Академический Документы

Профессиональный Документы

Культура Документы

Us3415189 PDF

Загружено:

checolonoskiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Us3415189 PDF

Загружено:

checolonoskiАвторское право:

Доступные форматы

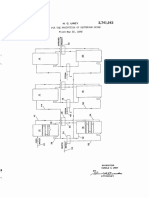

Dec.

10, 1968

3,415,189

W. D. TREVORROW

WATER DESTRUCTIBLE ELECTRIC MATCH

Filed March 24, 1967

FIG. 2

.r

FIG.;

INVENTOR.

William D. Trevorrow

M .x

United States Patent O

1

3,415,189

ICC

3,415,189

Patented Dec. 10, 1968

2

elevation and illustrating an electric explosion initiator;

WATER DESTRUCTIBLE ELECTRIC MATCH

William D. Trevorrow, Tamaqua, Pa., assigner to Atlas

Chemical Industries, Inc., Wilmington, Del., a corpora

and

FIG. 2 is an enlarged half-sectional View taken as a

side elevation and illustrating an embodiment electric

match for use in the initiator in FIG. l.

Filed Mar. 24, 1967, Ser. No. 625,736

12 Claims. (Cl. 102-28)

shell 12 in which may be positioned detonating base charge

ABSTRACT 0F THE DISCLOSURE

In the art of electric matches and electric explosion

initiators, a water destructible electric match lhaving a

priming charge is normally tired by electric match assem

bly 18 which may include heat shrunk plastic sleeve 20 for

controlling the variation `of ignition time between matches

and is thus particllarly useful in seismic detonators. Elec

tion of Delaware

coating or film generally characterized as a water dis

persible polymeric material which renders the match in

elective in the event of misre and which is particularly

useful for olfshore seismographic prospecting.

The present invention relates to a water destructible

electric match and to electric explosion initiators contain

ing same. More particularly, the present invention relates

to a water destructible electric match having a coating of

a water dispersible polymeric material and being useful

for detonators employed in seismographic exploration.

Electric explosion initiators usually include a metallic

shell encasing an explosive charge and an electric match

positioned in ring relationship with the charge. Custom

arily an electric match includes two elongated electrical

terminals separated by a non-conducting insulating mate 30

rial. The electrical terminals are connected at one `end by

means of a bridge wire about which is formed a match

head of an ignition composition. The ignition composition

is in contact with the bridge wire which is heated by an

electric current to a temperature at which the ignition

FIG. 1 illustrates electric explosion initiator 10 having

14 and superimposed thereon, is priming charge 16. The

tric match assembly 18 which is rendered water destructi

ble by addition of an outer coating of a water dispersible

polymeric material such as for example, polyvinyl alcohol

coating 22, may further include dellagrating composition

layer 24, and ignition composition layer 26 forming a

core of material about high electric resistance bridge wire

28.

Insulating material base 30 formed of an electric non

` conductive material such as, for example, cardboard, is

provided with electric conductive Iplates 32 and 34 gen

erally formed of a metallic material such as copper or

aluminum and applied upon opposite sides of insulating

material base 30. Lead wires 36 and 38 are connected to

the Iupper ends of electric conductive plates 32 and 34 by

a suitable solder material 40. Bridge wire 28 may be simi

larly sec-ured to the lower ends of electric conductive

plates 32 and 34.

Bridge wire 28 may be embedded in ignition composi

tion layer 26 which may, for example, include materials

such as cuprous acetylide, diazodinitrophenol, lead mono

nitroresorcinate, mixtures of lead mononitroresorcinate

and potassium chlorate, and related materials and mix

tures thereof. The ignition composition layer may be

applied in the plastic state about the bridge wire and

allowed to harden. Deagrating composition layer 24

composition fires and the initiator thus explodes.

Typically, the ignition composition formed about the

bridge wire is rendered waterproof by applying a coating

which may include mixtures such as ammonium picrate

of, for example, a lacquer or related waterproofing ma

terial. The lacquer usually employed for this purpose is 40 and potassium dichromate, or carbon and potassium

chlorate may next be applied and also permitted to harden.

a cellulose derivative lacquer, such as nitrocellulose which

Thereafter, one or more layers of, for example, polyvinyl

generally provides a good waterprooiing protection for the

alcohol coating 22 may be applied and permitted to dry.

match, thus rendering the match water non-destructible.

Shell 12 is desirably formed of metallic material such

Explosives used in marine seismographic prospecting,

include an electric initiator, and a main explosive charge 45 as copper or aluminum and includes aperture 42 to provide

which is fired under water. Occasionally, such an explosive

accidentally fails to lire or breaks away from the ring

line and sinks to the seabed. The initiators presently em

ployed can remain potentially usable under great depths

of sea water for long periods of time without desensitiza 50

tion of either the electric match or the detonator ex

plosive. A dangerous situation may thus exist from a mis

fired charge of a potentially usable initiator being washed

up or dragged from the sea.

It has now been found that by coating a water dispersi

ble polymeric material on an electric match for use in

an electric initiator having a convenient aperture for the

ingress of water, there results a water destructible elec

an ingress means for water which renders the assembly

water destructible. A water dispersible sealing plug, not

shown, may be included to seal aperture 42 which on

immersion in water resists the ingress of water into shell

12 for a precalculated period of time sufficient to permit

the detonator to be fired. Thereafter, the assembly will

be destroyed by water which enters shell 12 by aperture

42 and ultimately desensitizes electric match assembly 18

by dispersing polyvinyl alcohol coating 22 with water

saturating the layers coated thereby.

Although aperature 42 is illustrated near the bottom of

shell 12, it is recognized that the aperture may be posi

tioned at any convenient location on the shell such as

about bridge Wire assembly 18 which increases the rate at

which

the assembly may be destructed by water since

initiator in offshore seismographic prospecting.

60 less resistance by materials contained within shell 12 is

In accordance with this invention, an electric match is

present.

rendered water destructible with a coating comprising a

Sealing plug 44 is illustrated at one end of shell 12 for

water dispersible polymeric material. Preferably, the coat

supporting lead wires 36 and 38 coated with a suitable in

ing comprises polyvinyl alcohol either alone or in combi

nation with wetting agents, limited amount of insolubiliz 65 sulating material 46 such as polyvinyl chloride` Sealing

plug 44 may be formed of any suitable material such as

ing agents, plasticizers or other additives as desired.

rubber,

neoprene, or other material which is sufficient

The electric match assembly of the present invention

elastic for insertion into shell 12 during assembly.

may be prepared as illustrated in the accompanying draw

FIG. 2 further illustrates electric match assembly 18

ing in which like numerals represent the same elements

of FIG. 1 except that heat shrunk plastic sleeve 20 is

throughout the several views.

removed. The embodiment of FIG. 2 may be employed in

In the ligures:

an initiator assembly 10 as illustrated in FIG. 1 and is

FIG. 1 is an enlarged half-sectional View taken as a side

useful in instances where more rapid destruction of the

tric initiator which is useful in the event of misre of the

3,415,189

bridge wire assembly is desired. in the embodiment of

FIG. 2, water may attack, for example, polyvinyl alcohol

It may be found advantageous to incorporate in an

aqueous polyvinyl alcohol solution, a surface tension

reducing agent. In addition to uniform wetting, such

agents also have the advantage of decreasing the tendency

Ct for air bubbles to adhere to the surface of the assembly

plastic envelope 20 of FIG l.

during coating. Any of the common water-soluble wetting

The polyvinyl alcohol coating 22 used in the present

coating 22 about the entire area which which is is applied

as opposed to the limited area not covered by heat shrunk

invention as the water dispersible polymeric material is

and surface tension reducing agents known to the art

found to provide not only water destructible properties by

simply `being dispersed or dissolved when in contact with

which do not adversely affect deagrating composition

layer 24 and ignition composition layer 26 may be em

water but is also found to possess a hydrophilic nature

ployed. Wetting agents comprising sulfonation products

upon initial contact with the water. This hydrophilic

characteristic appears to increase the ability of water con

tained within the polyvinyl alcohol coating 22 to permeate

of higher aliphatic alcohols have been found to be par

into deflagrating composition layer 24 and initiating com

position layer 26 to thereby render such materials insensi

tive to initiation by bridge wire 28.

Polyvinyl alcohol films or resin-like materials for use

in the present invention may be characterized as a water

ticularly useful.

When it is desired to characterize the polyvinyl alcohol

coating less sensitive to water destruction, this may be

accomplished by using agents which tend to coagulate or

insolubilize polyvinyl alcohol. Examples of materials

which are suitable for this purpose are various inorganic

compounds such as borates, perborates, silicates, chromic

acid, chromates, dichromates, alum and ferrie chloride,

by the hydrolysis of polymerized vinyl esters such as 20 and organic hardening agents such as tannins, formalde

hyde, and other alde-hydes, azo dyes and the like. These

polyvinyl acetate. Polyvinyl alcohol may be yprepared in

insolubilizing agents may be applied as a separate thin

a number of different degrees of polymerization depend

layer independent of the polyvinyl alcohol layer or may

ing largely upon the extent to which the vinyl compound

be applied as part of the polyvinyl alcohol solution al

from which it is derived has been polymerized. The more

though this is not usually desirable for the reason that

highly polymerized forms of this water dispersible

such materials tend to increase the viscosity of the poly

polyvinyl compound are less soluble in water and produce

vinyl alcohol solution and render application thereof to

solutions of higher viscosities for equivalent concentra

the `[bridge wire assembly somewhat difficult. The polyvinyl

tions than the lower polymers. There are also a large

alcohol film may be rendered suciently water resistant

number of the so-called partial derivatives of polyvinyl

alcohol in which some of the hydroxyl groups in the 30 such that the film will not soften under varying humidity

conditions.

molecule are replaced by other radicals such as ester

Although polyvinyl alcohol film is generally elastic and

radicals or acetal radicals. Such partial derivatives may

exible and ordinarily does not require the addition of

be produced by the incomplete saponication of vinyl

softening agent, plasticizers may be employed to increase

esters or by the incomplete reaction of polyvinyl alcohol

the iiexibility of the lm if desired.

with aldehydes or other compounds which react with

The normal method of applying the layers of composi

hydroxyl groups. The properties of the partial derivatives

tions forming electric match assembly 18 is that of dip

of polyvinyl alcohol vary in accordance with the propor

ping the assembly in a liquid containing the required

tion of hydroxyl radicals that have been substituted by

ingredient for a particular layer being applied. A binding

other groups. When the hydroxyl radicals sufficiently

agent may be employed such as, for example, nitrocel

predominate, the partial derivatives show essentially the

lulose, and a solvent, for example, a-myl acetate may be

properties of polyvinyl alcohol and are soluble in water as

employed which is thereafter dried to remove the solvent

distinguished from the esters, acetals. etc., which are

and to deposit the layer of composition on t-he assembly.

soluble only in organic solvents. Consequently, the term

The aqueous polyvinyl alcohol solution may be simply air

polyvinyl alcohol as used herein designates polyvinyl

dispersible polymeric material which is usually obtained

alcohol and also such partial derivatives thereof as con

tain a sufhcient number of unsubstituted hydroxyl groups

as to render the compound soluble in water.

dried or alternately may be dried in warm air at a tern

perature such as for example, of about 50 C.

Various additional materials may be employed in place

of polyvinyl alcohol coating 22 as the water dispersible

In coating the match assembly, a suitable solution of

polymeric material which may also be -generally character

polyvinyl alcohol is applied to the surface of the match

and the solution is permitted to dry as a suitable solvent 50 ized as film forming ingredients. Additional materials

may include water dispersible cellulose ethers such as

such as water evaporates to produce a thin continuous

methylcellulose, carboxymethylcellulose, hydroxyethylcel

lm surrounding the match head. The concentration of the

lulose and the like; other water dispersible polyvinyl com

polyvinyl alcohol solution used for the coating may vary

pounds such as polyvinylpyr-rolidone, polyvinyl methyl

within considerable limits depending `largely on the degree

of polymerization of the particular form of polyvinyl 55 ether, and the like; and water dispersible `alkali rnetal

salts of polyacrylic acid `such as the :sodium and potassium

alcohol u-sed. In general, aqueous solutions ranging in

salts thereof. Additional water dispersible polymeric

concentration from about 2% by weight to about 20%

material for use 'herein will be readily apparent to those

by weight of polyvinyl alcohol may be used. However, it

has been found that an aqueous solution containing about

skilled in the art.

Since there is a limit to the thickness of a layer which

5% to about 8% iby weight polyvinyl alcohol is sufficient 60

may be deposited on dipping, it is recognized that in

for use in the present invention and is thus preferred. The

forming the match fusehead, two Ior more dips of each

polyvinyl alcohol in such instance is that having a viscosity

layer of composition may be applied. Moreover, suc

at 20 C. of about 22 to about 224 centistokes.

cesive ilayers may include compositions of different phys

In some instances, it is advantageous to heat the

aqueous polyvinyl alcohol solution to above room tem 65 ical or chemical ingredients, if desired.

Priming charge 16 is positioned adjacent to base charge

perature in order to decrease its viscosity and to remove

14 and in detonating relation thereto and to deflagrating

any entrained air bubbles which would give rise to the

composition layer 24. The priming charge may include

formation of imperfections in the resultant coating. The

any suitable material such as mannitol hexanitrate, dia

coating operation may be performed by im-mersionvof the

bridge wire assembly into a solution of polyvinyl alcohol 70 zodinitrophenol, mercury fulminate, lead azide, or mix

tures thereof with oxidizing agents such as potassium

which may be at a temperature of about 50 C. Satisfac

chlorate.

tory coating of polyvinyl alcohol may be obtained at

higher or lower temperatures and the solution may be

applied in other ways, as for example, by Spraying or by

brush application.

Base charge 14 may include any suitable detonable

material, for example, pentaerythritol tetranitrate, nitro

75 starch, trinitrotoluene, teryl or the like.

3,415,189

Deagration composition layer 24 positioned over the

ignition composition layer 26 as part of electric match

assembly 18 includes any suitable material such as for

example, a mixture of carbon and potassium chlorate.

Matches of the present invention may be used with elec

tric explosion initiators of other varieties than that spe

cically described. For example, the present matches may

be used with detonators having various charges and aux

6. The electric match assembly and electric explosion

initiator of claim 5 wherein the aperture for ingress of

water into the initiator is disposed near the base of the

initiator whereby ingress of water permeates the con

tained explosive composition prior to contacting the wa

ter dispersible polymeric material coating layer disposed

on said match head.

7. The electric explosion initiator of claim 5 wherein

iliary elements for special application in other devices

the contained explosive composition includes a detonating

where electric matches may be employed. The electric 10 charge and a priming charge in detonating position rela

explosive initiators may further include delay trains, if

tive to the electric match assembly.

desired.

8. The electric match assembly of claim 1 wherein the

It is understood that the foregoing detailed description

water dispersible polymeric material is a water dispersible

is given merely by way of illustration and that many vari~

polyvinyl compound.

ations may be made therein without departing from the 15

9. The electric match assembly of claim 8 wherein the

spirit and scope of the invention.

water dispersible polyvinyl compound is polyvinyl alcohol.

What is claimed is:

10. The electric match assembly of claim 1 wherein

1. An electric match assembly which comprises, a

the water dispersible polymeric material is a water dis

bridge wire assembly having a bridge wire electrically con

persible alkali metal salt of polyacrylic acid.

nected at one end thereof, a match head surrounding 20

11. The electric match assembly of claim 1 wherein

said bridge wire, and a water dispersible polymeric ma

the water dispersible polymeric material is a water dis

terial coating layer disposed on and surrounding said

persible cellulose ether.

12. The electric match assembly of claim 1 wherein

the water dispersible polymeric material coating layer

match head.

2. The electric match assembly of claim 1 wherein the

match head includes an ignition composition layer dis 25 is a polyvinyl alcohol coating layer applied as an aqueous

posed about the bridge wire and a fdeagrating compo

solution containing from about 2% to about 20% by

sition layer disposed about said ignition composition

layer.

weight of polyvinyl alcohol, said' solution having a vis

cosity at 20 C. of about 22 about 24 centistokes.

3. The electric match assembly of claim 1 having a

heat shrunk plastic sleeve disposed about a length of the 30

electric match assembly.

4. The electric match assembly of claim 3 in combi

nation with an electric explosion initiator having an outer

References Cited

UNITED STATES PATENTS

1,935,495

11/1933

Young __________ __ 102-28 X

3,279,372 10/ 1966 Patterson __________ __ 102-28

shell containing an explosive charge and provided with

an aperture for the ingress of water into the initiator, 35 3,322,066 5/1967 Gril-lith et al ________ __ 102-24

3,332,350

7/1967 Morfy _____________ __ 102-28

said combination for use in seismographic prospecting.

3,356,024 12/ 1967 Driscoll et al ________ __ 102-28

5. The electric match assembly of claim 1 disposed

3,358,601 12/1967 Dittmann et al ______ __ 102-28

in an electric explosion initiator having an outer shell

BENJAMIN A. BORCHELT, Primary Examiner.

containing an explosive composition and provided with

an aperture for the ingress of water into the initiator. 40 VERLIN R. PENDEGRASS, Assistant Examiner.

Вам также может понравиться

- Anti-Corrosion Methods and Materials: Article InformationДокумент6 страницAnti-Corrosion Methods and Materials: Article InformationchecolonoskiОценок пока нет

- جورنال عراقى (جامعة تكريت) PDFДокумент10 страницجورنال عراقى (جامعة تكريت) PDFchecolonoskiОценок пока нет

- Patent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentsДокумент9 страницPatent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentschecolonoskiОценок пока нет

- Benzocaine (2 Steps)Документ11 страницBenzocaine (2 Steps)checolonoski0% (1)

- Us4278480 PDFДокумент3 страницыUs4278480 PDFchecolonoskiОценок пока нет

- Us2741543 PDFДокумент6 страницUs2741543 PDFchecolonoskiОценок пока нет

- Us2942965 PDFДокумент2 страницыUs2942965 PDFchecolonoskiОценок пока нет

- Ravi2011 PDFДокумент11 страницRavi2011 PDFchecolonoskiОценок пока нет

- Us2589532 PDFДокумент7 страницUs2589532 PDFchecolonoskiОценок пока нет

- Us2344840 PDFДокумент3 страницыUs2344840 PDFchecolonoskiОценок пока нет

- Us857580 PDFДокумент2 страницыUs857580 PDFchecolonoskiОценок пока нет

- Urey1931 PDFДокумент9 страницUrey1931 PDFchecolonoskiОценок пока нет

- Handbook of Ammunition Used in Irak and Surrounding AreasДокумент319 страницHandbook of Ammunition Used in Irak and Surrounding Areasmalone6993% (15)

- Nitrate Solid Solution. I: Distributed byДокумент37 страницNitrate Solid Solution. I: Distributed bychecolonoskiОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- SIVACON 8PS - Planning With SIVACON 8PS Planning Manual, 11/2016, A5E01541101-04Документ1 страницаSIVACON 8PS - Planning With SIVACON 8PS Planning Manual, 11/2016, A5E01541101-04marcospmmОценок пока нет

- A Comparative Study of Public Private Life Insurance Companies in IndiaДокумент5 страницA Comparative Study of Public Private Life Insurance Companies in IndiaAkansha GoyalОценок пока нет

- CFD Turbina Michell BankiДокумент11 страницCFD Turbina Michell BankiOscar Choque JaqquehuaОценок пока нет

- Application of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionДокумент17 страницApplication of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionAmit Kumar GautamОценок пока нет

- Lady in The House, Her Responsibilities & Ambitions: Amrita DuhanДокумент7 страницLady in The House, Her Responsibilities & Ambitions: Amrita DuhanFitness FableОценок пока нет

- RARE Manual For Training Local Nature GuidesДокумент91 страницаRARE Manual For Training Local Nature GuidesenoshaugustineОценок пока нет

- Bcom (HNRS) Project Final Year University of Calcutta (2018)Документ50 страницBcom (HNRS) Project Final Year University of Calcutta (2018)Balaji100% (1)

- JCP4 XDOBursting EngineДокумент13 страницJCP4 XDOBursting Enginesubhash221103Оценок пока нет

- Alaba Adeyemi AdediwuraДокумент12 страницAlaba Adeyemi AdediwuraSchahyda ArleyОценок пока нет

- Genuine Fakes: How Phony Things Teach Us About Real StuffДокумент2 страницыGenuine Fakes: How Phony Things Teach Us About Real StuffGail LeondarWrightОценок пока нет

- Niveshdaily: From Research DeskДокумент53 страницыNiveshdaily: From Research DeskADОценок пока нет

- AДокумент54 страницыActyvteОценок пока нет

- Literature Review Template DownloadДокумент4 страницыLiterature Review Template Downloadaflsigfek100% (1)

- Ch-10 Human Eye Notes FinalДокумент27 страницCh-10 Human Eye Notes Finalkilemas494Оценок пока нет

- Mission and VisionДокумент5 страницMission and VisionsanjedОценок пока нет

- Full Project LibraryДокумент77 страницFull Project LibraryChala Geta0% (1)

- PDFДокумент3 страницыPDFAhmedraza123 NagdaОценок пока нет

- Boundary Value Analysis 2Документ13 страницBoundary Value Analysis 2Raheela NasimОценок пока нет

- MFE Module 1 .Документ15 страницMFE Module 1 .Adarsh KОценок пока нет

- A.meaning and Scope of Education FinalДокумент22 страницыA.meaning and Scope of Education FinalMelody CamcamОценок пока нет

- The Ovation E-Amp: A 180 W High-Fidelity Audio Power AmplifierДокумент61 страницаThe Ovation E-Amp: A 180 W High-Fidelity Audio Power AmplifierNini Farribas100% (1)

- Hare and Hyena: Mutugi KamundiДокумент18 страницHare and Hyena: Mutugi KamundiAndresileОценок пока нет

- A Content Analysis of SeabankДокумент13 страницA Content Analysis of SeabankMarielet Dela PazОценок пока нет

- Leadership and Management in Different Arts FieldsДокумент10 страницLeadership and Management in Different Arts Fieldsjay jayОценок пока нет

- 25 Middlegame Concepts Every Chess Player Must KnowДокумент2 страницы25 Middlegame Concepts Every Chess Player Must KnowKasparicoОценок пока нет

- China Training WCDMA 06-06Документ128 страницChina Training WCDMA 06-06ryanz2009Оценок пока нет

- CHARACTER FORMATION 1 PrelimДокумент15 страницCHARACTER FORMATION 1 PrelimAiza Minalabag100% (1)

- DirectionДокумент1 страницаDirectionJessica BacaniОценок пока нет

- The Rise of Australian NovelДокумент412 страницThe Rise of Australian NovelSampath Kumar GummadiОценок пока нет

- Lesson 1 3 Transes in Reading in Philippine HistoryДокумент17 страницLesson 1 3 Transes in Reading in Philippine HistoryNAPHTALI WILLIAMS GOОценок пока нет