Академический Документы

Профессиональный Документы

Культура Документы

Cerro Corona Relavera

Загружено:

RDario Dario RosemaryАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cerro Corona Relavera

Загружено:

RDario Dario RosemaryАвторское право:

Доступные форматы

Prepared forr:

Gold Fields Lim

mited La Ciima S.A. (GF

FLCSA)

A

Avenida

Via Principal

P

Nm

mero 155 Intt. 1401

San Isidro,

I

Lima 27 Per

T (511) 7066-0400

Tel:

CERRO

O CORO

ONA MIN

NE

ST

TAGE 4 TMF

T

CON

NSTRUC

CTION

DES

SIGN RE

EPORT

T

DRAFT

March 20110

Prepared by:

by

MWH

1801 Caalifornia Streeet, Suite 29000

Den

nver, Colorad

do 80202

(303) 291-22222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page i

March 2010

TABLE OF CONTENTS

Section No.

1.0

1.1

1.2

1.3

1.4

2.0

2.1

2.2

2.3

2.4

3.0

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

Page No.

INTRODUCTION ......................................................................................................... 1

BACKGROUND ........................................................................................................................... 1

MWH SCOPE OF WORK ............................................................................................................. 4

EXCLUDED WORK ..................................................................................................................... 5

LIMITATIONS .............................................................................................................................. 6

DESIGN STEWARDSHIP, OBJECTIVES, CRITERIA, AND BASIS ................... 7

DESIGN STEWARDSHIP ............................................................................................................ 7

DESIGN OBJECTIVES ................................................................................................................ 8

DESIGN CRITERIA ..................................................................................................................... 9

DESIGN BASIS........................................................................................................................... 11

GENERAL SITE CHARACTERIZATION ............................................................. 12

PROJECT LOCATION AND TOPOGRAPHY .......................................................................... 12

SITE LAYOUT ............................................................................................................................ 12

WATER RECOVERY AND TAILING PRODUCTION AND TRANSPORT .......................... 13

CLIMATE .................................................................................................................................... 13

SITE HYDROLOGY ................................................................................................................... 14

GEOLOGY .................................................................................................................................. 14

SEISMICITY ............................................................................................................................... 15

HYDROGEOLOGY .................................................................................................................... 15

GEOCHEMISTRY ...................................................................................................................... 17

4.0

DESCRIPTION OF THE STAGE 4 TMF RAISE ................................................... 18

5.0

PROPOSED FUTURE TMF RAISES ....................................................................... 20

5.1

5.2

5.3

6.0

6.1

6.2

6.3

6.4

7.0

PROPOSED TMF CONSTRUCTION SCHEDULE................................................................... 20

DESCRIPTION OF FUTURE TMF RAISES ............................................................................. 21

DOWNSTREAM EFFECTS OF PROPOSED ULTIMATE DAM DESIGN ............................. 22

UPDATED MATERIAL PROPERTIES .................................................................. 24

INTRODUCTION ....................................................................................................................... 24

TAILING EVALUATION .......................................................................................................... 24

EVALUATION OF ROCKFILL STRENGTH ........................................................................... 26

ZONE 1 AND 5 HYDRAULIC PROPERTIES........................................................................... 27

ENGINEERING ANALYSES .................................................................................... 28

7.1

INTRODUCTION ....................................................................................................................... 28

7.2

SEEPAGE ANALYSIS ............................................................................................................... 28

7.2.1 Introduction ............................................................................................................................. 28

7.2.2 Geometry and Evaluated Cases ............................................................................................... 28

7.2.3 Material Properties ................................................................................................................. 29

7.2.4 Boundary Conditions ............................................................................................................... 30

7.2.5 Seepage Analysis Results ......................................................................................................... 30

7.2.6 Conclusions ............................................................................................................................. 31

7.3

STABILITY ANALYSES ........................................................................................................... 32

7.3.1 Introduction ............................................................................................................................. 32

7.3.2 General Stability Analysis ....................................................................................................... 33

7.3.3 Additional Stability Analyses ................................................................................................... 38

7.4

PRELIMINARY SEISMIC DISPLACEMENT ANALYSIS ...................................................... 41

7.5

UPSTREAM FACE REINFORCEMENT ................................................................................... 42

7.5.1 Introduction ............................................................................................................................. 42

7.5.2 Gabions.................................................................................................................................... 43

7.5.3 Geosynthetic Reinforcement .................................................................................................... 44

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

March 2010

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page ii

8.0

REVIEW OF INDUSTRY PRACTICE .................................................................... 46

9.0

CONSTRUCTION QUANTITY ESTIMATES ........................................................ 48

9.1

9.2

9.3

10.0

10.1

10.2

10.3

10.4

11.0

INTRODUCTION ....................................................................................................................... 48

ESTIMATED STAGE 4 TMF RAISE CONSTRUCTION QUANTITIES ................................ 48

ESTIMATED FUTURE TMF RAISE CONSTRUCTION QUANTITIES................................. 50

CONCEPTUAL TAILING DEPOSITION PLANS AND ESTIMATED TMF

STORAGE CAPACITIES .......................................................................................... 51

INTRODUCTION ....................................................................................................................... 51

TAILING DEPOSITION PLANS ............................................................................................... 52

LARGE STRAIN CONSOLIDATION MODELING ................................................................. 53

ESTIMATED TMF CAPACITIES .............................................................................................. 54

REFERENCES ............................................................................................................ 56

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page iii

March 2010

LIST OF TABLES

Table No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Description

Stage 4 TMF Design Criteria

Stage 4 TMF Design Basis

Summary of Proposed TMF Construction Schedule

Estimated Strength of Materials in Tailing Profile

Summary of Saturated Hydraulic Conductivities Utilized in the Seepage Analysis

Summary of Estimated Seepage Rates

TMF Stages Evaluated in the General Stability Analysis

Summary of Strength Parameters Utilized in Each Loading Condition

Summary of Earthwork Material Properties Utilized in the General Stability

Analysis

Summary of Geosynthetic Parameters Utilized in the General Stability Analysis

Summary of the Results of the General Stability Analysis

Summary of Estimated Construction Quantities Stage 4 TMF Raise

Summary of Estimated Construction Quantities Future TMF Raises

Summary of Estimated TMF Capacities

Contribution of Design Changes to Capacity Increase

LIST OF FIGURES

Figure No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Description

Site Location

Overall Site Plan Stage 4 TMF

Las Aguilas Dam Section A

Las Gordas Dam Section B

Proposed TMF Construction Schedule (Conceptual Level)

Ultimate TFM Dam Plan (Conceptual Level)

Ultimate Las Aguilas Dam Section C (Conceptual Level)

Ultimate Las Gordas Dam Section D (Conceptual Level)

Ultimate La Hierba Dam Section E (Conceptual Level)

Ultimate Dam Details (Conceptual Level)

Original and Revised Ultimate Dam Plan (Conceptual Level)

Original and Revised Ultimate Dam Sections F and G (Conceptual Level)

Comparison of Rockfill Strength Envelopes

Comparison of Estimated PGA and Downstream Slopes for Selected Dams

Comparison of Height and Downstream Slopes for Selected Dams

Estimated Post-Stage 4 Construction Quantities

Estimated Post-Stage 4 Construction Quantities Zone 2B D/S

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page iv

March 2010

LIST OF APPENDICES

Appendix

Description

A

B

C

D

E

F

G

H

I

Tailing Evaluation

Evaluation of Rockfill Strength

Seepage Analysis

Stability Analyses

Preliminary Seismic Displacement Analysis

Review of Industry Practice Rockfill Dam Downstream Slopes

Tailing Deposition Plans and Estimated TMF Capacities

SICTA Testing and Large Strain Consolidation Modeling

Construction Drawings and Specifications

CONSTRUCTION DRAWINGS AND SPECIFICATIONS

(Revision 1 Dated March 1, 2010)

Drawing No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22-23

24-25

26-29

30-32

33-34

35-39

Title

Cover Sheet and Index of Drawings

Overall Site Plan

Stage 4 TMF Dam Plan

Las Aguilas Dam Section A

Las Gordas Dam Section B

Dam Transition Zone Profile C

Dam Transition Zone Plan Views (Sheet 1 of 2)

Dam Transition Zone Plan Views (Sheet 2 of 2)

Dam Transition Zone Section D

Dam Transition Zone Section E

Dam Transition Zone Section F

Dam Transition Zone Section G

Dam Transition Zone Section H

Dam Crest Details

Las Gordas Upstream Face Reinforcement Detail

La Hierba Dam Foundation Excavation

La Hierba Dam Plan

La Hierba Dam Sections J and K

La Hierba Dam Sections L and M

La Hierba Sections N and P

Estimated Construction Quantity Summary

Specifications Section 02222 Excavation and Foundation Prep

Specifications Section 02232 Drain and Filter Material

Specifications Section 02245 Foundation Drilling and Grouting

Specifications Section 0271 Gabions

Specifications Section 02274 Geosynthetic Reinforcement

Specifications Section 02290 Earthwork

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

March 2010

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page v

LIST OF ACRONYMS

CDA

CFRD

CPT

CST

GFLCSA

EFT

FHWA

GSHAP

H:V

HDPE

ICOLD

KP

LVU

MCE

MDE

MHW

OBE

PMF

PMP

PMP

PVC

RST

SENAMHI

TMF

UCB

USACE

USFS

VST

WMC

Canadian Dam Association

Concrete Faced Rockfill Dam

Cone Penetration Test

Cleaner scavenger tailing

Gold Fields La Cima S.A.

Extra Fine Tailing

Federal Highway Administration

Global Seismic Hazard Assessment Program

Horizontal to Vertical Unit Slope Ratio

High-density polyethylene

International Commission on Large Dams

Knight Piesold

Low volume underflow

Maximum Credible Earthquake

Maximum Design Earthquake

MWH Americas, Inc.

Operating Basis Earthquake

Probable Maximum Flood

Probable Maximum Precipitation

Probable Maximum Precipitation

Polyvinyl Chloride

Rougher scavenger tailing

Servicio Nacional de Meteorologa e Hidrologa

Tailing Management Facility

Upstream Containment Blanket

US Army Corps of Engineers

US Forest Service

Vane Shear Testing

Water Management Consultants

LIST OF UNITS

ha

km

l/s

m

masl

t/d

Hectares

Kilometer

Liters per second

Meter

Meters above mean sea level

Tonnes per day

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 1

March 2010

1.0

1.1

INTRODUCTION

BACKGROUND

Gold Fields La Cima S.A. (GFLCSA), a subsidiary of Gold Fields Limited, owns the

Cerro Corona mine, a copper mine with significant gold content. The mine is located in

northern Peru, approximately 760 km NNW of Lima and 80 km by road from the city of

Cajamarca, as shown in Figure 1. The mine is currently in operation with further mine

development underway and has an expected life of 14 years. The mine consists of an open

pit, a 20K tonne per day (tpd) concentrator and related ancillary infrastructure. Tailing

produced by the Cerro Corona processing plant will be stored in the tailing management

facility (TMF), located just north of the plant site in the Quebrada Las Aguilas and

Quebrada Las Gordas valleys.

The process engineering for the project was performed by Hatch out of their Santiago,

Chile office. Design of the earth and rock structures, which includes the TMF, was

initially performed by Knight Piesold (KP), who completed a design report in early 2006

(KP, 2006). While GFLCSA views KPs design for the TMF to be technically sound, they

found it to be challenged with many constructability issues such as the timing for

construction around the wet season, the ability to install a grout curtain at the base of the

starter dams and still provide time for construction of the rockfill, placement and

compaction of a low permeability core for the dams during the wet season, and the

availability of suitable rockfill. Accordingly, in January of 2007, GFLCSA contracted

MWH Americas, Inc. (MWH) to develop construction level designs for a rockfill starter

dam to impound tailing during startup and early operations of the mine.

In November of 2008, subsequent to work performed by MWH and KP, MWH submitted

a design package that included a design report and construction drawings to support

construction of the TMF Starter Dam (MWH, 2008). The design included detailed

designs for the Starter Dam and conceptual level designs for future raises above the

starter dam elevation. Starter dam construction was defined as construction of the TMF to

an elevation of 3720 meters above mean sea level (masl), which would require the

construction of two dams, one in the Quebrada Las Aguilas and one in the Quebrada Las

Gordas. As noted in the report, detailed engineering, construction drawings, and

specifications were not developed for dam raises above the starter dam level.

The construction concept presented in the Starter Dam design report is as follows:

Stage 1 Construct a starter dam to an elevation of 3720 masl in the Quebrada

Las Gordas for storage of the first year of produced tailing materials. This dam

was to be constructed of rockfill with a sloping core.

Stage 2 Construction of Stage 2 was sequenced to immediately follow Stage 1.

Stage 2 would involve constructing a starter dam to an elevation of 3720 masl in

the Quebrada Las Aguilas. The Quebrada Las Gordas and Quebrada Las Aguilas

are separated by the Las Flacas Ridge, a feature with a maximum elevation of

approximately 3720 m. It was estimated that after approximately 2 years of tailing

deposition, the impoundment level would rise above the elevation of the Flacas

Ridge, joining the two impoundments.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

March 2010

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 2

Stage 3 through Completion (conceptual) After Stage 2, the tailing dam was

to be raised in a series of annual center-line raises, eventually reaching the

ultimate dam elevation of 3800 masl. The raised dam was to consist of rockfill

with a vertical core. A major component of this method of dam raise is the

presence of a well-drained tailing beach with sufficient strength to serve as part of

the foundation for future dam raises.

Construction of the Las Gordas Starter Dam began in April of 2007 and was completed in

August of 2008 with sub-aqueous tailing deposition into the Quebrada Las Gordas

beginning shortly thereafter. During operations to date, the properties of the produced

tailing have varied from those utilized in the Starter Dam design. This variance is largely

attributed to two factors:

Increased alteration of the mined ore, which has resulted in a higher fines content

of the produced tailing than was expected. This has resulted in lower than

expected rates of flocculation and settlement of the deposited material.

Due to the large volume of initial water in the Las Gordas basin and the very large

rate of rise during the initial filing of the Las Gordas basin, a sub-aerial beach at

the face of the dam has not formed and therefore limited segregation of the tailing

has occurred.

As a result, the tailing densities that are currently being achieved are less than those

estimated during the starter dam design. Both visual observations and investigations of

the beach indicate a material with a relatively low strength and solids content. A

discussion regarding the investigation and evaluation of the tailing properties is included

in Section 6.2.

As a result of the variance in tailing properties, the TMF construction plan laid out in the

Starter Dam design (which assumed the presence of sufficiently strong tailing beaches for

construction of centerline raises for post Stage 2 construction) has been revised. MWH

has developed additional design packages for construction of the TMF that include

revisions to the original Starter Dam design and designs for further raises. These include

design drawings and field instructions detailing the raising of the TMF to elevation 3732

masl (MWH, 2009a and 2009b) and the construction of the Las Flacas dam (MWH,

2009c).

The following presents a brief summary of the current construction concept and the

current status of construction for the TMF and the revised stage numbering and sequence:

Stage 1 (Constructed) Construction of the Las Gordas Starter Dam to an

elevation of 3720 masl in the Quebrada Las Gordas as described in the Starter

Dam design (MWH, 2008) was completed in August of 2008. This construction

also included the Las Gordas Low Volume Underflow (LVU) facility in the valley

downstream from the dam. The purpose of the LVU is to collect seepage water

from the tailing impoundment.

Stage 2 (Under Construction) Construction of the Las Aguilas Starter Dam to

an elevation of 3732 m as described in the MWH design (2009a) is currently

underway. To provide a suitable upstream platform for future raises of the Las

Aguilas portion of the TMF dam, a zone is being constructed along the upstream

face of the Las Aguilas Starter Dam. This zone is being constructed using the La

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

March 2010

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 3

Jalca Tailing, a historic tailing pile located near the upstream toe of the Las

Aguilas Starter Dam. Construction of this zone will form a 25 m wide bench at its

maximum elevation of 3732 masl and will include cutting and regrading the

existing La Jalca Tailing. Additionally, Stage 2 includes the Las Aguilas LVU

facility, which is currently under construction in the valley downstream of the

TMF dam. Stage 2 work is currently underway and is based upon the design

drawings developed by MWH (2009a).

Stage 3 (Constructed) Stage 3 construction includes the raising of the Las

Gordas Dam to an elevation of 3732 masl and construction of the Las Flacas Dam.

Construction of the Stage 3 Las Gordas Dam raise was completed in September of

2009. Due to the lack of a suitable tailing beach against the upstream face of the

Las Gordas dam, the dam was raised using the optimized centerline method with a

geosynthetically reinforced upstream face, as presented in the 3732 m raise design

prepared by MWH (2009a) and a field instruction from MWH (2009b). The raise

method is described as an optimized centerline raise as it still relies on the

tailing material for upstream stability but to a lesser extent than the centerline

method.

Stage 3 construction also includes the construction of the Las Flacas dam, which

was completed in January of 2010. The Las Flacas Dam is a rockfill dam with a

geomembrane lined face located on the Las Flacas ridge to the west of the Las

Gordas Dam. The purpose of this dam is to form a temporary impoundment in the

Quebrada Las Gordas to allow for storage of tailing materials while construction

of the Las Aguilas Starter Dam is underway. It is expected that a channel will be

excavated through the Las Flacas Dam after the Las Aguilas Dam is constructed

to allow for tailing deposition into the Quebrada Las Aguilas.

Stage 4 (Proposed) After completion of Stage 2 and 3 TMF construction, both

the Las Aguilas and Las Gordas Dams will have been constructed to an elevation

of 3732 masl. To continue to increase the capacity of the impoundment, the TMF

will be raised to an elevation of 3740 masl. The selection of the Stage 4 crest

elevation is based upon conceptual level TMF construction scheduling performed

by MWH, as discussed in Section 5.1.

The Stage 4 raise will be constructed using the optimized centerline method for

the Las Gordas portion of the TMF dam with an upstream slope of 0.8 horizontal

units to 1 vertical unit (0.8H:1V). As the La Jalca Tailing bench will provide

upstream support, the Las Aguilas portion of the TMF dam will be raised using

the centerline method, with vertical internal zones and an upstream rockfill face

sloping at 1.4H:1V. The upstream face of the Las Gordas (sloped) portion of the

dam will be reinforced with geosynthetic and gabions to achieve surficial stability.

The downstream slope of the rockfill for the TMF will be steepened from the

current design slope of 1.5H:1V to 1.4H:1V. A discussion on industry precedence

to support this slope steepening is included in Section 8.

As a part of the Stage 4 raise, a small saddle dam will be constructed across the La

Hierba valley to the southwest of the Las Aguilas and Las Gordas dams. This

dam, known as the La Hierba dam, lies along the ultimate dam centerline and will

be constructed with vertical internal zones and upstream and downstream rockfill

zones sloping at 1.4H:1V.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 4

March 2010

The design of the Stage 4 TMF is presented in this report and is discussed further

in Section 4.0. Seepage and stability analyses and construction quantity estimates

were performed for the Stage 4 TMF raise. The results of these evaluations are

included in Sections 7 and 9, respectively.

Figure 2 presents an overview of the site with the proposed Stage 4 TMF.

Sections through the Stage 4 Dam in the Las Aguilas and Las Gordas valleys are

presented in Figures 3 and 4, respectively.

Future Raises (Conceptual) As the design of the Stage 4 TMF raise and future

raises are interdependent, conceptual level designs were developed for future

TMF raises. The proposed design concept assumes the centerline method will not

be suitable for any remaining raises due to the presence of weak tailing throughout

the life of the mine. This design represents a contingency plan as it is likely that

conditions in the impoundment will improve with time due to the addition of

flocculant and the increasing size of the impoundment.

The post-Stage 4 design concept consists of raising the dam using the optimized

centerline method with an upstream slope of 0.6H:1V and a downstream slope of

1.4H:1V. The upstream slope will be reinforced with geosynthetic and gabions to

achieve global and surficial stability.

A conceptual level schedule was developed to evaluate the required future raising

schedule while maintaining the required freeboard and minimizing the required

wet season construction work. Additionally, seepage and stability analyses and

quantity estimates were performed for the future dam raises. The results of these

evaluations are included in Sections 7 and 9, respectively. The proposed raising

schedule and TMF construction for future raises are described in further detail in

Section 5. Further information regarding the proposed design for future facility

raises is included in Section 5.

Figure 6 presents a plan view of the proposed conceptual level ultimate TMF

dam. Ultimate dam sections through the Las Aguilas, Las Gordas, and La Hierba

valleys are presented in Figures 7, 8 and 9, respectively.

1.2

MWH SCOPE OF WORK

The lack of a consolidated and well drained beach (to provide a suitable foundation for

future raises) has necessitated a review of the previously completed conceptual design to

identify construction methods for subsequent raises of the dam that will allow for storage

of the tailing materials while meeting stability criteria and minimizing any movement of

the downstream toe of the facility. The scope of this project consists of developing a

detailed design for the raise of the Cerro Corona TMF to an elevation of 3740 masl and

developing conceptual level designs for future raises. Specifically, the scope includes the

following components:

Investigation and evaluation of geotechnical properties of the deposited tailing

materials and the use of this information as an input to engineering analyses, as

appropriate.

Development of a conceptual level TMF dam construction schedule to estimate

the optimal crest elevations for future TMF raises.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 5

March 2010

Review and refinement of the dam material properties utilized in previous

analyses based on newly available information.

Completion of engineering analyses and a review of industry practice to support

any proposed revisions to the dam configuration.

Development of a detailed design complete with construction quantity estimates,

construction drawings, and construction specifications for raising the TMF dam to

an elevation of 3740 masl, termed Stage 4 construction.

Compilation of a design report to summarize the Stage 4 TMF raise design and

present the work performed in support of the design.

Development of conceptual level designs to construct the TMF to its ultimate

elevation, assuming that the optimized centerline design will be utilized

throughout the construction of the dam.

Development of conceptual level tailing deposition plans and capacity estimates

for the Stage 4 TMF and future TMF raises to be used in mine planning and

design of pumping and piping systems.

1.3

EXCLUDED WORK

The work performed in this study is limited to the development of a detailed design to

raise the Cerro Corona TMF to an elevation of 3740 masl and the development of

conceptual level designs for future raises. The scope of work does not include the

following:

Detailed Design for Facility Raises Beyond 3740 masl This project does not

include detailed designs for future facility raises (post-Stage 4). However, in order

to provide a feasible future construction concept and as the design of the Stage 4

TMF and future raises are interdependent, future facility construction was

considered on a conceptual level.

Ancillary Construction The construction of complementary items such as

access roads, expanded borrow facilities, and staging areas were not considered

and are not included as a part of this report.

Hydrology and Water Management The design presented in this report is not

thought to deviate significantly from that presented in the starter dam report in

terms of hydrology and water management. However, it is recommended that the

design presented in this report be utilized to update the site wide water balance.

Pumping and Piping Systems As the design presented in this report does not

deviate significantly from that presented in the starter dam report in terms of

pumping and piping, no significant revisions to the pumping and piping designs

presented in that report are deemed necessary. However, the current design

presented may alter the sequencing and placement locations of tailing delivery

lines due to variations from the original conceptual design and differences

between the Stage 4 Las Gordas and Las Aguilas dam raise methodologies. These

potential issues are not specifically addressed in this report and should be

considered by the TMF operators to ensure satisfactory operation of the facility.

However, to aid in the design of pumping and piping systems, conceptual level

tailing deposition plans were developed by MWH, as discussed in Section 10.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 6

March 2010

1.4

Facility Closure As the design presented in this report does not deviate

significantly from that presented in the starter dam report in terms of closure, no

revisions to the closure plan presented in that report were deemed necessary.

LIMITATIONS

This document contains the expression of the professional opinion of MWH as to the

matters set out herein, using its professional judgment and reasonable care. It is to be read

in the context of the agreement and signed amendments (the Agreement) dated

November 28, 2005 between GFLCSA and MWH, and the methodology, procedures and

sampling techniques used, MWHs assumptions, the circumstances and constraints under

which its mandate was performed. This document is meant to be read as a whole, and

sections or parts thereof should thus not be read or relied upon out of context.

Additionally, this report should be read in conjunction with the Starter Dam design report

developed by MWH (2008).

Professional judgments are presented in this report. These are based partly on evaluation

of technical information gathered, partly on our experience with similar projects, and

partly on our understanding of the characteristics of the project. The findings,

interpretations of data, recommendations, professional opinions, and conclusions that are

presented are within the limits prescribed by available information at the time the

analyses and designs were prepared, in accordance with generally accepted professional

engineering practice. In the event that there are any changes in the nature, design, or

characteristics of the project, or if additional data are obtained, the conclusions and

recommendations contained in the report will need to be reevaluated by MWH in light of

the proposed changes or additional information obtained. Variations from results

presented in the report should be expected due to uncertainties that are inherent in these

types of analyses. Therefore, decisions that are based on these results should consider

these variations as well as limitations of the analyses to predict future performance with a

high degree of accuracy.

Unless expressly stated otherwise, assumptions, data and information supplied by, or

gathered from other sources (including GFLCSA, other consultants, testing laboratories

and equipment suppliers, etc.) upon which MWHs opinion as set out herein is based has

not been verified by MWH and MWH makes no representation as to its accuracy and

disclaims all liability with respect thereto.

MWH disclaims any liability to any third party in respect of any reliance on this

document by any third party without the prior written consent of MWH. MWHs services

were performed within the limits prescribed by GFLCSA, with the usual thoroughness

and competence of the engineering profession. No other representation, expressed or

implied, is included or intended in our proposals, contracts, or reports.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 7

March 2010

2.0

2.1

DESIGN STEWARDSHIP, OBJECTIVES, CRITERIA,

AND BASIS

DESIGN STEWARDSHIP

The Cerro Corona TMF is a complex facility consisting of many components which rely

on strict adherence to stringent standards for construction quality control, construction

quality assurance, compliance with safe operating parameters, performance monitoring

and management accountability. The design of this facility assumes that minimum levels

of stewardship will be maintained during the construction, operation, closure and post

closure phases of the project. Compliance with these minimum standards is an integral

component of the design. Failure to comply with these minimum standards shall be

considered to be a material deviation from the design intent and will release MWH from

any responsibility related to the ongoing operation or performance of the facility. The

minimum standards shall include the following:

Compliance with the following standards for construction, operation and care of

tailing impoundments:

o Mining Association of Canada, A Guide to the Management of Tailings

Facilities, September 1998

o Australian National Committee on Large Dams, Guidelines on Tailings Dam

Design, Construction, and Operation, October 1999

o Mining, Minerals and Sustainable Development, Stewardship of Tailings

Facilities, April 2002

o ICOLD, Increasing Tailings Dam Safety, Critical Aspects of Management,

Design, Operation and Closure

An Engineer of Record who is familiar with the design intent, all design drawings

and specifications and relevant standards shall be employed to ensure that all

construction, operation and closure activities, as well as any design modifications

or interpretations are consistent with the original design intent and any applicable

standards and/or regulations.

The owner will prepare an operating strategy, operating manual, operating

procedures, safe work procedures and emergency response plan which must, in

the opinion of the Engineer of Record, comply with the original design intent.

Failure to build and/or operate the facility in accordance with these documents

may be considered a significant departure from the design.

The owner will establish and maintain an independent review board of

internationally recognized experts to review all design, construction, operation

and closure activities, and to make recommendations to the owner regarding

appropriate stewardship of the facility. The owner is not bound to implement the

recommendations of the independent review board, but unless the engineer of

record concurs with the owners decision, failure to do so may be considered to be

a significant departure from the design.

The owner will establish and maintain a suitable organizational structure and will

employ qualified and experienced personnel, consultants and contractors to build

and operate this facility. Failure to meet this criterion, in the opinion of the

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 8

March 2010

independent review board or the engineer of record, may be considered a

significant departure from the design.

These minimum standards form an integral part of this design.

2.2

DESIGN OBJECTIVES

The main objective of the TMF design presented in this report to develop constructionlevel designs and construction documents for raising the Cerro Corona TMF to an

elevation of 3740 masl in an environmentally responsible manner in accordance with

Peruvian and International practices.

Additional objectives include:

Satisfy relevant local and international design criteria associated with TMF

design, construction, and operation

Design and construct the TMF in accordance with internationally recognized

stability criteria

Design the TMF so that it does not impact the operation of the Las Gordas or Las

Aguilas LVU facilities.

Design a facility that can be constructed with material from onsite borrow sources

Develop conceptual level designs to construct the TMF to its ultimate elevation

while considering the potential for weak tailing throughout the life of the facility,

allowing for freeboard requirements, and minimizing wet season construction.

The design criteria and basis for the Stage 4 TMF raise are generally based upon those

developed for design work previously performed by MWH. The following sections

summarize the design criteria and basis adopted for the Stage 4 TMF raise. The following

documents were used in the development of the design basis and criteria and are

referenced as used in the design criteria and basis summary tables:

1. Knight Piesold, 2006. Mine Waste and Associated Water Management Facilities

Report on Design, Final report prepared for Gold Fields La Cima S.A. January

18, 2006.

2. MWH, Review of Existing Data and Engineering Judgment

3. Water Management Consultants (WMC), 2005. 24-hr PMF Volume at the Cerro

Corona Tailings Facility, Memorandum from Enrique Buschiazzo of WMC to

Frits Reidel. December 2, 2005.

4. Hatch, 2006. Civil Structural Design Criteria, Document no. H318608-000-C22-001. July 18, 2006.

5. Hidroenerga, 2006. Estudio de Peligro Ssmico, Cerro Corona Cajamarca,

Final Report Prepared for MWH Peru S.A. October, 2006.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 9

March 2010

6. MWH, 2005. Cerro Corona Frost Depth Analysis, January 10, 2005.

7. Independent Geotechnical and Tailing Review Board (IGTRB), Draft Third

Report.

8. US Army Corps of Engineers (USACE), 2003. Engineering and Design Slope

Stability, Engineering Manual 1110-2-1902. October 31, 2003.

9. Canadian Dam Association (CDA), 2007. Dam Safety Guidelines. 2007.

10. MWH, Results of Cerro Corona pH Monitoring Program (as of January 5th, 2010).

11. MWH, 2010. Cerro Corona Low Volume Underflow Facility Las Aguilas

Valley, Design Drawings, Revision 1. February, 2010.

12. MWH, 2008. Cerro Corona LVU Dam Design, Design Drawings, Revision 3.

September, 2008.

2.3

DESIGN CRITERIA

Following previous work performed by MWH, the Stage 4 TMF raise was designed

following the following national standards and other internationally accepted guidelines.

The following Ministry of Energy and Mines (MEM) standards and guidelines were used

to develop this design basis document:

Ministerial Resolution No. 0.5-95-EM-DGAA Governing the Design and

Reporting of Tailing Facilities (1995).

Guidelines for Preparing Environmental Studies for Mineral Tailing (1995).

Mine Closure Regulations (2003).

MWH also utilized the following international standards to develop the Stage 4 TMF

design:

Canadian Dam Safety Guidelines

Nevada Division of Water Resources Regulating and Permitting Guidelines

Pertaining to the Safety of Dams

Mining Association of Canada Tailing Management Guidelines

International Commission on Large Dams (ICOLD) Guidelines

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 10

March 2010

The design criteria that have been adopted for the Stage 4 TMF design are presented in

Table 1.

Table 1 Stage 4 TMF Design Criteria

ITEM

CRITERIA

DATA

(1)

SOURCE

General

Very High Canadian Dam Association

Facility Hazard Category

High Nevada Division of Water Resources

Seismicity

Arequipa, Peru 197, Bokajan, Burma, 1988, and Panchimilco,

El Salvador.

1/475 yr event

Maximum Credible Earthquake (MCE)

M = 8.0

PMP, 24 hr event

Flood volume resulting from occurrence of the 24-hr PMP event

Design Earthquake

Operating Basis Earthquake (OBE)

Maximum Design Earthquake (MDE)

Hydrology

Facility Design Storm

PMF

Facility Configuration and Construction

Vertical distance from maximum estimated level of reclaim

pond and the PMF to the dam crest

Store tailing, maximum estimated reclaim pond volume, and

PMF

USACE Stability Recommendations

CDA Dam Safety Guidelines

On-site Borrow

Will not impact the performance of the Las Gordas Low Volume

Underflow (LVU) facility or the Las Aguilas LVU facility

(currently under construction)

Freeboard

TMF Capacity

Stability Requirements

Static Dam Stability

Post-Cyclic Dam Stability

Facility Configuration and Construction

Dam Construction Material Source

Ultimate TMF Dam Maximum

Downstream Toe Location

1.

Data source numbers refer to the list of reference documents listed in Section 2.2.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 11

March 2010

2.4

DESIGN BASIS

The design basis that has been adopted for the Stage 4 Cerro Corona TMF design is

presented in Table 2.

Table 2 Stage 4 TMF Design Basis

BASIS

DATA

(1)

SOURCE

900 km NNW of Lima, Peru

ITEM

General Site Characteristics

Location

Elevation

Seasons

3500 to 4000 masl

Wet Season - October through March

Dry Season - April through September

Minimum Design Temperature

-1.0 C

Maximum Design Temperature

20.0 C

Frost Depth

0.0 m

Minimum Design Humidity

32%

Maximum Design Humidity

100%

Minimum Annual Design Precipitation

398 mm

Maximum Annual Design Precipitation

3,104 mm

Maximum Design Wind Speed

40 km/hr

Prevailing Wind Direction

East/East-Northeast

10.5 - 12

10

TMF pH Range

Seismic Conditions

Operating Basis Earthquake (OBE)

0.24g (1/500 yr)

5 and 7

0.50g

5 and 7

1.3

1.5

Maximum Design Earthquake (MDE)

Minimum Stability Requirements

Minimum Static Factor of Safety (End of Construction)

Minimum Static Factor of Safety (Long-Term)

Minimum Pseudo-Static Factor of Safety

None Based on Deformations

Minimum Post Cyclic Factor of Safety

1.2

501,291 m (Las Aguilas Valley)

Hydrologic Conditions

PMF

485,709 m (Las Gordas Valley)

Facility Configuration and Construction

Freeboard

Minimum Downstream Dam Slope

2m

1.4H:1V

Minimum Dam Crest Width

10 m

Minimum Dam Zone Width (Per Constructability)

3m

Maximum Exposed Life of Stage 4 Upstream Dam Face

2 years

Minimum Required Capacity of the Las Aguilas LVU Facility

11,300 m

Minimum Required Capacity of the Las Gordas LVU Facility

3,000 m

1.

2

3

Data source numbers refer to the list of reference documents listed in Section 2.2.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

11

12

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 12

March 2010

3.0

GENERAL SITE CHARACTERIZATION

The following subsections present a brief summary of the project setting and are based

upon more detailed information presented in the TMF Starter Dam design report

developed by MWH (2008), unless noted otherwise.

3.1

PROJECT LOCATION AND TOPOGRAPHY

The Cerro Corona mine is located in northern Peru, approximately 760 km NNW of Lima

and 80 km by road from the city of Cajamarca. The mine site is in the Department of

Cajamarca, approximately 1.5 km west-northwest of the village of Hualgayoc, as shown

in Figure 1. The project site is typical of mine sites in the Peruvian Andes with elevations

ranging from 3,500 to 4,000 masl. The site topography ranges from shallow valley floors

sloping at 5 degrees or less to steep rock bluffs sloping at angles up to 70 degrees.

Overall, the local topography slopes at an average of 10 to 35 degrees.

3.2

SITE LAYOUT

The Cerro Corona site is relatively compact, covering an area of approximately 200

hectares (ha). The site contains two major valleys, the Quebrada Las Gordas and

Quebrada Las Aguilas, which are separated by a north-south trending ridge, known as the

Las Flacas Ridge. The Las Flacas Dam was constructed along the Las Flacas ridge to

separate the Las Gordas and Las Aguilas impoundments. A rhyolite quarry is in operation

along the northern edge of the Las Gordas impoundment and the Corona open-pit mine is

located in the eastern portion of the site.

The westernmost valley, the Quebrada Las Aguilas, contains a historic tailing deposit

from previous mining activities at the site, known as the La Jalca Tailing. The Quebrada

Las Aguilas generally flows south to north with drainage exiting into the Tingo River.

The Las Aguilas Starter Dam is currently under construction to an elevation of 3732 masl,

with La Jalca tailing being placed and compacted against the upstream face of the dam.

Construction of this dam will serve to form the Las Aguilas portion of the Cerro Corona

TMF.

To the east of the Quebrada Las Aguilas is the Quebrada Las Gordas. This valley flows

southeast to northwest, with drainage exiting into the Tingo River. The Las Gordas

Starter Dam has been constructed and subsequently raised to an elevation of 3732 masl in

the downstream portion of this valley, near the Tingo River. Tailing is currently being

deposited into this valley, with the Gordas Dam serving to impound the material. The

rhyolite quarry and the concentrate plant are located in the southeastern portions of this

valley, upstream of the Gordas portion of the TMF. The upstream containment blanket

(UCB) is being constructed along the mine overburden facilities along the eastern and

southern portions of the Las Gordas impoundment. The UCB is an engineering

compacted clay barrier that is intended to reduce seepage and piping of tailing into the

karstic limestone.

The La Hierba valley is a smaller valley located west of the Las Aguilas Mountain. A

small saddle dam, termed the La Hierba dam, will be constructed across the saddle at the

top of the valley as a part of Stage 4 construction.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 13

March 2010

Figure 2 presents an overview of the site, including the major site components along with

the proposed Stage 4 TMF.

3.3

WATER RECOVERY AND TAILING PRODUCTION AND TRANSPORT

The TMF stores both rougher scavenger tailing (RST) and cleaner scavenger tailing

(CST). The RST is produced from the rougher flotation cells after a scavenging stage and

makes up the majority of the tailing produced in the project (approximately 85% to 95%

of the total tailing stream). The CST is produced from the cleaner flotation cells after a

scavenging stage and has a finer gradation as it is passed through a regrind stage. The

RST has a lower sulfide content as most of the sulfide mineralization is floated off in the

rougher circuit. At deposition into the TMF, the pH of the tailing streams is elevated due

to the addition of lime to the process.

The potential for acid generation from the CST is high while the potential for acid

generation from the RST is considered negligible. Currently, the CST is being co-mingled

with the RST material and is being deposited sub-aerially. It is understood that the comingling of the RST and CST tailing will only be allowed during the early years of

operations. Later in the mine life, the tailing streams will be separated and the CTS tailing

will be deposited sub-aqueously to prevent ARD generation.

Currently, the combined RST and CST tailing streams are being thickened to a solids

content of approximately 55% by weight prior to discharge into the TMF. The RST

generated at the concentrator plant is delivered to the tailing thickener area by means of a

gravity line. After thickening, the material is conveyed to the RST feeder box where it is

combined with the CST and then transported via a high-density polyethylene (HDPE)

gravity pipeline to its final discharge at the TMF. The RST delivery system includes a

series of drop pipes that enable the dissipation of excess energy.

Water is removed from the surface water pond and reclaimed to the mine process circuit

by floating decant pumps located in the TMF. As noted previously, slow rates of

flocculation and settlement of the tailing materials have reduced the pumping rates from

the facility.

LVU collection facilities are located downstream of both the Las Gordas and Las Aguilas

dams (the Las Aguilas LVU facility is currently under construction). The purpose of these

facilities is to collect seepage water from the tailing impoundments. Water collected in

the Las Aguilas LVU facility will be pumped to the Las Gordas LVU facility. From this

point, water will be pumped to the LVU pump station storage box prior to pumping back

to the TMF.

3.4

CLIMATE

The climate at the site is defined by two distinct seasons, a dry and a wet season. For

construction purposes, these seasons have been divided into a dry season from April

through September and a wet season from October through March. The Cerro Corona

Environmental Impact Assessment (EIA) (Knight Piesold 2005) has evaluated data from

a number of meteorological stations operated by the Servicio Nacional de Meteorologa y

Hidrologa (SENAMHI), together with data from a weather station located within the

GFLCSA property at the Carolina Site.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 14

March 2010

Based on an adjustment for elevation of the data from the Hualgayoc meteorological

station, average annual precipitation is reported as 1,398 mm with the wet and dry year

totals being 2,423 and 907 mm, respectively. An average annual catchment evaporation

of 507 mm has been calculated based on a 65% average annual pan evaporation estimate.

A new meteorological station has been installed at the site by GFLCSA and has been

taking site-specific data readings for over 2 years. This station will operate over the full

life of the mine and its data will be used to refine current data sets used for calculating

future water balances for the operation as well as for planning and designing the staged

expansions of the TMF, general project improvements and closure planning.

3.5

SITE HYDROLOGY

In the Cerro Corona project area, six sub-catchments can be defined: Quebrada Las

Aguilas, Chorro Blanco, Las Gordas, Las Flacas, Mesa de Plata, and Corona. The

Hualgayoc River, located south of the site, originates at an elevation of over 3,700 masl at

Cerro Coyomolache. The river flows from the southwest to the northeast. Both the

Quebrada Mesa de Plata and the Quebrada Corona sub-catchments flow to this river. The

Cerro Corona pit is located on the watershed between the Quebrada Mesa de Plata subcatchment and the Quebrada Corona sub-catchment.

The Quebrada Las Gordas, Las Aguilas, and Las Flacas drain to the Tingo River. The

Tingo River is the predominant river in this area. It originates at an elevation of 3,900

masl on the flanks of the Cerros de Tantahuatay. The river, which flows from east to

west, has a catchment area of 9 square kilometers (km2) above its confluence with the

Quebrada Las Aguilas. The river has an average annual flow of 241 liters per second (l/s)

downstream of its intersection with the Quebradas Las Aguilas and Las Gordas. The TMF

is located in the Las Gordas and Animas sub-catchments. The Hualgoyoc River originates

above 3,700 masl at Cerro Coyomolache and flows from the southwest to the northeast.

Site hydrology studies were completed by both KP and Water Management Consultants

(WMC). As WMC completed the most recent assessments, their studies were utilized.

WMC completed two hydrology studies. The first study (WMC, 2005) calculated the

Probable Maximum Flood (PMF) runoff volume upstream of the TMF dam. The second

study (WMC, 2006) evaluated the precipitation depth for the 100 yr, 1000 yr, and PMF

events. These studies can be found as appendices to the starter dam design report

developed by MHW (2008).

3.6

GEOLOGY

The rock structure in the Cerro Corona area includes Cretaceousage sandstones, Servicio

Nacional de Meteorologia y Hidrologia

quartzites, limestone and calcareous

mudstones of the Goyllarisquizga Group. The limestones are part of the Paritambo and

Yumagual formations. The regional dip of the limestone rock structure is between 15 and

35 degrees towards the southwest. The Yumagual formation exhibits karstic features such

as solutioned joints, shafts, caverns, and singles. Groundwater International (GWI), since

acquired by MWH, was contracted to investigate the karstic features at the site.

During the Tertiary period, (Eocene-Miocene) these sedimentary rocks were intruded by a

series of igneous bodies including the Cerro Corona intrusion. The Cerro Corona

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 15

March 2010

intrusive forms a near vertical tube, which is exposed over an area approximately 800 m

wide and 1000 m long, elongated in a north-south direction. The main body of the

intrusive is a porphyry diorite, with two smaller bodies (a diorite and a quartz diorite)

intruded in the southern part of the body. The two small bodies are located along a

northeast-southwest axis coincident with the main fault trend in the area, and suggesting

that the intrusions are partially fault controlled. The centre of the intrusion is extensively

silicified with numerous quartz veins, while outside this central core the intrusion is

weathered, as indicated by the development of clay minerals and iron oxides.

Another intrusive body outcrops on both sides of the Tingo River, approximately 6 km

west northwest of Cerro Corona. This intrusive is associated with the rhyolitic flows

which outcrop on the flanks of Cerro Las Gordas and Cerro Aguilas. The limestone host

rock shows little deformation related to the intrusion of the Cerro Corona body, with

some cleavage development or faulting along the contacts. Bedding within the limestones

is disturbed within a 10m zone around the intrusive contact. Skarn is developed within a

zone extending approximately 30 m from the intrusive contact. Rafts of limestone host

rock, up to 70 m in thickness are present within the intrusive body.

The surface deposits in the area include colluvial, morranic and fluvioglacial deposits.

Numerous landslips are seen associated with saturated superficial deposits, while a larger

scale landslide, affecting both superficial deposits and underlying bedrock is observed in

the Tingo River valley, below the confluence with the Las Gordas valley. The saturated

superficial deposits range from 0.5-4 m in thickness, while the colluvial and scree

deposits present in the Las Gordas and Aguilas valleys have thicknesses in the range of 520 m. These superficial deposits can form a shallow aquifer, which can transmit water to

the underlying basement rocks or feed local shallow spring flows.

3.7

SEISMICITY

The northern part of Peru in the Cerro Corona project area is characterized by significant

seismicity. The regional geologic structure is dominated by northeast-southwest trending

faults and related folds. In the Cajamarca area these are intersected by a series of eastwest trending structures.

A number of historic site seismic hazard documents were reviewed as a part of the Starter

Dam design. Based on recommendations from the Independent Geotechnical and Tailing

Review Board (IGTRB), MWH contracted URS to develop a new hazard study for the

project. URS was selected by MWH due to their familiarity with Peruvian seismicity as

they had recently completed a similar study for the Cerro Verde mine near Arequipa,

Peru. This report (URS, 2007) has since been used to obtain seismic input parameters for

a seismic deformation analysis, which was performed as a part of this report. A

description of this analysis and a summary of the preliminary results of this analysis are

presented in Section 7.4 of this report.

3.8

HYDROGEOLOGY

Due to the karstic nature of the site, a number of hydrogeologic studies have been

performed. WMC was contracted by GFLCSA to perform hydrological and

hydrogeological studies at the site. A summary of the key hydrogeologic findings from

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

March 2010

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 16

the WMC study, as presented in the Starter Dam design report (MWH, 2008) is as

follows:

The Cerro Corona intrusive body has a variable, but moderate permeability with

variations likely related to fracture development and variations in alteration

Zones of increased fracturing generally correlate with fault zones and with the

limestone intrusive contact areas.

The Cerro Corona intrusive body intruded into a sequence of carbonate rocks.

Groundwater flow in the carbonates is enhanced along faults, fractures, and local

karst features.

Groundwater elevation contours indicate that Cerro Corona represents a

groundwater high. Groundwater flow away from Cerro Corona follows

topography with flow occurring towards the north and east into the Mesa de Plata

basin and to the south-southeast into the Hualgayoc basin.

A hydrogeologic flow model was developed by WMC for GFLCSA (WMC, 2008). The

model was developed using the USGS three-dimensional groundwater flow code

MODFLOW. The results of hydrogeologic modeling are as follows:

The development of the TMF would affect the surface drainage and recharge of

the Las Gordas and Aguilas sub-catchments, potentially reducing the natural

baseflow of the Tingo River by 33.6 l/s or 19.5%

Three pit dewatering scenarios were evaluated. Modeling indicates that the

dewatering operations in the open pit for the base case scenario (pit dewatering of

30 L/s for 15 years) may reduce the baseflow at the confluence of the Hualgayoc

River with the Quebrada Mesa de Plata between 2% and 4% (approximately 3

L/s).

The cone of depression resulting from the base case pit dewatering may extend to

the topographic level of 3,620 masl, which may result in a reduction in certain

observed spring flows in the Quebrada Corona region.

However, the hydrogeologic model developed by WMC represents a preliminary model

and does not account for the karst formations present at the site. Accordingly,

GWI was contracted by GFLCSA to conduct a detailed karst hydrogeological assessment

of the Gordas Valley tailing and waste rock facilities. This study included field mapping,

drilling and installation of piezometers, hydraulic testing, speleological and dye tracer

studies, spring and water level monitoring, and three dimensional numerical modeling.

The following information was obtained from the karst hydrogeology study prepared by

GWI (2009). A summary of the key hydrogeologic findings from this study are as

follows:

The risk of seepage losses from the mine waste facilities within the Gordas Valley

via karstic limestone units is high if the pond comes in contact with the limestone

above the 3750 masl level.

The construction of the UCB along the mine overburden facilities reduces but will

not eliminate seepage.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 17

March 2010

Pumping from the drain behind the UCB will result in significant reductions of the

risk of off-site seepage.

With the UCB and the drain installed and functioning correctly, there will be a

low risk of offsite seepage associated with raising the tailing level in the

impoundment to an elevation of 3760 masl.

It may be possible to raise the tailing level above elevation 3760 masl if

monitoring of the UCB and the Hualgayoc seep collection systems indicate that

they are working correctly.

The risks of off-site water quality impacts are much higher from the mine waste

dumps as they are acid-generating and are within a karstic limestone recharge

area. It is understood that water from any impacted springs will be collected and

treated by GFLCSA.

3.9

GEOCHEMISTRY

Various geochemical characterization studies have been performed at the site. A brief

summary of the results of the geochemical characterization studies is presented below:

Material from the rhyolite quarry in the Gordas valley is not expected to generate

acidic drainage or leach elevated concentrations of metals.

A portion of the alluvial/colluvial material from the Aguilas valley contains

minimal net neutralization potential.

The La Jalca tailing materials are not suitable for construction considering their

geochemical properties. However, their use in Stage 3 construction against the

upstream face of the Las Aguilas Dam is considered acceptable as the placement

location is upstream of the Zone 1 core material.

The TMF will store two types of tailing, CST and RST. The CST contains a

greater concentration of sulfide-sulfur and a smaller net neutralizing potential than

the RST fraction of the tailing. Humidity cell testing indicates that the CST

fraction quickly turns acidic and produces leachate with increasing concentrations

of metals and decreasing pH values during the test period. The RST portion,

however, had stable concentrations of metals and circumneutral pH after 25

weeks. Accordingly, it was recommended that the CST be deposited subaqueously in the later stages of the mine life to mitigate acid generation while the

RST can be deposited in a subaerial manner.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 18

March 2010

4.0

DESCRIPTION OF THE STAGE 4 TMF RAISE

At the onset of Stage 4 construction, it is expected that the construction of stages 1

through 3 of the TMF will be completed. Stage 4 construction will consist of raising both

the Las Aguilas and Las Gordas Dams to an elevation of 3740 masl and constructing a

relatively small saddle dam across the La Hierba valley. At this elevation, both the Las

Gordas and Las Aguilas dams will be at a sufficient elevation to form a single connected

dam spanning both the Quebrada Las Aguilas and the Quebrada Las Gordas. A plan view

of the site, including the Stage 4 TMF, is presented in Figure 2.

Stage 4 TMF construction will be performed utilizing two raise methods, the optimized

centerline raise for the Las Gordas portion of the Stage 4 TMF raise and a vertical

centerline raise for the La Hierba Dam and the Las Aguilas portion of the Stage 4 TMF

raise. The Las Aguilas and La Hierba portions of the raise will be constructed with a

sloping rockfill zone (placed at a slope of 1.4H:1V) placed along the upstream face of the

raise to support the vertically placed adjacent material zones. For the Las Aguilas portion

of the raise, this upstream rockfill zone will be supported by the La Jalca tailing bench

while for the La Hierba dam, this upstream rockfill zone will be supported by the existing

ground.

The Las Gordas portion of the raise is described as an optimized centerline raise as it

still relies on the tailing material for upstream stability but to a lesser extent than the

centerline method. The upstream face and the internal material zones of the Las Gordas

portion of the Stage 4 TMF raise will be constructed at a slope of 0.8H:1V. Due to the

steepness of the upstream slope of the optimized centerline portion of the raise, gabion

facing with geosynthetic tails has been specified to provide lateral support for placement

and compaction of rockfill at the upstream face and to mitigate raveling during the service

life of the Stage 4 TMF. Further information regarding the gabion facing is presented in

Section 7.5.2 of this report and in the Construction Drawings included as Appendix I.

Near the middle of the main Stage 4 TMF dam (the Las Aguilas and Las Gordas portions

of the dam), the two raise methods intersect. The intersection of the two raise types will

be performed by sloping the optimized centerline raise method from its Stage 4 elevation

of 3740 masl down to the previous TMF dam elevation of 3732 masl. In this transition

zone, a vertical centerline raise method will be used above the sloped optimized

centerline method to bring the dam to its full Stage 4 elevation. Additional information

regarding the transition zone can be found in the construction drawings, located in

Appendix I.

To comply with the project stability criteria, the horizontal widths of the upstream Zone

2B and Zone 5 materials for the Stage 4 TMF dam have been altered from the values

presented in the Starter Dam report (MWH, 2008), which were used during construction

of the TMF to date. This alteration consists of increasing the horizontal width of the Zone

2B material from the original design value of 3 m to 6 m and an accompanying decrease

in the Zone 5 width from 9 m to 6 m.

To counteract the reduction in the Zone 5 width, the specification for the Zone 5 material

placed above elevation 3732 masl (for Stage 4 construction and beyond) has been revised

to require the placement of Zone 5 material with a reduced saturated hydraulic

conductivity (reduced from the Stage 3 specified value of 1 10-5 cm/s to 1 10-6 cm/s).

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

March 2010

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 19

Further information regarding the selection of the Zone 5 hydraulic parameters can be

found in Section 6.4. Seepage analyses were performed to evaluate the effect of the Zone

5 width and parameter revision on the estimated hydraulic gradients and seepage rates

through the dam. Further information regarding the seepage and stability analyses

performed in support of the Stage 4 design is included in Section 7.

For the entire TMF dam, the Stage 4 downstream rockfill slope will be steepened from

the design value of 1.5H:1V, as presented in the Starter Dam design (MWH, 2008) to a

slope of 1.4H:1V. This steepening is based on newly available information that was used

to revise the rockfill strength envelope and necessitated by the need to minimize any

downstream movement of the downstream embankment toe. Section 8 discusses the

industry precedent for this revision while Section 7 discusses the analyses performed to

evaluate the suitability of this revised slope.

Sections of the Las Aguilas and Las Gordas portions of the Stage 4 TMF dam raise are

presented in Figures 3 and 4, respectively. Additional information regarding the Stage 4

TMF dam design is included in the Construction Drawings.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 20

March 2010

5.0

PROPOSED FUTURE TMF RAISES

To evaluate the suitability of the Stage 4 TMF raise design and to provide a contingency

framework for future TMF construction, a conceptual level design was developed for

future TMF dam raises above the Stage 4 TMF crest elevation of 3740 masl. As a part of

this design, a conceptual level construction schedule and quantity estimates were

developed and seepage and stability analyses were performed. The proposed future TMF

raise design (for post-Stage 4 raises) represents a contingency plan, assuming that weak

tailing will be impounded within the TMF throughout the life of the facility. Accordingly,

the proposed design for future raises employs the optimized centerline method. The

following sections discuss the proposed TMF staging schedule and the proposed

configuration for future TMF raises.

5.1

PROPOSED TMF CONSTRUCTION SCHEDULE

A conceptual level TMF construction schedule was developed by MWH to estimate the

optimal crest elevations for the Stage 4 and other future TMF raises to the ultimate crest

elevation of 3800 masl. The major schedule objectives include the following:

Minimize wet season construction to the extent practical

Minimize the required number of raises to reduce the requirements for

construction fleet mobilization

Maintain a minimum of 2 m of freeboard at all times

The following assumptions and conditions were used to develop the schedule:

A uniform tailing deposition rate of 17,000 tpd

Historic construction rates from dam construction to date were used to estimate

the construction durations. To be conservative, a factor of safety of two was

applied to the duration times used in the schedule.

The impoundment volume is based upon stage-storage data developed from

surveys of the existing ground performed by GFLCSA in July and August of 2009

and assumes that the TMF dam will be raised using the centerline method for all

post Stage 3 raises.

The impoundment capacity is based upon the stage-storage data noted above and

expected tailing densities developed from large-strain consolidation modeling

performed by MWH. Additional information describing the large strain

consolidation modeling performed is included in Section 10.3.

Filling of the Las Aguilas impoundment will begin in April of 2010.

A summary of the major conclusions from the TMF construction schedule are as follows:

The proposed TMF construction schedule consists of utilizing an 8 m lift for the

Stage 4 TMF raise (from elevation 3732 masl to 3740 masl) and uniform 6 m lifts

for all subsequent raises, to Stage 14 at elevation 3800.

MWH * 1801 California Street, Suite 2900 * Denver, Colorado 80202 * (303) 291-2222

Gold Fields La Cima Cerro Corona Mine - Stage 4 TMF Raise 3740 m Page 21

March 2010

TMF construction can be performed largely in the dry season (April through

September), with three of the eleven stages being constructed entirely in the dry

season and eleven partially in the wet season. However, given the fact that a factor

of safety of two was applied to all duration times, it is likely that a majority of the

partial wet season construction campaigns could be performed entirely during the

dry season.

No construction is required in years 2016, 2019, 2021, and 2023.

A minimum freeboard of 2 m is maintained at all times, given the assumptions

listed above. The maximum freeboard during the construction of the TMF is 14 m

during the construction of the Stage 4 raise and 8.5 m for all subsequent raises.

Table 3 presents the conceptual level TMF schedule for Stages 4 through 14 (TMF

construction from elevation 3732 masl to elevation 3800 masl). Figure 5 presents the

results graphically, showing the crest elevation of the TMF dam, the UCB, and the TMF

pond with time.

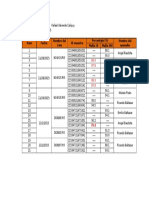

Table 3 Summary of Proposed TMF Construction Schedule

YEAR

FINAL DAM

CREST

ELEVATION

(M)

2010

3740

2011

3746

April

July

6.56

2.96

2012

3752

January

April

3.72

2012

3758

September

December

7.44