product literature.

Please note: The torch neck version for quick change adapter must be used.

Torch mount

KSC-1: with integrated safety-off mechanism

Reliable shut-off function in case of a collision

Integrated mounting flange for TBi RoboMIG torches

Very high repeatability

Automatic water shut-off valves (W-version)

FLC-1: without safety-off function

TBi KSC-1

TBi FLC-1

Rigid connection between torch and robot

Integrated mounting flange for TBi RoboMIG torches

Automatic water shut-off valves (W-version)

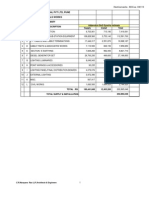

Ordering information

Part no.

KSC-1G

for air cooled torches

536P101402

KSC-1W

for water cooled torches

536P101404

FLC-1G

for air cooled torches

536P101410

FLC-1W

for water cooled torches

536P101412

Adapter flanges

The adapter must always be ordered in addition to the torch mount.

Interface between the torch mount and the robot

Electrical insulation between the torch mount and robot

Available for all robot types

Ordering information

Part no.

ABB

ABB IRB1600iD

536P101124

Fanuc

ArcMate 100iC, ArcMate 120iC, M10 iA, M20 iA

536P101117

Kuka

KR 5 arc HW, KR 16 L8 arc HW

536P101123

KR 16 arc HW

536P101132

Motoman

EA 1400N, EA 1900N, SSA 2000, MA 1400,

MA 1800, MA 1900, VA 1400

536P101116

Reis

RV20-xxHW

536P101127

4.1.65 TBi Infiniturn

TBi Infiniturn cable assemblies

With modern hollow wrist robots, the cable assembly is installed completely

inside the robot arm. Therefore, the outline of the robot can be much more

compact. However, a completely new type of cable assembly is needed.

For this application, TBi has developed a media coupling which is directly

integrated into the cable assembly. By the freedom of endless rotation, the

robot is not limited in its possibilities.

The TBi advantages

Standard features

Integrated media coupling

Endless rotation

Robust and reliable

The rotating coupling is

maintenance free

Euro central connector

Blow out function

Control line with open ends

Schematic

A Interface to torch mount

B

Control cable plug

Heat resistant outer cover

D Infiniturn media coupling

E

Euro central connector

Control cable

I

H

G

G Blow out hose

H Water in

(water cooled version only)

I Water return

(water cooled version only)

87.5 mm

Distance A

All common machine side connectors are available.

Ordering information for standard version

Part no.

for KSC-1

water cooled, Euro connector

672P100___*

air cooled, Euro connector

662P200___*

water cooled (w/o control cable), Euro con.

672P190___*

air cooled (w/o control cable), Euro con.

662P290___*

for FLC-1

Optional connector

*At the blank, please insert the distance A in centimeters, e.g. 098 for A=98 cm.

Technical information

Position

adjustable

30 mm

The TBi Infiniturn robot torch system is a modular system for

modern hollow wrist welding robots. It can be adapted perfectly to the application by choosing the right components.

The heart of the system is the robust cable assembly with the

integrated TBi Infiniturn media coupling. This newly developed component guarantees uninterrupted supply of power,

water and gas to the torch.

Distance A

Feeder

Please note:

For optimum performance of the system, the correct length

of the cable assembly must be exactly determined. When

ordering, we need you to indicate the distance A according

to the adjoining drawing.

We recommend the use of the Euro central connector and of

wire feeder cabinets which have been specifically developed

for use with hollow wrist robots.

TBi High-End products for automation

Torch cleaning stations

TBi JetStream

Wire feeders

Robot welding torches

Spraying unit

TBi PowerPull Box

Twin wire welding torches

Perfect result

Planetary drive head

Plasma welding torches

2010 TBi Industries GmbH. All rights reserved. Subject to change without notice. Excerpts and reprints not permitted. Nr. DOKP141652, 10/2010.

TBi Industries GmbH

Ruhberg 14

D-35463 Fernwald-Steinbach

P.O. Box 67

D-35461 Fernwald-Steinbach

Tel. + 49 6404 9171-0

Fax. + 49 6404 9171-40

Internet: www.tbi-industries.com

E-mail: info@tbi-industries.com

Вам также может понравиться

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Create or Generate QR Code in ASPДокумент5 страницCreate or Generate QR Code in ASPmtkkumaranОценок пока нет

- Dse7510 Installation InstДокумент2 страницыDse7510 Installation InstZakia Nahrisyah100% (1)

- TBi InfiniturnДокумент13 страницTBi InfiniturnAlejandro MaciasОценок пока нет

- BushingДокумент8 страницBushingrasheed313Оценок пока нет

- Esab Aristo Torches Factsheet CatalogueДокумент4 страницыEsab Aristo Torches Factsheet CatalogueDenis TsvetkovОценок пока нет

- Origo™ Tig 3000i AC/DC, TA24 AC/DC: For Demanding TIG Welding ApplicationsДокумент2 страницыOrigo™ Tig 3000i AC/DC, TA24 AC/DC: For Demanding TIG Welding Applicationsandresboy123Оценок пока нет

- Current Transformer Iosk 1Документ8 страницCurrent Transformer Iosk 1Dumitru Tănase0% (1)

- Axial Fan 7028 PDFДокумент9 страницAxial Fan 7028 PDFHuyОценок пока нет

- Flex Buffalo - w000266150 - en - Noc36993Документ8 страницFlex Buffalo - w000266150 - en - Noc36993silvestre_25Оценок пока нет

- Catalogo Polysoude - CompletoДокумент42 страницыCatalogo Polysoude - CompletoMarcos AndréОценок пока нет

- Equipment Catalogue 2014 - ENДокумент48 страницEquipment Catalogue 2014 - ENIonut SaucaОценок пока нет

- F02 Brochure 09-2010Документ22 страницыF02 Brochure 09-2010Giovanni DiniОценок пока нет

- Bifurcared Axial Flow Fans: High Performance, Low Maintenance, 'Motor Out of Airstream' For Complete Peace of MindДокумент11 страницBifurcared Axial Flow Fans: High Performance, Low Maintenance, 'Motor Out of Airstream' For Complete Peace of MindKhalid SaqallahОценок пока нет

- ALXION STK 4 Wind Turbine Permanentni GeneratorДокумент15 страницALXION STK 4 Wind Turbine Permanentni GeneratorOgnjen Apendzija PuljicОценок пока нет

- W - Section 1 - Mma Welding - Saf Fro General Catalogue68475045296859596 PDFДокумент8 страницW - Section 1 - Mma Welding - Saf Fro General Catalogue68475045296859596 PDFputriОценок пока нет

- JAVAC Welding Technology 0910 EnglДокумент33 страницыJAVAC Welding Technology 0910 Englaisman8Оценок пока нет

- Gis TOSHIBAДокумент18 страницGis TOSHIBATan Hong TatОценок пока нет

- Caddy Mig C200i: Portable MIG/MAG Welding Unit With Built-In Wire Feeder For Ø200 MM SpoolsДокумент2 страницыCaddy Mig C200i: Portable MIG/MAG Welding Unit With Built-In Wire Feeder For Ø200 MM SpoolsDjordjeОценок пока нет

- Instrument TransformersДокумент6 страницInstrument TransformerspraswОценок пока нет

- ABB CatalogueДокумент9 страницABB CatalogueSai KiranОценок пока нет

- 242pmi90 2GNM110092Документ12 страниц242pmi90 2GNM110092Pao PawОценок пока нет

- C LineДокумент16 страницC LineSunil Kumar VishwakarmaОценок пока нет

- 3 Ante Middle EastДокумент2 страницы3 Ante Middle EastYasinYasinОценок пока нет

- Summary Fan Data SheetДокумент3 страницыSummary Fan Data Sheetlijo johnОценок пока нет

- L&T CHANGEOVER SW C-Line Catalogue PDFДокумент15 страницL&T CHANGEOVER SW C-Line Catalogue PDFchidambaram kasi67% (3)

- In313 PR1Документ35 страницIn313 PR1wellbr123Оценок пока нет

- Our Mission: The Coax LeaderДокумент3 страницыOur Mission: The Coax LeaderArindam BanerjeeОценок пока нет

- ATU 500 Owner ManualДокумент24 страницыATU 500 Owner ManualBudi ArdyanОценок пока нет

- Trench Bushings Cot 24kv To 550kvДокумент24 страницыTrench Bushings Cot 24kv To 550kvdsanmi0% (1)

- Neojv 0040 enДокумент0 страницNeojv 0040 enLuis GuevaraОценок пока нет

- MNL 043 02Документ70 страницMNL 043 02George Iankov100% (2)

- Led Elevated Taxiway Edge Light: CompliancesДокумент4 страницыLed Elevated Taxiway Edge Light: CompliancesanupamkhannaОценок пока нет

- Electrical Works - Package 2B Addendum BoQ Synefra EstimateДокумент46 страницElectrical Works - Package 2B Addendum BoQ Synefra Estimatemsdixit2006100% (4)

- Kotef: Combined Metering Unit To KVДокумент4 страницыKotef: Combined Metering Unit To KVLarocque11Оценок пока нет

- Ats Acb Brochure enДокумент1 страницаAts Acb Brochure enrhap_0925060Оценок пока нет

- Fire and Smoke Spring Return Actuators FSLF230 (-S) US, FSLF24 (-S) USДокумент2 страницыFire and Smoke Spring Return Actuators FSLF230 (-S) US, FSLF24 (-S) USSrikanth TagoreОценок пока нет

- Airflow SwitchДокумент3 страницыAirflow SwitchHonka VoxОценок пока нет

- Servo Weld Guns - VC TYPE: 120.000 Hours - MTBF 100% Body in WhiteДокумент2 страницыServo Weld Guns - VC TYPE: 120.000 Hours - MTBF 100% Body in WhiteLuciana LuОценок пока нет

- Mig 4004i PulseДокумент4 страницыMig 4004i PulseOkan KöksalОценок пока нет

- Designing Inherently Short-Circuit-Proof, Potted Safety Transformers Up To 10VA With Rale Design System, in Accordance With IEC 61558Документ15 страницDesigning Inherently Short-Circuit-Proof, Potted Safety Transformers Up To 10VA With Rale Design System, in Accordance With IEC 61558PredragPeđaMarkovićОценок пока нет

- Three Phase Fully Controlled RectifierДокумент2 страницыThree Phase Fully Controlled RectifierArvind Katiyar KatiyarОценок пока нет

- Summary Fan Data Sheet: Technical Data Performance ChartДокумент2 страницыSummary Fan Data Sheet: Technical Data Performance ChartDanish QaziОценок пока нет

- W Section 2 Tig Welding Saf Fro General Catalogue3005009245853932523Документ18 страницW Section 2 Tig Welding Saf Fro General Catalogue3005009245853932523Rolando DaclanОценок пока нет

- РЕВЕРСИВНЫЕ РУБИЛЬНИКИ-1SCC301012C0201 PDFДокумент16 страницРЕВЕРСИВНЫЕ РУБИЛЬНИКИ-1SCC301012C0201 PDFfmv fmvОценок пока нет

- GR KPL&KWMДокумент12 страницGR KPL&KWMHeri SulasionoОценок пока нет

- Amted399086en (Web)Документ180 страницAmted399086en (Web)aleksandaralОценок пока нет

- Esab Origo Mig 510Документ2 страницыEsab Origo Mig 510Khaled MekhamerОценок пока нет

- Chapiter3 - Mig Mag Welding50931Документ22 страницыChapiter3 - Mig Mag Welding50931Augusto SoaresОценок пока нет

- Susol MCCBДокумент18 страницSusol MCCBMauro VanegasОценок пока нет

- Reference Costing 040419Документ24 страницыReference Costing 040419Bency ThomasОценок пока нет

- Gas Insulated Ring Main UnitДокумент4 страницыGas Insulated Ring Main UnitshashankhariharanОценок пока нет

- Amphenol Connex Cable Assembly CatalogДокумент32 страницыAmphenol Connex Cable Assembly CatalogAmphenolConnexОценок пока нет

- 06-POWER AND CONTROL CABLE - Rev5 PDFДокумент14 страниц06-POWER AND CONTROL CABLE - Rev5 PDFSanjay RoutОценок пока нет

- Linear 180269 Micro Pulse Pro Compact BrochureДокумент6 страницLinear 180269 Micro Pulse Pro Compact BrochureBalluff SensorsОценок пока нет

- Katalogos Genikos Ot-Oetl FortioyДокумент82 страницыKatalogos Genikos Ot-Oetl FortioyMarco OlazabalОценок пока нет

- Biflow SB (Con)Документ7 страницBiflow SB (Con)elaineurbОценок пока нет

- Midewest Melissa MOTHERLESS - COM ™Документ1 страницаMidewest Melissa MOTHERLESS - COM ™girlОценок пока нет

- Mastering 3D PrintingДокумент2 страницыMastering 3D PrintingTamás KissОценок пока нет

- Meek PETS 2015 PDFДокумент19 страницMeek PETS 2015 PDFjuan100% (1)

- AN2399Документ20 страницAN2399Drew AlbaneseОценок пока нет

- Erik Ellams: Software EngineerДокумент1 страницаErik Ellams: Software Engineerapi-724989957Оценок пока нет

- Simple Facts About FlaskДокумент2 страницыSimple Facts About FlaskAny O'NeillОценок пока нет

- Software Quality Factors and Software Quality Metrics To Enhance Software Quality AssuranceДокумент27 страницSoftware Quality Factors and Software Quality Metrics To Enhance Software Quality AssurancearijayantiОценок пока нет

- Calculate Distance Point and LineДокумент9 страницCalculate Distance Point and LineaapОценок пока нет

- Birchwood MDS Brochure (2) - MinДокумент18 страницBirchwood MDS Brochure (2) - MinMustafizur Rahman RafeeОценок пока нет

- IJACSA Volume10No9 PDFДокумент617 страницIJACSA Volume10No9 PDFAli AbbasОценок пока нет

- An5289 Building Wireless Applications With Stm32wb Series Microcontrollers Stmicroelectronics 1Документ163 страницыAn5289 Building Wireless Applications With Stm32wb Series Microcontrollers Stmicroelectronics 1fabioОценок пока нет

- Simple Msba ResumeДокумент1 страницаSimple Msba Resumeapi-309271555Оценок пока нет

- Theory of Computation - Part - A - Questions BankДокумент5 страницTheory of Computation - Part - A - Questions BankbhuvangatesОценок пока нет

- Computer Questions Examvedacom Dhiman NathДокумент83 страницыComputer Questions Examvedacom Dhiman NathSenghy Mao100% (1)

- Microsoft Certificate Lifecycle Manager Quick Start GuideДокумент8 страницMicrosoft Certificate Lifecycle Manager Quick Start GuidevicogeoОценок пока нет

- SE-6104 Data Mining and Analytics: Lecture # 12 Rule Based ClassificationДокумент62 страницыSE-6104 Data Mining and Analytics: Lecture # 12 Rule Based ClassificationHuma Qayyum MohyudDinОценок пока нет

- RecoveryДокумент14 страницRecoveryprofahmedОценок пока нет

- fs1550 PDFДокумент65 страницfs1550 PDFNippur de LagashОценок пока нет

- ADB SAFEGATE Tower PortfolioДокумент57 страницADB SAFEGATE Tower PortfolioManuel BaladronОценок пока нет

- Golang Cheat Sheet: by ViaДокумент3 страницыGolang Cheat Sheet: by ViaSamОценок пока нет

- Oaisys Version 8 Administration GuideДокумент145 страницOaisys Version 8 Administration Guidemichael guereroОценок пока нет

- Automatic College Bell Using RTC ECE ProjectДокумент6 страницAutomatic College Bell Using RTC ECE ProjectchandravmОценок пока нет

- Csi Sap2000 Aisc-Dam-Guide DraftДокумент9 страницCsi Sap2000 Aisc-Dam-Guide DraftMehdi Alaoui ChrifiОценок пока нет

- Servo Magazine - April 2010Документ84 страницыServo Magazine - April 2010dan_m_huОценок пока нет

- SAP ABAP - Sample Report Program On WRITE, COLOR, HOTSPOT KeywordsДокумент37 страницSAP ABAP - Sample Report Program On WRITE, COLOR, HOTSPOT Keywordsapraju403Оценок пока нет

- Decentralized & Collaborative AI On BlockchainДокумент9 страницDecentralized & Collaborative AI On BlockchainabhilashОценок пока нет

- Manual Pokemon Omega Ruby EspañolДокумент74 страницыManual Pokemon Omega Ruby EspañolCristian VelasquezОценок пока нет

- Project DIVA Map Editor Readme Google TranslateДокумент16 страницProject DIVA Map Editor Readme Google TranslateImron Adi Laksono100% (1)