Академический Документы

Профессиональный Документы

Культура Документы

E 10 K

Загружено:

nknfiveОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

E 10 K

Загружено:

nknfiveАвторское право:

Доступные форматы

Corporate Engineering Standard

Engineering Standard: E10K

Electrical Technology Network

E10K

Electrical Trace Heating for Freeze Protection

of Safety Showers

Table of Contents

1. User guidance ....................................................................................................................................................2

1.1 Scope .........................................................................................................................................................2

1.2 Applicability ................................................................................................................................................2

1.3 Benefits ......................................................................................................................................................2

1.4 Definitions...................................................................................................................................................2

1.5 References .................................................................................................................................................2

2. General ................................................................................................................................................................3

3. Design .................................................................................................................................................................3

3.1 Pre-fabricated.............................................................................................................................................3

3.2 Field-Built....................................................................................................................................................3

4. Temperature control ..........................................................................................................................................4

4.1 Pre-Fabricated............................................................................................................................................4

4.2 Field Built....................................................................................................................................................4

4.3 Excessive Water Temperature Protection..................................................................................................4

5. Monitoring & Alarms Considerations ..............................................................................................................5

5.1 Pre-fabricated and Field-built units ............................................................................................................5

6. Installation of field built safety shower units. .................................................................................................6

List of Figures

Figure 1. Typical heating pre-fabricated safety shower.............................................................................................7

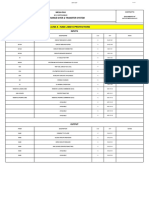

List of Tables

Table 1. Typical heat loss & heating cable for safety showers ...............................................................................4

Red text indicates revisions made in the February 2008 issue.

Vendors and merchandise designations are given to describe materials and may not include all acceptable products.

Substitutions by suppliers are to be made only on approval of the local authority initiating the use of this standard.

Document revised February 2008 / Entire document reaffirmed February 2008

Contact Valerie.S.Lamison@usa.dupont.com by e-mail for more information.

This document may be used and reproduced for DuPont business only.

Copyright 2001, 2005, 2008 E.I. du Pont de Nemours and Company. All Rights Reserved. (Unpublished)(Engineering)

Page 1 of 7

E10K

1.

Electrical Trace Heating for Freeze Protection of Safety Showers

User guidance

1.1 Scope

This standard provides details and information for the selection of electrical traced, pre-fabricated

safety shower units, and for the installation of electrical heat tracing on field-fabricated safety

showers as described in DuPont Corporate Safety Standard S1E which are subject to freezing in

outdoor or unheated indoor areas.

This standard generally does not apply to Tempered Water Systems as described in S1E. Due to

the potential for scalding and high cost, Tempered Water Systems require the combined support

of SHE, process/power function and electrical heating specialists to manage the need, regulatory

requirements, safety issues that may include bacteria growth, thermal burn, solar gain, and

temperature uniformity. System design, hazard analysis, equipment selection, safety

devices/controls, temperature control, system monitoring and alarms are inclusive considerations

for these systems.

1.2 Applicability

The DuPont sites worldwide that follow the requirements of the U.S. National Electrical Code

should follow this standard.

1.3 Benefits

Using this standard will:

Provide a basis for freeze protecting emergency safety shower eyewash units in alignment

with the NEC (NFPA 70) and DuPont Standard S1E.

Establish a minimum essential design threshold.

Facilitate selection of pre-fabricated safety showers.

1.4 Definitions

Runaway Pipe Temperature: The highest equilibrium pipe temperature that occurs when the

heating cable is continuously energized at the maximum ambient temperature.

1.5 References Links to the following standards can be accessed from this section.

DE1H

Design & Application of Electrical Resistance Heat Tracing for Pipelines

E7K

Electrical Pipeline Heat Tracing -Installation Details

E16L

Safety Shower Indicating Light

S1E

Safety Shower & Eyewash Facilities

SE32.3B

Electric heat Tracing, Cables and Panels

SE40.4B

Thermostats for Pipeline and Vessel Heating Circuits

NFPA 70 (National

Electrical Code, NEC)

National Fire Protection AssociationSpecific articles of the

NEC are referenced throughout the text.

Document revised February 2008 / Entire document reaffirmed February 2008

Copyright 2001, 2005, 2008 E.I. du Pont de Nemours and Company. All Rights Reserved. Used under Copyright License.

Page 2 of 7

E10K

2.

Electrical Trace Heating for Freeze Protection of Safety Showers

General

The basic requirements for Safety Shower and Eyewash installations are covered in S1E. Based

on cost of installation and operation, electric heat tracing has become the first choice for

protecting safety shower units from freezing, replacing past popular use of low-pressure steam for

this purpose.

Safety shower units can be field-built or purchased as pre-fabricated units. Pre-fabricated units

are widely used and available from both emergency equipment suppliers and electric heating

manufacturers that are listed by the manufacturer for both non-classified and hazardous areas.

Pre-Fabricated units often include a wide selection of optional features such as location light,

power monitoring lights, flow alarms, mechanical anti-scald & freeze prevention valves, and more.

Field built units commonly have minimum essential features and require the user to incorporate

devices that are listed for the intended use in a manner that meets installation codes and

standards.

3.

Design

Safety shower freeze protection is somewhat different that freeze protection of water pipes.

Section C in S1E limits water temperature to a maximum of 38C (100F), S1E recommends the

maximum water temperature of 25C (77F) to reduce the potential for bacterial growth and a

minimum water temperature of 16C (60F).

In order to balance the prevention of freezing from the possibility of excessive water temperatures,

the design basis for safety showers commonly selects a safety factor of 10% for heat-loss

calculations as opposed to higher safety factors applied to process or other freeze protection

applications. Typical calculated heat loss values for 1 & 1.5 thick polyisocyanurate insulation are

indicated in Table 1.

Ground-fault protection is required by the NEC and IEC for electric heat tracing circuits. The

required protection can be provided by a dedicated ground-fault circuit breaker (typically a 30ma

trip equipment protection device) or an electronic heating controller with integral (fixed or

adjustable) ground-fault protection.

3.1 Pre-fabricated

Verify the manufacturers design basis for operation at the site by considering the minimum

ambient temperature along with calculated runaway pipe temperature based on site conditions.

Note: The application of optional mechanical anti-freeze valves that cause water to flow in freezing

temperatures may eliminate the need for electric tracing in geographical areas that only

experience freezing temperatures of short duration in a 5 to 10 year climatic event.

3.2 Field-Built

Low-temperature self-regulating heat tracing cable shall be selected per SE32.3B - Section 5.1.

These cables provide the minimum heat to keep the water temperature in the shower to 16C

(60F) at the designated site minimum ambient temperature, with a 32 kilometer per hour (20 mph

wind), and a 10% safety factor in heat-loss calculations.

Document revised February 2008 / Entire document reaffirmed February 2008

Copyright 2001, 2005, 2008 E.I. du Pont de Nemours and Company. All Rights Reserved. Used under Copyright License.

Page 3 of 7

E10K

Table 1.

Electrical Trace Heating for Freeze Protection of Safety Showers

Typical heat loss & heating cable for safety showers

Minimum Ambient design Temp. C (F)

-12C (10F)

-17.7C (0F)

-23C (-10F)

-28C (-20F)

Differential Temperature to maintain

15.5C (60F)

27.5oC (50oF)

33oC (60oF)

38.5oC (70oF)

43.5oC (80oF)

Watts/linear meter (foot) 1

polyisocyanurate Insulation

7.2 (2.2)

8.5 (2.6)

10 (3.1)

11.5 (3.5)

Watts/linear meter (foot) 1.5

polyisocyanurate Insulation

5.6 (1.7)

6.5 (2.0)

7.9 (2.4)

8.8 (2.7)

Note: Based on 1-1/2 galvanized steel pipe, Rigid Polyisocyanurate Thermal Insulation, 10% Safety Factor. Output of typical

heating self-regulating heating cables (Thermon BSX or Tyco Thermal BTV family) at 60F is 8.5 W/m (2.6 W/ft) for a 10

W/m (3 W/ft) cable and 14.8 W/m (4.5 W/ft) for a 16 W/m (5 W/ft) cable.

4.

Temperature control

Temperature control considerations for safety showers include fixed temperature immersion, pipe

sensing and ambient sensing depending on fabrication method and risk of excessive water

temperature.

4.1 Pre-Fabricated

Pre-fabricated safety shower/eyewash units as supplied by emergency equipment manufacturers

are normally supplied with fixed-temperature, immersion type thermostats that sense water

temperature. Pre-fabricated safety shower/eyewash units supplied by electric heating equipment

manufacturers commonly use fixed-temperature pipe sensing thermostats. Either of these

methods meets the needs of basic temperature control but the immersion thermostats are difficult

to test for operation. A second layer of temperature protection may be required to prevent

excessive water temperature as described in section 4.3.

Pre-fabricated units are commonly available with optional mechanical-type scald and/or freeze

valves that activate in freezing temperatures and allow sufficient water to flow to prevent freezing.

The optional freeze valves may be justified where power may be lost in freezing weather, or as a

measure of protection to prevent excessive water temperature, see section 4.3.

4.2 Field Built

Field built units should use either a pipe-sensing electro-mechanical thermostat or electronic

controller set at 16C (60F). The sensing bulb should be taped to the pipe in an area that will

remain full of water and self-adhesive aluminum heat-transfer tape should be used to secure the

sensing bulb (or RTD) to the pipe. A second layer of temperature protection may be required to

prevent excessive water temperature as described in section 4.3.

4.3 Excessive Water Temperature Protection

A potential high water temperature hazard exists if the temperature control device fails in a

manner where power is continuously supplied to the heat tracing. As the ambient temperature

rises above 16C (60F) the water temperature can reach a temperature in excessive of the stated

limit of 37.7C (100F). Both 10 W/m (3 W/ft) and 16 W/m (5 w/ft) heating cables will result in the

same condition but the ambient crossover temperature will vary. In most cases a failure of the

temperature control device in safety shower applications can go undetected for long periods

of time.

Document revised February 2008 / Entire document reaffirmed February 2008

Copyright 2001, 2005, 2008 E.I. du Pont de Nemours and Company. All Rights Reserved. Used under Copyright License.

Page 4 of 7

E10K

Electrical Trace Heating for Freeze Protection of Safety Showers

S1E, section 5.5.1 defines testing frequency for safety showers that vary from daily to weekly

depending on shower location and hazard exposure. Safety showers that are tested daily or

tested each time before work is performed with a minimum 30 second flush time should provide

for protection from excessive water temperature without the need for extra layers of protection.

If safety showers are not tested daily or before each activity as described above a second layer

of protection shall be provided. The second layer of protection can include (but is not limited to)

the following:

5.

A single heating-controller that includes a high-temperature alarm that is wired to a manned

location (process control system) and must be acknowledged before reset.

A second pipe for sensing water temperature which functions as a high-limit temperature

control device. If this option is used consider an electronic controller with a digital temperature

display, local alarm or other method to provide an alert that the primary temperature control

has failed.

Use an ambient sensing electronic controller to control a group of safety shower with a hightemperature limit in each unit. Pre-fabricated safety showers can often be ordered with a highlimit in place of the standard temperature at no extra cost for units with fixed-temperature

immersion thermostats. Other pre-fabricated units using a pipe sensing thermostat can change

the temperature set-point to act as a high-limit.

Purchase pre-fabricated units with a mechanical temperature-actuated (scald) valve. Note:

Discuss performance of valves with manufacturer with respect to leaking in-service.

Monitoring & Alarms Considerations

Monitoring requirements for safety shower and eyewash units range from simple monitoring for

presence of voltage to the heating circuit, to a signal that emergency flushing is in progress.

5.1 Pre-fabricated and Field-built units

The minimum essential method within DuPont for monitoring the heat tracing power is to power

the Green Safety Shower Indicating Light that is commonly provided at each shower (E16L) to the

same circuit as the heat tracing. In this case if the green light is not operating it is expected that

personnel will investigate the trouble to determine if the problem is the light bulb failure or loss of

circuit power.

Another monitoring method, that may be especially useful at remote locations, is to connect a

heating manufacturers standard end-of-line monitoring light into the heat-trace circuit. In this

case it is expected that operating personnel would check the light as part of testing the unit for

operation before engaging in work and/or cold-weather patrols would check the light. Unless there

are administrative controls establishing procedures for monitoring the light it is often an

unnecessary cost.

Alarms that signal that emergency flushing is in progress shall be provided on safety shower and

eyewash units located in rigid enclosures and are particularly important in remote, high-hazard

areas or operating units with low occupancy rates. Alarms of this type are used to initiate

emergency response measures. Safety shower in-use alarms are commonly initiated by noncontact (proximity-type) valve-position switches. Paddle-type flow-switches may also be used as

long as they activate on the low flow associated with eyewash units.

Document revised February 2008 / Entire document reaffirmed February 2008

Copyright 2001, 2005, 2008 E.I. du Pont de Nemours and Company. All Rights Reserved. Used under Copyright License.

Page 5 of 7

E10K

Electrical Trace Heating for Freeze Protection of Safety Showers

When safety shower availability is required for process operation, as in some highly-hazardous

processes, a heating circuit loss-of-voltage condition should be signaled to the process

control system.

6.

Installation of field built safety shower units.

Select the heating cable based on site conditions per section 3. Install the heating cable on the pipe

using the recommended heat tracing installation details (E7K) using installers trained by the

manufacturer. Provide required extra heating cable at fittings, pipe supports or other heat-sinks.

Note: self-regulating heating cable may be overlapped as required. Fasten cable to pipe and fittings

using glass cloth tape from the heating manufacturer. Install thermal insulation to cover the entire

heated section of the assembly. Use self-adhesive aluminum heat transfer tape for heating supplier

to secure temperature sensors to pipe.

Where the water is supplied from underground pipelines the tracing should extend 0.6 m (2 ft) below

the ground-level inside the thermal insulation.

Document revised February 2008 / Entire document reaffirmed February 2008

Copyright 2001, 2005, 2008 E.I. du Pont de Nemours and Company. All Rights Reserved. Used under Copyright License.

Page 6 of 7

E10K

Figure 1.

Electrical Trace Heating for Freeze Protection of Safety Showers

Typical heating pre-fabricated safety shower

Front elevation

Side elevation

Note: Tyco Thermal Controls, one of the DuPont Companys heat-tracing Strategic Alliance Agreement Suppliers,

offers a pre-traced safety shower (shower guard) with multiple equipment options.

Document revised February 2008 / Entire document reaffirmed February 2008

Copyright 2001, 2005, 2008 E.I. du Pont de Nemours and Company. All Rights Reserved. Used under Copyright License.

Page 7 of 7

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Furnace - Bryant Plus 80 Users ManualДокумент12 страницFurnace - Bryant Plus 80 Users Manualbspisak100% (1)

- Rotork ActuatorsДокумент10 страницRotork Actuatorsthavaselvan80% (5)

- Abb Ge Cross ReferenceДокумент4 страницыAbb Ge Cross ReferencenknfiveОценок пока нет

- Soil Report Al AinДокумент102 страницыSoil Report Al AinnknfiveОценок пока нет

- HVCapacitors ApplicationGuide en 32044A LTR 2018 04 R001 LRДокумент26 страницHVCapacitors ApplicationGuide en 32044A LTR 2018 04 R001 LRnknfiveОценок пока нет

- Pm0504 Mud Fault Data FormДокумент1 страницаPm0504 Mud Fault Data FormnknfiveОценок пока нет

- 61G15, F.A.C: As of August 10, 2018Документ75 страниц61G15, F.A.C: As of August 10, 2018nknfiveОценок пока нет

- Capacitors - LMVPFC ApplicationGuide EN 974I LTR 2018 04 R001 - LR PDFДокумент56 страницCapacitors - LMVPFC ApplicationGuide EN 974I LTR 2018 04 R001 - LR PDFnknfiveОценок пока нет

- Vendors ListДокумент4 страницыVendors ListnknfiveОценок пока нет

- Q-438222 Urban Mining - Phase 2 - REV0 - DNДокумент14 страницQ-438222 Urban Mining - Phase 2 - REV0 - DNnknfiveОценок пока нет

- S Aa Cps MV LV Prot (Rev 0 2015)Документ46 страницS Aa Cps MV LV Prot (Rev 0 2015)nknfiveОценок пока нет

- Mv-Swgr-Tie: Spare SpareДокумент1 страницаMv-Swgr-Tie: Spare SparenknfiveОценок пока нет

- Krishna Namala - ResumeДокумент1 страницаKrishna Namala - ResumenknfiveОценок пока нет

- SLDДокумент5 страницSLDnknfiveОценок пока нет

- Protection Study SOWДокумент1 страницаProtection Study SOWnknfiveОценок пока нет

- Pages From 1415aaph-33kv Gis Single Line DiagramДокумент1 страницаPages From 1415aaph-33kv Gis Single Line DiagramnknfiveОценок пока нет

- A-11184 - Detailed Scope of WorkДокумент56 страницA-11184 - Detailed Scope of WorknknfiveОценок пока нет

- Ba REG D en 2016 07 WebДокумент432 страницыBa REG D en 2016 07 WebnknfiveОценок пока нет

- S Aa Cps MV LV Prot (Rev 0 2015)Документ46 страницS Aa Cps MV LV Prot (Rev 0 2015)nknfiveОценок пока нет

- Line Protection With L60Документ93 страницыLine Protection With L60nknfiveОценок пока нет

- Furse - Flat Tape SystemДокумент12 страницFurse - Flat Tape SystemnknfiveОценок пока нет

- 1TWD026202S0101Документ25 страниц1TWD026202S0101nknfiveОценок пока нет

- Substation Work SpecifiationДокумент98 страницSubstation Work SpecifiationnknfiveОценок пока нет

- Relay Logic Diagram SampleДокумент16 страницRelay Logic Diagram SamplenknfiveОценок пока нет

- ETAP Sample Report - Complete LGДокумент12 страницETAP Sample Report - Complete LGnknfiveОценок пока нет

- 1TWD026202N0101Документ65 страниц1TWD026202N0101nknfiveОценок пока нет

- Protection Relay Coordination Study - Comments From Middle East ClientДокумент4 страницыProtection Relay Coordination Study - Comments From Middle East ClientnknfiveОценок пока нет

- ETAP 3-ph Fault - CompleteДокумент12 страницETAP 3-ph Fault - CompletenknfiveОценок пока нет

- Relay ATS IO ListДокумент7 страницRelay ATS IO ListnknfiveОценок пока нет

- Uponor Underfloor Heating Installation GuideДокумент56 страницUponor Underfloor Heating Installation GuidePetre Iosub100% (1)

- SH-Testing and Commissioning of DOAS - AHU Unit-Clin 3Документ24 страницыSH-Testing and Commissioning of DOAS - AHU Unit-Clin 3Ali ElHelfawyОценок пока нет

- Ariston Lsi46 37184850000Документ43 страницыAriston Lsi46 37184850000PIKO MOBОценок пока нет

- Adt-Let UsaДокумент20 страницAdt-Let UsaDaniel PuertaОценок пока нет

- EGVUSE09-07C - A VRV Basic Operation Guide PDFДокумент40 страницEGVUSE09-07C - A VRV Basic Operation Guide PDFShaikhMazharAhmed100% (1)

- Siemens RDG 100 T H. DocumentatieДокумент66 страницSiemens RDG 100 T H. DocumentatieDaniel MocanuОценок пока нет

- DanfossДокумент8 страницDanfossjagoda2015Оценок пока нет

- Theben Ramses 811 TopДокумент16 страницTheben Ramses 811 ToppucascОценок пока нет

- Johnson 2017 PDFДокумент240 страницJohnson 2017 PDFbk2 dingoОценок пока нет

- Acelerador ElectronicoДокумент14 страницAcelerador ElectronicoJeferson AnchatuñaОценок пока нет

- AC COLEMAN-USA RV MARINE COFOR OptДокумент16 страницAC COLEMAN-USA RV MARINE COFOR OptElio BATONI0% (1)

- HD BE Easy Installation ManualДокумент18 страницHD BE Easy Installation ManualHedefsan TradeОценок пока нет

- BYC08HE Programming Heating ThermostatДокумент4 страницыBYC08HE Programming Heating ThermostatZivko JajaloОценок пока нет

- Error Codes For Env06 Tumble Dryer BoardsДокумент6 страницError Codes For Env06 Tumble Dryer BoardsAdriana MirelaОценок пока нет

- Air Con Ventilation and AccessoriesДокумент52 страницыAir Con Ventilation and AccessoriesBala KrishnaОценок пока нет

- Frost Control Strategies For Airxchange Enthalpy WheelsДокумент6 страницFrost Control Strategies For Airxchange Enthalpy Wheelsenlightened1718Оценок пока нет

- Uponor IOM Smatrix Wave PULSE en 1095344 v2 202006Документ116 страницUponor IOM Smatrix Wave PULSE en 1095344 v2 202006daveОценок пока нет

- Iron Provapor ®Документ6 страницIron Provapor ®pukymottoОценок пока нет

- Fundamentals of HVAC ControlsДокумент68 страницFundamentals of HVAC Controlsbenson100% (2)

- ACES Standard Product BrochureДокумент2 страницыACES Standard Product Brochuresajjad147Оценок пока нет

- Foundation, Electric Installation, Operation, and Maintenance GuideДокумент32 страницыFoundation, Electric Installation, Operation, and Maintenance Guideapi-279886039Оценок пока нет

- Samsung VRF Installation Trend For BuildingДокумент55 страницSamsung VRF Installation Trend For BuildingNaseemОценок пока нет

- LennoxДокумент32 страницыLennoxRobertОценок пока нет

- 1967-68 Mustang Without Factory AirДокумент23 страницы1967-68 Mustang Without Factory AirnilusomegaОценок пока нет

- Webasto-Blue Line Premium A-C SystemДокумент12 страницWebasto-Blue Line Premium A-C Systemhayrierenli100% (1)

- Ecm Operation Manual: For Use With Models: OH5-85DE OL5-85FDE OL5-85RDE OH11-105DE OL11-105FDE OL11-105RDEДокумент17 страницEcm Operation Manual: For Use With Models: OH5-85DE OL5-85FDE OL5-85RDE OH11-105DE OL11-105FDE OL11-105RDEFDRbardОценок пока нет

- RT Svu02c en (User's Manual)Документ8 страницRT Svu02c en (User's Manual)jfisher54Оценок пока нет