Академический Документы

Профессиональный Документы

Культура Документы

7 Daniel Sanmartin KTP Conference 2013 - Paper - Edited

Загружено:

Muhammad AliАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

7 Daniel Sanmartin KTP Conference 2013 - Paper - Edited

Загружено:

Muhammad AliАвторское право:

Доступные форматы

A MECHANICAL DESIGN FLOW USING OPEN SOURCE TOOLS:

DEVELOPMENT OF PRESSURE TRANSDUCERS AS A CASE STUDY

D. Rodriguez Sanmartin,a, b A. Lawal,b P. Cooper,b G. Awcock,a S. Busbridge,a

a

The University of Brighton, Faculty of Science and Engineering, Lewes Road,

Brighton, BN2 4GJ, UK

b

PSM Instrumentation Ltd, Unit 3, Burrell Road, Haywards Heath, West Sussex,

RH16 1TW, UK

E-mail: D.RodriguezSanmartin@brighton.ac.uk

Abstract:

PSM Instrumentation Ltd. (PSM), a UK firm specialising in instrumentation for liquid level measurement

for the marine industry, and the University of Brighton are currently collaborating in a 2 year Knowledge

Transfer Partnership. Its aims include introducing new-to-company technologies into PSM, such as

alternative manufacturing methods and design tools, and to use them to design products which could

be taken from concept to commercialisation.

The development of Computer Aided Engineering (CAE) design and modelling tools has transformed

how research and development is carried out over the last decade. CAE platforms speed up

development of new products by using computer models, generally based on Finite Element Analysis

(FEA), which allow for the analysis of different physics such as thermal, stress and electromagnetic.

This result in more robust designs whilst also reducing the number of prototype iterations needed,

which reduces development costs.

Open source CAE platform, are now able to offer SMEs sophisticated and competent capabilities at

zero capital cost, although indirect cost such as learning how to use the tools would be initially

incurred. Therefore, open source tools pave the way to a scalable alternative to commercial packages,

such that CAE capabilities could be embedded within an SME as a result of a KTP.

This presentation describes a mechanical design flow using open source tools including:

the creation of 3D models for visualisation purposes;

finite element analysis (FEA) for the calculation of thermal and mechanical stresses;

visualisation of FEA result;

the generation of parts manufacturing drawings.

The development of a pressure transducer at PSM will be used as a case study to demonstrate how

open source tools were used in its development.

Keywords: Small to Medium Enterprises (SMEs), Knowledge Transfer Partnerships (KTP), Computer

Aided Engineering (CAE), Finite Element Analysis (FEA), Open Source software.

1. Introduction

The

development of

Computer Aided

Engineering (CAE) design and modelling tools

has

transformed

how

research

and

development is carried out over the last

decade. CAE platforms speed up development

of new products by using computer models,

generally based on Finite Element Analysis

(FEA), which allow for the analysis of different

physics such as thermal, stress and

electromagnetic. These methods result in more

robust designs which in turn reduce the number

of prototype iterations needed and thus reduces

development costs.

For Small and Medium Enterprises (SMEs)

commercial CAE platforms still represent a

costly option, which, at best, may limit access to

a sub-optimal number of licensed seats and/or

software modules, at worst, may deter them

completely from engaging with these powerful

tools. Open source CAE platforms, however,

are now able to offer SMEs sophisticated and

competent capabilities at zero capital cost,

though indirect cost such as learning how to

use the tools would be initially incurred. Thus

open source CAE tools could pave the way to a

scalable alternative to commercial packages,

such that CAE capabilities could be embedded

within an SME as a result of a KTP.

Developments in both commercial and Open

Source Platforms leave SMEs with three

possible scenarios for the incorporation of CAE

capabilities:

Procuring software licences to access a

CAE platform which would have upfront

cost capital expenditure in the region of

15-25k (per license) depending on the

design and modelling capabilities required;

Engaging on incorporation of Open Source

CAE capabilities, which would not require

an initial capital expenditure, but other

issues such as difficult access to support or

training, could be an issue. Also, for some

specialised applications, such as solving of

piezoelectric equations, open source tools

are

not

appropriate

compared

to

commercially available packages.

Commercial CAE

The third option would be to use a

combination of both, where different

software tools would be used at different

steps of the design / modelling process.

The Table 1 below shows a strengths,

weaknesses opportunities and threats (SWOT)

analysis for both commercial and open source

CAE platforms. The decision on whether to

incorporate a commercial, open source or a

combination of both would depend on the SMEs

objectives, both short and long term.

Risks or threats to an SME committing to the

procurement of commercial packages includes

obsolescence of the tools, either because the

tools themselves become obsolete or the

organization needs change. Also, if these tools

are not used to full capacity their procurement

would represent a waste of expensive

resources. On the other hand, open source

tools present the risk for the SME of not being

able to successfully handover projects unless

there is a strategy in place to do so as would be

the case of an SME engaging on a KTP project.

Open Source CAE

Strengths

Weaknesses

Strengths

Weaknesses

Support and training from

providers.

Access to off the shelf

Tailored capabilities.

Easier to achieve short

term goals.

Licensing costs (15-25k)

Licensing

cost

(to

increase

number

of

licences)

Expensive

packages

needed

to

solve

multidisciplinary

problems.

No

upfront

licensing

costs.

Free software updates.

Access

to

multi-disciplinary software

tools.

Unlimited

number

of

licenses.

Access to source code.

Lack of training / support.

Expertise

required

introducing

these

capabilities into an SME.

Tools

need

more

validation (slow).

Risk of under-delivering

on short term goals.

Opportunities

Threats

Opportunities

Threats

Leveraging

knowledge

and

experience

of

commercial companies.

Achieving short term

goals.

Obsolescence (licences

need to be renewed every

5-8 years).

Procured packages not

adapting to future SME

needs.

Waste

of

expensive

resources if not used.

Collaboration with other

open source users.

Developing

in

house

tailored tools.

Continuous improvement

of CAE capabilities.

Adaptability to changing

SME needs.

Project handover

Incompatibility

with

commercial packages.

Lack

of

specialised

personnel

on

these

packages.

Table 1: Strengths, Weaknesses, Opportunities and Threats (SWOT) analysis for commercial and Open

Source CAE platforms in the context of an SME.

The first part of the paper provides the context

of the KTP project and describes some of the

technical

challenges

involved

in

the

development of a pressure transducer. These

include the choices of technology and materials

and the different physical problems involved

such as stress-strain analysis and temperature

induced stress.

The second part describes a general design

process flow including:

the creation of 3D models for visualisation

purposes;

finite element analysis (FEA) for the

calculation of thermal and mechanical

stresses;

the visualisation of FEA results;

the generation of parts manufacturing

drawings.

The third part of the presentation explores the

scenario in which only open source tools are

used in the design and development process

and aims to demonstrate how this general

design process flow can be implemented using

open source tools, using the development of a

pressure transducer in the KTP project as a

case study.

2. Technical

challenges

involved in the design of a

pressure

transducer

for

marine environments

PSM Instrumentation Ltd. (PSM), a UK firm

specialising in instrumentation for liquid level

measurement for the marine industry, and the

University of Brighton are currently collaborating

in a 2 year research programme funded by a

KTP. Its aims include introducing new-tocompany technologies into PSM, such as

alternative manufacturing methods and design

tools, and to use them to design products which

could

be

taken

from

concept

to

commercialisation.

One of the aims of the KTP project is to

incorporate into PSM CAE capabilities which

would be used for the design of pressure

sensors. From a modelling perspective,

pressure sensors represent a challenging

problem because there are different physics

involved in their design such as the fluid

structure interaction between a diaphragm and

a liquid for which the pressure needs to be

measured. The deflection of the diaphragm is

them transform into other magnitude (such as a

change in capacitance, or resistance).

In addition, devices working in the marine

industry encounter very harsh environments

when deployed in the field. For example, they

can be exposed to substances such as crude

oil or seawater. They also need to meet

different legislation requirements to operate in

potentially explosive atmospheres (ATEX

legislation), and ensure they are immune to

electromagnetic interference (EMC).

Typical operation requirements of pressure

transducers for tank gauging applications are

shown in Table 2 below. A 1 bar sensor is being

used as an example, though in practice

different transducers would be used to cover a

wide range of pressures (from 0.1 to 10 Bar).

These include the specification of a proof

pressure, i.e. the pressure up to which the

transducer can be subject to without

compromising its performance.

Another requirement of pressure sensors is that

these should produce a measurement which is

independent of the specified temperature

o

o

range, typically between -40 C and +80 C for

PSM applications. This is achieved by

designing structures which have very low

temperature drifts, which can be achieved by

the selection of materials with very similar

thermal expansion coefficients.

All these design requirements, make pressure

transducers devices where the coupling of

different physics, such as pressure and

temperature, needs to be minimized at the

design stage and compensated for during the

device operation. In addition, the transducers

need to remain linear during their specified

pressure ranges.

Parameter

Pressure range

Proof Pressure

Burst Pressure

Accuracy

(@20C and 1Bar)

Values

0-1Bar

3Bar

10Bar

0.001Bar (0.1% of the pressure

range)

Operating temperature

range

-30oC to +80oC

Legislation compliance

ATEX, legislation on explosive

atmospheres

EMC, legislation on

electromagnetic compatibility.

Table 2: Typical technical requirements of a 1Bar

pressure

transducer

for

tank

gauging

applications. Pressure ranges for tank gauging

vary typically from 0.1 to 10Bar [1].

In terms of sensor design, these requirements

mean, independently of the transducer

technology used, that two problems need to be

addressed:

The repeatability of the device output for

the pressure range, independently of the

transducer technology used, in order to

maintain the resolution of the sensor.

Compensation for temperature induced

strain.

For example, in the case when a flat diaphragm

is used, the diaphragm will have a pressure

range for which it would behave linearly.

However, when the pressure applied is too

A transducer technology under evaluation in the

KTP project is the use of strain gauges, bonded

to the back of a diaphragm. The idea being that

changes in pressure would result in a change in

the resistance of the strain gauges.

The equations governing the deformation of an

ideal diaphragm is a well understood problem

and has a regular stress/strain distribution for

ideal structure. For example the strain gauge

manufacturer has an application note on this

subject[2]. This, together with the desirable

values of change in resistance in strain gauges

can be used to make a first guess of the

diaphragm key dimensions (thickness and

diameter).

Temperature induced strain is an undesirable

effect in pressure transducers which may occur

as a result of the strain generated due to

differences in the coefficients of thermal

expansion of different materials constituting the

transducer and/or when there is a mismatch in

temperatures between different regions of a

device. In terms of transducer design it ought to

be minimised in order to obtain a predictive drift

with temperature which can then be corrected

by the sensors electronics.

Common

strategies

to

minimise

the

temperature induced strain are:

The matching of the CTEs of the materials

involved in the design. For example, strain

gauges are commonly specified by their

manufacturers

to

match

different

substrates.

The mechanical decoupling of parts of the

sensor subject to temperature gradients, for

example corrugated diaphragms are used

for this purpose on the design of LVDT

(linear variable differential transformer)

based sensors.

In the case of real geometries where chamfers

and/or fillets are used for ease of manufacture,

the use of three dimensional models, combined

with FEA models can help to visualise and

predict the stress distribution. These, together

with characterisation data, could help to gain a

further understanding of the device during the

design process.

3. A general design process

flow

The previous section described common issues

which need to be addressed in the design of

pressure transducers.

A general design process is represented in

block diagram form in Figure 1. It consists of

three main stages: Concept generation;

prototype design; and manufacture and

prototype testing.

1. - Device concept

2. - Device Modelling

3. Is it feasible from a

manufacturing perspective?

Prototype

Iterations

high, the diaphragm will suffer a plastic

deformation and will not return to its original

position after the pressure is relieved.

Concept

Iteration

s

4. Device design

5. Prototype manufacturing

and assembly

6. Prototype characterisation

7. Lessons learned

8. Does the device concept

need refining?

Figure 1: A general design process including

concept

generation,

manufacturing

and

characterisation.

The first stage is the concept generation, which

can be validated using models of the device. At

this stage manufacturing issues, such as the

cost of manufacturing parts, need to be taken

into consideration. If unsuccessful the concept

needs to be rejected or modified and the

concept generation process iterated again.

The second stage is the device design and

manufacturing.

At

this

stage

detailed

manufacturing drawings and specifications of all

the elements need to be produced, and drawing

files adapted for the manufacturing processes

used produced (designs of silicon etching

masks, laser or CNC machining files, and

device parts and assembly drawings, are

examples of manufacturing processes which

may need to be considered). Once all the

elements of the prototype assembly are

manufactured, the prototype assemblies need

to be carried out.

The final step is device testing to verify that the

expected performance was obtained and to

explore how the device could be optimised.

After the device characterisation and the

analysis of results the device design and

manufacturing cycle can be iterated to produce

successive generations of prototype devices.

Advances in CAE over the last decade allow

detailed CAD drawings of geometry or a device,

to be meshed and then be analysed using Finite

Element Analysis (FEA). These numerical

methods can be used to solve complex

problems with coupled physics and/or the

complex geometries which would be difficult to

solve using analytical methods. FEA tools in

turn allow a higher number of iterations at the

design concept stage which has the effect of

reducing the number of prototype iterations

needed to obtain a device ready for

commercialisation

thus

reducing

the

development time and costs.

of multinational companies, such as EDF which

has developed the open source SALOME

platform over the last 10 years incorporating

open source tools[13].

A possible choice of open source design tools

that can be used for the design process

described on the previous section are

highlighted on the diagram below:

1. FreeCAD

Parametric drawings

Concept

Iteration

s

2. Salome

Also, Open Source FEA packages which are

also capable of solving multi physics problems

are available. These include ELMER which was

developed at the University of Finland [9],

CodeSaturne for CDF analysis developed by

the EDF group in France [10], and OpenFoam,

a CDD analysis tool developed by the Open

Foam foundation which is now part of the SGI

group, Fremont, US [11].

4. Implementing

a

design

process flow using open

source tools

The open source movement, originated by

Richard Stallman in 1983 with the goal of

creating a freely available Unix based operating

system, has been developing CAE tools which

are available under the General Public Licence

(GNU)[12]. Some of the best examples are

Elmer, an FEA package for the solving of

coupled physics and OpenFoam CFD. The

potential of these tools has caught the attention

Prototype

Iterations

Meshing

A number of FEA packages are commercially

available, and some examples are: ANSYS by

ANSYS Inc. Southpoint, US [3]; ABAQUS by

SIMULIA, a subsidiary of Dassault Systmes,

Providence, US [4]; COMSOL MultiPhysics by

COMSOL Ltd. US[5]; and LUSAS, a trade mark

of Finite Element Analysis Inc., Kingston upon

Thames, Surrey, UK[6]. Other tools such as

SolidWorks (Dassault Systmes SolidWorks

Corp, Concord, US)[7], which were previously

specialised on design incorporate now FEA

capabilities in their products. Commercial

packages tend to be specialized on particular

applications. Two examples are: LUSAS which

is used for civil engineering projects; and

PZFlex (Wiedlinger Associates Inc, US) [8]

which is used for prototyping of ultrasound

transducers and wave propagation analysis.

3. Elmer

Finite element analysis solver

4. ParaView

Visualization

5. NanoCAD

Manufacturing drawings

6. Prototype characterisation

7. Lessons learned

8. Does the device concept

need refining?

Figure 2: Open source tools that can be used for

the design and modelling of a pressure

transducer.

The design process would consist of:

Using FreeCAD to create parametric

models of the geometry under study which

can be easily modified.

Import models from FreeCAD into the

Salome platform using the industry

standard .step file format.

Define the domains (surfaces, volumes and

borders) of interest and create a mesh of

the part in Salome.

Export the meshed part from Salome into

Elmer using the .unv mesh file format.

Define boundary conditions and solver to

use in Elmer, linear elasticity and

temperature for example, and solve the

finite element analysis (FEA) problem.

Export the FEA results to ParaView using

the .vtk file format.

Analyse the FEA results in ParaView and

compare different simulation runs.

Finally, NanoCAD can be used to produce

CAD drawings, in the industry standard

.dwg file format, for the manufacturing of

parts.

FEA results would then need to be validated

using characterisation data obtained using

prototype devices to identify which areas of the

device would need further optimization.

These open source packages can be installed

on a single computer, though a dual-boot

technique to install Linux and Windows on the

same computer would need to be used due to

their operating system compatibilities as shown

in the Table 3 below:

Software

package

FreeCAD

(ver. 0.13)

(*)

Salome

(ver. 7.2.0)

Elmer

(ver. 7.0)

ParaView

(ver. 3.00.0)

NanoCAD

(ver. 4.5)

Linux

Windows

(Ubuntu)

32

64

(Vista or 7)

32

64

32

(OX)

64

Figure 3 below shows a possible way in which

the drawings of a part can be defined in

FreeCAD. By defining constraints on a section

of a part, an outline of the sections of the part is

produced which can then be revolved along an

axis to obtain a 3D model of the part. Changes

on constraints of the 2D sketch, will result in a

change of the 3D part, which allows for the

quick production of design variants.

a)

Mac

b)

c)

Table 3: Operating system compatibility for

FreeCAD, the Salome platform, paraView and

NanoCAD for Linux, Windows and Mac. (*) The

previous version of Salome was compatible with

Windows 32bit systems, but for the latest and

current version it will only be available for Linux.

Minimum

recommended

hardware

requirements for the above tools are: 2GB

RAM, 4GB of storage, 500MB of video memory,

and Pentium 4 processor or equivalent, which

can be readily accessible on low cost

computers. However, and depending on the

application, higher hardware requirements are

required when dealing with large data sets.

4.1 Using

the

FreeCaD

parametric modeller for

design evaluation

FreeCaD is a parametric modeller which can be

used to quickly draw 3D models of parts, and

be used for visualization purposes. Being a

parametric modeller means that the basic

components of a part are drawn and then

constraints are applied to them until the number

of degrees of freedom of the part is zero. The

advantage of this drawing technique is its

flexibility and the ability to very quickly produce

several design variations from the same

drawing, just by changing some of the

constraints applied to the part. This would be

more difficult to do using the GEOM module of

the Salome platform.

Figure 2: Drawings of a pressure port with a

grooved neck made drawn in FreeCAD. a)

Snapshot of some of the constraints used to

draw a section of the part. b) Section of the part

which was revolved around the vertical axis to

obtain the 3D part. c) Side view of the 3D part. c)

Isometric view of the 3D part.

One of the features of FreeCAD is that

drawings can be exported using step files, a

common standard for 3D drawings which can

be imported into other design tools. For

example, FreeCAD drawings can be imported

into the Salome platform when saved as step

files.

4.2 Finite

element

analysis

using open source tools

As described in the previous section, it is

important to understand both the pressure

induced strain, in order to predict the device

performance, and to minimise the temperature

induced strain.

Finite element analysis can be used to gain a

further understanding of these characteristics

for complex geometries where the use of ideal

models may not be suitable. FEA allows for the

analysis of different design options using

models and, combined with the analysis of test

results, can reduce the amount of iterations

needed in the prototyping phase of the design.

As previously described, Elmer, OpenFoam and

Code Saturne are open source FEA tools. They

all have in common the need to generate a

mesh representing the model purpose of the

study.

The approach proposed in this paper is to

import step files from the parametric FreeCad

modeller into the Salome Meca platform[13].

Once the model is opened in Salome the model

can be defined further, for example by defining

the boundaries which will be subject to changes

in applied pressure or temperature, and

defining the different materials in the part. The

mesh module of the Salome Platform can then

be used to generate the mesh files which can

be imported into a FEA modeller, such as

Elmer.

using the Mesh module of the Salome platform

can then be exported into Elmer using the .unv

mesh file format.

Once the geometry is imported into Elmer, the

multi-physics problem under study can be

defined. For example, Elmer allows for the

calculation

of

electromagnetic

fields,

stress/strain in linear elasticity problems and

temperature induced stress.

The final step of the FEA is the visualization

and analysis of the results. ParaView[14], which

is also included as one of the modules in the

Salome platform. ParaView is a very powerful

visualization package developed in the US for

the visualization of very large data sets which

can be used for analysing FEA data. Results of

the FEA in Elmer can be exported into

ParaView using the .vtk file format as shown in

Figure 4 below:

Figure 3 below shows how the part designed

using FreeCAD was meshed using the mesh

module of the Salome Platform.

Figure 3: Picture of a mesh produced using the

Salome Platform, where surfaces of interest have

been defined. The original drawings were

created in FreeCad and then exported to Salome

using the .step file format. In practice finer

meshes would be generated to carry out FEA.

Figure 4: Vonmises stress on a diaphragm

(0.2mm 24mm diameter), subject to a pressure

of 10Bar generated using Elmer and visualised in

ParaView. For visualization purposes a clipping

through the middle of the structure was used

and the displacements in the structure were

exaggerated by a factor of 50. The top picture

shows the whole of the pressure port and the

bottom picture a closed up view of the

diaphragm and the mesh used for the simulation.

The domains of interest, such as such as the

surfaces of the diaphragm and the volume of

the device are also defined at this stage so they

can be identified by the FEA modeller to assign

materials and boundary conditions such as

pressure or temperature. Meshes produced

The figure depicts the Vonmises stress on a

diaphragm (0.2mm 24mm diameter), subject

to a pressure of 10Bar and how the ParaView

can be used as a visualization to interrogate the

data. For example, in the figure a clipping

through the middle of the structure was used

and the displacements in the structure were

exaggerated by a factor of 50.

native .dwg support, an industry standard

interface, and an open architecture.

The model could be used to calculate the

stresses and strains in the structure for different

boundary conditions, such as applied pressure

or temperature, and to optimise the geometry of

the design such as the thickness of the

diaphragm. In addition the model could predict

what would happen if a different material was

used by changing the material properties used

in Elmer.

So far, NanoCAD has 100,000 users in Russia

and

is

now expanding

internationally.

Nanosofts business is based upon gaining

revenues by providing support and tailoring

NanoCAD for specific applications, in contrast

to the traditional approach of gaining revenues

for licensing.

4.3 Producing

manufacturing

drawings with NanoCAD Eng

NanoCad is an open source computer aided

design application released by the Russian

CAD vendor Nanosoft in March 2012. It has

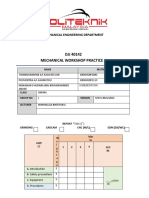

An example of how NanoCAD was used during

the KTP project is shown in Figure 5 below,

depicting the CAD drawings that were used for

manufacturing and a picture of the part on the

insert. In particular, this part is being used as a

tool for manipulating test pressure ports during

machining and assembly.

Insert:

Picture of the

manufactured part

Figure 5: Example of a manufacturing drawing drawn using NanoCad Eng 4.5. In particular these

drawings were used to manufacture a fixture to assist with the handling of pressure ports. The insert

shows a picture of the manufactured part.

5. Summary and Conclusions

CAE platforms have changed design processes

over the last decade, reducing developing time

and costs. There are both commercial and

Open Source CAE platforms available. In some

industries, such as car manufacturers for the

modelling of vehicle aerodynamics have

adopted the strategy of using a combination of

commercial and open source software

packages to carry out their finite element

analysis.

A SWOT analysis of both commercial and open

source packages, which highlights that the right

choice for an SME would depend on its

organizational objectives. Licensing costs and

the risk of obsolescence being major issues for

commercial packages; whereas difficult access

to training and support the major disadvantage

of open source.

5.

A general design process and how it could be

implemented using open source tools has been

described. In the proposed design process the

parametric modeller FreeCad would be used for

design visualization and evaluation. FEA

analysis would be carried out using the GEOM

and mesh modules of the Salome platform for

the mesh generation, Elmer for solving multiphysics problems, and ParaView for the

visualization and analysis of the FEA results.

For the production of 2D manufacturing

drawings in the standard dwg file format, the

tool NanoCAD is being used.

6.

These tools can be used to simulate the effects

of different physics such as stress-strain and

pressure,

which

are

typical

problems

encountered on the design of pressure

transducers, which can help to optimise devices

at the design stage.

7.

8.

9.

10.

Finally, the KTP scheme can provide a platform

for the incorporation of open source CAE tools

into an SEM, as done in the project between the

University of Brighton and PSM instrumentation

for the development pressure sensors.

11.

6. Acknowledgements

The authors wish to thank Knowledge Transfer

Partnerships for funding the collaborative

project between PSM Instrumentation Ltd and

The University of Brighton (KTP 7864).

7. References

1.

2.

3.

4.

PSM Marine ict 1000 datasheet.

2013; Available from:

http://www.psmmarine.com/docum

entation/ict-1000-marine/datasheets.

(2010) Desing considerations for

diaphragm pressure transducers Application note TN-510-1.

ANSYS website:

http://www.ansys.com/en_uk. 2012

[cited 2012 01/04/2012].

Abaqus Website:

http://www.3ds.com/products/simuli

a/portfolio/abaqus/overview/. 2012

[cited 2012 01/04/2012].

12.

13.

14.

COMSOL multiphysics UK website:

http://www.uk.comsol.com/. 2012

[cited 2012 01/04/2012].

LUSAS website:

http://www.lusas.com/. 2012 [cited

2012 01/04/2012].

SolidWorks Website:

http://www.solidworks.com/. 2012

[cited 2012 01/04/2012].

PZFlex website (last accessed on

1st May 2013). 2013; Available

from:

http://www.pzflex.com/default.aspx

.

Elmer Website:

http://www.csc.fi/english/pages/elm

er. 2012 [cited 2012 01/04/2012].

Code-Saturne

http://research.edf.com/researchand-the-scientificcommunity/software/codesaturne/introduction-code-saturne80058.html. 2012 [cited 2012 0104-2012].

Open Foam website:

http://www.openfoam.com/. 2012

[cited 2012 01/04/2012].

GNU General Public Licence,

Version 3, 29 June 2007. Accesible

at:

http://www.gnu.org/licenses/gpl.htm

l. 2007 [cited 2012 01/04/2012].

The Salome Platform Website:

http://www.salome-platform.org/.

2012 [cited 2012 01/04/2012].

ParaView website (last accessed

01-05-2013). 2013 [cited 2013;

Available from:

http://www.paraview.org/.

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Comprehensive Pack-Banking PDFДокумент100 страницComprehensive Pack-Banking PDFMuhammad AliОценок пока нет

- Snapshot BankingДокумент8 страницSnapshot BankingMuhammad AliОценок пока нет

- Power Pack-Banking PDFДокумент38 страницPower Pack-Banking PDFMuhammad AliОценок пока нет

- AnuragRaj CVДокумент2 страницыAnuragRaj CVMuhammad AliОценок пока нет

- InterferenceДокумент19 страницInterferenceMuhammad AliОценок пока нет

- Higher Algebra - Hall & KnightДокумент593 страницыHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Handout - 20475 - AU 2016 Class Handout - Revit and Dynamo For Landscape ArchitectureДокумент58 страницHandout - 20475 - AU 2016 Class Handout - Revit and Dynamo For Landscape ArchitectureKelvinatorОценок пока нет

- Devansh FullCV Jan2021Документ2 страницыDevansh FullCV Jan2021DEVANSH DHRAFANIОценок пока нет

- VPM Basic Training Module01 Version07Документ67 страницVPM Basic Training Module01 Version07nishant_satyamite100% (1)

- LacingДокумент1 страницаLacingRajveer SaeОценок пока нет

- Solid Edge Books - tcm1224-119682Документ8 страницSolid Edge Books - tcm1224-119682Soupramanien KathirvelouОценок пока нет

- Mid Term Report of InternshipДокумент16 страницMid Term Report of InternshipHafiz TalhaОценок пока нет

- Creo Mold Flow AnalysisДокумент2 страницыCreo Mold Flow AnalysisKishore KОценок пока нет

- Brochure CFD-ACE+ PDFДокумент12 страницBrochure CFD-ACE+ PDFFikri SiplhoОценок пока нет

- Unit I Fundamentals of Computer GraphicsДокумент25 страницUnit I Fundamentals of Computer GraphicsChockalingamОценок пока нет

- April 3&4 Business Management Lectures AnandiДокумент94 страницыApril 3&4 Business Management Lectures AnandiNishita AroraОценок пока нет

- Siemens NXДокумент10 страницSiemens NXIhsan1991 YusoffОценок пока нет

- Integrated Urban Microclimate Assessment Method As A Sustainable Urban Development and Urban Design ToolДокумент4 страницыIntegrated Urban Microclimate Assessment Method As A Sustainable Urban Development and Urban Design ToolstevekardinaljusufОценок пока нет

- HF-All Tutorials Update 9-04-2010Документ164 страницыHF-All Tutorials Update 9-04-2010JorgeA.C.JuniorОценок пока нет

- GG 184 Specification For The Use of Computer Aided Design-WebДокумент75 страницGG 184 Specification For The Use of Computer Aided Design-WebsebipaОценок пока нет

- Nov161498 PDFДокумент8 страницNov161498 PDFvinodОценок пока нет

- 01 Gen 360 - Modeling Techniques and GuideДокумент88 страниц01 Gen 360 - Modeling Techniques and GuideJohn Paul UmaliОценок пока нет

- CAD Lab ManualДокумент59 страницCAD Lab ManualmktutyОценок пока нет

- Calypso C-M-M-GUIDEДокумент586 страницCalypso C-M-M-GUIDEMark Hauser100% (15)

- Revit Mep Training Guide TechfuhrerДокумент27 страницRevit Mep Training Guide TechfuhrerKris TolentinoОценок пока нет

- Caase18 Preliminary Agenda Mar20 v1Документ277 страницCaase18 Preliminary Agenda Mar20 v1Anonymous oTrMzaОценок пока нет

- Open Steel Design and GraphicsДокумент2 страницыOpen Steel Design and GraphicsNiranjanAryanОценок пока нет

- Engr. Roberto R. Cabrera: Address: 1499 Barracks II Tala Caloocan City Cellular No.: 09234277621Документ4 страницыEngr. Roberto R. Cabrera: Address: 1499 Barracks II Tala Caloocan City Cellular No.: 09234277621roberto cabreraОценок пока нет

- Naval Department: Difference Between Cad and CamДокумент7 страницNaval Department: Difference Between Cad and CamHany EmadОценок пока нет

- Unisoft Prontoplace Quick Start Manual: Revised 2/3/2012Документ34 страницыUnisoft Prontoplace Quick Start Manual: Revised 2/3/2012A2 TEAMОценок пока нет

- Report CadcamДокумент38 страницReport CadcamDhana KumaranОценок пока нет

- Your Name - Assignment 2 RIICWD533E Prepare Detailed Design of Civil Concrete StructuresДокумент17 страницYour Name - Assignment 2 RIICWD533E Prepare Detailed Design of Civil Concrete StructuresMohammad SufianОценок пока нет

- FineLIFT 14 Quick Guide enДокумент53 страницыFineLIFT 14 Quick Guide enolgfОценок пока нет

- 1 2 3 & 4 Sem ME-M Tech - PDF 1Документ9 страниц1 2 3 & 4 Sem ME-M Tech - PDF 1R.n. PatelОценок пока нет

- TukacadДокумент17 страницTukacadajay kalangiОценок пока нет

- Flare Piping Stress NalysisДокумент7 страницFlare Piping Stress Nalysisgpskumar22100% (1)