Академический Документы

Профессиональный Документы

Культура Документы

Pressure Transducer PTH

Загружено:

LibinАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pressure Transducer PTH

Загружено:

LibinАвторское право:

Доступные форматы

92 100/112 ED

PTH

PRESSURE TRANSDUCER

SERIES 20

p max 40 - 100 - 250 - 400 bar

DESCRIPTION

This series of pressure transducers has been designed in order to be used for the main industrial applications and on moving

machines.

The main feature of this transducer is to ensure its functioning also in bad working conditions, especially for what concerns the

fluid temperature range which can go from a minimum of - 40 C up to a maximum of + 120 C

The functioning of this transducer is based on the strain-gauge principle, which is powered by an electric circuit developed

according to the SMT technology which ensures a high reliability and maximum resistance to vibrations and mechanical

stress.

Every component which is in contact with the fluid is made of stainless steel and the transducer is completely fluid-proof.

The protection class of the electrical connection is IP65 for the version with DIN connector, while the version with the M12

connector has a protection class IP67.

They are available with current output signal 4 20 mA or with voltage output signal 0 10 V and they have the reverse

polarity protection.

These transducers are available in 4 different pressure ranges, from 40 to 400 bar.

HYDRAULIC SYMBOLS

TECHNICAL CHARACTERISTICS (see paragraph 3)

Nominal pressure PN

bar

40 - 100 - 250 - 400

High dynamic pressure

% PN

75

Maximum pressure

% PN

200

Class of precision

% PN

0,5

V

mA

0 10

4 20

-40 / +120

Output signal

voltage

current

Working temperature range

92 100/112 ED

PTH-*/20E0-*

PTH-*/20E1-*

1/4

PTH

SERIES 20

1 - IDENTIFICATION CODE

P T H -

/ 20 E

Electrical connection

K10 = Reduced electrical

connector DIN 43650

(standard)

K12 = electrical connector

M12 (on request)

Pressure transducer

High dynamic performance

Output signal

0 = 0 10 V

1 = 4 20 mA (standard)

(Other types of output

signal are available on

request)

Nominal pressure

040 = 40 bar

250 = 250 bar

100 = 100 bar

400 = 400 bar

(other pressure values are available upon request)

Series N. (the overall and mounting dimensions remain

unchanged from 20 to 29)

Integrated electronics with analogic output

NOTE: the standard hydraulic connection is with threaded port of G 1/4 DIN 3852 and integrated seal.

Other types of connection are available upon request.

2 - OVERALL AND MOUNTING DIMENSIONS

PTH-*/20E*-K10

dimensions in mm

1/4"BSP

29.5

Integrated plain seal in

viton

Hexagonal: spanner 27

Tightening torque

25 Nm max

Reduced electrical

connector DIN 43650

delivered with the

transducer

19

25

2

12

Pg7

37.5

76

PTH-*/20E*-K12

92 100/112 ED

Integrated plain seal in

viton

Hexagonal: spanner 27

Tightening torque

25 Nm max

Electrical connector 5 pin

M12 - IP67 PG7

EC5S/M12L/10 cod.

3491001001 (to be

ordered separately)

2/4

PTH

SERIES 20

3 - TECHNICAL CHARACTERISTICS

bar

40

100

250

400

Maximum pressure

x PN

x2

x2

x2

x2

Cracking pressure

x PN

x6

x5

x4

x 3,5

Nominal pressure PN

E0

E1

0 10 V

4 20 mA

mA

< 12

23

Supply voltage

DC V

12 30

10 28

Load resistance

2,5

see par.. 4.2

Response time

ms

<1

Class of precision

% PN

0,5

Hysteresis

% PN

0,2

Repeatability

% PN

0,05

Linearity

% PN

0,2

Stability after 1 million cycles

% PN

0,1

- 40 / + 120

% PN

Output signal

Max current consumption

Working temperature range

Thermal drift from 0 to + 100 C

Immunity 61000-6-2

Emission 61000-6-3

In compliance with EC standards

Vibration resistance

> 20 G

Pressure connection

G 1/4 with integrated seal

3 poles + earth DIN 43650 reduced connector for K10 connection

Electrical connection

M12x1 4 pin straight connector for K12 connection (upon request)

Protection class (EN 60529)

IP 65 for K10 connection

IP 67 for K12 connection

Ambient temperature range

- 20 / + 80 for K10 connection

- 25 / + 85 for K12 connection

Body material

AISI 304

0,1 kg

Mass

4 - TRANSDUCERVOLTAGE

1000

4.1 - PTH-*/20E0-*

We report the functioning diagram of the transducer.

The VTA area represents the functioning zone of the transducer

related to the chosen load resistance RL . We recommend a power

supply voltage of 24 VDC and a load resistance of 700 Ohm.

VT

600

MA

500

MI

NI

400

300

200

10

VRL (Volts)

700

MASSIMA V TA

4.2 - PTH-*/20E1-*

800

RL (Ohms)

These transducers have been equipped with voltage stabilizer

which supplies the electric circuit with constant voltage,

independently from power supply voltage.

We recommend a stabilized power supply voltage of 24 VDC.

20

900

AREA V TA

100

0

0

10

15

20

24 28

25 30

VTA (Volts)

35

40

45

50

N.B. Outside the VTA area the correct functioning of the

transducer is not assured.

92 100/112 ED

3/4

PTH

SERIES 20

5 - WIRING DIAGRAMS

PTH-*/20E0-K10

3

REG

1

OP

2

3

1 = output 0 10 V

2=0V

3 = 12 30 VDC

4 (indicated on the connector by the symbol

) = GND

1 = output 4 20 mA

2 = 10 28 VDC

3 = not connected

4 (indicated on the connector by the symbol

) = GND

PTH-*/20E1-K10

2

REG

1

OP

2

3

PTH-*/20E0-K12

2

REG

OP

3

5

1

1 = not connected

2 = 10 30 VDC

3=0V

4 = output 0 10 V

5 = GND

PTH-*/20E1-K12

4

REG

1

OP

3

5

1

1 = output 4 20 mA

2 = not connected

3 = not connected

4 = 10 28 Vdc

5 = GND

DUPLOMATIC OLEODINAMICA S.p.A.

20015 PARABIAGO (MI) Via M. Re Depaolini 24

Tel. +39 0331.895.111

Fax +39 0331.895.339

www.duplomatic.com e-mail: sales.exp@duplomatic.com

92 100/112 ED

REPRODUCTION IS FORBIDDEN. THE COMPANY RESERVES THE RIGHT TO APPLY ANY MODIFICATIONS.

4/4

Вам также может понравиться

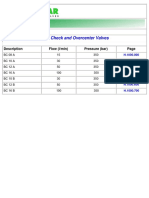

- Pilot Check and Overcenter Valves: Description Flow (L/min) Pressure (Bar)Документ1 страницаPilot Check and Overcenter Valves: Description Flow (L/min) Pressure (Bar)LibinОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Needle Valves: Description Flow (L/min) Pressure (Bar)Документ1 страницаNeedle Valves: Description Flow (L/min) Pressure (Bar)LibinОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

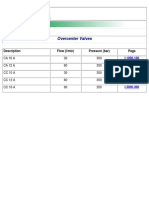

- Overcenter Valves: Description Flow (L/min) Pressure (Bar)Документ1 страницаOvercenter Valves: Description Flow (L/min) Pressure (Bar)LibinОценок пока нет

- Solenoid Valves: Description Flow (L/min) Pressure (Bar)Документ1 страницаSolenoid Valves: Description Flow (L/min) Pressure (Bar)LibinОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- 7 ValvesДокумент6 страниц7 ValvesLibinОценок пока нет

- Sequence Valves: Description Flow (L/min) Pressure (Bar)Документ2 страницыSequence Valves: Description Flow (L/min) Pressure (Bar)LibinОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Check Valves: Description Flow (L/min) Pressure (Bar)Документ1 страницаCheck Valves: Description Flow (L/min) Pressure (Bar)LibinОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Solenoid Valves: Dimensions (MM) Hydraulic DiagramДокумент2 страницыSolenoid Valves: Dimensions (MM) Hydraulic DiagramLibinОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Sequence Valves: Description Flow (L/min) Pressure (Bar)Документ1 страницаSequence Valves: Description Flow (L/min) Pressure (Bar)LibinОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Solenoid Valves: Dimensions (MM) Hydraulic DiagramДокумент2 страницыSolenoid Valves: Dimensions (MM) Hydraulic DiagramLibinОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Vaa /ru /DL 38: Pressure Relief ValvesДокумент2 страницыVaa /ru /DL 38: Pressure Relief ValvesLibinОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Conversion ChartДокумент1 страницаConversion ChartLibinОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Hydraulic Integrated Circuits: Description Flow (L/min) Pressure (Bar)Документ1 страницаHydraulic Integrated Circuits: Description Flow (L/min) Pressure (Bar)LibinОценок пока нет

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramДокумент2 страницыPressure Relief Valves: Dimensions (MM) Hydraulic DiagramLibinОценок пока нет

- VC 5 VДокумент3 страницыVC 5 VLibinОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- High Performance Vane Pump: V A N E P U M P SДокумент2 страницыHigh Performance Vane Pump: V A N E P U M P SLibinОценок пока нет

- VM3B / VM3B1: High Performance Vane MotorДокумент2 страницыVM3B / VM3B1: High Performance Vane MotorLibinОценок пока нет

- Vaddl 38: Pressure Relief ValvesДокумент2 страницыVaddl 38: Pressure Relief ValvesLibinОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Suction StrainerДокумент2 страницыSuction StrainerLibinОценок пока нет

- INOX 350bar LeafletДокумент6 страницINOX 350bar LeafletLibinОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Flow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3Документ4 страницыFlow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3LibinОценок пока нет

- High Performance Double Vane Pumps: Porting DiagramsДокумент1 страницаHigh Performance Double Vane Pumps: Porting DiagramsLibinОценок пока нет

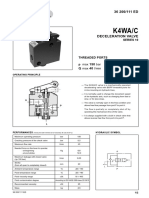

- Decceleration Valve, Cam Operated K4WA CДокумент2 страницыDecceleration Valve, Cam Operated K4WA CLibinОценок пока нет

- Modular Throttle Valve NG4, Type QTM2Документ2 страницыModular Throttle Valve NG4, Type QTM2LibinОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- El MeligyДокумент7 страницEl Meligysystematic reviewОценок пока нет

- Hedayati2014 Article BirdStrikeAnalysisOnATypicalHeДокумент12 страницHedayati2014 Article BirdStrikeAnalysisOnATypicalHeSharan KharthikОценок пока нет

- Uji Stabilitas Tablet Floating Ranitidin HCL: Pengaruhnya Terhadap Sifat Fisik Dan Profil Disolusi Dalam Medium SGF Tanpa PepsinДокумент16 страницUji Stabilitas Tablet Floating Ranitidin HCL: Pengaruhnya Terhadap Sifat Fisik Dan Profil Disolusi Dalam Medium SGF Tanpa PepsinZeaa MaysОценок пока нет

- Upper Gi f1 Survival GuideДокумент1 страницаUpper Gi f1 Survival GuideNathan Hovis JeffreysОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Human Evolution SE Skull Analysis GizmoДокумент9 страницHuman Evolution SE Skull Analysis GizmoTamia WashingtonОценок пока нет

- Governance, Business Ethics, Risk Management and Internal ControlДокумент4 страницыGovernance, Business Ethics, Risk Management and Internal ControlJosua PagcaliwaganОценок пока нет

- Boge FLEX PET SystemsДокумент4 страницыBoge FLEX PET SystemsAir Repair, LLCОценок пока нет

- Audio AmplifierДокумент8 страницAudio AmplifierYuda Aditama100% (2)

- FRMUnit IДокумент17 страницFRMUnit IAnonОценок пока нет

- AIPMT 2009 ExamДокумент25 страницAIPMT 2009 ExamMahesh ChavanОценок пока нет

- Aplication Pipe and Tube - Nippon SteelДокумент29 страницAplication Pipe and Tube - Nippon Steelmatheus david100% (1)

- Apport D Un Fonds de Commerce en SocieteДокумент28 страницApport D Un Fonds de Commerce en SocieteJezebethОценок пока нет

- API Filter Press - Test ProcedureДокумент8 страницAPI Filter Press - Test ProcedureLONG LASTОценок пока нет

- ICT ContactCenterServices 9 Q1 LAS3 FINALДокумент10 страницICT ContactCenterServices 9 Q1 LAS3 FINALRomnia Grace DivinagraciaОценок пока нет

- EarthWear Clothier MaterialsДокумент1 страницаEarthWear Clothier MaterialsZhining LimОценок пока нет

- Jis C 8156-2017, EngДокумент32 страницыJis C 8156-2017, Eng7620383tlОценок пока нет

- Carotenoids-Birkhäuser Basel (1971)Документ934 страницыCarotenoids-Birkhäuser Basel (1971)feghbalibОценок пока нет

- Stas Final ReviewerДокумент8 страницStas Final ReviewerShane SaynoОценок пока нет

- Revised Man As A Biological BeingДокумент8 страницRevised Man As A Biological Beingapi-3832208Оценок пока нет

- הרצאה- אנמיה וטרומבוציטופניהДокумент87 страницהרצאה- אנמיה וטרומבוציטופניהliatfurmanОценок пока нет

- Evolution of Fluidized Bed TechnologyДокумент17 страницEvolution of Fluidized Bed Technologyika yuliyani murtiharjonoОценок пока нет

- EdExcel A Level Chemistry Unit 4 Mark Scheme Results Paper 1 Jun 2005Документ10 страницEdExcel A Level Chemistry Unit 4 Mark Scheme Results Paper 1 Jun 2005MashiatUddinОценок пока нет

- RX Gnatus ManualДокумент44 страницыRX Gnatus ManualJuancho VargasОценок пока нет

- Primary Tooth Pulp Therapy - Dr. Elizabeth BerryДокумент52 страницыPrimary Tooth Pulp Therapy - Dr. Elizabeth BerryMihaela TuculinaОценок пока нет

- Industrial Attachment ReportДокумент34 страницыIndustrial Attachment ReportOtsile Charisma Otsile Saq100% (1)

- Calamansi: Soil and Climatic RequirementsДокумент4 страницыCalamansi: Soil and Climatic Requirementshikage0100% (1)

- Celgene V Actavis AbraxaneДокумент131 страницаCelgene V Actavis AbraxaneiphawkОценок пока нет

- 006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapДокумент20 страниц006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapEko Budi HartantoОценок пока нет

- An Agriculture Testament Albert HowardДокумент297 страницAn Agriculture Testament Albert Howardjagadeeshsunkad100% (1)

- Lecture 8: Separation DesignДокумент45 страницLecture 8: Separation DesignRavi Kiran MОценок пока нет