Академический Документы

Профессиональный Документы

Культура Документы

AC-150-5370-10G-Errata-sheet - Errata Sheet For Advisory Circular 150 - 5370-10G, Standards For Specifying Construction of Airports

Загружено:

bala subramanyamИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AC-150-5370-10G-Errata-sheet - Errata Sheet For Advisory Circular 150 - 5370-10G, Standards For Specifying Construction of Airports

Загружено:

bala subramanyamАвторское право:

Доступные форматы

FAA

Airports

Errata Sheet for Advisory Circular 150/5370-10G, Standards for Specifying Construction of

Airports

Last Update: 7/13/2015

This errata sheet logs content and/or coding errors identified after the AC was signed on July 21, 2014. These errors have been corrected in the PDF version of

the AC available on the FAA website.

Description of Correction

Corrects last sentence of cover sheet paragraph 4 to

Location in

Document

Rationale

Date Error

Corrected

Cover sheet par. 4

Corrects incorrect reference to paragraph 2.

7/13/2015

Par. 100-01

Corrects amount and clarifies FAAs role in QA

workshop.

7/13/2015

Removes second paragraph in the Engineering Note

Par. 101-3.2

Clarifies use and removes an incorrect reference.

7/13/2015

at the end of par. 101-3.2.

Engineering Note

Corrects numbering of par. 101-3.9.1, Preparation of

Par. 101-3.9.1

Corrects issue of two paragraphs numbered 101-3.9.1.

7/13/2015

reference paragraph 3 instead of paragraph 2.

2

Replaces $250,000 with $500,000 and removes

the words and the FAA prior to or in the first

sentence of the last paragraph.

Cracks in Flexible Pavement, to 101-3.9.

Errata Sheet for AC 150/5370-10G

The first should be 101-3.9.

Updated 7/13/2015

ARP

Page 1 of 9

Description of Correction

Location in

Document

Rationale

Date Error

Corrected

Corrects numbering of paragraph 158-6.5.

Par. 158-6.5

Corrects the appearance of the first number of the

paragraph number (1) on the previous line.

7/13/2015

Replaces the reference to ASTM C112 with C117 at

the end of the first sentence in the Sampling and

Par. 209-2.2.a

Corrects erroneous reference to ASTM C112.

7/13/2015

Par. 401-1.1,

Engineering Note

Clarifies text to be consistent with FAA Order 5300.1

and other P specs.

7/13/2015

Par. 401-3.2

Clarifies that if a new test strip is required, the

7/13/2015

testing for gradation subparagraph a.

7

Revises last paragraph of Engineering Note to read:

The use of state highway department specifications

for airfield pavements subject to aircraft loading by

aircraft > 12,500 pounds and less than 60,000 pounds

requires a modification to standards in accordance

with FAA Order 5100.1.

In the last paragraph before Table 1, which starts

The JMB for each mixture shall be in effect . . .,

revises the third sentence to read: After the initial

contractor bears the cost.

production JMF has been approved by the Engineer

and a new or modified JMF is required for whatever

reason, the subsequent cost of the Engineers

approval of the new or modified JMF, including a new

test strip when required by the engineer, will be borne

by the Contractor.

9

Removes the word maximum from the last sentence

Par. 401-3.2

of the first paragraph of the Engineering Note so the

sentence now reads: The aggregate size should be

(below Table 3,

first version)

Errata Sheet for AC 150/5370-10G

Corrects mistaken presence of the word maximum.

Updated 7/13/2015

ARP

7/13/2015

Page 2 of 9

Description of Correction

Location in

Document

Rationale

Date Error

Corrected

no greater than 1/4 the lift thickness to be

constructed.

10

Revises the text directly below Table 3 to read: The

Engineer is only to specify Gradation 3 for leveling

Par. 401-3.2

(below Table 3,

course, airfield shoulders, and roadways.

showing

Clarifies when Gradation 3 can be specified.

7/13/2015

7/13/2015

Gradations 1-3)

11

Replaces last sentence of Engineering Note with the

Par. 403-101,

Clarifies text to be consistent with FAA Order 5300.1

following: The use of state highway department

specifications for airfield pavements subject to aircraft

Engineering Note

and other P specs.

Par. 501-1.1,

Engineering Note

Clarifies text to be consistent with FAA Order 5300.1

and other P specs.

7/13/2015

Par. 501-1.1,

Engineering Note

Clarifies text to be consistent with FAA Order 5300.1

and other P specs.

7/13/2015

loading by aircraft > 12,500 pounds and less than

60,000 pounds requires a modification to standards in

accordance with FAA Order 5100.1.

12

Adds new first paragraph to Engineering Note that

reads: This specification is intended to be used for

the surface course for airfield rigid pavements subject

to aircraft loadings of gross weights greater than

12,500 pounds (5670 kg) and is to apply within the

limits of the pavement designed for full load bearing

capacity.

13

Replace last sentence of Engineering Note with the

following: The use of state highway department

specifications for airfield pavements subject to aircraft

loading by aircraft > 12,500 pounds and less than

Errata Sheet for AC 150/5370-10G

Updated 7/13/2015

ARP

Page 3 of 9

Description of Correction

Location in

Document

Rationale

Date Error

Corrected

60,000 pounds requires a modification to standards in

accordance with FAA Order 5100.1.

14

In the table Limits for Deleterious Substances in

Coarse Aggregate for Concrete, corrects the text in

Par. 501-2.1c

Fixes a typographic error.

7/13/2015

Replaces the first paragraph of the Engineering Note

Par. 501-3.2,

Clarifies text to allow 600 to 700 psi and to be

7/13/2015

to read: The Engineer shall specify a minimum

flexural strength for airport pavements between 600

Engineering Note

consistent with AC 150/5320-6, which is being updated

to provide similar clarification.

Revises the second sentence of Note 2 under the

Par. 501-8.1a,

Clarifies that the decision must include the FAA and

Price Adjustment Schedule table to read: However, if

the Engineer and the FAA have decided to allow the

Price Adjustment

Schedule

incorporates the reference to Section 50-02.

the ASTM column for Chert (less than 2.40 Sp Gr.) to

read 2.40 instead of 2.0.

15

psi and 700 psi (4136 kPa and 4826 kPa) per ASTM

C78. However, if local materials utilized consistently

produce above the lower design strength limit, the

Engineer may allow a flexural design strength of

greater than 700 psi (4826 kPa) with approval of the

FAA. Refer to AC 150/5320-6.

16

7/13/2015

rejected lot to remain in accordance with Section 5002 after the Engineer and Contractor agree in writing

that the lot shall not be removed, it shall be paid for at

50% of the contract unit price and the total project

payment limitation shall be reduced by the amount

withheld for the rejected lot.

Errata Sheet for AC 150/5370-10G

Updated 7/13/2015

ARP

Page 4 of 9

Description of Correction

17

Adds the word two to the final sentence of the

paragraph so it reads The minimum course thickness

Location in

Document

Rationale

Date Error

Corrected

Par. 601-1.1

Fixes a typographic error.

7/13/2015

Par. 601-3.2

Corrects the text to indicate that hydrated lime is not

7/13/2015

shall be one inch (25mm) and the maximum course

thickness shall not exceed two inches (50 mm).

18

In the first paragraph under Table 1, (1) deletes the

second sentence (The application rate of hydrated

lime shall be a minimum of 1% by weight of the mix)

required but may be needed.

and (2) revises the first sentence to read: The use of

hydrated lime or a liquid anti-strip agent may be

required for all hot mix asphalt produced for the

project.

19

Revises the last sentence of the Engineering Note to

Par. 608-1.1,

read: A typical asphalt pavement candidate is one

with a structural condition index (SCI) deduct value of

Engineering Note

(p. 391)

Fixes a typographic error.

7/13/2015

7/13/2015

less than 10 and a PCI equal to or greater than 60.

20

Changes the first paragraph of the Engineering Note

Par. 608-2.1,

Clarifies the responsibilities of the Engineer and the

to read: Locally available sand or abrasive material

may be available that is slightly outside of the

Engineering Note

Manufacturers representative.

gradation requirements listed below. These may be

submitted for review and approval by the Engineer. It

is recommended to obtain concurrence for use by the

seal coat manufacturer; and the Engineer and

manufacturers field representative should verify

acceptance during application of test sections

Errata Sheet for AC 150/5370-10G

Updated 7/13/2015

ARP

Page 5 of 9

Description of Correction

Location in

Document

Rationale

Date Error

Corrected

indicated under paragraph 608-3.2.

21

In the Limits column of the table Emulsion Residue

Par. 608-2.2

Fixes a typographic error.

7/13/2015

Par. 608-3.2

Clarifies the responsibilities of the Engineer and

Manufacturers representative.

7/13/2015

After the first paragraph, adds the following

Par. 608-3.2,

Clarifies the responsibilities of the Engineer and

7/13/2015

Engineering Note: If the Engineer has experience

and is knowledgeable with the material, procedures,

Engineering Note

Manufacturers representative.

Par. 608-3.2a

Clarifies the responsibilities of the Engineer and

by Distillation or Evaporation Tests, changes the item

that reads 50 dmm minimum to 50 dmm maximum.

22

Changes the first paragraph to read: A qualified

manufacturers representative shall be present in the

field to assist the Contractor in applying test areas

and/or test sections to determine the appropriate

application rate of both emulsion and sand to be

approved by the Engineer.

23

and equipment described in the specification, for test

areas described in 608-3.2.a. the varying application

rates recommended by the qualified manufacturers

representative can be provided from a site visit which

the representative observe pavement condition within

one month prior to application.

24

In the first sentence, changes the word specified to

advised and adds acceptable to the before the

word Engineer.

Errata Sheet for AC 150/5370-10G

7/13/2015

Manufacturers representative.

Updated 7/13/2015

ARP

Page 6 of 9

Description of Correction

25

In the first sentence, changes the word stipulated to

recommended and adds acceptable to the before

Location in

Document

Rationale

Date Error

Corrected

Par. 608-3.2b

Clarifies the responsibilities of the Engineer and

Manufacturers representative.

7/13/2015

Par. 608-5.2

Clarifies the responsibilities of the Engineer and

7/13/2015

the word Engineer.

26

In the second sentence, removes the words from the

seal coat Manufacturer and changes the word

Manufacturers representative.

certified to qualified.

27

28

In the first paragraph, removes the sentence that

Par. 610-2.2

read: Crushed stone aggregate shall have a

durability factor, as determined by ASTM C666,

Requirements were included in new paragraph 6102.2.1, Aggregate susceptibility to durability (D)

greater than or equal to 95.

cracking; and if deleted sentence remained, it would

contract the new requirements.

Revises paragraph title to read Admixtures and

Par. 610-2.6

supplementary cementitious material.

29

Removes sentence that was inadvertently left in.

Adds a new paragraph 610-2.6e:

Adds in supplementary cementitious material, which

7/13/2015

7/13/2015

was inadvertently not included.

Par. 610-2.6e

Adds in supplementary cementitious material, which

7/13/2015

was inadvertently not included; ASTM C618 is already

referenced under Material Requirements at the end of

Fly ash. Fly ash shall meet the requirements of

ASTM C618, with the exception of loss of ignition,

where the maximum shall be less than 6%. Fly ash

the section.

for use in mitigating alkali-silica reactivity shall have a

Calcium Oxide (CaO) content of less than 13%.

30

Changes titanium dioxide minimum to 8%.

Par. 620-2.2 c

Fixes a typographic error.

7/13/2015

(1)(a)

Errata Sheet for AC 150/5370-10G

Updated 7/13/2015

ARP

Page 7 of 9

Description of Correction

Location in

Document

Rationale

Date Error

Corrected

31

Changes titanium dioxide minimum to 1%.

Par. 620-2.2 c

(1)(b)

Fixes a typographic error.

7/13/2015

32

Changes shore hardness to 60.

P620-2.2 c (8)

Fixes a typographic error.

7/13/2015

33

Changes (1) the second sentence of the first

P620-3.3

Adds brackets to reflect the paint removal option and

7/13/2015

paragraph to replace without with minimizing; (2)

the third paragraph to read: [ At least 24 hours prior

clarifies the removal of loose markings.

to remarking existing markings, [ loose ] existing

markings must be removed such that [ 75% ] [

90% ] [ 100% ] of the [ loose ] existing markings

are removed. After removal, the surface shall be

cleaned of all residue or debris either with sweeping

or blowing with compressed air or both. ]; and (3) the

first clause of the third paragraph to read: Prior to the

application of any markings.

34

Adds new second and fourth paragraphs to the

Par. 620-3.3,

Clarifies how to incorporate paint removal,

Engineering Note.

Engineering Note

differentiating between removal of loose markings

7/13/2015

when remarking and removal of markings.

35

Changes second sentence of the first paragraph to

Par. 629-2.1

Clarifies material certification requirements.

7/13/2015

Par. 629-2.2

Clarifies material certification requirements.

7/13/2015

read: The thermoplastic coal tar emulsion shall be

manufactured as a complete product and tested at

the manufacturing plant for material certification.

36

Changes first sentence to read: The Contractor shall

Errata Sheet for AC 150/5370-10G

Updated 7/13/2015

ARP

Page 8 of 9

Description of Correction

Location in

Document

Rationale

Date Error

Corrected

furnish the manufacturers certification that each

consignment of thermoplastic coal tar emulsion

shipped to the project meets the requirements

indicated in 629-2.1 and elsewhere in this

specification.

37

Deletes last sentence in the second paragraph.

Par. 629-3.2

Clarifies material certification requirements.

7/13/2015

38

In the first sentence, removes the word bid before

submittal and changes the phrase through field

Par. 632-2.2a

Corrects erroneous addition of the word bid and adds

back the words independent testing laboratory.

7/13/2015

testing by/for using agencies to read through field

testing by independent testing laboratory for using

agencies.

Errata Sheet for AC 150/5370-10G

Updated 7/13/2015

ARP

Page 9 of 9

Вам также может понравиться

- Reducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemОт EverandReducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemОценок пока нет

- Errata Sheet For Advisory Circular (AC) 150/5370-10H, Standard Specifications For Construction of AirportsДокумент23 страницыErrata Sheet For Advisory Circular (AC) 150/5370-10H, Standard Specifications For Construction of AirportsToby KuntaОценок пока нет

- Errata Sheet 150 5370 10HДокумент18 страницErrata Sheet 150 5370 10HArivin WijayОценок пока нет

- TW Z1 Hangar 6 99% REVISED Review 2-2-07Документ8 страницTW Z1 Hangar 6 99% REVISED Review 2-2-07api-3857887Оценок пока нет

- Draft 150 5320 6G Industry LetterДокумент1 страницаDraft 150 5320 6G Industry LetterToby KuntaОценок пока нет

- Structure Design Manual 032016Документ255 страницStructure Design Manual 032016M Refaat FathОценок пока нет

- Easa Ad Us-2007-12-14 1Документ11 страницEasa Ad Us-2007-12-14 1Enrico Miguel AquinoОценок пока нет

- Airworthiness Directive: Federal Register Information Header InformationДокумент7 страницAirworthiness Directive: Federal Register Information Header InformationEdson Caillavi LafuenteОценок пока нет

- 15 2004erratasheet6 11 07Документ1 страница15 2004erratasheet6 11 07mohamed sameirОценок пока нет

- Specification Bulletin CPACE DIC N1 Dec2019Документ5 страницSpecification Bulletin CPACE DIC N1 Dec2019Talha UrgancıОценок пока нет

- FAARFIELD 1 - 4 Readme PDFДокумент4 страницыFAARFIELD 1 - 4 Readme PDFsurajОценок пока нет

- Airworthiness Directives: Header InformationДокумент7 страницAirworthiness Directives: Header InformationEdson Caillavi LafuenteОценок пока нет

- Amendment of Annexes 2,11Документ6 страницAmendment of Annexes 2,11hypnomateОценок пока нет

- TSO-C27 Amendment 2Документ1 страницаTSO-C27 Amendment 2Mark Evan SalutinОценок пока нет

- 16444-Part 1 - A1-2017 PDFДокумент2 страницы16444-Part 1 - A1-2017 PDFHOD Scitpl [Sands]Оценок пока нет

- Double Bottom Engine RoomДокумент6 страницDouble Bottom Engine RoomTapas ChaudhuriОценок пока нет

- Dubai Extract Pavement Design ManualДокумент4 страницыDubai Extract Pavement Design Manualgasol24Оценок пока нет

- Standards For Airport MarkingsДокумент172 страницыStandards For Airport MarkingsPete AndreОценок пока нет

- FT Benning FP GuideДокумент98 страницFT Benning FP GuideRandy BjorensenОценок пока нет

- 150 5320 6G Pavement DesignДокумент195 страниц150 5320 6G Pavement DesignVasaОценок пока нет

- 15 2001erratasheet - 3 16 09Документ1 страница15 2001erratasheet - 3 16 09Abhisek MilanОценок пока нет

- Ad 98-01-06Документ4 страницыAd 98-01-06Bruno BrazОценок пока нет

- API 510 Errata 1 (2023)Документ1 страницаAPI 510 Errata 1 (2023)Bunner FastОценок пока нет

- Comments and Deviations: Technical & Economical Bid. Fist PhaseДокумент8 страницComments and Deviations: Technical & Economical Bid. Fist PhaseklmОценок пока нет

- 2023-05-05Документ9 страниц2023-05-05Mehdi SammoudОценок пока нет

- 6544 00 16 71 Ad 14Документ2 страницы6544 00 16 71 Ad 14Andy PhoenixОценок пока нет

- Draft Discussions On 4TH Amendment of Is 456Документ6 страницDraft Discussions On 4TH Amendment of Is 456Santhosh Kumar BaswaОценок пока нет

- Summary of 2019 California Building Standards Code ChangesДокумент6 страницSummary of 2019 California Building Standards Code ChangeszeemasОценок пока нет

- Appendix F - Revision HistoryДокумент7 страницAppendix F - Revision HistoryMiguel EspinozaОценок пока нет

- Construction Contract Administration Manual PDFДокумент214 страницConstruction Contract Administration Manual PDFcomandoОценок пока нет

- Federal Register / Vol. 76, No. 182 / Tuesday, September 20, 2011 / Rules and RegulationsДокумент1 страницаFederal Register / Vol. 76, No. 182 / Tuesday, September 20, 2011 / Rules and RegulationsMarketsWikiОценок пока нет

- 2011 Addenda ASME Code Synopsis by OneCIS Insurance Co PDFДокумент59 страниц2011 Addenda ASME Code Synopsis by OneCIS Insurance Co PDFMehta MehulОценок пока нет

- 150 5370 10H PDFДокумент727 страниц150 5370 10H PDFRen G'meszaОценок пока нет

- Advisory CircularДокумент739 страницAdvisory CircularOscar Vasquez EsquivelОценок пока нет

- Crust PavementДокумент9 страницCrust PavementBhadresh LavriОценок пока нет

- Add. 1Документ97 страницAdd. 1MuhammadAhmadОценок пока нет

- Offshore Helicopter Landing Areas - Guidance On Standards Annex 1 - CAP 437 6 Edition Comparison TableДокумент9 страницOffshore Helicopter Landing Areas - Guidance On Standards Annex 1 - CAP 437 6 Edition Comparison TableΑγγελος ΠιλατηςОценок пока нет

- Easa Ad Us-2023-03-15 1Документ9 страницEasa Ad Us-2023-03-15 1Tarek Mahmood KhandakerОценок пока нет

- 150 5340 1M CHG 1 Airport MarkingsДокумент175 страниц150 5340 1M CHG 1 Airport MarkingsPo DixeОценок пока нет

- Changes To API 650, Twelfth Edition Welded Tanks For Oil StorageДокумент3 страницыChanges To API 650, Twelfth Edition Welded Tanks For Oil StorageOkan KarabugaОценок пока нет

- Design of Composite Bridges Use of BS 5400: Part 5: 1979: The Highways Agency BD 16/82Документ23 страницыDesign of Composite Bridges Use of BS 5400: Part 5: 1979: The Highways Agency BD 16/82Bobby WongОценок пока нет

- TN223260 20180423T130036 Staff Analysis of Air Filter Pressure Drop and Air Filter SizinДокумент11 страницTN223260 20180423T130036 Staff Analysis of Air Filter Pressure Drop and Air Filter Sizinryan_keller_23Оценок пока нет

- Flexible Pavement Design Spreadsheet:: F806FAAДокумент12 страницFlexible Pavement Design Spreadsheet:: F806FAAMilica JovovicОценок пока нет

- CONSTRUCTION INSTRUMENTATION AND CHARACTERIZATION OF A DIDACTIC CLOSED LOOP WIND TUNNEL - FinalДокумент11 страницCONSTRUCTION INSTRUMENTATION AND CHARACTERIZATION OF A DIDACTIC CLOSED LOOP WIND TUNNEL - FinalLucas Ramos E SilvaОценок пока нет

- Easa Ad Us-2017-18-14 1Документ6 страницEasa Ad Us-2017-18-14 1RAMON CALDERONОценок пока нет

- BS en 1756-1-2001+a1-2008 PDFДокумент87 страницBS en 1756-1-2001+a1-2008 PDFSaleh Ettehadi50% (2)

- Pavement 33Документ656 страницPavement 33dinoОценок пока нет

- Code Adoption Document OldДокумент7 страницCode Adoption Document OldalexhanafyОценок пока нет

- Faa Ad 2012-05-02Документ11 страницFaa Ad 2012-05-02nphonsaiОценок пока нет

- Ata 38Документ2 страницыAta 38Mark Bryan BiansonОценок пока нет

- 150 5300 13a Airport DesignДокумент322 страницы150 5300 13a Airport DesignDulce A Martinez OОценок пока нет

- 2019 Key Changes Section VIII-2Документ59 страниц2019 Key Changes Section VIII-2Niniza Sibusiso Prince DlaminiОценок пока нет

- 2024-01-06Документ9 страниц2024-01-06Francis Albert TingsonОценок пока нет

- EXW-GENL-0000-PE-KBR-IP-00010 Interim Advice Note 010Документ25 страницEXW-GENL-0000-PE-KBR-IP-00010 Interim Advice Note 010Henry Tugano0% (1)

- Compressed Air CommentsДокумент4 страницыCompressed Air CommentsEslam ElsayedОценок пока нет

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusОт EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusОценок пока нет

- Aircraft Weight and Balance Handbook: FAA-H-8083-1AОт EverandAircraft Weight and Balance Handbook: FAA-H-8083-1AРейтинг: 5 из 5 звезд5/5 (1)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisОт EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- IS 9417 - 2018 Welding of High Strength Steel Bars For Reinforced Concrete Construction - Recommendations (Second Revision)Документ17 страницIS 9417 - 2018 Welding of High Strength Steel Bars For Reinforced Concrete Construction - Recommendations (Second Revision)bala subramanyam100% (2)

- Is 13094 - 1992 (Ra 2016) Selection of Ground Improvement Techniques For Foundation in Weak SoilsДокумент12 страницIs 13094 - 1992 (Ra 2016) Selection of Ground Improvement Techniques For Foundation in Weak Soilsbala subramanyamОценок пока нет

- IS 1199 - (RA 2018) Methods of Sampling and Analysis of ConcreteДокумент46 страницIS 1199 - (RA 2018) Methods of Sampling and Analysis of Concretebala subramanyam100% (3)

- Is SP 24 Concrete Strength Formula For DaysДокумент1 страницаIs SP 24 Concrete Strength Formula For Daysbala subramanyamОценок пока нет

- Methodology Brick Bat CobaДокумент1 страницаMethodology Brick Bat Cobabala subramanyamОценок пока нет

- World Quality Day - WikipediaДокумент3 страницыWorld Quality Day - Wikipediabala subramanyam0% (1)

- Specifying Visual ConcreteДокумент23 страницыSpecifying Visual Concretebala subramanyamОценок пока нет

- Is 215 - 1995 (Ra 2011) Road Tar SpecificationДокумент13 страницIs 215 - 1995 (Ra 2011) Road Tar Specificationbala subramanyamОценок пока нет

- Is 363 Specification For Hasps and Staples PDFДокумент9 страницIs 363 Specification For Hasps and Staples PDFbala subramanyamОценок пока нет

- Circuit Regulating Valve STRÖMAX 4218 GFДокумент14 страницCircuit Regulating Valve STRÖMAX 4218 GFMario Mô Ri AОценок пока нет

- Code PICДокумент6 страницCode PICsongbao527Оценок пока нет

- Omni PageДокумент98 страницOmni Pageterracotta2014Оценок пока нет

- Implementation 3-Axis CNC Router For Small Scale Industry: Telkom Applied Science School, Telkom University, IndonesiaДокумент6 страницImplementation 3-Axis CNC Router For Small Scale Industry: Telkom Applied Science School, Telkom University, IndonesiaAnonymous gzC9adeОценок пока нет

- Active Suspension System of Quarter CarДокумент70 страницActive Suspension System of Quarter CarMarcu SorinОценок пока нет

- Lowel LightsДокумент80 страницLowel LightsSaulo Valley100% (1)

- Causes of Boiler Tube Leakage and MeasuresДокумент19 страницCauses of Boiler Tube Leakage and MeasuresNhật TuấnОценок пока нет

- LRS Trading StrategyДокумент24 страницыLRS Trading Strategybharatbaba363Оценок пока нет

- 4.1 OUM Cloud Approach Presentation-ManagerДокумент24 страницы4.1 OUM Cloud Approach Presentation-ManagerFeras AlswairkyОценок пока нет

- TUPT AdmissionDegreeLadderizedДокумент1 страницаTUPT AdmissionDegreeLadderizedromerqazwsxОценок пока нет

- Hyperloop 170201003657Документ29 страницHyperloop 170201003657RafaelLazoPomaОценок пока нет

- NASA MissionsДокумент62 страницыNASA MissionsRoman FlorinОценок пока нет

- Physics 2Документ2 страницыPhysics 2MarcusKlahnTokoeJr.Оценок пока нет

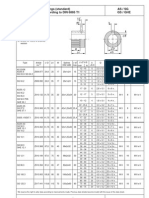

- As / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1Документ1 страницаAs / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1hadeОценок пока нет

- XMEye Android User ManualДокумент32 страницыXMEye Android User Manualaxelkal ck50% (2)

- Washing MachinesДокумент6 страницWashing MachinesAnonymous wK36hLОценок пока нет

- Presentation 1Документ12 страницPresentation 1Varun MaheshwariОценок пока нет

- Faqs: Instant Credit Card Approval and IssuanceДокумент1 страницаFaqs: Instant Credit Card Approval and Issuancedaong_84Оценок пока нет

- Adnan PDFДокумент3 страницыAdnan PDFmudassarhussainОценок пока нет

- Truwater - TCM SeriesДокумент12 страницTruwater - TCM SeriesnkhhhОценок пока нет

- Fingerstyle Guitar - Fingerpicking Patterns and ExercisesДокумент42 страницыFingerstyle Guitar - Fingerpicking Patterns and ExercisesSeminario Lipa100% (6)

- Astm C-743Документ4 страницыAstm C-743IyaadanОценок пока нет

- Colphenebswh 1816Документ2 страницыColphenebswh 1816vinoth kumar SanthanamОценок пока нет

- (BDDJ-2016-0006) Introduction of New Printer NKG-901Документ4 страницы(BDDJ-2016-0006) Introduction of New Printer NKG-901じゃしゅてぃん ぅうОценок пока нет

- SPC & MSA PresentationДокумент84 страницыSPC & MSA PresentationRaajha Munibathiran100% (3)

- NASA Facts Apollo 17 Preflight SummaryДокумент4 страницыNASA Facts Apollo 17 Preflight SummaryBob Andrepont100% (1)

- FGRU URAN 08.12.2015 Rev.02Документ3 страницыFGRU URAN 08.12.2015 Rev.02Hitendra PanchalОценок пока нет

- Kota StationДокумент5 страницKota StationshashankjeeОценок пока нет

- Macmillan English Grammar in Context Advanced PDFДокумент3 страницыMacmillan English Grammar in Context Advanced PDFAnonymous l1MDLhBFXОценок пока нет