Академический Документы

Профессиональный Документы

Культура Документы

Check List For New Company Registration: Page 1 of 21

Загружено:

Tuyen NguyenИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Check List For New Company Registration: Page 1 of 21

Загружено:

Tuyen NguyenАвторское право:

Доступные форматы

Page 1 of 21

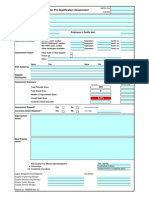

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

1.1 International

Standards

Certification(3)

Description

1.Standards

Management (9)

marks

score

N/A

a b c

Assessment guideline

Point per Mark

ISO9000Cer ca on

1.5

-ObtainedISO9000Certification

a:Yesc:No

A(1.5),C(0)

Addi onalInterna onal

Certification

1.5

-AdditionalCertification(i.eQS9000,TS16949,TL9000,

ISO14000,OHSAS18000)

a:Yesc:No

A(1.5),C(0)

Agreementorapproval

processfromrelevant

departmentpriorto

publicationofStandards

1.2 Standards

Management

status(3)

Distribu

result

tion

Iden ca onof

responsibledepartments

uponstandards

publicationand

managementof

distributionhistory

No ca onortraining

onpublishedstandardsat

site

1.5

0.5

-Reviewitsprocessonstandardspublication,approval,

modificationandabolition

Select2samplestandardsrecentlypublishedor

modifiedandchecktherelatedapprovaloragreement

A(1.5),B(0.75),C(0)

statuspriortopublication

a:Bothsamplesfulfiltherequirement

b:Onesamplefulfilstherequirement

c:Bothsamplesfailtherequirement

-Checkforthebelowconditions

Clearindicationofresponsibledepartment

Managementofdistributionhistoryincluding

responsibledepartment,quantityofdistributionand

distributiondates

Noinvalidstandardsstillusedonsite

a:Fulfilsall3requirement

b:Fulfils2requirements

c:Fulfils1orless

-Select2samplepublishedstandardsatsiteandcheck

ifnecessarynotificationandtraininghasbeengivento

theemployees

A(0.5),B(0.25),C(0)

a:Notificationandtrainingcompletedonboth

samples

b:Notificationandtrainingcompletedon1sample

c:Notcompleted

21 1

A(1),B(0.5),C(0)

Page 2 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

Regularinternalquality

audit

Distribu

result

tion

1.5

marks

score

N/A

a b c

Standardson

temperatureand

humiditycontrolin

warehouseand

implementationof

standards

2.1 Warehouse

management(5)

Systema cstoragerack

forFIFOandmaterial

managementusing

labellingsystem

(weekly/monthly)

1.5

1.5

1.5

Point per Mark

-Obtainlatestannualinternalqualityauditplanand

relatedreportsandcheckiftheauditcarriedoutin

linewiththeplan

a:Auditcarriedoutinlinewiththeplan

b:Auditcarriedoutwithoutpresetplan

c:Noaudithasbeencarriedout

A(1.5),B(0.75),C(0)

-Select2issuesfromthepreviousauditandcheckif

therequiredimprovementactionhasbeentaken

withinthegivenschedule

a:Actionscompletedonbothissues

b:Actioncompletedon1issue

c:Noactiontaken

A(1.5),B(0.75),C(0)

(SQCI)

-Visitthewarehouseandcheckthefollowing3

conditions

Cleannessofsite

Standardsontemperature&humiditycontrol

Implementationofstandards

a:Fulfils3conditions

b:Fulfils2conditions

c:Fulfils1orlesscondition

A(1.5),B(0.75),C(0)

(SQCI)

-Checkthematerialstoragesystemandfindoutusing

2materialsamples

FIFO(firstinfirtout)isimplemented

FIFOismanagedbylabellingsystem

(weekly/monthly)

a:Fulfilsbothconditions

b:Fulfils1condition

c:Nil

A(1.5),B(0.75),C(0)

1.3 Internal Quality

Audit(3)

Improvementac onon

internalqualityaudit

result

Assessment guideline

21 2

Page 3 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

Managementof

materialwithvaliditysuch

aspaint,glue,fluxand

Alcohol

Periodicinventory

checkandadequate

countermeasureon

discrepancy

Distribu

result

tion

1.5

0.5

marks

score

N/A

a b c

A(1.5),B(0.75),C(0)

-Checkiftheoptimisedinventorylevelis

acknowledged

andtheperiodicinventorycheckisbeingconducted

a:Periodicinventorycheckisbeingconducted

b:Non-Periodicinventorycheckisbeingconducted

c:Noinventorycheckisbeingconducted

A(0.5),B(0.25),C(0)

(SQCI)

-Select2materialfromcompletedincominginspection

andcheckiftheconditionsmeetthecreteriaby

comparingthedatafromCertification,Inspection

A(2),B(1),C(0)

StandardsandResultreport(i.eInspection

items,Qty,measuringdataandresult)

a:Bothsamplesmeetthecondition

b:1samplemeetthecondition

c:Nil

(SQCI)

-Checkiftheanalysisonincominginspectionisbeing

reportedonperiodicbasis

a:Periodicanalysisisbeingreported

b:Non-periodicanalysisisbeingreported

c:Noanalysisisbeingreported

2.2 Incoming

Inspection(2.5)

Periodicanalysis

(weekly/monthly)on

Incominginspection

result

0.5

Point per Mark

(SQCI)

-Visitthewarehouseandcheckthevalidityof2

samplematerial

ifthebest-before-datehasnotpassed

a:bothmaterialwithinthevalidity

b:1materialwithinthevalidity

c:Nil

2.Incoming

inspection (10)

Coherenceon

Certification,Inspection

StandardsandResult

reportonIncoming

inspection

Assessment guideline

21 3

A(0.5),B(0.25),C(0)

Page 4 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

Awri enrequestfor

Improvementondefects

Lotandacquisitionofthe

improvementplan

Distribu

result

tion

1.5

marks

score

N/A

a b c

Managementof

MeasuringEquipmentList

andontimeCalibration

Point per Mark

(SQCI)

-Select2randomsamplesfromdefectslotand

checkiftheimprovementrequestwassentoutand

improvementplanhavebeenacquired

a:Improvementplanreceivedforbothsamples

b:Improvementplanreceivedfor1sample

c:Nil

Ifthere'snodefectslot,selectN/A

A(1.5),B(0.75),C(0),N/A

(SQCI)

-Select2sampleswiththereceivedimprovement

plansandcheckifthepostmanagementis

implemented

a:Postmanagementimplementedonbothsamples

b:Postmanagementimplementedon1sample

c:Nil

Ifthere'snodefectslot,selectN/A

A(1),B(0.5),C(0),N/A

(SQCI)

-Checkifthere'sameasuringequipmentlisttocontrol

andchecktheserialno,installationplace,calibration

period&calibrationhistoryandactualcalibration

wereconductedontime

a:Allcalibrationwereconductedinaccordancewith

themeasuringequipmentlistontime

b:Measuringequipmentlistexistbutsome

equipment'scalibrationisoverdue

c:Calibrationwithoutanyequipmentlist

A(2),B(1),C(0)

2.3 Control of Defects

Lot(2.5)

Postmanagementon

improvementplan

(Verificationonnext

incomingLot)

Assessment guideline

21 4

Page 5 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

3.1 Calibration

control for

Measuring

Equipment(4)

Description

Neglectedmeasuring

equipmentonproduction

lineinidleordefective

condition

Distribu

result

tion

marks

score

N/A

a b c

Selfinspec onon

measuringequipmentnot

requirescalibration

0.6

Point per Mark

(SQCI)

-Checkifanyneglectedmeasuringequipmentleftout

onproductionlineinidleordefectiveconditionalong

withtheidentificationstickers

a:Storedinsecurelocationwithidentificationsticker

b:Neglectedonproductionlinebutidentification

stickerattached

c:Neglectedonproductionlineandnoidentification

stickerattached

A(1),B(0.5),C(0)

(SQCI)

-Checkifthecalibrationreportisbeingmaintained

withoutlossorimpairmentandvisitthesitetoseethe

calibrationlabelsoneachequipmentandverifyits

validity.Alsocheckthelabelsareattachedonall

measuringequipment

a:Allcalibrationstickersarevalidandattachedtoall

equipment

b:1issuedetected

c:2ormoreissuesdetected

A(1),B(0.5),C(0)

(SQCI)

-Obtainmeasuringequipmentlistforselfinspection

andchecktheinspectionresult

a:Onscheduleinspectioncarriedoutbasedonthe

list

b:Inspectioncarriedoutbutnolist

c:Noselfinspectioncarriedout

A(0.6),B(0.3),C(0)

3.Maintenance

of Measuring

Equipments (5)

Maintenanceof

Calibrationreportand

Calibrationlabel

Assessment guideline

3.2 Self Inspection(1)

21 5

Page 6 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

Distribu

result

tion

marks

score

N/A

3.2 Self Inspection(1)

Selfinspec onresulton

Equipment

Cleannesson

4.1 Management on

productionsiteand

Production site(1)

Equipmentsurrounding

Standardsfor

PreventiveMaintenance

ofEquipments

0.4

a b c

Assessment guideline

Point per Mark

(SQCI)

-Select2measuringequipmentsfromthesiteand

checktheselfinspectionresultisattachedtothe

equipment

a:Inspectionresultfoundonbothequipment

b:Inspectionresultfoundononeequipment

c:Noresultattached

A(0.4),B(0.2),C(0)

-Visittheproductionsiteandcheckthefollowing

conditions

Cleannessofproductionsiteandequipment

surrounding(anyleakageorfallenparts)

Designatedlocationoftools

Tidyarrangement

a:Fulfils3conditions

b:Fulfils2conditions

c:Fulfils1condition

A(1),B(0.5),C(0)

(SQCI)

-Select2mainequipmentandcheckifthe

maintenancestandardsonthefollowingitemsareset

up(maintenanceperiod,decisioncriteriaandrepair

request)

a:Standardsaresetupforbothequipments

b:standardissetupforoneequipment

c:Nostandardssetup

A(2),B(1),C(0)

4.2 Equipment

21 6

Page 7 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

Distribu

result

tion

marks

score

N/A

a b c

4.2 Equipment

Management(6)

Managementof

equipmentmaintenance

planandimplementation

On meno ca on

uponallmaterialchange

pointandarchivingofall

customerfeedbackon

eachcase

Point per Mark

(SQCI)

-Checkifthemaintenanceplan(yearly,monthly,etc)

is

implementedandperformedaccordingtothe

Maintenancestandardsbysampling

a:Maintenanceplanperformedinaccordancewith

thestandards

b:Irregularmaintenanceperformedwithoutplan

c:Nomaintenanceperformed

A(4),B(2),C(0)

(SQCI)

-Checkmanagementstatusofarchivedreportsand

feedbacksoneachmaterialchangepointcase

a:Allchangepointhistoryisarchivedalongwithits

feedback

b:Allchnagepointhistoryisarchivedwithout

feedback

c:Nodataarchived

Ifnohistoryofmaterialchangepoint,it's

consideredasnomanagementofmaterialchnage

point(PleaseselectC)

A(4),B(2),C(0)

(SQCI)

-Obtainshippinginspectionresultsheetandselect2

itemswhichisnotifiedthechangepointand

checkthemarkof'TheInitialProductofChangePoint'

a:2itemsaremarked

b:1itemismarked

c:Nil

A(2),B(1),C(0)

4.3 Management of

Material change

point(6)

Checkif'TheIni al

ProductofChangePoint'

ismarkedonshipping

inspectionresultsheet

wheninspectioninitial

product(change/new)

Assessment guideline

21 7

Page 8 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

Establishmentof

Manufacturingprocess

andoperationmanual

priortomassproduction

anditsapplicationon

massproduction

Managementofhistory

onrevisionorrenewalof

operationmanualandits

legitimateapprovalstatus

Distribu

result

tion

marks

score

Assessment guideline

Point per Mark

(SQCI)

-Select2samplesandcomparetheproductiondateof

firstLotwiththedateofmanufacturingprocessand

operationmanual

a:Bothsamplesfulfiltherequirement

b:1samplefulfiltherequirement

c:Bothsamplesfailedtherequirement

A(2),B(1),C(0)

(SQCI)

-Select2sampleswiththerevisionhistoryonits

operationmanualandchecktheapprovalstatuson

eachrevision

a:Bothsamplesfulfiltherequirement

b:1samplefulfiltherequirement

c:Bothsamplesfailedtherequirement

A(3),B(1.5),C(0)

(SQCI)

-Obtaininspectionreportoncomplianceofoperation

manualandcheckitsvalidity

a:Regularinspectionandreportmorethan1/month

b:Regularinspectionandreportlessthan1/month

c:Noregularinspectionconducted

A(3),B(1.5),C(0)

(SQCI)

-Select2sampleswithissuedduringinspectionand

checktheimprovementplanhasbeenimplemented

a:Improvementplansetuponbothsamples

b:Improvementplansetupon1sample

c:Noimprovementplanhasbeensetup

Ifthere'snoregularinspection,selectC

A(1),B(0.5),C(0)

N/A

a b c

4.4 Compliance of

Operation

Standards(9)

Regularstatusreporton

complianceofoperation

manual(morethan

1/month)

Improvementplanson

issuesdetectedduring

inspection

21 8

Page 9 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

4.Process

Control (40)

Description

Establishmentof

standardsforprocess

inspection(inspection

period,process,number,

criteriaofdecision,etc..)

Distribu

result

tion

marks

score

N/A

a b c

Dailycollec on/analysis

ondefectsbydesignated

personnel

1.5

Point per Mark

(SQCI)

-Checkthefollowingcriteriaonprocessinspection

(includingCTQ)

Inspectionitems

Inspectionperiod

Inspectionqty

Inspector

Cleardefinitionofcriteriaon

a:Allcriteriafulfilstherequirement

b:4criteriafulfilstherequirement

c:3orlesscriteriafulfilstherequirement

A(1),B(0.5),C(0)

(SQCI)

-Select2samplesfromcompletedprocessinspection

reportsandchecktherequiredcriteriasmeetthe

requirement

a:Bothsamplesfulfiltherequirement

b:1samplefulfiltherequirement

c:Nil

A(1.5),B(0.75),C(0)

(SQCI)

-Checkthecollectionboxandstatusofdefectsand

select2productionlineandreviewthereportson

defectsanalysis

a:Bothproductionlinemanagedthereportson

defectsanalysis

b:1productionlinemanagedthereportsondefects

analysis

c:Nil

A(2),B(1),C(0)

4.5 Implementation

of Process

Inspection(2.5)

PerformanceofProcess

Inspectioninaccordance

withtheStandards

Assessment guideline

21 9

Page 10 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

Weekly/monthly

analysisreportson

defectsrate

4.6 Defects

Control(5.5)

Improvementplanon

worstdefectscases

Checkifdefectsisinput

tothepreviousprocessof

inspectionprocessafter

repairing

Checkifinputslotfor

repairedproductis

marked

Distribu

result

tion

0.5

marks

score

N/A

a b c

Assessment guideline

Point per Mark

(SQCI)

-Select2productionlineandobtaintheirreportson

defectsanalysisandcheckthereports

a:Bothproductionlinereportedfordefectsanalysis

b:1productionlinereportedfordefectsanalysis

c:Nil

A(1),B(0.5),C(0)

(SQCI)

-Select2samplesofworstdefectscasesandcheckthe

improvementplanisinpractice

a:Improvementplanisinpracticeonbothsamples

b:Improvementplanisinpracticeon1sample

c:Nil

A(1),B(0.5),C(0)

(SQCI)

-Select2productionlineandchecktheRepaired

productsisinputtothepreviousprocessofinspection

process

a:Bothproductionlinefulfiltherequirement

b:1productionlinefulfiltherequirement

c:Nil

Ifnorepairprocess,selectN/A

A(1),B(0.5),C(0),N/A

(SQCI)

-Select2productionlinesandchecktheindicationof

inputslotforrepairedparts

a:Bothlinehaveclearindicationforrepairedparts

b:1productionlinehasanindicationforrepaired

partsc:Nil

Ifnorepairprocess,selectN/A

A(0.5),B(0.25),C(0),N/A

21 10

Page 11 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

Periodicinspec onon

CTQprocess(morethan

3/day)

4.7 SPC

management(2)

Checkifdailytrendis

beingmanagedbydaily

Cpkmeasurement

Checkifitscauseis

analyzedand

countermeasureistaken

whentheCp/Cpkvalue

exceedsthemanagement

spec

4.8 Defects rate on InternalDefectsrate

Process(8)

management

Distribu

result

tion

0.5

0.5

marks

score

N/A

a b c

Assessment guideline

Point per Mark

(SQCI)

-VisittheCTQprocesslineandchecktheperiodic

inspectiononCTQprocess

a:morethan3/day

b:2/day

c:1/dayorless

A(1),B(0.5),C(0)

(SQCI)

-ReviewCpkmeasurementreportandcheckdaily

analysis

a:Dailymanagement

c:Nodailymanagement

A(0.5),C(0)

(SQCI)

-Select2samples(spec-out)andchecktheanalysisand

actiontakenoneachcase

a:Bothsamplesshowsanalysisandrequiredaction

taken

b:1sampleshowsanalysisandrequiredactiontaken

c:Noactiontaken

A(0.5),B(0.25),C(0)

-Target20%improvementondefectsrateofthe

productssuppliedtomainbuyers

Exceed100%oftarget(8)

Exceed80%oftarget(5)

Exceed70%oftarget(2)

Achievelessthan70%oftarget(0)

Exceed100%oftarget

(8)

Exceed80%oftarget(5)

Exceed70%oftarget(2)

Achievelessthan70%of

target(0)

21 11

Page 12 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

Historymanagementon

renewalorrevisionof

ShippingInspection

Standards

Dataconformityon

Approvals,Inspection

StandardsandShipping

InspectionResultReport

Distribu

result

tion

marks

score

N/A

a b c

Point per Mark

(SQCI)

-Obtainhistoryofrenewedorrevisedshipping

inspection

standardsandchecktheapprovalstatusoneachcase

a:Approvalcompletedpriortoitsrenewal/revision

b:Renewal/revisionhistoryismanagedbutwiththe

necessaryprocessisbreached

c:Nohistorymanagementfound

A(1),B(0.5),C(0)

(SQCI)

-Select2samplesonmassproductionandcompare

thedataoncustomerapproval,shippinginspection

standardsandshipping

inspectionresultreport

a:Alldataareconsistentonalldocument

c:Inconsistentdatafound

A(2),C(0)

(SQCI)

-Select2samplesfromdefectsLotandcheckif

improvementrequestisissuedandtheimprovement

planisreceived

a:Improvementrequestandplanreceivedonboth

samples

b:Improvementrequestandplanreceivedon1

sample

c:Nil

Ifthere'snodefectslot,selectN/A

A(1),B(0.5),C(0),N/A

5.1 Status of

Shipping

Inspection(5)

Awri enrequestfor

improvementand

preparationofthe

improvementplanfor

defectsLOT

Assessment guideline

21 12

Page 13 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

Periodiccollec onand

analysisonShipping

IspectionResult

(weekly/monthly)

Establishmentof

environmentalcontrol

standardsontemperature

andhumidityat

warehouse

5.Shipping

inspection (7)

5.2 Warehouse

Management(1)

Controlondirect

sunlightanddustinflow

atwarehouse

Distribu

result

tion

0.3

0.3

marks

score

N/A

a b c

Assessment guideline

Point per Mark

(SQCI)

-Obtaintheshippinginspectionresultreportand

checkifthestatusofperiodicanalysisandreportis

performed

a:Periodicanalysisandreportisperformed

b:Non-periodicanalysisandreportisperformed

c:Noanalysisandreportisperformed

A(1),B(0.5),C(0)

(SQCI)

-Visitthewarehouseandcheckthefollowing

conditions

Cleanness

Controlstandardsontemperature/humidity

Monitoringifthestandardsareinpractice

a:Fulfilsall3conditions

b:Fulfils2conditions

c:Fulfils1orlesscondition

A(0.3),B(0.15),C(0)

(SQCI)

-Checkthefollowingconditions

ifdirectsunlightisblocked

notraceofdustonproduct

a:Fulfilsbothconditions

b:Fulfils1condition

c:Nil

A(0.3),B(0.15),C(0)

21 13

Page 14 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

StatusofWarehouse

Storagesystem

(Overloading/Mixed

Loading/Reversed

Loading)

Implementa onofFIFO

(FirstinFirstOut)per

eachLot

Distribu

result

tion

0.4

0.5

marks

score

N/A

a b c

0.5

Point per Mark

(SQCI)

-Visitthewarehouseandcheckthefollowing

conditions

Overloading

MixedLoading

ReversedLoading

BoxDamage

a:Noissuesfound

b:1issuefound

c:2ormoreissuesfound

A(0.4),B(0.2),C(0)

(SQCI)

-Select2samplesandchecktheloadingstatusfor

FIFO(basedontheproductiondate)

a:FIFOimplementedonbothproducts

b:FIFOimplementedon1product

c:Nil

IfthereismixedloadofvariousLotsandifnewLot

isstackedontopofoldLot,

consideritasfailedimplementionofFIFO

A(0.5),B(0.25),C(0)

-Obtaintheinbound/outboundcontrolreportand

checkthefollowingconditions

Inbound/OutboundControlstatus

Inventorymanagementstatus

a:Managementonbothconditions

b:Managementon1condition

c:Nomanagementisconducted

A(0.5),B(0.25),C(0)

5.3

Inbound/Outbound

Control(1)

Managementof

InventoryLeveland

OutboundControl

Assessment guideline

21 14

Page 15 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

6.1 Control of

Customer

complaints(4)

Description

Liaisonwithrelevant

departmentwithinD+1

fromthereceiptof

customercomplaints

(Sales/Quality)

Improvementplansset

uponalllistedcustomer

complaints

Modica onof

standardstoprevent

recurrentcustomer

complaints

6. Customer

complaints

Management (6)

6.2 Post

management of

Customer

complaints(2)

Monitorandrecordof

theprogress

Improvementplanson

customercomplaints

Managementof

complaintshistoryper

customer

Distribu

result

tion

0.4

0.6

marks

score

Assessment guideline

Point per Mark

(SQCI)

-Select2customercomplaintsandcheckthehandling

historyandprocess

a:BothsampleswereliaisedwithinD+1

b:1samplewasliaisedwithinD+1

c:Nil

A(2),B(1),C(0)

(SQCI)

-Select2randomsamplesandcheckimprovement

plan

a:Bothsampleshaveimprovementplan

b:1samplehasimprovementplan

c:Nil

A(2),B(1),C(0)

(SQCI)

-Select2sampleswithimprovementplansand

checktheplanhasbeenreflectedonthestandards

a:Bothsampleswerereflectedonthestandards

b:1samplewasreflectedonthestandards

c:Nil

A(0.4),B(0.2),C(0)

(SQCI)

-Select2sampleswithimprovementplansandcheck

theimplementionofplanwasproperlymonitored

a:Bothsamplesweremonitored

b:onesamplewasmonitored

c:Nil

A(1),B(0.5),C(0)

(SQCI)

-Checkthecustomercomplaintsmanagement

data(managementperproductisalsovalid)

a:Datamanagementpercustomer(product)

c:Nomanagementhistory

A(0.6),C(0)

N/A

a b c

21 15

Page 16 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

Cleardeni onofIT

department'srole

7.1 ERP

Management(3)

Standardiza onof

Materialcode

AdequateProduc on

PlanManagement

Distribu

result

tion

0.5

1.5

marks

score

N/A

a b c

0.8

Point per Mark

-CheckthestatusofITDepartmentandtheman

powertomaintainEPRsystem

a:BothITdepartmentandafulltimemanpower

b:Hiresub-contractedITservice

c:NospecificITdepartmentwithintheorganization

Ifsub-contractedserviceismorethan8hr/week,

itcanbeconsideredasfulltimemanpower

A(0.5),B(0.25),C(0)

-Checkifmaterialcodeassignmentprocedureis

standardizedandcheckifdiscontinuedmaterialsor

repairmaterialsaremanagedbythesystemaccording

tothecompany'sERP.

a:Standardizedmaterialcodesystemexist

b:ERPimplementedbutnostandardisedmaterial

codesystem

c:ERPnotimplemented

A(1),B(0.5),C(0)

-CheckthestatusofactualproductionplanontheERP

systemontheweekofaudit

a:ProductionplanismanagedbyERPsystem

b:ERPimplementedbutproductionplanisnot

managedbyERP

c:ERPnotimplemented

A(1.5),B(0.75),C(0)

-CheckifPOisissuedinconjunctionwiththeir

productionplansusingMRP(MaterialRequirement

Plan)byreviewingthePOhistoryonERPsystem

a:POmanagementviaERP

b:ERPimplementedbutnotusedforPO

management

c:ERPnotimplemented

A(0.8),B(0.4),C(0)

7.ERP system (6)

AdequatePO

management

Assessment guideline

21 16

Page 17 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

7.2 Application of

ERP(3)

Description

Ecientmanagement

onmonthendprocess

Seamlesscoordina on

betweenLogisticsand

FinanceonERPsystem

Supplierregistra onin

compliancewiththe

vendorselectionprocess

Distribu

result

tion

0.8

1.4

0.3

marks

score

N/A

a b c

0.5

Point per Mark

-Checkifpreviousmonth'smonth-endclosingwas

performedbasedoneachdivision'smonth-endclosing

planreflectedonERPsystem

a:Month-endprocessviaERPsystem

b:ERPimplementedbutnotusedformonth-end

closing

c:ERPnotimplemented

A(0.8),B(0.4),C(0)

-CheckifmodulesforLogisticsandFinanceare

established

inconjunctionwitheachotherontheirERPsystem.

a:BothmodulesarelinkedonERPsystem

b:EachmoduleisrunonERPsystemseparately

c:ERPnotimplemented

A(1.4),B(0.7),C(0)

(SQCI)

-Checkthevendorselectionprocessandselect2new

suppliersandseeiftheselectionwasincompliance

withtheprocess

A(0.3),B(0.15),C(0),N/A

a:Bothnewsuppliers'selectionfulfilsthecondition

b:1supplierselectionfulfilsthecondition

c:Nil

Ifthere'snonewsupplierforpast1year,SelectN/A

(SQCI)

-Select2newsuppliersandchecktheauditreportif

QAtookpartintheaudit

A(0.5),B(0.25),C(0),N/A

a:QAattendedforbothaudits

b:QAattendedforoneaudit

c:Nil

Ifthere'snonewsupplierforpast1year,SelectN/A

8.1 Supplier

Registration(0.8)

Newsupplier

RegistrationAuditby

QualityTeam

Assessment guideline

21 17

Page 18 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

PeriodicalSupplier

Auditinaccordancewith

thepre-setauditplan

Distribu

result

tion

marks

score

N/A

a b c

Improvementplansand

postmanagementon

identifiedissuesfrom

Audits

Managementprocess

setuponMaterialchange

pointnotification

0.2

Point per Mark

(SQCI)

-Obtainthisyearsauditplanand

checkiftheauditisconductedinaccordancewiththe

plan

a:Auditcarriedout100%inaccordancewiththeplan

b:Auditplanissetbutsomeauditwerenotcarried

out

c:Nopre-setperiodicalauditplan

A(1),B(0.5),C(0)

(SQCI)

-Obtainauditreportson2suppliersandcheckifthe

improvementplanhasbeensubmitted

a:Bothsupplierssubmittedtheimprovementplan

b:1suppliersubmittedtheimprovementplan

c:Noimprovementplanhasbeensubmitted

A(0.2),B(0.1),C(0)

(SQCI)

-Checkifthere'sprocessonmaterialchangepointand

verifytheactualchangepointnotificationfromtheir

2ndvendorisinaccordancewiththeprocess

a:Processissetupandmanagedunderadequate

process

b:Processissetupbutnotalwaysmanagedunder

process

c:Noprocessissetup

A(1),B(0.5),C(0)

8.2 Periodical

Supplier Audit(1.2)

8.Supplier

management

(4.5)

Assessment guideline

21 18

Page 19 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

8.3 Management of

Material change

On mefeedbackon

point(2.5)

Materialchangepoint

notification

Incominginspec on

resulton'TheInitial

ProductofChangePoint'

ofthe2ndVendor

CEO'sposi vea tude

towardsnewtechnology

development

9.1 Capability of

Advanced

Development(8.5)

9.Technology

standard (12.5)

Earlylaunchofnew

productspriortotheir

competitors

Distribu

result

tion

0.5

3.5

2.5

marks

score

N/A

a b c

Assessment guideline

Point per Mark

(SQCI)

-Select2samplesofmaterialchangepoint

notification(2ndvendor's)

andcheckifthefeedbackwasgivenwithinthe

deadline

a:Feedbackforbothsamplesweregivenontime

b:Feedbackforonesamplewasgivenontime

c:Nofeedbackwasgiven

(SQCI)

-Select2sampleswithmaterialchangepoint

notificationandchecktheresultofincominginspection

A(1),B(0.5),C(0)

on'TheInitialProductofChangePoint'

a:Inspectionwasconductedonbothsamples

b:Inspectionwasconductedon1sample

c:Noinspectionwasconducted

-ReviewtheinvestmentplanandstrategyonR&D

scope

andnewtechnologydevelopment.

Thencompletetheassessmentwiththeinterview

withCEO

a:Superiorlevelwithinthesameindustry

b:Averagelevelwithinthesameindustry

c:Insufficientlevelwithinthesameindustry

A(3.5),B(1.75),C(0)

-Checkthesuppliers'newproductdevelopmentdata

a:Superiorlevelwithinthesameindustry

b:Averagelevelwithinthesameindustry

c:Insufficientlevelwithinthesameindustry

A(2.5),B(1.25),C(0)

21 19

A(0.5),B(0.25),C(0)

Page 20 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Description

Regularprovisionof

Roadmaptoenhance

buyer'scapabilityandthe

company'simprovement

operationsfor

competitiveadvantage

9.2 Secured Patent(4)

NumberofTechnical

Certification

Distribu

result

tion

2.5

subtotal

Additional point (only supplier of HQ)

Supplier with AEO AEOcer ca on

(domestic/overseas)

certification

100

marks

score

N/A

a b c

Assessment guideline

Point per Mark

-Checkthesupplier'scompanyroadmapisprovided

andithelpsitsemployees

a:Superiorlevelwithinthesameindustry

b:Averagelevelwithinthesameindustry

c:Insufficientlevelwithinthesameindustry

A(2.5),B(1.25),C(0)

-Checkthenumberofpatent,technologicalawards,or

officialcertifications.

a:morethan3patents

b:morethan1patent

c:Nopatent

A(4),B(2),C(0)

-1additionalpointforAEOcertificatedimport/export

supplier

AEOequivalentcertification

-US:C-TPAT,EU:AEO,JAPAN:AEO,SpecificExport

declaration

China:AAgradedcompany,Singapore:STP,

Canada:PIP

Sweden:StairSEC,NewZealand:SES(onlyifthe

certificationacquired)

A(1),C(O)

21 20

Page 21 of 21

. Check list for New Company Registration

Whenyouselectthe"result",thescorewillbecalculatedautomatically

Category

Check list

Supplier without

AEO certification

(Incoming

inspection)

AEO

certification(1)

Description

Conrma on,

inspection,solutionfor

shortage,surplusor

damageofgoodatthe

timeoftakingoverthe

goods

Supplier without

Accesscontrolfor

AEO certification

unauthorisedgoodsand

(Warehouse

persons

Management)

Maintenancefor

Containersandtrailers

sealing

Supplier without

AEO certification

(Outbound Control) Driver'siden ty

Procedures

maintenanceofshipment,

loading,supplyofgoods

Distribu

result

tion

0.2

0.2

0.2

0.2

0.2

marks

score

N/A

a b c

Assessment guideline

Point per Mark

-Checktheshortage,surplus,damageand

unauthorisedgoodsentry,ifanyunusualdetected,

checkifthecausehasbeeninvestedandappropriate

actionsaretaken

a:possessionofmeansofdetectionandsolution

procedures

c:noproceduresinpossession

Especiallyforbondedcargoes,procedurestoreport

tocustomofficefordocumentunmatched,illegal

cases

A(0.2),C(O)

-Checkinpersonandresponsiveactionsforaccess

control(i.eCCTV,securityguard,alarm,lock,PIC,

visitorreport,etc)

a:Accesscontrolsysteminoperation

c:Noaccesscontrol

A(0.2),C(O)

-Checkthestatusofaccesscontrolforunauthorised

personsandcontainersealwhenusingcontainers

a:controlsysteminoperation

c:nocontrolinoperation

Ifthesupplierdoesnotloadandsealthemselves,

SelectN/A

A(0.2),C(O),N/A

-Checkifthedriver'sIDischeckedwhendispatching

a:CheckandmaintaintheIDdetail

c:Nocheckormaintenance

A(0.2),C(O)

-Trackthegoodsroute,deliverystatusafter

dispatching(UseofGPS,etc)

a:Trackingsysteminoperation

c:Notrackingsystem

A(0.2),C(O)

21 21

Вам также может понравиться

- Above and Beyond: Guidelines To An Aerospace Quality Management SystemДокумент12 страницAbove and Beyond: Guidelines To An Aerospace Quality Management SystemEduardo Ramirez LasoОценок пока нет

- Guide To Implement AS9100 Rev. C by Ashish Jude MichaelДокумент20 страницGuide To Implement AS9100 Rev. C by Ashish Jude Michaelsam2388Оценок пока нет

- JIS H4100-2006 - Aluminium and Aluminium Alloy Extruded ShapeДокумент36 страницJIS H4100-2006 - Aluminium and Aluminium Alloy Extruded ShapeTuyen NguyenОценок пока нет

- Reasons of Keeping Business RecordsДокумент50 страницReasons of Keeping Business RecordsJhianne EstacojaОценок пока нет

- ISO 9001 and ISO 9004 WorkshopДокумент90 страницISO 9001 and ISO 9004 Workshopvfcerezo67% (3)

- Ch. 5 Finance Function Transformation - KPIs and ReportingДокумент26 страницCh. 5 Finance Function Transformation - KPIs and ReportingTrang NgoОценок пока нет

- Iso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailОт EverandIso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailРейтинг: 5 из 5 звезд5/5 (3)

- NQA Business Profile 2019Документ38 страницNQA Business Profile 2019denny simamoraОценок пока нет

- Module - 5 TQM (Mgmcet) FinalДокумент31 страницаModule - 5 TQM (Mgmcet) FinalSiddharth PatilОценок пока нет

- Iso 9001 Checklist For Audit PreperationsДокумент3 страницыIso 9001 Checklist For Audit Preperationskarthi keyanОценок пока нет

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1От EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Рейтинг: 4.5 из 5 звезд4.5/5 (2)

- The AS9100C, AS9110, and AS9120 Handbook: Understanding Aviation, Space, and Defense Best PracticesОт EverandThe AS9100C, AS9110, and AS9120 Handbook: Understanding Aviation, Space, and Defense Best PracticesОценок пока нет

- Quality Dictionary - Terms and Definitions Common To ISO and SAE Standards As Found in AS9100-related Audit Processes and Procedures.Документ23 страницыQuality Dictionary - Terms and Definitions Common To ISO and SAE Standards As Found in AS9100-related Audit Processes and Procedures.granburyjohnstevensОценок пока нет

- Two Days Short Course ON ISO 9001:2000: Quality Management System 24-25 May, 2008Документ152 страницыTwo Days Short Course ON ISO 9001:2000: Quality Management System 24-25 May, 2008Ahmed Jahanzab Chouhan0% (1)

- 5 - ERP MarketДокумент105 страниц5 - ERP Marketsakthy82Оценок пока нет

- #7 QC Tools-A) Check Sheet, Pareto Diagram, Stratification, Cause and Effect Diagram, Histogram, Scatter Diagram, Control ChartsДокумент8 страниц#7 QC Tools-A) Check Sheet, Pareto Diagram, Stratification, Cause and Effect Diagram, Histogram, Scatter Diagram, Control Chartsvamsi262Оценок пока нет

- 2016 ISO 9001 External Audit ReportДокумент19 страниц2016 ISO 9001 External Audit ReportMinh Vuong Tran100% (1)

- TC 132 - en 12258-3-2003Документ30 страницTC 132 - en 12258-3-2003Tuyen NguyenОценок пока нет

- Purpose: 2. Inclusions in This Document:: Master Inspection Characteristics (MIC)Документ20 страницPurpose: 2. Inclusions in This Document:: Master Inspection Characteristics (MIC)nikku115Оценок пока нет

- Intermediate Accounting 1: Following? A. PAS 1 B. PAS 2 C. Pas 7 D. PAS 8Документ20 страницIntermediate Accounting 1: Following? A. PAS 1 B. PAS 2 C. Pas 7 D. PAS 8Ginoong OsoОценок пока нет

- EFQM Framework For Corporate Data Quality ManagementДокумент40 страницEFQM Framework For Corporate Data Quality Managementrambo7799100% (1)

- ProQC ExampleReport TS16949 Audit PDFДокумент39 страницProQC ExampleReport TS16949 Audit PDFpandajayОценок пока нет

- Sap Calibration ProcessДокумент20 страницSap Calibration Processsachin100% (2)

- 01 Supplier Pre-Qualification AssessmentДокумент18 страниц01 Supplier Pre-Qualification AssessmentChinh Lê Đình100% (1)

- Sources of Supply Chain Disruptions, PDFДокумент38 страницSources of Supply Chain Disruptions, PDFUmang SoniОценок пока нет

- ISO 9001-2015 Transition Checklist C 01 Rev AДокумент4 страницыISO 9001-2015 Transition Checklist C 01 Rev Avikkasverma.in100% (1)

- Iso/ts 16949:2002Документ46 страницIso/ts 16949:2002Edgar Castillo MedinaОценок пока нет

- Iso 9000 SeriesДокумент10 страницIso 9000 SeriesMahendar Sd100% (1)

- Analyzing Primark Financial Performance Using Financial Ratios Models CaseДокумент14 страницAnalyzing Primark Financial Performance Using Financial Ratios Models CaseSamОценок пока нет

- ISO 9000 Solutions, Inc.: Free Download - 2000Документ11 страницISO 9000 Solutions, Inc.: Free Download - 2000tlidiaОценок пока нет

- Supplier QMS Survey and Audit ExampleДокумент7 страницSupplier QMS Survey and Audit ExampleHaleem Ur Rashid BangashОценок пока нет

- Guide To Quality Costs ASQДокумент50 страницGuide To Quality Costs ASQEdgar Omar PalaciosОценок пока нет

- Alloy and Temper DesignationДокумент14 страницAlloy and Temper DesignationKrishna KishoreОценок пока нет

- 01 Alison 9001Документ34 страницы01 Alison 9001Thant AungОценок пока нет

- Ibm Maximo Key ConceptsДокумент63 страницыIbm Maximo Key ConceptsRangith RamalingamОценок пока нет

- Boeing Quality Management SystemДокумент10 страницBoeing Quality Management Systemselinasimpson1801100% (1)

- Iso TS 16949Документ35 страницIso TS 16949dyogasara2Оценок пока нет

- Status of ISO 9000 Family of StandardsДокумент4 страницыStatus of ISO 9000 Family of StandardsRajan SteeveОценок пока нет

- Tqm-I - 09 - Iso 9000Документ15 страницTqm-I - 09 - Iso 9000Saransh GoelОценок пока нет

- ISO 9001 Overview Section 1Документ20 страницISO 9001 Overview Section 1Mahesan100% (1)

- ISO 9000 Awareness Presentation 8-27-15Документ19 страницISO 9000 Awareness Presentation 8-27-15mahinda100% (1)

- Quality Management: Prof. S K ChakrabortyДокумент25 страницQuality Management: Prof. S K ChakrabortyRik DharОценок пока нет

- Opito Oco DiagramДокумент21 страницаOpito Oco DiagramwinhlaingooОценок пока нет

- Like This Article?Документ3 страницыLike This Article?UnknownОценок пока нет

- MSC Automotive BrochureДокумент12 страницMSC Automotive BrochureFabiano SanninoОценок пока нет

- ISO 9001 Presentation - IntroductionДокумент11 страницISO 9001 Presentation - IntroductionAmmar11111Оценок пока нет

- VlovbdДокумент5 страницVlovbdramasamy838Оценок пока нет

- Kongu Engineering College, Perundurai Erode - 638 060 Continuous Assessment Test 3 Answer Key 14get71 - Total Quality ManagementДокумент5 страницKongu Engineering College, Perundurai Erode - 638 060 Continuous Assessment Test 3 Answer Key 14get71 - Total Quality ManagementJanОценок пока нет

- 02 Alison 9001Документ17 страниц02 Alison 9001Thant AungОценок пока нет

- ISO/IAF Auditing Practices Group PapersДокумент2 страницыISO/IAF Auditing Practices Group Paperscock_cowОценок пока нет

- RoadMap ISO9001Документ5 страницRoadMap ISO9001rivelino70Оценок пока нет

- Scope of QMS in ISO 9001Документ3 страницыScope of QMS in ISO 9001antiantiiОценок пока нет

- Quality Certification: Click To Edit Master Subtitle StyleДокумент31 страницаQuality Certification: Click To Edit Master Subtitle StyleRaj DangeОценок пока нет

- 0.0 Start Here-Instruction To Delegates-Oct 2015Документ2 страницы0.0 Start Here-Instruction To Delegates-Oct 2015Khaleel RehmanОценок пока нет

- Quality AssuranceДокумент1 страницаQuality Assurance872292014Оценок пока нет

- IATF 16949:2016: Quality Management Systems DocumentationДокумент10 страницIATF 16949:2016: Quality Management Systems DocumentationKhaoula RezzoukОценок пока нет

- IATF 16949:2016: Quality Management Systems DocumentationДокумент28 страницIATF 16949:2016: Quality Management Systems DocumentationMariyappanОценок пока нет

- Lista Standarda QM Sa Internet Prezentacije ISO - 2011-08-19Документ2 страницыLista Standarda QM Sa Internet Prezentacije ISO - 2011-08-19vladuljevОценок пока нет

- CL 27 01 011e Vda6 2Документ40 страницCL 27 01 011e Vda6 2fmfs60Оценок пока нет

- EUR-SCM-AE-0002 Nemak QuestionnaireДокумент12 страницEUR-SCM-AE-0002 Nemak Questionnaireesivaks2000Оценок пока нет

- Summary of Saatca Requirements For Auditor RegistrationДокумент28 страницSummary of Saatca Requirements For Auditor RegistrationJoaquin Garcia GarciaОценок пока нет

- QMS FormДокумент4 страницыQMS FormsarvaОценок пока нет

- ISO 9001:2008 Certification: A Step Up To Higher QualityДокумент2 страницыISO 9001:2008 Certification: A Step Up To Higher QualityTanzeel LiaqatОценок пока нет

- Quality SystemsДокумент31 страницаQuality SystemsfriendОценок пока нет

- CSA Group DivisionsdДокумент4 страницыCSA Group Divisionsdsam1hi5Оценок пока нет

- Audit Evidence Improvement Score Audit QuestionДокумент1 страницаAudit Evidence Improvement Score Audit QuestionHaleem Ur Rashid BangashОценок пока нет

- Process Effectiveness Assessment Report (PEAR) : Derived From SAE AS9101 Rev DДокумент1 страницаProcess Effectiveness Assessment Report (PEAR) : Derived From SAE AS9101 Rev DKenton CharlesОценок пока нет

- Quality Management AssociationДокумент9 страницQuality Management Associationselinasimpson2901100% (1)

- Codification of Statements on Standards for Attestation Engagements, January 2018От EverandCodification of Statements on Standards for Attestation Engagements, January 2018Оценок пока нет

- TC 132 - en 1592-3-1998Документ10 страницTC 132 - en 1592-3-1998Tuyen NguyenОценок пока нет

- TC 132 - en 14121-2009Документ12 страницTC 132 - en 14121-2009Tuyen NguyenОценок пока нет

- TC 132 - en 1592-4-1998Документ10 страницTC 132 - en 1592-4-1998Tuyen NguyenОценок пока нет

- TC 132 - en 1396-1997Документ22 страницыTC 132 - en 1396-1997Tuyen NguyenОценок пока нет

- Removal MagnesiumДокумент2 страницыRemoval MagnesiumEduardo LopesОценок пока нет

- TC 132 - en 12258-2-2004Документ42 страницыTC 132 - en 12258-2-2004Tuyen NguyenОценок пока нет

- Launder ModelДокумент1 страницаLaunder ModelTuyen NguyenОценок пока нет

- Extract Pages From ASTM B209M - Aluminum Plate & SheetДокумент1 страницаExtract Pages From ASTM B209M - Aluminum Plate & SheetTuyen NguyenОценок пока нет

- Packing Type 1 (11 Layer) PDFДокумент1 страницаPacking Type 1 (11 Layer) PDFTuyen NguyenОценок пока нет

- Packing Type 1 (11 Layer)Документ2 страницыPacking Type 1 (11 Layer)Tuyen NguyenОценок пока нет

- 58497-175704 AluminumdoortechmanualabДокумент35 страниц58497-175704 AluminumdoortechmanualabTuyen NguyenОценок пока нет

- Elidron 201Документ2 страницыElidron 201Tuyen NguyenОценок пока нет

- Micro 171 PDFДокумент8 страницMicro 171 PDFTuyen NguyenОценок пока нет

- 352 1135 1 PBДокумент10 страниц352 1135 1 PBTuyen NguyenОценок пока нет

- Aluxal 108Документ2 страницыAluxal 108Tuyen Nguyen100% (1)

- Aluswirler Chips en 02 10Документ2 страницыAluswirler Chips en 02 10Tuyen NguyenОценок пока нет

- Aluxal 108Документ2 страницыAluxal 108Tuyen Nguyen100% (1)

- Prolad: Molten Metal Level ControlДокумент2 страницыProlad: Molten Metal Level ControlTuyen NguyenОценок пока нет

- Ep 1980651 A2 20081015 (En) : (2006.01) (2013.01) (2013.01) Y10t 428/12 (2013.01) Y10t 428/12993 (2013.01)Документ2 страницыEp 1980651 A2 20081015 (En) : (2006.01) (2013.01) (2013.01) Y10t 428/12 (2013.01) Y10t 428/12993 (2013.01)Tuyen NguyenОценок пока нет

- Jis H2211-1999Документ8 страницJis H2211-1999Tuyen NguyenОценок пока нет

- Molten Metal Level Control: - Digital Camera SensorДокумент2 страницыMolten Metal Level Control: - Digital Camera SensorTuyen NguyenОценок пока нет

- TXP 10Документ2 страницыTXP 10Tuyen NguyenОценок пока нет

- Molten Metal Level Control: - Digital Camera SensorДокумент2 страницыMolten Metal Level Control: - Digital Camera SensorTuyen NguyenОценок пока нет

- TXP 6eДокумент2 страницыTXP 6eTuyen NguyenОценок пока нет

- TXP 2Документ2 страницыTXP 2Tuyen Nguyen0% (1)

- MFX 01Документ2 страницыMFX 01Tuyen NguyenОценок пока нет

- Molten Metal Level ControlДокумент2 страницыMolten Metal Level ControlTuyen NguyenОценок пока нет

- Capítulo 10, Chopra - Inventario de Ciclo en La Cadena de SuministroДокумент44 страницыCapítulo 10, Chopra - Inventario de Ciclo en La Cadena de SuministroBräyän MüñöszОценок пока нет

- Analysis For Financial Management 10th Edition Higgins Test BankДокумент23 страницыAnalysis For Financial Management 10th Edition Higgins Test BankEdwinMyersnayzsОценок пока нет

- Group Work - Inventory Cost Flow and LCNRVДокумент2 страницыGroup Work - Inventory Cost Flow and LCNRVKawhileonard LeonardОценок пока нет

- Practice Exam 2Документ15 страницPractice Exam 2Comennius YayoОценок пока нет

- 2019 ODT 200 Year Test 2 Solution PDFДокумент10 страниц2019 ODT 200 Year Test 2 Solution PDFHardcore GamerОценок пока нет

- IS-344 Computing Applications in Business Spring 2015 Week 6Документ103 страницыIS-344 Computing Applications in Business Spring 2015 Week 6Faded RianbowОценок пока нет

- Professional Industrial Engineering Program: Technical EnglishДокумент15 страницProfessional Industrial Engineering Program: Technical EnglishFabio fernandezОценок пока нет

- Heizer - 01 Operations and ProductivityДокумент37 страницHeizer - 01 Operations and ProductivityDawood HusainОценок пока нет

- RMA and ReturnsДокумент19 страницRMA and Returnsविजय शर्माОценок пока нет

- Cost Accounting Chapter 2 2020Документ28 страницCost Accounting Chapter 2 2020magdy kamelОценок пока нет

- Ibrahim CVДокумент2 страницыIbrahim CVdxhussain533Оценок пока нет

- Chapter 3Документ32 страницыChapter 3Abd El-Rahman El-syeoufyОценок пока нет

- 10.1 Thesis - FachiДокумент85 страниц10.1 Thesis - FachiMadalitso MukiwaОценок пока нет

- Chapter 14Документ16 страницChapter 14Kristian Romeo NapiñasОценок пока нет

- A Study On Financial Analysis of Maruthi Suzuki India Limited CompanyДокумент9 страницA Study On Financial Analysis of Maruthi Suzuki India Limited CompanyVandanaОценок пока нет

- Purchase PlanningДокумент15 страницPurchase PlanningSavindra TiwariОценок пока нет

- Budgeting Bobads PDFДокумент13 страницBudgeting Bobads PDFShaiannah Veylaine Recinto ApostolОценок пока нет

- Lesson 6Документ43 страницыLesson 6Quyen Thanh NguyenОценок пока нет

- Professional Level - Options Module, Paper P6 (MYS) Advanced Taxation (Malaysia) September/December 2016 Sample Answers 1Документ8 страницProfessional Level - Options Module, Paper P6 (MYS) Advanced Taxation (Malaysia) September/December 2016 Sample Answers 1kok kuan wongОценок пока нет

- Post-Hoc Demand Forecasting With Supply-Chain InformationДокумент23 страницыPost-Hoc Demand Forecasting With Supply-Chain Information张宇Оценок пока нет

- Internship Report GuideДокумент7 страницInternship Report GuideJeivi AndoloОценок пока нет