Академический Документы

Профессиональный Документы

Культура Документы

Brief Solar Steam Generating Systems

Загружено:

Jatin GaurАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Brief Solar Steam Generating Systems

Загружено:

Jatin GaurАвторское право:

Доступные форматы

Solar Steam generating Systems

Two types of solar steam generating systems; one based on fixed receiver E-W automatically tracked

concentrating technology (Scheffler) and the other on fully tracked receiver on dish technology (Arun) are

under promotion in the country. Whereas the fixed receiver technology is in promotion for last many years

and about 70 systems covering over 20,000 sq. m of dish area have been installed, the fully tracked

technology is under pilot scale demonstration and only 10 dishes with area 1690 sq. m have been installed

as on date.

Fixed receiver E-W tracked technology

A solar steam generating system based on this technology comprises elliptically shaped parabolic solar

concentrators (each of 16 sq. m. size in general) arranged in pairs of sleeping and standing dishes in parallel

modules, aligned in a perfect east west direction. Receivers (heat exchangers painted black) are placed in

the focus of each pair of dishes. Above the receiver is a header pipe half-filled with water. Cold water enters

the receiver through the inner pipe coming from header. Solar rays falling onto the dishes are reflected and

concentrated onto the receivers. Due to the high temperatures achieved, the water within the receiver is

converted into steam.

The steam generated in the system is stored in the upper half (empty portion) of the header pipe and if the

steam is not drawn, the pressure of steam keeps on increasing. The steam is then drawn / sent to the kitchen

for cooking food or to other units for variety of applications including laundry, process heat, sterilization, air

conditioning etc. Each set of dishes of the system is connected with a metal wire rope which is further

connected to a winch having DC motor fixed with a timer mechanism. This mechanism keeps on moving the

dishes in the direction of the sun. This type of tracking system is called central tracking. To ensure that steam

is available even when sun is not there (at night and on cloudy days in monsoon) the Solar Steam

Generating system is connected with a Fuel fired boiler which acts as a back-up system. A typical

photograph of the system installed at Mount Abu may be seen at Annexure-I.

A solar steam system comprising of 96 sq.m of dish area of this technology (6 dishes each of 16 sq. m) may

generate around 150 to 200 kg of steam in a day depending on location and various other features can save

around 4,500 liters of diesel in a year.

Fully automatically tracked large dish technology

It is a Fresnel paraboloid reflecting concentrator (named Arun 160) mounted on a flat dish with downward

facing cavity receiver at its focus designed to absorb the concentrated solar energy and to transfer it for

useful application. The concentrator tracks the sun on two axes, continuously facing it to capture maximum

amount of solar radiation over a day. The dish concentrator along with the receiver is mounted on a specially

designed tower. The system is equipped with a heat retrieval mechanism (which may consist of piping and

fittings, insulation, fluid circulating pump, etc.), and system controls related to tracking, thermal system and

security/ emergency measures.

The configuration of an industrial process heat solar system depends on the respective application. Broadly,

it may consist of one (or more) number of solar dish, specially designed heat exchangers for transferring

solar heat to the existing thermal system in the user industry, fluid pre-treatment equipment and storage

vessel (if required), apart from piping/ fittings, fluid circulating pump(s), insulation, control valves etc. on

application side for delivery of heat as per the requirements. A unit of ARUN-160 dish concentrator having

160 square meter of aperture area was developed and installed at Mahanand Dairy at Latur in Maharashtra

for pasteurization of about 20,000 to 25,000 liters of milk under MNRE sponsored R&D and has been working

satisfactorily since 2006. The dishes are now being installed at various places for different applications under

a field evaluation demonstration project of MNRE.

Each dish of this technology having a weight of around 20 tonne could generate around 600 to 700 of steam

in a day depending on the solar insolation and steam pressure. More dishes could be installed for meeting

the required steam in an establishment at desired temperature and pressure but the initial investment will be

too high. Photograph of a typical two dish system under installation at M/s Maurya Hotel, Delhi for meeting

their part requirement of steam for laundry, kitchen and hot water for guest rooms may be seen at AnnexureII

****

Annexure-I

A Solar steam cooking system installed at Brahmakumaris Ashram, near Mount Abu in Rajasthan

Annexure-II

Solar steam generating system 2 Nos. of Arun dishes at M/s Maurya Hotel, Delhi

Вам также может понравиться

- Depth of ImaginationДокумент2 страницыDepth of ImaginationJatin GaurОценок пока нет

- Abstract FinalДокумент1 страницаAbstract FinalJatin GaurОценок пока нет

- Nehi pata kal hoga kyaДокумент6 страницNehi pata kal hoga kyaJatin GaurОценок пока нет

- Electronic Devices Objective QuestionsДокумент32 страницыElectronic Devices Objective QuestionsJatin GaurОценок пока нет

- Course File ContentДокумент2 страницыCourse File ContentJatin GaurОценок пока нет

- Monitoring in AgricultureДокумент3 страницыMonitoring in AgricultureJatin GaurОценок пока нет

- Auto Car ParkДокумент7 страницAuto Car ParkJatin GaurОценок пока нет

- Two Bit MullДокумент2 страницыTwo Bit MullJatin GaurОценок пока нет

- Optimization MethodsДокумент24 страницыOptimization MethodsJatin GaurОценок пока нет

- Important DI 30 PDFДокумент67 страницImportant DI 30 PDFAvik DasОценок пока нет

- SBI Prelim Model PaperДокумент25 страницSBI Prelim Model PaperCodMwОценок пока нет

- 1011261290767928quantitative AptitudeДокумент5 страниц1011261290767928quantitative Aptitudesweta23mОценок пока нет

- ANNLectДокумент16 страницANNLectJatin GaurОценок пока нет

- Paper WritingДокумент19 страницPaper WritingRiaz KhokharОценок пока нет

- My RM-5 PDFДокумент21 страницаMy RM-5 PDFJatin GaurОценок пока нет

- BSNL TTA Sample Paper 10Документ11 страницBSNL TTA Sample Paper 10konsamОценок пока нет

- Speech CodingДокумент9 страницSpeech CodingsirajbtechОценок пока нет

- Closed and Open Loop Gain LectureДокумент5 страницClosed and Open Loop Gain LectureTaimoor AhmmedОценок пока нет

- Northern India Engineering CollegeДокумент2 страницыNorthern India Engineering CollegeJatin GaurОценок пока нет

- Digital Circuits and Systems Number RepresentationДокумент12 страницDigital Circuits and Systems Number RepresentationJatin GaurОценок пока нет

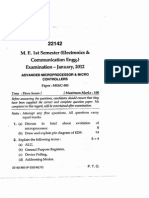

- 2012 M.tech. Ece Cdma System 3rd Sem.Документ4 страницы2012 M.tech. Ece Cdma System 3rd Sem.Jatin GaurОценок пока нет

- MIND: FRIEND OR FOE? HOW TO CONTROL YOUR MINDДокумент1 страницаMIND: FRIEND OR FOE? HOW TO CONTROL YOUR MINDJatin GaurОценок пока нет

- 2011 Jan. Ec Advanced Microprocessor and ControllersДокумент2 страницы2011 Jan. Ec Advanced Microprocessor and ControllersJatin GaurОценок пока нет

- Attendance Report For S4: Roll Number Name of Student Etcs 212 Etme 212 Etcs 202 Etec 204 Etec 208 Etec 206 Etec 210Документ8 страницAttendance Report For S4: Roll Number Name of Student Etcs 212 Etme 212 Etcs 202 Etec 204 Etec 208 Etec 206 Etec 210Jatin GaurОценок пока нет

- 2012-m.tech.-Ece-Advanced Microprocessor & Micro Controllers-1st Sem.Документ2 страницы2012-m.tech.-Ece-Advanced Microprocessor & Micro Controllers-1st Sem.Jatin GaurОценок пока нет

- Syllabus For Written Examination of Work Experience TeacherДокумент8 страницSyllabus For Written Examination of Work Experience TeacherJatin GaurОценок пока нет

- Investigation On Annular-Ring Patch Antenna With EBG StructureДокумент5 страницInvestigation On Annular-Ring Patch Antenna With EBG StructureJatin GaurОценок пока нет

- Antennas PatternsДокумент17 страницAntennas PatternsJohn HakimОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- San Jose Police Department - Joe Gomez IncriminationДокумент2 страницыSan Jose Police Department - Joe Gomez Incriminationchase manuelОценок пока нет

- HW3Документ3 страницыHW3Noviyanti Tri Maretta Sagala0% (1)

- Method Statement of Static Equipment ErectionДокумент20 страницMethod Statement of Static Equipment Erectionsarsan nedumkuzhi mani100% (4)

- RoboticsДокумент2 страницыRoboticsCharice AlfaroОценок пока нет

- CVP Solution (Quiz)Документ9 страницCVP Solution (Quiz)Angela Miles DizonОценок пока нет

- Quality Risk ManagementДокумент29 страницQuality Risk ManagementmmmmmОценок пока нет

- RF Power Measurements Basic PrinciplesДокумент27 страницRF Power Measurements Basic PrinciplesHector Velasco100% (1)

- Assignment 2 - p1 p2 p3Документ16 страницAssignment 2 - p1 p2 p3api-31192579150% (2)

- Machine Design - LESSON 4. DESIGN FOR COMBINED LOADING & THEORIES OF FAILUREДокумент5 страницMachine Design - LESSON 4. DESIGN FOR COMBINED LOADING & THEORIES OF FAILURE9965399367Оценок пока нет

- City Gas Distribution ReportДокумент22 страницыCity Gas Distribution Reportdimple1101100% (9)

- Data Collection Methods and Tools For ResearchДокумент29 страницData Collection Methods and Tools For ResearchHamed TaherdoostОценок пока нет

- Personal InsuranceДокумент11 страницPersonal InsuranceSumit Kumar SharmaОценок пока нет

- Software Engineering Modern ApproachesДокумент775 страницSoftware Engineering Modern ApproachesErico Antonio TeixeiraОценок пока нет

- Optimize Coverage and Performance with 12dB MTMA AmplifierДокумент3 страницыOptimize Coverage and Performance with 12dB MTMA AmplifierpecqueurОценок пока нет

- Macdonald v. National City Bank of New YorkДокумент6 страницMacdonald v. National City Bank of New YorkSecret SecretОценок пока нет

- ApudДокумент53 страницыApudlatifahОценок пока нет

- PHASE 2 - Chapter 6 Object ModellingДокумент28 страницPHASE 2 - Chapter 6 Object Modellingscm39Оценок пока нет

- Leyte Geothermal v. PNOCДокумент3 страницыLeyte Geothermal v. PNOCAllen Windel BernabeОценок пока нет

- Telangana Budget 2014-2015 Full TextДокумент28 страницTelangana Budget 2014-2015 Full TextRavi Krishna MettaОценок пока нет

- The Essence of Success - Earl NightingaleДокумент2 страницыThe Essence of Success - Earl NightingaleDegrace Ns40% (15)

- Exercise Manual For Course 973: Programming C# Extended Features: Hands-OnДокумент122 страницыExercise Manual For Course 973: Programming C# Extended Features: Hands-OnAdrian GorganОценок пока нет

- Library Management System (Final)Документ88 страницLibrary Management System (Final)Ariunbat Togtohjargal90% (30)

- Business Advantage Pers Study Book Intermediate PDFДокумент98 страницBusiness Advantage Pers Study Book Intermediate PDFCool Nigga100% (1)

- Management Reporter Integration Guide For Microsoft Dynamics® SLДокумент22 страницыManagement Reporter Integration Guide For Microsoft Dynamics® SLobad2011Оценок пока нет

- (NTA) SalaryДокумент16 страниц(NTA) SalaryHakim AndishmandОценок пока нет

- Dubai Healthcare Providers DirectoryДокумент30 страницDubai Healthcare Providers DirectoryBrave Ali KhatriОценок пока нет

- Top Machine Learning ToolsДокумент9 страницTop Machine Learning ToolsMaria LavanyaОценок пока нет

- Dewatering Construction Sites Below Water TableДокумент6 страницDewatering Construction Sites Below Water TableSOMSUBHRA SINGHAОценок пока нет

- Sugar Milling Contract DisputeДокумент3 страницыSugar Milling Contract DisputeRomy IanОценок пока нет

- Sound Wave Interference and DiffractionДокумент79 страницSound Wave Interference and DiffractionMuhammad QawiemОценок пока нет