Академический Документы

Профессиональный Документы

Культура Документы

Effect FSW For Aperreance PDF

Загружено:

Mulyanto MulyonoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Effect FSW For Aperreance PDF

Загружено:

Mulyanto MulyonoАвторское право:

Доступные форматы

International Journal of the Physical Sciences Vol. 6(19), pp.

4595-4601, 16 September, 2011

Available online at http://www.academicjournals.org/IJPS

DOI: 10.5897/IJPS11.866

ISSN 1992 - 1950 2011 Academic Journals

Full Length Research Paper

Effects of friction stir welding process parameters on

appearance and strength of polypropylene composite

welds

G. H. Payganeh, N. B. Mostafa Arab*, Y. Dadgar Asl, F. A. Ghasemi and M. Saeidi Boroujeni

Faculty of Mechanical Engineering, Shahid Rajaee Teacher Training University, Tehran, Iran.

Accepted 29 July, 2011

Friction stir welding is a solid-state joining process that has gained acceptable progress in recent

years. This method which was first used for welding of aluminum and its alloys is now employed for

welding of other materials such as polymers and composites. In this article, friction stir welding has

been used for butt joining polypropylene composite plates having 30% glass fiber by weight. The

effects of important process parameters such as tool pin geometry, tool rotational speed, work linear

speed and tool tilt angle on weld appearance and tensile strength were investigated experimentally.

Different tool pin geometries were used to find their effects on weld quality. Using the tool pin which

produced the best weld quality, the effects of other process parameters on weld quality were also

investigated. The results indicated that tool pin geometry had a significant influence on weld quality

and the effects of rotational speed and tilt angle on weld appearance and strength were more than that

of work linear speed.

Key words: Friction stir welding, polypropylene composite, glass fiber, weld appearance, tensile strength.

INTRODUCTION

Friction stir welding (FSW) is a solid-state joining process

which welds the materials whose characteristics must

remain unchanged as far as possible. Unweldable and

weldable alloys can be joined by this process without

melting and recasting (Shinoda, 2001). Welding defects

such as porosity and hot cracking are not an issue in

FSW and joints with low residual stresses, improved

dimensional stability, good mechanical properties and

high surface finish are produced which require no post

weld cleaning (Barcellona et al., 2006; Kallee and Mistry,

1999; Dickerson and Pryzdate, 2003). Absence of toxic

fumes and spatter of molten material increases FSW

safety. Because of the absence of weld pool and

consumable requirements, such as, shielding gas and

filler material, welding operation in all positions is

possible. Important FSW process parameters are tool

*Corresponding author. E-mail: n.arab@srttu.edu.

Abbreviations: UTS, ultimate tensile strength; FSW, friction stir

welding; GF, glass fibre; pp, polypropylene.

rotational speed, work linear speed, axial force, and tilt

angle. A number of research works have been reported

to study the effects of the above parameters on material

flow, microstructure formation and mechanical properties

of FSW joints for metals and composites (Saeid et al.,

2008; Ren et al., 2007; Cavaliere et al., 2006, 2008;

Abbasi et al., 2006; Amirizad et al., 2006). The effects of

process parameters, TiC percentage, and tool profile on

ultimate tensile strength (UTS) of aluminium matrix

composite were investigated and it was found out that the

welding speed and tool pin profile had the most

significant influence on UTS (Gopalakrishnan and

Murugan, 2011). Kumbhar et al. (2011) investigated the

microstructure of the FSW of aluminum alloy AA5052 in

four regions of base material, nugget, advancing side and

retreating side and reported that most of the specimens

fractured away from the nugget and showed ductile mode

of failure. Sundaram and Murugan (2010) investigated

the tool pin profile, tool rotational speed, welding speed,

and tool axial force influence on UTS and tensile

elongation of dissimilar FSW of aluminum alloys 2024- T6

and 5083-H321. Vijay and Murugan (2010) studied the

effect of tool pin profile on metallurgical and mechanical

4596

Int. J. Phys. Sci.

Table1. Characteristics of the raw material.

Polypropylene

Base

GF (Wt.

(Wt.%)

30

Ultimate strength (MPa)

35

Elongation (%)

2

Figure 1. Stress-strain

strain curve for the raw material.

properties of friction stir welded Al10

10 wt.%TiB2 metal

matrix composites and concluded that joints welded with

straight square pin profile had better mechanical

properties compared to other pin profiles.

Polypropylene (pp) and pp composites are commonly

joined by some of the welding or bonding techniques

(Rudolf et al., 1999; Maguire, 1989; Yousefpour et al.,

2004). Kiss and Czigany (2007) studied the FSW of PP

and found out that the strength of weld area is less than

50% of the original material and weld area toughness is

higher

her than the farther areas. They explained this

behavior by considering the distribution of generated heat

at the weld line and regions around it which causes non

nonuniform crystallization rate of material in these regions.

Scialpi et al. (2007) used titanium

m tool for FSW of PP

extruded sheets and compared it with that of common

welding methods such as hot gas welding and extrusion.

They concluded that mechanical properties of the welds

and the welding speed of FSW are higher than the other

two methods. Considering

dering the research works done on

pp composites, it is observed that a serious lack of

published report regarding their weldability by FSW

exists. Due to this, in the present research work, a study

is carried out to assess FSW of PP composites with 30%

glass

ss fibre (GF). The effects of several FSW parameters

such as tool pin geometry, tool rotational speed, work

linear speed and tool tilt angle on weld appearance and

tensile strength of this composite are also investigated.

MATERIALS AND METHODS

Parent material

PP composite plates with 30% random chopped or particle GF and

100 mm 50 mm 5 mm size with characteristics given in Table1

and Figure 1 were used as the raw material.

FSW tools

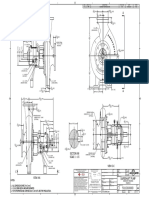

The rotating tools were made of heat treated steel. In order to study

s

the tool geometry effect on weld appearance and strength, four

different friction stir tools with different pins and shoulders were

used and experiments conducted. Details of these tools are shown

in Figure 2 and Table 2. The shoulder diameter and pin length of

the tools were 15 and 4.8 mm, respectively as dictated by thickness

of plates.

Welding procedure

Square-butt

butt joint configurations were prepared to weld the plates.

The plates were welded on a vertical milling machine along their

length after fixing them in a proper position using mechanical

clamps.

This research work was carried out in two stages. In the first

stage, tools with different pin geometries and their effects on weld

appearance and strength were studied to select

selec the tool which

produces better welds. For this phase of the work, a number of trial

runs were conducted and the tool rotational and work linear speed

and tilt angle were selected to be 500, 12 mm/min. and 1

respectively. In the second stage, the selected

sele

tool was used to

Payganeh et al.

4597

Figure 2. FSW tools with different pins and shoulders.

Table 2. Different pin geometries of friction stir tools.

Tool #

1

2

3

4

Description of pin geometry

Taper pin with groove

Triangle pin with screw thread

Triangle pin

cylindrical pin with groove

Large diameter of pin (mm)

5

5

5

5

Small diameter of pin (mm)

3

5

5

5

Table 3. Range of FSW parameters.

Rotational speed (rev./min.)

400

630

1000

Work linear speed (mm/min.)

8

16

20

Tilt angle (degree)

0

1

2

were prepared according to ASTM (2002) from the middle of the

welded plates to eliminate the start and end effects of the welding

process.

RESULTS AND DISCUSSION

Effect of tool geometry on weld appearance

Figure 3. Tensile test specimens geometry and dimensions (mm).

carry out extra trial runs to establish range of FSW parameters

given in Table 3 to investigate the effects of other process

parameters (tool rotational speed, work linear speed and tool tilt

angle) on weld tensile strength.

Tensile test specimen preparation

The tensile test specimens whose dimensions are given in Figure 3

Weld appearance is one of the important characteristics

of a high quality weld whose properties must be similar to

the base material as much as possible. Figure 4 shows

the surface appearance of welds made with different

friction stir tools. The visual examination of these welds

shows that the best weld appearance was obtained using

friction stir tool # 1 (taper pin with groove). The welds

produced by this tool had a clean appearance with

uniform width, and no obvious surface defects could be

found. This feature of the weld may be because of larger

contact surface between this tool and the plates which

causes more frictional heat. The higher generated heat

4598

Int. J. Phys. Sci.

Figure 4. Weld surface appearance with different tools: (a) tool # 1, (b) tool # 2, (c) tool # 3, (d) tool # 4.

Figure 5. The tensile test results.

and better mixing of the material through the weld may be

the reasons for better surface appearance. Tool # 3

which has a pin of triangular cross section contacts the

workpiece at only three edges or points and therefore

generates lowest frictional heat and consequently lowest

stirring and mixing of the weld. Tool # 2 which has a pin

of triangular cross section with screw thread stirs the

weld better than tool # 3 and causes a better weld

surface appearance. Similarly, the contact surface of tool

# 4 with the workpiece is more than that of tools # 2 and

# 3, therefore the higher frictional heat generated results

in better blending of the weld material and hence better

weld surface appearance is obtained by this tool.

Effect of tool geometry on tensile strength

The effects of different tool pin geometries on tensile

strength of friction stir welds are compared with the help

of stress-strain curves shown in Figure 5. All the tensile

test specimens fractured from the weld zone as shown in

Figure 6 indicating this zone is the weakest part of the

Payganeh et al.

4599

459

Figure 6. The tensile test fractured specimen.

Figure 7. Tunnel defect in stir zone.

joint.

Figure 5 shows that the UTS of the weld made by tool #

1 is about 9 MPa which is almost 25% of the UTS of the

parent PP composite. Welds produced by other tools

were much weaker in strength than the weld produced by

tool #1. The same argument mentioned ear

earlier for better

weld surface appearance when welding with tool #1 could

also be one of the reasons for higher tensile strength of

welds with this tool. The presence of surface and

probably subsurface defects, such as tunnel defects

shown in Figure 7 may be the other reasons for lower

tensile strength of welds made by other tools.

Effect of process parameters on tensile strength

In order to study the welding process parameters effects

on tensile strength of the joints, tool # 1 which produced

better welds was used.

Figure 8 shows the effect of tool rotational speed on

tensile strength of the joints. The maximum UTS of about

7 MPa was obtained at the tool rotational speed of 630

rev./min.

With the rotational speed of 400 rev./min, the wormhole

phenomenon at the retreating side of the weld due to

insufficient frictional heat generation and insufficient

matrix

transportation

which

is

reported

by

Lakshminarayanan and Balasubramanian (2008), may be

the reason for lower strength of the joint. The lower

strength of the joint with the rotational speed of 1000

rev./min., can be a result of the tunnel defect (Figure 7)

formed. The formation of this defect may be attributed to

excessive turbulence of the weld caused by high tool

rotational speed. Therefore, with the rotational speed of

630 rev./min., a just sufficient amount of frictional heat is

generated which with proper turbulence of the weld

w

results in the highest tensile strength.

The effect of work linear speed on tensile strength of

the joints is not significant as shown in Figure 9. This is

more obvious especially at speeds higher than 16

mm/min. When the linear speed is increased from 8 to 16

mm/min., the tensile strength decreases with a sharp

slope compared to the speed between 16 and 20

mm/min. The excessive heat input per unit length of the

weld at higher linear speeds and inadequate flow of the

matrix which may cause tunnel defect could be the

factors contributing to lower strength of the joints at

higher linear speeds

The influence of tool tilt angle on tensile strength of the

welds is illustrated in Figure 10. Tilt angle affects the

vertical and horizontal flow of the weld material.

materi Improper

tilt angle may cause tunnel and crack-like

crack

defects in the

welds. At 0 tilt angle, the insufficient vertical and

horizontal flow of the weld material may cause these

defects that reduce the strength of a weld. Increasing the

tilt angle, improves the flow characteristics of the weld

4600

Int. J. Phys. Sci.

Figure 8. Effect of rotational speed on tensile strength.

Figure 9. Effect of linear speed on tensile strength.

Figure 10. Effect of tilt angle on tensile strength.

Payganeh et al.

material and hence, tool movement forges the weld

material better to fill the defects and consequently

increases the weld strength.

Conclusions

In this paper, pp composite plates with 30% GF were

welded using FSW process. The effect of tool pin

geometry on weld appearance and tensile strength was

first investigated experimentally to select a proper tool

design to produce quality welds. The effects of tool

rotational speed, work linear speed and tool tilt angle on

tensile strength of the welds were also studied. The

results indicated that:

1. Although the tensile strength of the welded specimens

was about 9 MPa which is almost 25% that of the base

plate, the FSW process can be employed to weld pp

composites with 30% GF. Further research is

recommended in this respect.

2. The tool pin geometry had a significant effect on weld

appearance and tensile strength.

3. Increasing the tool rotational speed had an increasing

and then a decreasing effect on weld tensile strength.

The tool rotational speed of 630 rev./min. produced the

strongest weld.

4. Increasing the work linear speed from 8 to 20 mm/min.

had a decreasing effect on tensile strength.

5. Tensile strength of the welds increased when tilt angle

was changed from 0 to 2.

ACKNOWLEDGMENTS

This work was supported by a grant from Shahid Rajaee

Teacher Training University.

REFERENCES

Abbasi GM, Kokabi AH, Daneshi GH, Shalchi B, Sarrafi R (2006). The

influence of the ratio of rotational speed/traverse speed (o/v) on

mechanical properties of AZ31 friction stir welds. Int. J. Mach. Tools

Manufact., 46: 19831987.

Amirizad M, Kokabi AH, Abbasi Gharacheh M, Sarrafi R, Shalchi B,

Azizieh M (2006). Evaluation of microstructure and mechanical

properties in friction stir welded A356+15%SiC cast composite.

Mater. Lett., 60: 565568.

ASTM Standard D 3039 (2002). Standard test method for Tensile

Properties of Polymer Material. Annual book of ASTM standard, p.

15.03.

Barcellona A, Buffa G, Fratini L, Palmeri D (2006). On microstructural

phenomena occurring in friction stir welding of aluminum alloys.

Mater. Proc. Technol., 177: 340-343.

Cavaliere P, Squillace A, Panella F (2008). Effect of Welding

Parameters on Mechanical and Microstructural Properties of AA6082

Joints Produced by Friction Stir Welding. J. Mater. Proc. Technol.,

200: 364372.

4601

Cavaliere P, Campanile G, Panella F, Squillace A (2006). Effect of

Welding Parameters on Mechanical and Microstructural Properties of

AA6056 Joints Produced by Friction Stir Welding. J. Mater. Proc.

Technol., 180: 263270.

Dickerson TL, Pryzdatek J (2003). Fatigue of friction stir welds in

aluminium alloys that contain root flaws. Int. J. Fat. 25 (12): 13991409.

Gopalakrishnan S, Murugan N (2011). Prediction of tensile strength of

friction stir welded aluminium matrix TiC particulate reinforced

composite, Materials and Design, 32: 462467.

kallee SW, Mistry A (1999). Friction stir welding in the automotive body

in white production. 1st International Symposium on Friction Stir

Welding Thousand Oaks, pp. 14-16.

Kiss Z, Czigany T (2007). Applicability of friction stir welding in

polymeric materials. Per. Pol. Mech. Eng., 51/1, 15-18.

Kumbhar NT, Sahoo SK, Samajdar I, Dey GK, Bhanumurthy K (2011).

Microstructure and microtextural studies of friction stir welded

aluminum alloy 5052. Materials and Design, 32: 16571666.

Lakshminarayanan AK, Balasubramanian V (2008). Process

parameters optimization for friction stir welding of RDE-40 aluminum

alloy using Taguchi technique. Trans., Nonferrous Met. Soc. China,

18: 548-554.

Maguire DM (1989). Joining Thermoplastic Composites. SAMPE J., 25:

1114.

Ren SR, Ma ZY, Chen LQ (2007). Effect of welding parameters on

tensile properties and fracture behavior of friction stir welded AlMg

Si alloy. Scripta Materialia, 56: 6972.

Rudolf R, Mitschang P, Neitzel M, Rueckert C (1999). Welding of HighPerformanceThermoplastic Composites. Polymer and Polymer

Composites, 7: 309315.

Saeid T, Abdollah zadeh A, Assadi H, Malek Ghaini F (2008). Effect of

friction stir welding speed on the microstructure and mechanical

properties of a duplex Stainless steel. Mater. Sci. Eng., 496: 262

268.

Scialpi A, Troughton M, Andrews SL (2007). In-Line Reciprocating

Friction Stir welding of Plastics. Joining Plastics Magazine, p.1.

Shanmuga Sundaram N, Murugan N (2010).Tensile behavior of

dissimilar friction stir welded joints of aluminium alloys. Materials and

Design, 31: 41844193.

Shinoda T (2001). Recent development of friction stir welding - new

solid-state joining technology. Int. J. Mater. Prod. Technol., 2: 453

460.

Vijay SJ, Murugan N (2010). Influence of tool pin profile on the

metallurgical and mechanical properties of friction stir welded Al10

wt.% TiB2 metal matrix composite. Materials and Design, 31: 3585

3589.

Yousefpour A, Hojjati M, Immarigeon JP (2004). Fusion

bonding/welding of thermoplastic composites. J. Thermoplast.

Compos. Mater., 17: 303341.

Вам также может понравиться

- 0104 9224 Si 21 2 146 PDFДокумент10 страниц0104 9224 Si 21 2 146 PDFMulyanto MulyonoОценок пока нет

- A New Refill Friction Spot Welding Process For Aluminum Po - 2017 - Composite STДокумент12 страницA New Refill Friction Spot Welding Process For Aluminum Po - 2017 - Composite STMulyanto MulyonoОценок пока нет

- Efect FSW PDFДокумент8 страницEfect FSW PDFMulyanto MulyonoОценок пока нет

- Application of Taguchi Method To Optimize Friction Stir Welding Parameters For Polypropylene Composite Lap Joints PDFДокумент17 страницApplication of Taguchi Method To Optimize Friction Stir Welding Parameters For Polypropylene Composite Lap Joints PDFMulyanto MulyonoОценок пока нет

- Friction Stir Welding and ProcessingДокумент78 страницFriction Stir Welding and Processingdrey127Оценок пока нет

- Evaluation of Lubrication Methods How To Generate A Comparable Lubrication For Dry Granules and Powder Material For Tableting Processes 2014 Powder TeДокумент11 страницEvaluation of Lubrication Methods How To Generate A Comparable Lubrication For Dry Granules and Powder Material For Tableting Processes 2014 Powder TeMulyanto MulyonoОценок пока нет

- Friction Stir Welding of Small Dimension Al3003 and Pure Cu Pipes - 2015 - Journal of Materials Processing TechnologyДокумент46 страницFriction Stir Welding of Small Dimension Al3003 and Pure Cu Pipes - 2015 - Journal of Materials Processing TechnologyMulyanto MulyonoОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Soundness Test On Cement by Le - Chatelier MethodДокумент4 страницыSoundness Test On Cement by Le - Chatelier MethodShahrukh NiazОценок пока нет

- Fca 501Документ3 страницыFca 501Al JameelОценок пока нет

- Toyo - Heat Exchanger-1Документ70 страницToyo - Heat Exchanger-1alokbdas100% (1)

- Tooling by Design - Shaving and Burnishing Guidelines - MetalForming MagazineДокумент2 страницыTooling by Design - Shaving and Burnishing Guidelines - MetalForming MagazineSIMONEОценок пока нет

- Hardtop One Technical Data SheetДокумент5 страницHardtop One Technical Data SheetGurdeep Sungh AroraОценок пока нет

- Zinga: Physical Data and Technical InformationДокумент6 страницZinga: Physical Data and Technical Informationasanka100% (1)

- Wrought IronДокумент28 страницWrought IronDurham bryleyОценок пока нет

- Student Copy-Manufacturing Process SelectionДокумент49 страницStudent Copy-Manufacturing Process SelectionAnishMendisОценок пока нет

- Iso 683 1 2012Документ13 страницIso 683 1 2012Haluk TOKGÖZОценок пока нет

- TDS Tankguard Storage GB English ProtectiveДокумент5 страницTDS Tankguard Storage GB English ProtectiveAdverОценок пока нет

- IKA RV 10 Service ManualДокумент11 страницIKA RV 10 Service Manualco2captureОценок пока нет

- Laser Cutting Machine Main Accessories Price ListДокумент1 страницаLaser Cutting Machine Main Accessories Price Listjaiveer.comОценок пока нет

- Best Speakers EVARДокумент4 страницыBest Speakers EVARAccording To HondaОценок пока нет

- Tig Welding W19 12 3 LSiДокумент2 страницыTig Welding W19 12 3 LSiKoen BidlotОценок пока нет

- Title: Connection of Various Member of Steel StructureДокумент25 страницTitle: Connection of Various Member of Steel StructureArnav DasaurОценок пока нет

- BombaДокумент1 страницаBombaBruno Gomes SoaresОценок пока нет

- Ak-90le SuezДокумент1 страницаAk-90le Suezinversiones del peruОценок пока нет

- Chapter 7 - (Welded Connections)Документ73 страницыChapter 7 - (Welded Connections)TobiОценок пока нет

- InkjetcareДокумент1 страницаInkjetcareEric KramerОценок пока нет

- Elotex TdsДокумент2 страницыElotex TdsnanoОценок пока нет

- Final Roller PrintingДокумент16 страницFinal Roller PrintingMobbin Ahmed67% (3)

- Korethan H.B. UH279 (Two-Component) : Physical PropertiesДокумент2 страницыKorethan H.B. UH279 (Two-Component) : Physical PropertiesTrịnh Minh KhoaОценок пока нет

- ECE Catalog 2012Документ52 страницыECE Catalog 2012xerlinoОценок пока нет

- Tool Steel, Carbon: Standard Specification ForДокумент12 страницTool Steel, Carbon: Standard Specification ForVivi VargasОценок пока нет

- Smithy Forging PCTEIETДокумент2 страницыSmithy Forging PCTEIETSurjit Kumar GandhiОценок пока нет

- Conplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsДокумент2 страницыConplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsRaghavendra GaОценок пока нет

- Compressor Wash System RB211Документ15 страницCompressor Wash System RB211masdikaОценок пока нет

- Docmaster: Uncontrolled Copy When PrintedДокумент44 страницыDocmaster: Uncontrolled Copy When PrintedBaCres100% (2)

- How To Make Fake - 20 NotesДокумент4 страницыHow To Make Fake - 20 NotesPaulo ExtoОценок пока нет

- Rolairtrol/SRS Manual Blowdown Valve: Submittal A-329AДокумент1 страницаRolairtrol/SRS Manual Blowdown Valve: Submittal A-329AissamalhitiОценок пока нет