Академический Документы

Профессиональный Документы

Культура Документы

17013

Загружено:

zrilek1Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

17013

Загружено:

zrilek1Авторское право:

Доступные форматы

R. S.

L a d d t

Preparing Test Specimens Using Undercompaction

I D Inside diameter

L Cyclic strength index

Au Change in pore ,water pressure

Aac Change in cell pressure

REFERENCE: Ladd, R. S., "Preparing Test Specimens Using

Undereompaetion," Geotechnical Testing Journal, GTJODJ, Vol. 1,

No. 1, March 1978, pp. 16-23.

ABSTRACT: A specimen preparation procedure is presented that

offers an improved method of preparing reconstituted sand specimens

for cyclic triaxial testing. The method leads to more consistent and

repeatable test results. This procedure (1) minimizes particle segregation, (2) can be used for compacting most types of sands having a

wide range in relative densities, and (3) permits determination of the

optimum cyclic strength of a given sand at a given dry unit weight.

Introduction

The specimen preparation procedure most commonly described

in the literature on cyclic triaxial strength testing [1-3] requires

the sand to be saturated, poured into a water-filled forming mold

(usually attached to the bottom pedestal of a triaxial cell), and

then densified to the required density by some means, usually

by vibrations. This method is referred to herein as the wet-pouring

(pluvial) method.

Several problems are associated with this wet-pouring method.

The two most significant are (1) the segregation of particles when

using silty and relatively well-graded sands, and (2) the difficulty

of readily preparing test specimens having a prescribed dry unit

weight with uniform density. A more precise means of preparing

specimens is needed so that cyclic test results will be consistent,

repeatable, and less influenced by specimen preparation.

Presented herein is a method of reconstituting cyclic triaxial

strength test specimens that minimizes most of the problems

outlined previously. In addition, the concepts presented can be

applied to the preparation of reconstituted test specimens for

other types of tests and materials. It should be noted that there

is no inference here that this method of reconstitution results in

specimens which are representative of in-situ conditions.

The procedure incorporates a tamping method of compacting

moist coarse-grained sand in layers. Each layer is compacted to a

selected percentage of the required dry unit weight of the specimen; this procedure differs from the application of a constant

compactive effort to each layer required by ASTM Tests for

Moisture-Density Relations of Soils, Using S.5-1b (2.5-kg) Rammer and 12-in. (304.8-mm) Drop (D 698-70) and ASTM Tests

for Moisture-Density Relations of Soils, Using 10-1b (4.5-kg)

Rammer and 18-in. (457-mm) Drop (D 1557-70). This new

approach was selected since it is generally recognized (especially

for loose- to medium-dense sands) that when a typical sand is

compacted in layers, the compaction of each succeeding layer can

further densify the sand below it. The method uses this fact to

achieve uniform specimens by applying the concept of undercompaction. In this case, each layer is typically compacted to a

lower density than the final desired value by a predetermined

amount which is defined as percent undercompaction U,. The

U, value in each layer is linearly varied from the bottom to the

top layer, with the bottom (first) layer having the maximum

U. value. The method of variation is illustrated in Fig. 1. (See

KEY WORDS: sands, compaction, triaxial tests, specimen preparation, percent undercompaction, dynamic testing

Nomenclature

~3c Effective isotropic consolidation stress

+--Od Cyclic axial deviator stress

D10, D30, Soil diameters of which 10, 30, 50, and 60% of

D50, and D6o soil weights are finer, respectively

Cc Coefficient of curvature

c. Coefficient of uniformity

D, Relative density

+ tYd/2ff3c Applied cyclic stress ratio

epp Peak-to-peak axial strain

N Number of loading cycles

Ne Number of loading cycles to obtain a given peakto-peak axial strain

Number of loading cycles to failure

N / N f Normalized number of cycles

W T Total wet weight of material required

3/dr Required dry unit weight of test specimen

Wa Average water content (as a decimal) of prepared

material

Vm Final volume of compacted material

WL Weight of material required for each layer

h. Height of compacted material at the top of the

layer being considered

ht Final (total) height of the specimen

nt Total number of layers

n Number of the layer being considered

u. Percent undercompaction for layer being considered

Uni Percent undercompaction selected for first layer

Unt Percent undercompaction selected for final layer

ni First (initial) layer

u. Average percent undercompaction for layers

compacted

1Associate and laboratory director, Woodward-Clyde Consultants,

Clifton, N.J. Member of ASTM.

0149-6115/7810003-0016500.40

16

1978 bythe American Society for Testing and Materials

17

LADD ON SPECIMEN PREPARATION USING UNDERCOMPACTION

in this paper. In addition, to illustrate how the cyclic behavior is

affected by the Uni value selected, a series of cyclic triaxial

strength tests was performed on specimens of Monterey No. 0

sand in which the Uni value was varied.

MaximumValue

nder m

8

,,=,

r~

5

~ n t l

n in la

,on

~x~

Material Tested

-ilerfa~tilrc=nt ii(ir_

The particle size distribution curve and the selected index

properties of the Monterey No. 0 sand, obtained by Mulilis [4],

are shown in Fig. 2 and Table 1, respectively. The sand is a

washed uniform medium-to-fine beach sand (SP). The maximum

and minimum dry unit weight determinations were performed in

general accordance with ASTM Test for Relative Density of

Cohesionless Soils (D 2049-69) and Kolbuszewski's method [5],

respectively. The specimens tested had initial relative densities

Dr of approximately 60%.

compaction

==

MinimumValue

(usuallyzero) n i = 1

nt

LAYER NUMBER

Where: A. Percentunder-compactionin layerbeingconsidered,Un

Un = Uni

pUni- u.tl

L n--~-~_

1 x (n- 1)

Specimen Preparation Procedure

B. Averagepercentunder-compactionfor layerscompacted, On

_ Un

Un= ~

Each test specimen, 74 mm (2.9 in.) in diameter and 152 mm

(6 in.) high, had an initial molding water content of approximately 6% and was compacted in eight layers in a split compaction mold not attached to the triaxial cell ("external" split

compaction mold). Further details of this method of specimen

preparation are given in Appendix A.

After compaction, the split mold was removed and the weight,

height, and diameter of the specimen were measured. The specimen was then placed in the triaxial cell and confined with a

rubber membrane. The triaxial cell was filled with deaerated

water, and a cell pressure o3~ of 36 k N / m z (750 psf) was applied.

Uni = Percentunder-compactionselectedfor first layer

Unt = Percentunder-compactionselectedfor final layer(usuallyzero)

n

= Numberof layerbeingconsidered

ni = First (initial) layer

nt = Total numberof layers(final layer)

FIG. 1--Concept of undercompaction procedure.

also Appendix A.) If this method of variation is appropriate and

the proper/.1, value is selected for the first layer (U,i), the end

product is a specimen having a virtually uniform unit weight

throughout.

The method used to arrive at this proper U,i value is presented

COBBLES

COARSE

FINE

DIAMETER

6"

I-

I-r

r~

so!

70

>.

so

gD

Z

F-

O

rr

4" 3"

s0

4o

20

MEDIUM

3/4"

3/8 "

10

20

l [ Ill ] [

1

1 lI l

~____ [! [ !

I~l

L

1-~

Ig]

I.

3o]

Each specimen was saturated prior to being consolidated by

flushing deaerated water through the specimen under a back

pressure of between 625 and 960 kN/m 2 (13 000 and 20 000 psi).

UNIFIED SOIL CLASSIFICATION SYSTEM

40

60

I

100

200

IliIl'~ I

J Ill

]l[I[

~I]lll

II

Illl

Ill

]l',I]i

[

i!;i

llJ]

-

! II J '.....

' "

'....

+ ~

III[~I[ I I--

.....

IIIt:[:t.:[-

200

100

10

--Ill!Ill- I

1,0

0.1

GRAIN SIZE iN MILLIMETERS

FIG. 2--Particle size distribution curve.

i

i

[I

I

-I-.. -I ....

SILT OR CLAY

FINE

U,S. STANDARD SIEVE SIZE

l'h"

1]:1

Ill[

I~l

Igl

]~l

lffl

[~[

cq,ARSE [

Test Procedure

I[

I

I

I

0.01

0.001

18

GEOTECHNICAL TESTING JOURNAL

TABLE 1--Index data for Monterey No. 0 sand.

Unified soil classification system symbol

Particle size data

Ds0, mm

Cc~

Cu

Dry unit weight data e

Maximum, lb/ft 3

Minimum, lb/ft 3

Test Results and Discussion

The results of the cyclic triaxial strength tests are summarized

in Table 2. A plot of the cyclic strength index versus the percent

undercompaction of the first layer of each specimen is given

in Fig. 3. The cyclic strength index Ic is defined as the ratio of

the number of cycles to obtain a given peak-to-peak axial strain

Are to the product of relative density in percent D, and applied

stress ratio _+ad/2F3~, that is, Ne/Dr( +-Od/253c); Ic was used to

normalize small differences in relative density and applied stress

ratio from one test to another.

The data show that Ic, which is directly related to the cyclic

strength, varies with U,i or the uniformity of dry unit weight

within a test specimen. For the U,i values evaluated (0 to 18%),

the number of cycles to obtain a peak-to-peak axial strain of

10% at an applied stress ratio of 0.26 varied between 16 and 41

(see Table 2). Furthermore, a peak Ic value (optimum cyclic

strength) was obtained. The U,i value where this peak occurred

is defined as the optimum percent undercompaction.

Another important factor in understanding the cyclic behavior

of sand is its strain development characteristics. Axial strain in

compression and extension versus the logarithm of the number of

loading cycles is plotted in Fig. 4. The shapes of the curves vary

considerably, and it was almost impossible to determine trends

visually. To determine whether there was a relationship between

U,i and the strain development characteristics, as was found with

cyclic strength, the cyclic data were normalized. The curves of

the normalized peak-to-peak strain versus the normalized number

of cycles are plotted in Fig. 5. The normalized peak-to-peak

strain e,p/~pp = 10% is defined as the ratio of peak-to-peak

strain at a given number of cycles N to a peak-to-peak strain of

10% (selected failure criteria), while the normalized number of

cycles N / N f is defined as the ratio of the number of cycles required to obtain a given e,p to the number of cycles required to

obtain an Epp of 10%. This figure shows that as U,~ becomes

closer to the optimum percent undercompaction, the normalized

strain development curves become more concave.

SP

0.36

0.9

1.5

105.7

89.3

aCc= (1)30)2/(960 D10).

bcu = D60/D~o.

c 1 lb/ft 3 = 16 kg/m 3.

During back-pressuring, an effective confining stress of 36 k N / m 2

(750 psf) was maintained. This low confining stress minimizes

unrecorded volume changes during saturation; however, if the

specimen has a tendency to swell, higher values should be selected.

In addition, a small axial stress, sufficient to maintain the specimen in an isotropic state of stress, was applied. Saturation was

assumed when the B factor (ratio of the change in pore water

pressure Au to the change in cell pressure Aa~) was equal to or

greater than 95%.

The specimen was then consolidated to the required effective

stress F3~. Changes in volume and axial height were recorded

during consolidation. The relative density of the specimen prior

to cyclic loading is based on these measurements.

The specimens were cyclically loaded without drainage by

using an eleetrohydraulic closed-loop loading system manufactured

by the MTS Systems Corp. The MTS system applied a sinusoidally

varying load about an ambient load at a frequency of 1 Hz.

Therefore, a cyclic sinusoidally varying axial deviator stress +_oa

was applied to the specimen in which the stress varied between

peak compression and peak extension values. During cyclic

loading, the cell pressure was kept constant, and the changes in

axial load, axial deformation, and pore water pressure were

recorded.

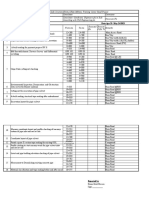

TABLE 2--Summary of results of tests preformed on Monterey sand No. O.

Water Content,

Dry Unit

%

Weight, lb/ft 3a

Test

1

2

3

4

5

6

7

8

9

10

Number of Cycles for

Dr, %

Percent

After

,After

After

Initial

UnderConsoliConsoliConsoliLiquecompaction Initial dation Initial dation Initial dation +_Od/2iY3

c faction

0

2

4

6

8

10

12

14

16

18

6.0

8.8

6.0

5.8

5.8

6.3

5.7

6.0

6.0

6.0

24.7

24.8

24.6

25.6

23.8

24.9

24.2

24.6

25.1

25.3

98.3

98.6

98.5

98.4

98.8

98.0

98.2

98.5

98.5

98.5

99.2

99.4

99.7

99.3

99.5

98.9

99.1

99.3

99.3

99.6

59.2

60.8

60.3

59.8

61.7

57.2

58.7

60.3

60.1

60.4

64.0

65.5

67.2

65.0

66.3

62.6

63.8

65.0

65.0

66.9

0.26

0.25

0.26

0.26

0.26

0.25

0.26

0.26

0.26

0.26

24

23

33

33

20

22

19

30

18

10

Peak-to-Peak

Strain, %

2.5

10

20

Remarks b

24

22

33

33

19

22

18

28

18

9

26

24

36

36

22

24

20

30

20

11

30

28

41

40

27

29

25

35

24

16

54

42

67

57

62

47

44

64

130

43

see Note 1

see Note 1

see Note 1

see Note 1

see Note 1

see Note 1

see Note 1

a 1 lb/ft 3 = 16 kg/m 3.

b Notes:

1. A significant (> 10%) decrease in peak-to-peak axial load occurred after a peak-to-peak axial strain of 10% had occurred.

2. Test specimens were 74 mm (2.9 in.) in diameter by 152 mm (6 in.) in height and were compacted in eight layers by using the moist tamping method presented in Appendix A.

3. Consolidation pressure 03c equaled 44.6 kN/m 2 (2088 lb/fl 2).

19

LADD ON SPECIMEN PREPARATION USING UNDERCOMPACT~ON

Symbol

Peak to Peak

Axial Strain, %

O

A

5

lO

Test Conditions

Relative Density, Dr (%)

After

(~-3c

ConsoliInitial

Ib/ft 2

57-62

Note:

63-67

2,088

Stress

Ratio

+_ l:Td/2 ~3c

0.25-0.26

1 KN/m 2 = 20.88 Ib/ft 2

Number of Cycles to Obtain a Given

X

,,'

E3

z

-1iL9

zuJ

n~

.J

~D

>cD

Cyclic Strength Index = Peak to Peak Axial Strain

Relative Density (%) x Stress Ratio

Optimum Cyctic

Strength Index - ~

/0

A --. _ A l l

E)

O

~ 1

I

0

I

2

I

4

Optimum Percent Under-Compaction

6

I

8

I

10

I

12

I

14

I

16

I

18

PERCENT UNDER-COMPACTION OF FIRST LAYER

FIG. 3--Cyclic strength index versus percent undercompaction of first layer for Monterey No. 0 sand.

Conclusions

A specimen preparation procedure is presented in Appendix A

that offers an improved method of preparing reconstituted sand

specimens for cyclic strength testing. The method leads to more

consistent and repeatable test results and a reduction in the

number of uncertainties inherent in presently used procedures.

This procedure, termed the undercompaction procedure, (1) minimizes particle segregation, (2) can be used for compacting most

types of sands, which have a wide range in relative densities, and

(3) permits determination of the optimum cyclic strength of a

given sand at a given dry unit weight.

Acknowledgment

Portions of this investigation were sponsored by the Professional

Development Program of Woodward-Clyde Consultants (WCC).

This support is acknowledged with appreciation. Special acknowledgment is given to P. Dutko of WCC who developed the percent

undercompaction equations. Members of the staff of WCC who

made considerable contributions are, in particular, K. Hau,

H. M. Horn, Y. Kim, and J. H. Wilson. Special thanks are also

due to D. Koutsoftas of Dames and Moore, M. L. Silver of the

University of Illinois at Chicago Circle, and D. J. Leery of Langan Engineering Associates for their reviews of and comments on

this paper.

APPENDIX A--RECONSTITUTED

SPECIMEN PREPARATION PROCEDURE

FOR COARSE-GRMNED SOILS

A procedure is presented below for preparing coarse-grained

specimens for dynamic cyclic testing or static triaxial testing.

The procedure (1) produces specimens that have a relatively

uniform stress-strain response, (2) minimizes the tendency for

particle segregation, and (3) can be used to compact most types

of coarse-grained soils, with a relative density ranging between

very loose and very dense. Although the procedure has been

developed for the preparation of cohesionless test specimens, the

concepts presented can be applied to the preparation of many

different material types for various types of tests.

Specimens can be prepared either by attaching a split mold to

the bottom pedestal of the triaxial cell ("internal" split mold), as

shown in Fig. 6, or in a split mold which is separate from the

triaxial cell ("external" split mold), as shown in Fig. 7. A split

mold is required since it eliminates many of the problems associated with the extrusion of the compacted specimen from a nonsplit mold. Most specimens, especially those containing fines,

compacted in an external split mold at relative densities above

about 50%, will have sufficient strength as a result of capillary

force so that they may be set up in the triaxial cell without significant change in their fabric. However, extreme care is required

in transferring specimens to avoid disturbing the specimen.

1. Adjust the water content of the air-dried material so that

that initial degree of saturation of the compacted material will be

between 20 and 70%. Oven-drying of the material is not recommended. The lower the percentage of fines in the material, the

lower the degree of saturation required. A degree of saturation

greater than 70% can be used if water does not bleed from the

specimen during compaction. The material should be mixed with

water about 16 h before use.

2. Determine the average water content of the prepared material using a minimum of t~vo determinations.

3. Assemble and check all the necessary equipment to be

used in preparing the test specimen. Determine the inside diameter and the height of the mold to within _+0.02 mm ( 0.001

20

GEOTECHNICAL TESTING JOURNAL

20

15

10

uJ

Percent under c o m p a c t i o n value

'for first layer

Z

<

eT-

.~_

10

i I

~pp = 10%

@

20

<

X

<

15

UJ

o.

10

15

10

50

100

200

NUMBER OF CYCLES

FIG. 4--Axial strain versus number o f cycles for Monterey No. 0 sand.

in.) and calculate the volume based on these measurements. If an

internal split mold is used, correct the diameter measurement for

the average thickness of the rubber membrane.

4. Select the number of layers to be used in the preparation of

the specimen. The maximum thickness of the layers should not

exceed 25 mm (1 in.) for specimens having diameters less than

102 mm (4 in.). Typically, the required number of layers increases

as the required dry unit weight increases. Layers having a thickness of about 12 mm (V2 in.) are recommended.

5. Determine the total wet weight of material required for

sample preparation:

WrfT~r

x (1 + w = ) x

Vm

6. Determine the moist weight of material required for each

layer:

WL = WT/nt

7. For the first layer to be compacted, select a value of Uni.

Typically, this value ranges between zero for the preparation of

dense specimens to about 15% for the preparation of very loose

specimens. For the preparation of very dense specimens, it has

been found that negative values are sometimes required. Each

subsequent layer receives a lesser percentage of undercompaction,

conforming to the relationship shown in Fig. 1.

The correct (optimum) value of percent undercompaction may

be determined experimentally by one of the following methods:

a. Run a series of cyclic triaxial strength tests with the same

effective consolidation stress and applied stress ratio, but with

different U,i values, to determine the optimum value (see Fig. 8).

b. Observe the behavior of the specimen during cyclic loading. Excessive necking or bulging in a layer or layers, either at

LADD ON SPECIMEN PREPARATIONUSING UNDERCOMPACTION

21

1.0

O Percent-under-compaction

of First i a y e r

//~J

II

Q.

t~

z"

<n o0

v

<

LU

0.75

0.5

,ncreasingCyc,,cStrength

v

<

LU

a.

E3 0.25

LU

N

.J

<

nO

z

0.2

0.4.

0.6

0.8

NORMALIZEDNUMBEROF CYCLES,N/Nf = N/N Cpp = 10%

1.0

FIG.5--Normalized peak-to-peak strain versus normalized number of cycles.

6-in.Travel---..._.~.~

Vertical Dal ~[~

~Tamping Rod

I-

~ Z ~ )

Rae

fmep~n~

eG~i~llarAssembiy

Bushings

I

MembraneProtection

Collar

RubberMembrane

CompactionF o o t ~

I--]

(Diameter=V2ID

~L]TJ

of Mold)

- ' ~

PorousStone ~

VacuumApplied

~

Split Mold

v"/////'~ n l ~

1I

TriaxialCell

=~[.

n

O-Ring

~[ ~ B o t [lt o m Drani age

ValvesLine

Top DrainageLine

FIG.6--Split compaction mold attached to triaxial cell ("internal" split mold).

22

GEOTECHNICAL

6-In. Travel

Vertical

TESTING

JOURNAL

Dial

Vertical Dial Setting-h n, Inches

?

~i

Reference-Collar

~j~

/',

____~

Ihitial'Vertieal S~tting R, Inches

I-~

-Bushing.

~,f---Tamping Guide Assembly

--.

I

I~"

/'I,I

Collar-~

I1

i\ .,.,%

lI' l _l

E=

Compaction Foot

///~-

(Diameter='A ID

of Mold)

~/Spacer'/~

/ 1 / /

II

Bottom Porous Stone

2 " I X / /1

K////'/

SYSTEM PRIOR TO COMPACTION

t~-~

"1

II

II

II

II

I//A/

/J

Air Outlets

' I

/

/ / / / //

SYSTEM DURING COMPACTION

~/,Spacer//

If

, !

i;l

I;i

l,,

Ill

'11

Hi

'

//

III I

'

IP

X / / /

,i i

/V

II./

/

Spacer-Disk Assembly

, rCo

.~

L/

iv"

,I

ar

"~

I1

~-~

Sintered Brass

Disk

SYSTEM FOR COMPACTIONOF FINALLAYER

FIG. 7--"External" s p l i t

the top or at the bottom of the specimen, indicates a specimen

with an inappropriate value of U.z.

c. Observe the behavior of the specimen during unconsolidated-undrained loading. Nonuniform vertical strains indicate

an inappropriate value of U.z.

d. Observe the fabric of the specimen. A honeycomb structure at either the top or the bottom of the specimen indicates an

inappropriate value of U.i.

e, Measure the dry unit weight of the prepared test speci-

compaction

mold.

men as a function of its height. A dry unit weight not uniform

with height indicates an inappropriate value of U.i.

8. Calculate the required height of the specimen at the top of

thenth layer:

23

LADD ON SPECIMEN PREPARATION USING UNDERCOMPACTION

"',\

cl

I

15

i~ 8

~

u

o

~g

I

I

I

I

~-

Material sensitive t o percent under compaction

\

\

\

\

\

Material relatively insensitiveto percent

under compaction

PERCENT UNDER COMPACTION OF FIRST LAYER

FIG. 8--Expected relationship between strength index and percent

undercompaction of first layer.

9. Weigh the amount of material required for the layer, as

determined in Step 6, and place it into a closed container. If

each layer requires a weight greater than about 80 g, it is usually

easier to weigh the amount of material required for each layer

and place it into small closed containers.

10. Adjust the reference collar on the tamping rod to obtain

the proper h , . Weigh, if you have not already done so, the

amount of material required for the layer, and place it into the

mold. During weighing, care must he taken to lose as little

moisture as possible. Using the tamping rod, guided by the

tamping guide assembly, compact the surface of the material

(after it has been leveled) in a circular pattern starting at the

periphery of the mold and working toward the center of the mold.

Initially, a light tamping force should be used to distribute and

seat the material uniformly in the mold. The force should then

be gradually increased until the reference collar uniformly hits

the top of the tamping rod guide assembly. For the last few coverages, it may be necessary to hit the tamping rod with a rubber

mallet in order to compact the material into a dense state. Next,

scarify the compacted surface to a depth equal to about one tenth

of the thickness of the layer.

11. Repeat Steps 9 (if required) and 10 until the last layer is in

place. During the compaction of the last layer, the tamping rod

should be used until the surface of the compacted material is

about 0.4 mm (1/64 in.) higher than required. Then, for specimens

prepared in an external split mold, place the spacer disk assembly into position and lightly strike it with a rubber mallet

until it is seated; see Fig. 7. For specimens prepared with the

internal split mold, place the top cap and the porous stone

directly on the specimen. The top cap should be attached to the

loading piston, which, in turn, should be guided by the bushing

located in the top of the triaxial cell. Then lightly strike the

loading piston with a rubber mallet until the compacted material

reaches the prescribed height. This procedure ensures that there

is proper alignment and seating of the top cap in relation to the

specimen and the loading mechanism of the triaxial cell.

12. For specimens compacted in an external split mold,

remove the specimen from the split mold (using extreme caution

to prevent disturbance) and obtain its weight, height, and diameter. The weight should be determined to the nearest 0.01 g;

however, for specimens weighing greater than 1000 g, measuring

to the nearest 0.1 g is adequate. The height and diameter should

be determined to the nearest 0.02 mm (0.001 in.) using a dial

gage comparator. The dial gage contact points on these instruments should have a flat surface with a minimum diameter of

about 5 mm (IA in.).

For specimens compacted in an internal split mold, the initial

weight cannot be directly checked. Therefore, the oven-dry

weight of the specimen should be checked after the test. However, the height and diameter of the compacted specimen should

be measured after a slight vacuum is applied and the mold is

removed. A pi tape (Pi Tape, Lemon Grove, Calif.) is recommended for measuring the diameter.

The author has also used this procedure, with some modifications, for compacting fine-grained soils and found that appropriate specimens are obtained much more readily than when the

Harvard compaction apparatus [6] is used. In the latter case, one

must determine experimentally the appropriate compactive effort

(number of layers, number of tamps per layer, and the tamping

force) required to obtain the prescribed value of ~/dr"

A brief description of the required modifications is as follows:

a. A U,i value of zero should be used.

b. The compaction of each layer is initiated by using a Harvard tamping device [6], having a spring force of 18 kg

(40 Ib) and with a compaction foot having a diameter

equal to about 1/4 the diameter of the specimen. The

compaction is continued by using this tamper until the

surface of the material is relatively level. The tamping

force should be reduced if the compaction foot appears to

penetrate below the proper h, value. Then the tamping

rod, as mentioned in Step 10, is used to compact the

material to the proper h, value.

References

[1] Finn, W. D. L., Picketing, D. J., and Bransby, P. L., "Sand

Liquefaction in Triaxial and Simple Shear Tests," Journal of the

Soil Mechanics and Foundations Division, Proceedings of the American Society of Civil Engineers, Vol. 97, No. SM4, April 1971, pp.

639-659.

[2] Lee, K. L. and Fitton, J. A., "Factors Affecting the Cyclic Loading

Strength of Soil," in Vibration Effects of Earthquakes on Soils and

Foundations, STP 450, American Society for Testing and Materials,

Philadelphia, 1969, pp. 71-95.

[3] Lee, K. L. and Seed, H. B., "Dynamic Strength of Anisotropically

Consolidated Sand," Journal of the Soil Mechanics and Foundations

Division, Proceedings of the American Society of Civil Engineers,

Vol. 93, No. SM5, Sept. 1967, pp. 169-190.

[4] Mulilis, J. P., "The Effects of Method of Sample Preparation on the

Cyclic Stress-Strain Behavior of Sands," Ph.D. dissertation, University of California, Berkeley, 1975.

[5] Kolbuszewski, J. J., in Proceedings of the Second International Conference on Soil Mechanics and Foundation Engineering, Rotterdam,

1948, Voi. 7, pp. 47-49.

[6] Wilson, S. D., "Suggested Method of Test for Moisture-Density

Relations of Soils Using Harvard Compaction Apparatus," in

Special Procedures for Testing Soil and Rock for Engineering Purposes, STP 479, American Society for Testing and Materials, Phila-

delphia, 1970, pp. t01-103.

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Bearing Capacity of Shallow FoundationДокумент49 страницBearing Capacity of Shallow FoundationMuhammad Faisal Habib JanjuaОценок пока нет

- Fib HandbookДокумент75 страницFib Handbooknandi_scrОценок пока нет

- Topic 4 Cable Size and Wiring MethodДокумент64 страницыTopic 4 Cable Size and Wiring MethodYuen Chan100% (1)

- Coarse Grained Soil Vs Fine Grained SoilДокумент1 страницаCoarse Grained Soil Vs Fine Grained Soilnixen99_gellaОценок пока нет

- Design of An Elevated Compressor Table Top Structure Considering Soil-Pile-Structure InteractionДокумент11 страницDesign of An Elevated Compressor Table Top Structure Considering Soil-Pile-Structure InteractionMin KhantОценок пока нет

- Simpson Strong-Tie CFS Designer ManualДокумент44 страницыSimpson Strong-Tie CFS Designer ManualCarsonBakerОценок пока нет

- BPC Bridge Beam Manual 3rd Edition V2Документ62 страницыBPC Bridge Beam Manual 3rd Edition V2Eloy Jimenez OntiverosОценок пока нет

- EC3 - Tension Member - 2021Документ27 страницEC3 - Tension Member - 2021MUHAMMAD AMIRUL ASYRAF BIN MOHD RANIОценок пока нет

- 751.24 LFD Retaining Walls Sept 2011Документ94 страницы751.24 LFD Retaining Walls Sept 2011Robert BallОценок пока нет

- 1.5 Practice Questions & Answers - 1 PDFДокумент5 страниц1.5 Practice Questions & Answers - 1 PDFMega GamesОценок пока нет

- 21 Mar 17Документ1 страница21 Mar 17zrilek1Оценок пока нет

- 17mar17 PDFДокумент1 страница17mar17 PDFzrilek1Оценок пока нет

- 17mar17 PDFДокумент1 страница17mar17 PDFzrilek1Оценок пока нет

- 16jan17 PDFДокумент1 страница16jan17 PDFzrilek1Оценок пока нет

- DETERMINATIN OF THECONTENTOfDELTAFERRITE IN AUSTENITIC STAINLESS STEEL NITRONIC 60 PDFДокумент4 страницыDETERMINATIN OF THECONTENTOfDELTAFERRITE IN AUSTENITIC STAINLESS STEEL NITRONIC 60 PDFEmad A.AhmadОценок пока нет

- Metallurgy II - Annealing Normalizing and TemperingДокумент3 страницыMetallurgy II - Annealing Normalizing and TemperingTamás HalasiОценок пока нет

- Finite Element Considerations Mat FoundionДокумент7 страницFinite Element Considerations Mat FoundionAhmed Al-Amri100% (1)

- Federal Highway Administration PublicationsДокумент6 страницFederal Highway Administration PublicationsaduladorОценок пока нет

- Design of Staircase: Prof Ts DR Abd Latif Saleh Assoc Prof DR Izni Syahrizal IbrahimДокумент95 страницDesign of Staircase: Prof Ts DR Abd Latif Saleh Assoc Prof DR Izni Syahrizal IbrahimRuben OoiОценок пока нет

- Sealfl Ex: Description Method of UseДокумент4 страницыSealfl Ex: Description Method of UseramiОценок пока нет

- Ambo University Hachalu Hundessa CampusДокумент22 страницыAmbo University Hachalu Hundessa Campusmagnifco100% (1)

- Design of Truss Roof: University of Engineering & Technology, TaxilaДокумент21 страницаDesign of Truss Roof: University of Engineering & Technology, TaxilaSanthaguru KaruppagnaniarОценок пока нет

- Tribological Aspects of Engine ComponentsДокумент39 страницTribological Aspects of Engine Componentsjamesv52_743942786Оценок пока нет

- AITC Technical Note 19Документ7 страницAITC Technical Note 19klb75Оценок пока нет

- CV311 Assignment 1Документ4 страницыCV311 Assignment 1Rolland JohnОценок пока нет

- Surveying Monthly Report MAY 2023.Документ3 страницыSurveying Monthly Report MAY 2023.AshebirОценок пока нет

- Civil715 S2 2018Документ9 страницCivil715 S2 2018Cheng FuОценок пока нет

- Analysis of Doubly Reinforced Concrete BeamДокумент4 страницыAnalysis of Doubly Reinforced Concrete BeamAnton_Young_1962Оценок пока нет

- Aerodinamica InglesДокумент42 страницыAerodinamica InglesGabriela AlcantarОценок пока нет

- Reinforced - Successful Case StudyДокумент12 страницReinforced - Successful Case Studyemadsafy20002239Оценок пока нет

- LabEx No. 2 Flexural Strength of WoodДокумент6 страницLabEx No. 2 Flexural Strength of WoodianzkieeОценок пока нет

- Revised IRR To National Building Code InjunctionДокумент70 страницRevised IRR To National Building Code InjunctionrolandoriОценок пока нет

- Columns and Struts ModifiedДокумент140 страницColumns and Struts ModifiedManoj CmОценок пока нет

- Superior DVT8 Installation PDFДокумент35 страницSuperior DVT8 Installation PDFMark NelsonОценок пока нет