Академический Документы

Профессиональный Документы

Культура Документы

Preparation of HVAC Ducting Layout

Загружено:

arunima04Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Preparation of HVAC Ducting Layout

Загружено:

arunima04Авторское право:

Доступные форматы

WORK INSTRUCTION

SEI-HC-PS-W400

INSTRUCTION FOR PREPARATION OF HVAC DUCTING LAYOUT

Rev.

Date

: 01

2014.02.03

SAMSUNG ENGINEERING INDIA

1.

PURPOSE:

This document defines the process of preparing HVAC ducting layout with

respect to ITB specification and good engineering practice.

2.

SCOPE:

This Work Instruction indicates basic technical requirements to design HVAC

Ducting Layout.

3.

REFERENCES:

4.

Civil, Structure and Architecture drawing.

HVAC air flow data.

HVAC equipment schedule.

False ceiling & floor drawings.

Architectural Reflected ceiling plan (RCP)

ITB specification.

Code and standard consideration.

DEFINITIONS:

RCP

BOD

IDC

IFA

IFC

ASHRAE

SMACNA

5.

Reflected ceiling plan

Bottom of duct

Inter discipline check

Issued for approval

Issued for construction

American Society of Heating, Refrigerating and Air Conditioning

Engineers

Sheet Metal and Air Conditioning Contractors National Association.

INSTRUCTIONS:

5.1 The HVAC duct routing, sizing, and levelling (BOD) to be decided based on

the ITB specification, good engineering practice (ASHRAE & SMACNA

standards) maintainability, constructability and the space available in the

building. Ducting layout to be prepared based on constant friction method.

The air velocity consideration as follows.

8-10m/s in plant room

6-8m/s in main ducting

4-6m/s in branch ducting

The aspect ratio of duct should be less than 1:4. The size of duct can be

customize as per space limitation.

5.2 Fittings

Duct fittings selection should be based on ITB requirement & good

engineering practice.

General fittings for HVAC ducting:

Gas tight Damper:- To prevent outsides hazardous gas enter as fresh air

in the system, Gas tight damper require in the fresh air inlet line.

Volume control Damper: - VCD to be installed to control volume of air in

every branch duct and as well as terminals.

Fire Damper: - Fire Damper to be installed in ducting that crosses any fire

rated wall or plant room wall to prevent fire to spread.

Duct Heater: - Duct Heater to be installed in supply duct for heating of air.

Sound Attenuator: - Sound attenuator shall be selected to maintain desire

room noise level inside the room.

Diffuser, Grille etc: - Grille, diffusers are used to distribute required air in

side the room.

5.3 Routing and Bottom of Duct

Duct routing and BOD of duct should be co-ordinated with all building

services, layout and space availability.

5.4 Insulation and support

Insulation and support of duct to be decided based on ITB specification,

HVAC typical drawings and good engineering practice.

5.5 Access Door in Duct

Access doors to be provided on all required location for easy access to duct

and fittings for operation and maintenance.

5.6.

Project Phases

5.6.1 IDC

Information (layout Dwg.) to be given to other discipline (CSA,

Electrical, Instrumentation, Piping layout etc.) for comments and

considerations.

5.6.2 IFA

Incorporating IDC comments in layout, the drawing to be issued for

approval to Client, Consultant and other discipline.

5.6.3 IFC

Approved layout to be issued to PMC and Client for approval to proceed

construction activities.

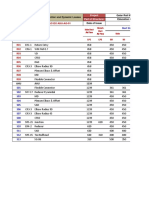

6. ATTACHMENTS:

1. Reference HVAC Ducting layout

7. REVISION HISTORY

No.

Date

Page

Reason for Revision

- Company Standard Document Registration of Internal

Document

- Department

: Piping Speciality-HVAC

Prepared by : Chandan Bhattacharjee

00

2013. 06. 14

New Issue

Reviewed by : Pradeep Kumar Suman

Approved by : Rakesh Kumar

- Department

: Piping Speciality-HVAC

Prepared by : Chandan Bhattacharjee

01

2014. 02. 03

1-5

Reviewed by : Pradeep Kumar Suman

Approved by : Rakesh Sharma

Вам также может понравиться

- External Static Pressure Calculation: Hvac 3/27 M.M 4 June 2014 MA/CAL/3Документ3 страницыExternal Static Pressure Calculation: Hvac 3/27 M.M 4 June 2014 MA/CAL/3Engr.MmosaadОценок пока нет

- Ahu & Chiller OkДокумент40 страницAhu & Chiller OkAndy DwiОценок пока нет

- CHW Pipe Straight Pressure DropДокумент2 страницыCHW Pipe Straight Pressure DropDesigner ForeverОценок пока нет

- 1 Chilled Water Pump Head CalculationДокумент6 страниц1 Chilled Water Pump Head CalculationMohammed TanveerОценок пока нет

- Estimating Exteranl and Internal Pressure Drop For AHU and FCUДокумент6 страницEstimating Exteranl and Internal Pressure Drop For AHU and FCUfghabboonОценок пока нет

- L&T MLCP East Block HVAC Heat Load SUMMARYДокумент3 страницыL&T MLCP East Block HVAC Heat Load SUMMARYSatheesh Kumar NatarajanОценок пока нет

- Condensate Drain Calculation Lab AHU PDFДокумент1 страницаCondensate Drain Calculation Lab AHU PDFAri RizaldiОценок пока нет

- Im j1 Personnel Cooling Load Estimation 2014Документ40 страницIm j1 Personnel Cooling Load Estimation 2014Melvin SanchezОценок пока нет

- Hvac OtДокумент4 страницыHvac OtshreyaОценок пока нет

- Chilled Water and Condensor Water Pump Head CalculaitonДокумент3 страницыChilled Water and Condensor Water Pump Head CalculaitonYusuf RampОценок пока нет

- Final ReportДокумент94 страницыFinal ReportAJITH KUMARОценок пока нет

- Ventilation DBRДокумент16 страницVentilation DBRVignesh GandhirajОценок пока нет

- Ahu Coil SelectionДокумент6 страницAhu Coil SelectionpsjjoshiОценок пока нет

- FAHUДокумент4 страницыFAHUSundar DAACОценок пока нет

- Huntair Coplanar Silencer 1107Документ2 страницыHuntair Coplanar Silencer 1107Tu Burin DtОценок пока нет

- Fan Coil Units External System Resistance Calculation (Static Pressure)Документ4 страницыFan Coil Units External System Resistance Calculation (Static Pressure)Adnan AttishОценок пока нет

- Expansion Tank CalculationsДокумент5 страницExpansion Tank Calculationspsjjoshi0% (1)

- Ventilation Summary For Carpark & VRV System: (M /S) (M /S)Документ4 страницыVentilation Summary For Carpark & VRV System: (M /S) (M /S)sachinsaklani23Оценок пока нет

- Mechanical CommentsДокумент6 страницMechanical Commentspsn_kylmОценок пока нет

- Dedicated Outdoor Air Systems (Doas) : Indoor Air Quality + Energy Recovery + Humidity ControlДокумент39 страницDedicated Outdoor Air Systems (Doas) : Indoor Air Quality + Energy Recovery + Humidity Controlhtanh100% (1)

- AHUДокумент5 страницAHUksahunkОценок пока нет

- Acmv Technical ReportДокумент10 страницAcmv Technical Reportarun kurlanОценок пока нет

- Chiiler Design PDFДокумент24 страницыChiiler Design PDFNeal JohnsonОценок пока нет

- Machinery Room Ventilation Analysis ToolДокумент48 страницMachinery Room Ventilation Analysis ToolDon Quijote de la ManchaОценок пока нет

- Presentation 1Документ20 страницPresentation 1SMBEAUTYОценок пока нет

- Electrical Loading Estimation WorkstageДокумент15 страницElectrical Loading Estimation WorkstageansonchongОценок пока нет

- Heat Load Calculation ExampleДокумент5 страницHeat Load Calculation ExampleJoshua RanjithОценок пока нет

- CHW Pump - HotelДокумент7 страницCHW Pump - HotelTiffany CombsОценок пока нет

- Hvac Condensate Calculator: Difference in Specific Humidity gr/ft3Документ4 страницыHvac Condensate Calculator: Difference in Specific Humidity gr/ft3Pradeep SukumaranОценок пока нет

- Technical Document On Smoke Extract & Car Park FansДокумент4 страницыTechnical Document On Smoke Extract & Car Park FansTanveer AzizОценок пока нет

- Calculation Storm PipeДокумент10 страницCalculation Storm PipesenghouОценок пока нет

- 01-Hvac Panel PDFДокумент9 страниц01-Hvac Panel PDFM.K.RameshОценок пока нет

- Chiller Flow Rates and Guidelines For Chilled Water System PipingДокумент3 страницыChiller Flow Rates and Guidelines For Chilled Water System PipingTanveer Aziz100% (3)

- AHU Friction Loss CalculationsДокумент4 страницыAHU Friction Loss CalculationsAdnan AttishОценок пока нет

- Halton Design Guide enДокумент54 страницыHalton Design Guide enimtiyaz94Оценок пока нет

- Example Kitchen Ventilation CalculationДокумент4 страницыExample Kitchen Ventilation Calculationwillis0000Оценок пока нет

- HVAC ComparisonДокумент283 страницыHVAC Comparisonmilindskulkarni2005@yahoo.co.in100% (1)

- Honeywell Single Duct VAV - VAV Box Schema Eelctrica, Descriere, Mod de FunctionareДокумент24 страницыHoneywell Single Duct VAV - VAV Box Schema Eelctrica, Descriere, Mod de FunctionareViorel CatalinОценок пока нет

- Ayra WSM 02 03 Mkii Fog Machine User ManualДокумент9 страницAyra WSM 02 03 Mkii Fog Machine User ManualareefОценок пока нет

- Duck Work Calculation (Inch)Документ2 страницыDuck Work Calculation (Inch)pratheeshОценок пока нет

- Generator Exhaust Pipe Diameter Calculations: Marina Towers L9959Документ4 страницыGenerator Exhaust Pipe Diameter Calculations: Marina Towers L9959febousОценок пока нет

- Duct CalculationДокумент57 страницDuct CalculationMohamed AsifОценок пока нет

- Optimizing Central Chilled Water SystemsДокумент56 страницOptimizing Central Chilled Water Systemsapi-328841994Оценок пока нет

- Hvac Pipe SizingДокумент1 страницаHvac Pipe SizingRaja Antony100% (1)

- Ariston Electric Water HeatersДокумент2 страницыAriston Electric Water HeatersSuresh SubbarayanОценок пока нет

- S&W CalculationДокумент10 страницS&W CalculationSameera LakmalОценок пока нет

- HVAC Professional Heat Load SheetДокумент8 страницHVAC Professional Heat Load Sheet45saulОценок пока нет

- ESP Calculation For FAHU: Section Air Flow Duct Size L/S CFM W (MM) X H (MM) W (In) X H (In) L (M) FPM M/s 983.20 4.99Документ11 страницESP Calculation For FAHU: Section Air Flow Duct Size L/S CFM W (MM) X H (MM) W (In) X H (In) L (M) FPM M/s 983.20 4.99Jitheesh Sahadevan100% (1)

- Staircase Pressurization Calculation SheetДокумент4 страницыStaircase Pressurization Calculation SheetTariq AsgharОценок пока нет

- 1a Domestic Water Meter Installation in Villas and Sheds DrawingPEWSTDAMI001Документ1 страница1a Domestic Water Meter Installation in Villas and Sheds DrawingPEWSTDAMI001Designer ForeverОценок пока нет

- Expansion Joints Rubber Type 40Документ7 страницExpansion Joints Rubber Type 40Anonymous K3FaYFlОценок пока нет

- Combining DOAS and VRF, Part 2 of 2Документ9 страницCombining DOAS and VRF, Part 2 of 2miniongskyОценок пока нет

- Chiller Performance Template - Air CooledДокумент7 страницChiller Performance Template - Air CooledBasil OguakaОценок пока нет

- PICV Vs Manual Balancing With DP ControllerДокумент1 страницаPICV Vs Manual Balancing With DP ControllermajortayОценок пока нет

- Load Check FiguresДокумент1 страницаLoad Check FiguresArshavin Watashi WaОценок пока нет

- Project Standard Specification: Metal Ducts 15815 - Page 1/12Документ12 страницProject Standard Specification: Metal Ducts 15815 - Page 1/12adel rihanaОценок пока нет

- 090 IT Consultant ScopeДокумент4 страницы090 IT Consultant ScopeĐức Huấn ĐỗОценок пока нет

- Air Conditioning System SpecificationДокумент16 страницAir Conditioning System Specification123agattarОценок пока нет

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Surging in Axial or Centrifugal CompressorДокумент1 страницаSurging in Axial or Centrifugal Compressorarunima04Оценок пока нет

- API Plan 01: Integral (Internal) Re Cir Cu La Tion From The Pump Dis - Charge To The Seal ChamberДокумент3 страницыAPI Plan 01: Integral (Internal) Re Cir Cu La Tion From The Pump Dis - Charge To The Seal Chamberarunima04Оценок пока нет

- Centrifugal CompressorДокумент23 страницыCentrifugal CompressorTono UnyilОценок пока нет

- Integrally Geared Centrifugal Compressors - Processing MagazineДокумент10 страницIntegrally Geared Centrifugal Compressors - Processing Magazinearunima04Оценок пока нет

- API Plan 99 - ENДокумент3 страницыAPI Plan 99 - ENarunima04Оценок пока нет

- Positive Displacement Pumps Selection Guide - Types, Features, ApplicationsДокумент11 страницPositive Displacement Pumps Selection Guide - Types, Features, Applicationsarunima04Оценок пока нет

- ANSI Vs API Pumps - What's The DifferenceДокумент4 страницыANSI Vs API Pumps - What's The Differencearunima04Оценок пока нет

- API Plan 14 - ENДокумент3 страницыAPI Plan 14 - ENarunima04Оценок пока нет

- Article On Pump Minimum FlowДокумент5 страницArticle On Pump Minimum Flowarunima04100% (1)

- Energies: Two-Stage Evaporative Inlet Air Gas Turbine CoolingДокумент17 страницEnergies: Two-Stage Evaporative Inlet Air Gas Turbine Coolingarunima04Оценок пока нет

- How To Read A Centrifugal Pump CurveДокумент15 страницHow To Read A Centrifugal Pump Curvearunima04Оценок пока нет

- API682Документ16 страницAPI682peach5Оценок пока нет

- Summary of API 610, 12th EditionДокумент4 страницыSummary of API 610, 12th EditionTyas Utami83% (6)

- How Do FPSOs WorkДокумент3 страницыHow Do FPSOs WorkAnonymous cekPJylABoОценок пока нет

- Compressors - Rotary, Positive Displacement Type Compressors - Mechanical KnowledgeДокумент3 страницыCompressors - Rotary, Positive Displacement Type Compressors - Mechanical Knowledgearunima04Оценок пока нет

- Surging in Axial or Centrifugal CompressorДокумент1 страницаSurging in Axial or Centrifugal Compressorarunima04Оценок пока нет

- API Plan 31 - ENДокумент3 страницыAPI Plan 31 - ENarunima04Оценок пока нет

- API 682 4th Edition Application GuideДокумент31 страницаAPI 682 4th Edition Application Guidearunima04Оценок пока нет

- API Plan 32 - ENДокумент3 страницыAPI Plan 32 - ENarunima04Оценок пока нет

- Summary of API 610, 12th EditionДокумент4 страницыSummary of API 610, 12th EditionTyas Utami83% (6)

- Project Standards and Specifications Pig Catcher Package Rev01Документ9 страницProject Standards and Specifications Pig Catcher Package Rev01hiyeonОценок пока нет

- Article On Pump Minimum FlowДокумент5 страницArticle On Pump Minimum Flowarunima04100% (1)

- Draftsman HVAC: Job SummaryДокумент1 страницаDraftsman HVAC: Job Summaryarunima04Оценок пока нет

- Pip Resp002Документ16 страницPip Resp002arunima04Оценок пока нет

- 28 Psychrometric ProcessesДокумент19 страниц28 Psychrometric ProcessesPRASAD326100% (7)

- HVAC Design Engineer JDДокумент1 страницаHVAC Design Engineer JDarunima04Оценок пока нет

- DK Ep Mec Gde 0001 Rev 1.0 Eng07 343 XJBR DGL 12 Hvac Systems - 7 - 0Документ26 страницDK Ep Mec Gde 0001 Rev 1.0 Eng07 343 XJBR DGL 12 Hvac Systems - 7 - 0arunima04Оценок пока нет

- Guidelines Provide Offshore HVAC Design Criteria - Oil & Gas JournalДокумент8 страницGuidelines Provide Offshore HVAC Design Criteria - Oil & Gas Journalarunima04Оценок пока нет

- DK Ep Mec Gde 0001 Rev 1.0 Eng07 343 XJBR DGL 12 Hvac Systems - 7 - 0Документ26 страницDK Ep Mec Gde 0001 Rev 1.0 Eng07 343 XJBR DGL 12 Hvac Systems - 7 - 0arunima04Оценок пока нет

- Hourly Analysis Program HVAC SystemДокумент9 страницHourly Analysis Program HVAC Systemarunima04Оценок пока нет

- Sow - Om CHP PDFДокумент16 страницSow - Om CHP PDFSuresh SОценок пока нет

- Experiment 3 - Flow Over Supersonic AirfoilДокумент14 страницExperiment 3 - Flow Over Supersonic AirfoilSanthosh KumarОценок пока нет

- DKOM Lab ManualДокумент24 страницыDKOM Lab Manualaakash chakrabortyОценок пока нет

- K GBДокумент18 страницK GBLuis Fernando Juchani MoralesОценок пока нет

- A 320 Â " A 320M Â " 01 - QTMYMC0WMQДокумент7 страницA 320 Â " A 320M Â " 01 - QTMYMC0WMQhОценок пока нет

- Equipment Erection, Static and RotaryДокумент8 страницEquipment Erection, Static and RotaryHamada ELaraby60% (5)

- Grasso SC PDFДокумент86 страницGrasso SC PDFСергей Конкин100% (1)

- Egyptian Code of PracticeДокумент263 страницыEgyptian Code of PracticeyhszaОценок пока нет

- Potter Air Relief Valve - 5401165 - PavДокумент3 страницыPotter Air Relief Valve - 5401165 - PavFrancisco AlarconОценок пока нет

- Volume 01 Principles of FlightДокумент303 страницыVolume 01 Principles of FlightYousif AL AyoubiОценок пока нет

- 2 Polyflow 12.1 Polyflow A IIДокумент95 страниц2 Polyflow 12.1 Polyflow A IIwoongs73Оценок пока нет

- Brilliant: Physics Olympiad Model ExaminationДокумент9 страницBrilliant: Physics Olympiad Model ExaminationKalyani BaijuОценок пока нет

- Abbasnezhad Et Al-2015-Food Science NutritionДокумент9 страницAbbasnezhad Et Al-2015-Food Science NutritionJulio Mauricio Vidaurre-RuizОценок пока нет

- Die-Casting Machines 1913 PDFДокумент48 страницDie-Casting Machines 1913 PDFOceanОценок пока нет

- Directory of Suppliers To Cement Industry: Product Category-WiseДокумент1 страницаDirectory of Suppliers To Cement Industry: Product Category-WiseAneeshОценок пока нет

- Homogenizer Commisioning Checklist 2014Документ4 страницыHomogenizer Commisioning Checklist 2014Victor Alberto Ramos BarronОценок пока нет

- Economic Optimization of Pipe Diameter For Complete TurbulenceДокумент4 страницыEconomic Optimization of Pipe Diameter For Complete Turbulenceazamshafiq100% (1)

- Airplane Flight Manual Z 242 LДокумент40 страницAirplane Flight Manual Z 242 LFeksesОценок пока нет

- Pw4084 Engine Testing in Altitude & Sea Level Test FacilitiesДокумент16 страницPw4084 Engine Testing in Altitude & Sea Level Test Facilities128mansouriОценок пока нет

- Screw Type - Elite Air CompressorДокумент1 страницаScrew Type - Elite Air Compressorimron rosyadiОценок пока нет

- JT Plants: PC LiquidsДокумент2 страницыJT Plants: PC LiquidsJimenez ArgenisОценок пока нет

- Camion Articulado 730C2 Plano HYD 2016 SISДокумент2 страницыCamion Articulado 730C2 Plano HYD 2016 SISFabrizio Jesus Morales SalirrosasОценок пока нет

- FM End-Sem Question Paper - 2021Документ1 страницаFM End-Sem Question Paper - 2021Anshu MeenaОценок пока нет

- NOx Reduction MethodsДокумент7 страницNOx Reduction Methodsmithunsingh90Оценок пока нет

- Resonance and Analysis of Barton's Pendulum PDFДокумент17 страницResonance and Analysis of Barton's Pendulum PDFmailbox_afeef2Оценок пока нет

- MT4400 Front Brakes (Carlisle)Документ15 страницMT4400 Front Brakes (Carlisle)Brian CareelОценок пока нет

- GPG216 Energy Saving in The Filtration and Drying of Compressed AirДокумент31 страницаGPG216 Energy Saving in The Filtration and Drying of Compressed AirIppiОценок пока нет

- LPS 1240-Issue 1.1-Requiremects For LPCB Approved Fire Sprinkler Pump Set Used in Automatic Sprinkler Installations PDFДокумент14 страницLPS 1240-Issue 1.1-Requiremects For LPCB Approved Fire Sprinkler Pump Set Used in Automatic Sprinkler Installations PDFHazem HabibОценок пока нет

- Gears and Gear TrainsДокумент127 страницGears and Gear TrainsVikki KotaОценок пока нет

- J54-100 Parte1Документ45 страницJ54-100 Parte1angel gabriel perez valdezОценок пока нет