Академический Документы

Профессиональный Документы

Культура Документы

FRS Electrical Panel Spec EOI

Загружено:

Travis WoodОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

FRS Electrical Panel Spec EOI

Загружено:

Travis WoodАвторское право:

Доступные форматы

GOVERNMENT OF INDIA

MINISTRY OF RAILWAYS

lR;eso t;rs

FUNCTIONAL REQUIREMENT SPECIFICATION

FOR

MANUFACTURE & SUPPLY OF MODULAR AND FLEXIBLE

ELECTRICAL PANELS

RESEARCH DESIGNS & STANDARDS ORGANIZATION

MANAK NAGAR, LUCKNOW - 226 011

Page 2 of 20

FUNCTIONAL REQUIREMENT SPECIFICATION FOR

MANUFACTURE & SUPPLY OF MODULAR AND FLEXIBLE ELECTRICAL

PANELS

0.0

FORWORD:

This Specification defines the objective guidelines and requirement for the design

manufacture and supply of modular and flexible electrical panels & enclosures.

1.0

GENERAL:

1.0.1 The tenderer shall furnish the following information:1.0.2 Name of manufacturer & country of manufacture.

1.0.3 Credentials of firm as manufacturer of panels.

1.0.4 Description of electrical panels installed during the last five years with the

name of the parties/buyers to whom supplies was made, date of installation and

performance certificate thereafter.

1.0.5 Details of testing facilities at manufacturers works.

1.0.6 Whether manufacturer has technical collaboration with another firm, if so

provide details regarding the same.

1.2 The tenderer shall bring out clearly any additional feature which he deems fit

to include to give a complete and comprehensive offer. He shall, however, explain

reasons for offering such additional features/items in his proposal.

2.0

SCOPE:

The scope of supply & services shall include the design manufacturing, testing &

supply of panels as per enclosed list.

3.0

CLIMATIC CONDITIONS:

3.1 The Panels should be manufactured accordance to covered all the following

mentioned conditions.

3.2 The climatic condition specified in this clause are average conditions, any

specific conditions specified in the tender documents shall override these.

Atmospheric

temperature

Humidity

Reference

site

conditions

(a) Short term peak : +50C

(b) Maximum on a 24Hours avg. : +35C

to 40C

(c) Minimum temp. : -10C

100% saturation during rainy season.

i)

Ambient Temp. : 50 C

ii)

Relative Humidity : 50% at 40C

iii)

Altitude: 1000m above sea level

Page 3 of 20

Rain fall

Atmosphere

during hot

weather

Pollution

level

Wind speed

4.0

Very heavy in certain areas.

Extremely dusty and desert terrain in

certain areas. The dust concentration in

air may reach a high value of 1.6 mg/m.

In many iron ore and coalmine areas, the

dust concentration is very high affecting

the filter and air ventilation system.

Humid and salt laden atmosphere with

maximum. pH value of 8.5, sulphate of

7mg per liter, max. concentration of

chlorine 6 mg per liter and maximum

conductivity of 130 micro siemens/cm.

High wind speed in certain areas, with

wind pressure reaching 150kg/m

STANDARDS

The Panel shall conform to the following Indian / international Standards as

amended /revised till date unless stated otherwise, as applicable:

S.No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Specification No.

IEC60051/ IS - 1248

Description

For Direct acting indicating analogues

electrical measuring instrument

IEC60947/IS-13947

For Low-voltage switchgears & control

gear

IEC 60439-1

For Low voltage switchgear & control

gear assemblies.

IEC 60529 / IS For Degree of protection provided by

13947 part 1

enclosures ( IP Codes )

EN 61641

For accidental arc conditions

DIN - 43671

For Bus-bar Current rating.

DIN - 3168

For climate control unit for distribution

box / concept testing marking.

DIN VDE 0100

For Outdoor panels painting.

DIN 50961-2000 and

For mounting plates.

IS 1573-1986

DIN 43668

For cam lock with double-bit insert

IS : 5138

For quality of sheet steel

IS : 3072

For installation of switchgear

IS : 1554

For control wiring

IS : 2516

For Air-circuit breaker

IS : 7098 (part-1)

For LT Cables

IS : 2705 part-III 1964 For CTs

IS: 3043

For earthling

IS: 2384-1964

For capacitors

DIN EN ISO 1520,

For Anodic dip coat priming.

2815 & 2409

DIN EN ISO 1520,

For Textured powder coating

Page 4 of 20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

2815 & 2409 &

9227NSS

DIN 53 577

For Testing elastic foamed material.

Determination of the compress strength

DIN 53 504

For Testing of rubber. Tensile test

DIN EN ISO 1798

For Flexible cellular polymeric materialsdetermination of the tensile strength and

elongation strength ( ISO 1798 : 1997);

German version EN ISO 1798 : 1999

DIN 53 508

For Testing of rubber. Accelerated ageing

DIN75200

For Determination of burning behavior of

interior materials in motor vehicles

EN ISO 1856

For Flexible cellular polymeric materials.

Determination of the compression set

IEC 60255

For Electrical Relays

IEC 60255 / IS - 3231 For Electrical Relays

IEC 609473 / IS - For On load isolators

13947

IEC 60629 2 / IS For Low voltage fuses

13705

IEC 60439-1 / IS - For Low voltage switchgear & control

8623

gear assemblies.

IEC 60947-2/IS13947 For MCCB,

-part 2.

IEC 60898/IS 888281995

IEC 60947-4-1

UL 489/ IEC 609472/ IS13947 -part 4.

For MCB

For Contactors

For MPCB

For material of copper Bus-Bars

DIN EN 13601

IEC 60439-1: 1999, For guidelines for the different

separation types

Annex D,

Other standards shall be applicable provided the stipulation of such a

standard is at least equal to the requirement of the specified standards.

5.0

PANEL SPECIFICATION:

5.1

General :

Frequency

Voltage Variations

Frequency Variations

5.2

50Hz.

+10%.

+3%.

33 kV.

11 kV.

System :

High Voltage Level

Medium Voltage Level

Page 5 of 20

Low Voltage Level

Design Form

5.3

415V.

3 Phase, 4-wire ( TPN )

Construction

5.3.1. Enclosure:

Enclosure should be of Single sheet sturdy frame section construction of sheet

steel as per IS: 5138, consisting of folded rolled hollow frame section punching in

25mm DIN pitch pattern. All profile edges are radiuses. The corners are stiffened

with welded zinc die-cast corner connectors with load bearing capacity of 1.5 Tons

of static load.

5.3.2 Rear wall:

Rear Panel /Rear Wall should be made with 1.5mm thick cold rolled sheet steel,

with foamed-on seal which should be removable.

5.3.3 Roof panel:

Roof panel should be made with 1.5 mm thick sheet steel with foamed-on seal and

should be removable.

5.3.4 Side panels:

Side panel should be made with 1.5mm thick sheet steel, with a foamed-on seal

and fixing screws. All parts should have been prepared for the attachment of earth

straps.

5.3.5 Surface finish:

Sheets should be cleaned and Nano ceramic coated, electro-dip coat primed and

powder coated with textured polyester RAL 7035.

5.3.6 Doors:

Doors should be made with 2 mm sheet steel, flush-mounted, with foamed-in seal,

vertical perforated mounting strips fitted on both sides (door stiffeners) and screwfastened hinges. Hinges can be fitted on the left or right for single-door enclosures,

130 opening angle as per VDI (retrofittable to 180), cam lock with double-bit

insert as per DIN 43668

5.3.7 Mounting plate:

The mounting plate should be as per DIN 50961 2000 and IS: 1573 1986, 2 - 3

mm sheet steel with system punchings, depth-adjustable stud mountings, without

spangles, zinc-plated @ 120 GSM (Gram per Square Meter).

Page 6 of 20

5.4

Busbar System

5.4.1 Bus bar & associated connections shall be constructed from 99.98% E-Cu

(Electrolytic Grade of Copper) with tinning thickness of 4 to 5 microns as per DIN

EN13601 with bus-bar rating according to DIN 43 761 standard. Tiniing is done to

avoid oxidation of copper.

5.4.4 The bus-bar support shall be of Polymide fiberglass reinforced with fire

protection corresponding to UL 94 V0.

5.4.5 The bus-bar system shall be capable of withstand stress due to fault current

of up to.

35kA for one second below 800A.

50kA for one second 800 1600A.

75kA for one second 1600 3200A

110 kA for one second for 4000A.

The bus-bar cover shall be complied with UL 94 V0. Tested under IEC60439.

5.4.6 Heat shrinkable sleeves should be provided for identification and protection.

5.4.7 Hardware used in bus-bar system should be of high tensile strength of grade

8.8 or better.

5.5

Painting / Surface treatment

5.5.1 The manufacturer should have RoHS compliance for painting process &

painting should comply with DIN EN ISO 1520, 2815 2409. Anodic dip coat

painting & textured powder coating performance shall be as per DIN EN ISO 9227

NSS. Alternatively, Painting process should comply with IS 3618- class -c for

phosphating (Tri catena zinc - phospahte)& Powder coating as per IS 101 & IS

13871 and Coating weight to confirm the requirement of IS 2618. In order to

ensure optimum corrosion protection in all climatic zones, Aluminum or

Galvanized/zinc plated metal with subsequent Nano-ceramic/zinc-phosphate &

powder coating should be used with the materials that are specified to be intended

for outdoor application.

5.5.2 The thickness of paint should be 70 135 micron.

5.5.3 Properties of Powder Paint

5.5.3.1 External Applications

The Polyester powder paint should be cured polyester powder paint; Triglycidyl

Isocyanurate (TGIC) should provide a wide range of desirable properties.

5.5.3.2 Indoor Applications

Page 7 of 20

For indoor applications, Epoxy painting should be used. Epoxy has excellent

property for corrosion resistance but inferior in case of UV.

5.5.3.3 Other Properties

The powder paint should resist any corrosion resulting from scratches, and nicks.

Even without a primer coat, powder paint should provide excellent resistance to

corrosion. The paint should also offers excellent protection at sharp edges on metal

fabricated items. Powder painting is stated to be the most flexible coating on the

market. The paint should not crack or lose adhesion when exposed to a bend with

a radius of 1/8 inch or impact of 160 inch pounds. TGIC should have flexibility

properties of the E-coating as well as withstand long-term exposure to heat up to

300F. Corrosion resistance properly should be confirmed as per ASTM B-117.

5.6

Gasket

The gasket should be of tri functional (functioning as a sealant, elastic in nature

and non- water absorbant), CFC free Polyurethane Gasket to provide maximum IP

protection & can withstand a temperature range of -40C to +90C.

It should comply with burning behavior According to DIN755200; also flexible

cellular polymeric materials should be used according to EN ISO 1856 and DIN EN

ISO 1798. Gasket should with stand Compress strength of 5 kPa to 200 kPa (at

25% compression) according to DIN 53 577. Gasket should with stand tensile

strength up to 2 MPa [N/cm] according to DIN53 504. Gasket should be long

lasting according to DIN 53 508. Gasket should be with stand high temperature

according to DIN 75200.

5.6.1

It should Capacity to withstand high temperature: PU gasket should

withstand 180 C/15 minutes.

5.6.2 High Adhesiveness:

Gasket should be with good quality of Adhesive or mixture of liquid Polyurethane

and Isocyanide (Resin & Hardener) & should be poured on the door/covers by a

CNC machine. Upon drying the mixture should solidifies and gets bonded to the

surface of the part permanently.

5.6.3 It should have Hygroscopic feature that is Polyurethane gasket should be non

hygroscopic.

5.7 Control wiring

All control wiring, indication etc. shall be carried out using 650V grade 1.5 sqmm

copper conductor cables PVC insulated conforming to IS 1554 Part-I. CT wiring

shall be with 4/2.5 sqmm copper conductor with suitable CT shorting links. Wiring

shall be suitably protected within the switchboard. Runs of wires shall be neatly

bunched and suitably supported and clamped. Means shall be provided for easy

identification of the wires. Identification ferrules shall be used at both the ends of

the conductors.

5.8

Earthing

Page 8 of 20

The panel shall be provided with copper earth bus running throughout its length as

per IS: 3043. Suitable earthing eyes/bolts shall be provided on the main earthing

bus to connect the same to the earth grid at site. Sufficient no. of star washers

shall be provided at joints to achieve earth continuity between panels and sheet

metal parts.

5.9

LT Cables

All cables shall be of suitable size copper & Aluminium Conductor, armoured,

XLPE insulated and rated for 1.1kV grade as per IS 7098 (part-1) 1998.

5.10 Terminals

All the control, instrumentation and protection wiring shall be provided with

COMPUTERISED Printed PVC ferrules at both ends for long life.

5.11 Name Plate

The panel as well as the feeder compartments door shall be provided with the name

plates giving the feeder description as required.

5.12 Basic Design Parameter

5.12.1 The enclosure should be provided with a degree of protection as per IEC

60529 / IS: 13947 part 1, of not less than IP-54 for indoor and IP-55 with Rain

Canopy and Fan-Filter /outlet filter with Hood for all outdoor mounted panels.

5.12.2 The enclosure should be provided with bus-bar cover (UL 94 V0) made of

Polymide (PA6.6) running all along the length of the switchgear in a separate

enclosure & also It should compliance for any accidental arc conditions as per EN 61641.

5.12.3 Vertical Bus bars shall run at the middle of two adjacent panels to take off

for individual feeders. The Bus bars shall be fully shrouded with bus-bar cover (UL

94 V0) heat shrinkable PVC sleeve to ensure safety of operation when rear doors

are opened.

5.12.14 The switchgear and distribution panels with ACBs & MCCB`s shall be

front operated with Breaker operating knobs clearly indicating position of Breaker

ON / OFF / TRIP.

5.12.15 The switchgear and distribution panels shall be interlocked from door

such that only after tripping of the ACB`s or MCCBs the front door can be opened.

5.12.16 Even with the door closed,

shall be achieved. Rack in / Rack

position can be done with the door

facility to lock the Breakers in service

the test / service position of Breaker (ACB)

out of Breaker from above test to isolated

closed from outside. It shall have a locking

& test positions.

5.12.17 The enclosure should be with insertion of an extended arm the Breaker

can be fully drawn out from the compartment but remains mechanically attached

Page 9 of 20

to the panel so that routine inspection and maintenance checks can be easily

carried out.

5.12.18 The Panel should be Form 1 for LT distribution Panels below 800A as per

IEC 60439-1: 1999, Annex D

5.12.19. The Panel should be Form 4a for LT distribution Panels above 800A as per

IEC 60439-1: 1999, Annex D,

5.12.21 Incomer shall have facility to receive emergency stop push button from

field. These buttons through relay contacts shall be wired to incomer shunt trip in

a way that it trips the breaker whenever emergency push button pressed in field.

Incomer all have operating handle at the outside of that door and an emergency

stop push button.

5.12.22 Incomer shall have RYB lamp indication, On Off & Trip indication, &

Digital ammeter shall be operated through CT and suitably rated PT shall be

provided for Digital Voltmeter

5.12.23 All bus-bar shall be made with Electrolytic Grade of Copper E-Cu 99.98%

purity as per DIN EN 13601with current rating acc. to DIN 43 761.

5.12.24 All cable shall be FRP type with copper conductor.

5.12.25 CTs wherever used shall be resin cast type.

5.12.26 The selection of components shall be made in accordance with feeder

rating keeping 20% extra.

5.12.27 There shall be suitable provision for termination of cable Cu. / Al. from

field.

5.12.28 There shall be separate bus-bar chamber at the top for horizontal busbar.

5.12.29 Minimum 300mm clearance shall be maintained between floor & last

terminal row.

5.12.30 MCC shall have 3 phase 4 wire 50 Hz system i.e. TPN.

5.12.31 In future MCC should have provision to get expended at both ends.

5.12.32 The Panels shall be of single front, double access type having feeder

controls located in the front and vertical Bus bars and cable chamber located in the

rear. Control and selector switches, Push Buttons, indicating instruments, lamps

protective relays, single phasing relays shall be mounted on the front doors of the

respective compartments. Current Transformers and Circuit Breaker control

circuits shall be mounted on the fixed portion of the compartment; CTs shall not be

directly mounted on the Buses.

5.12.33 Suitable liberally designed barriers shall be placed between Circuit

Breakers and all control protective and indication circuits, equipment including

Instrument Transformers. External cable connections shall be carried out in a

Page 10 of 20

separate cable compartment. Separate cable chambers shall be provided for Power

& Control cables.

5.12.34 After isolation of the power and control connections of a circuit, it shall be

possible to safely carry out maintenance in a compartment with the Bus bars and

adjacent circuit in `live' condition.

5.12.36 All the assembly or installation for Low-voltage switchgears & control

gears assemblies should be as per IEC 60947 or IEC 60439 1, & IS : 3072.

5.12.37 All the enclosure climate control unit, like panel AC, etc, if required

should be as per DIN 3168.

5.13 Cable Entry

5.13.1.1 Cable entries in the Cabinets/ SCADAs, /Power/Control cubicles &

other equipments shall be sealed with EPDM Modular based Cable sealing

system with technology based on Multidiameter.

5.13.1.2 The EPDM Modules should be "Low Smoke Index, Halogen free crosslinkable rubber compound based on EPDM (Ethylene - Propylene Diene

Terpolymer).

5.13.1.3 One single module should seal a cable of several different diameters.

5.13.1.4 The system should ensure foolproof protection against hazards induced

by" Water, Dust, Humidity, & Rodents. The sealing system must have built in

spare capacity i.e. option for adding more cables in to the same system.

5.14 Switchgear

The typical requirements of switchgear required to be housed in the electrical

panels are given as under:

5.14.1 ACB

5.14.1.1 Air circuit breaker shall be suitable for a continuous current rating as

specified for each type of panels. Air circuit breakers shall be with microprocessor

release of O/L, S/C, E/F conforming to IS2516. The typical requirements for a

1600 A ACB are as follows:Rated service voltage:

Rated insulation voltage:

Rated impulse withstand voltage:

Continuous rated current:

Capacity of the neutral pole:

Short circuit breaking capacity:

Short circuit making capacity:

Operating temperature:

Frequency:

Version:

Protection:

600 VAC

1000 VAC

12 kV

1600 A

1600 A

42 kA min

80 kA min

[C] -25+70

f [Hz] 50 - 60

Electrically operated drawout type.

O/L, S/C & E/F

5.14.1.2 Necessary isolating plugs and sockets.

Page 11 of 20

5.14.1.3 Necessary independent manual spring closing mechanism with

mechanical ON/OFF indicator as well as electrical ON/OFF indication to be

provided at front panel.

5.14.1.4 Necessary set of auxiliary switches and indication, metering requirements

such as ON/OFF indication, selector switches fuses.

5.14.1.5 ACB shall have motor operated charging system and suitable under

voltage relay.

5.14.1.6 Whenever two or more supplies are available /ACB's shall be electrically

& mechanically interlocked by providing suitable control circuit& devices.

5.14.2 MCCB

5.14.2.1 All the MCCBs shall be rated for at least 35 kA and from the approved

makes.

5.14.2.2 Operating mechanism shall be Quick-make, quick-break, trip free.

5.14.2.3 This shall be independent of manual speed of operation. Contacts shall

not be teased into position, nor can the breaker be held closed under fault

conditions.

5.14.2.4 Shall have Clear indication of ON, OFF and TRIP position.

5.14.2.5 All MCCBs shall be provided with operating handles to be fixed on the

panel door.

5.14.2.6 Facility to push to trip to verify healthiness of mechanism shall be in

built.

5.14.2.7 All parts of circuit breaker shall be enclosed in heat resistance insulating

material housing

5.14.2.8 Silver alloy contacts should have long electrical life and there should be

no arcing on the current carrying part of the contact

5.14.2.9 Terminals shall have large dimensions to accept links or cable lugs are

separated by insulated barriers with adequate clearances.

5.14.2.10 The MCCBs shall comply with the requirements of IEC 609472/IS13947 -part 2.

5.14.3 Capacitors

5.14.3.1 The capacitor shall be of heavy duty suitable for 3ph, 440V, 50Hz as per

IS 13340/1993

and shall be available in 5, 10, 15, 20 and 25 KVAR capacities. . The capacitors

above 15 KVAR Module shall be hermetically sealed and assembled easily in sheet

steel containers with Stud type Terminals. Capacitors shall be suitable for Indoor

use up to ambient temp. of 55 degree C. Sealed in strudy corrosion proof, sheet

steel Containers and impregnated with non-inflammable Synthetic liquid. The

capacitors above 15 KVAR Module shall be hermatically sealed and assembled

easily in sheet steel containers with Stud type Terminals.

5.14.4.2 Capacitors shall be hermitically sealed in sturdy corrosion proof, sheet

steel containers and impregnated with non-inflammable synthetic liquid. The

capacitors shall withstand voltage of 2500V (power frequency test voltage). The

insulation resistance shall not be less than 50 megohm when tested with 500V

megger.

5.14.4 MPCB

Page 12 of 20

5.14.4.1 There should be manual and local control, when the motor circuitbreaker is used on its own, and automatic and remote control when combined with

a contactor

5.14.4.2 Motor protection should provided by thermal-magnetic devices built into

the circuit-breaker

5.14.4.3 No live parts should be accessible to direct finger contact

5.14.4.4 The addition of an undervoltage trip enables the motor circuit-breaker to

be tripped if voltage is lost

5.14.4.5 The addition of a shunt trip should enable remote control of tripping

5.14.4.6 The control for the open or enclosed motor circuit-breaker should be

locked in the N/C" position using 3 padlocks

5.14.4.7 The MPCB should comply with the requirements UL 489/ IEC 60947-2/

IS13947 -part 4.

5.14.5 MCB

5.14.5.1 The fault current of MCBs shall not be less than 10KA at 230 V. The

MCBs shall be flush mounted and shall be provided with trip free manual operating

mechanism.

5.14.5.2 The circuit breaker dollies shall be of the trip free pattern to prevent

closing the breaker on a faulty circuit.

5.14.5.3 The MCB contacts shall be silver nickel and silver graphite alloy and tip

coated with silver. Proper arc chutes shall be provided to quench the arc

immediately.

5.14.5.4 MCBs shall be provided with magnetic fluid plunger release for over

current and short circuit protection. The overload or short circuit device shall have

a common trip bar in the case of DP and TPN miniature circuit breakers. All the

MCBs shall be tested and certified as per Indian Standards, prior to installation.

5.14.5.5 The MCB should comply with the requirements IEC 60898/IS 888281995

5.14.6 Contactors

5.14.6.1 The contactors shall have minimum making and breaking capacity in

accordance with utilization category AC3 and shall be suitable for minimum Class

II intermittent duty.

5.14.6.2 If the contactor forms part of a distribution board then a separate

enclosure is not required, but the installation of the contactor shall be such that it

is not possible to make an accidental contact with live parts.

5.14.6.3 The Contactor should comply with the requirements IEC 60947-4-1.

5.14.7 Current Transformer

CT s should be cast resin type. They shall be of accuracy class 10 P 10/5 P 10 ( as

per requirement) of IS 2705 part-III 1964, Where ammeters are called for C.T.s

shall be provided for current measuring. Each phase shall be provided with

separate current transformer of accuracy Class I and suitable VA burden for

operation of associated metering and controls.

Page 13 of 20

5.14.8 Push Buttons

The push button unit shall comprise of the contact element, a fixing holder, and a

push button actuator. The push button shall be momentary contact type. The

contacts shall be of silver alloy and rated at 10 Amps. continuous current rating.

The actuator shall of standard type and colour as per its usage for ON, OFF and

TRIP. Wiring for Remote ON, OFF push button is to be required.

5.14.9 Indicating Lamps

Indicating lamps assembly shall be screw type with built in resistor having non

fading color lens. LED type lamps are required. Wiring for Remote ON, OFF, TRIP

indicating lamp is required.

5.14.10 Indicating Instrument & Metering

5.14.10.1 All electrical indicating instruments shall be of digital type with 25mm,

3 digital display as per IS : 1248 or IEC - 60051. The size of the meter shall be 96

Sq.mm and shall be suitable for flush mounting with only flanges projecting on

vertical panels. Instruments shall conform to latest IS and shall have accuracy

class of 1.0. All meters of reputed make and approved by the Corporation shall be

supplied.

5.14.10.2 Wattmeter shall be of static type with accuracy Class of 1.0 type.

5.14.10.3 Voltage and Current circuits shall be arranged in such a way that they

do not appear in adjacent terminal blocks.

b. Care shall be taken to see that no block shall have more than two wires in a

terminal.

5.14.10.4 KWH meter shall be of 3 Phase microprocessor based of accuracy class

0.5, suitable for measurement of unbalanced loads in 3 Phase, 4 wire circuits.

Ammeter, voltmeter and wattmeter shall be of reputed make and approved by

Corporation.

5.14.11Terminals

5.14.11.1 Terminal blocks (both for power and control circuits) shall be of the

650V grade stud type, links between each pair of studs, washers, nuts & lock

nuts. The studs shall be securely locked within the mounting base to prevent their

turning. Insulated barriers shall be provided between adjacent terminals.

5.14.11.2 Terminal blocks shall be adequately rated to carry the current of the

associated circuit.

5.14.11.3 Terminal blocks shall be arranged with at least 50mm Clearance

between two sets of terminal blocks,

5.14.11.4 Control terminals for external connection shall be suitable for

terminating at least conductors each of 2.5Sq.mm size.

5.14.12 Space Heaters & Lighting Outlets

Page 14 of 20

Space heaters of capacity 60W suitable for connection to the single phase A.C

supply shall be provided inside all Cubicles, Panels and Switch boards at the

bottom to prevent condensation of moisture. Wiring connected to the space heaters

in the cubicle shall have porcelain beaded insulation over a safe length from the

heater terminals. All switchboards, cubicles etc., shall be provided with suitably

located lighting outlets and 15A, 3 pin powers plugs with sockets. The lighting

switch shall be provided inside each entrance door at the back of the panels.

5.14.13 Name & Identity Plates

5.14.13.1 Name & identity plate should be 25mm wide white/black Aluminium

plates.

5.14.13.2 All components (i.e. MCCBs, MCBs, Fuses, Contactors, auxiliary

contactors, relays, switches etc.,) inside the panel and out side the panel shall be

labeled with the above mentioned plastic plates and fixed permanently on the panel

beneath each component.

5.14.13.3 All labels shall comprise of black letters on white background. Labels

shall be made of 3ply lamicoid. They shall be properly fixed, with provision to

prevent distortion due to expansion.

Size of labels and lettering are subject to

Corporations approval.

5.14.14Ventilation

The rear enclosing sheets, and all front covers for the Breakers of heavy capacity if

considered necessary, shall be provided with Fan-Filter and outlet filter unit

combination to prevent entry of dust and vermin into the panel and giving IP

54 protection.

5.15 Make of Components

The make of the components to be used in the Electrical panel should be from the

CEEs approved list of the concerned zonal railway. In case, the item doesnt feature

in the list then it should procured from sources having proven design in similar

applications

6.0

SCHEDULE OF TESTS

6.1.0

GENERAL

6.1.1 Only after all the designs and drawings have been approved and

clearance given to this effect by RDSO, the manufacturer shall take

up manufacture of the prototype unit.

6.1.2 The contractor shall submit a detailed test plan, for approval of

RDSO, consisting of test procedures, schematic/circuit diagrams,

items/parameters to be checked and values required as per

specification for each of the tests and the number of days required to

Page 15 of 20

complete all the tests at one stretch. The schedule shall also indicate

the venue of each of the tests.

6.1.3 The routine/acceptance/type tests to be carried out on the panels, as

part of above inspection, are given in para 6.2.0 below.

6.1.4 Prototype inspection shall be witnessed by RDSO as per the approved

test plan. RDSO reserve the right to witness the complete or part of

the tests at their discretion.

6.1.5 During the process of type testing or even later, the DG/EM/RDSO,

Lucknow, reserves the right to conduct any additional test(s), besides

those specified in the test plan herein, on any equipment/item so as

to test the equipment/item to his satisfaction.

6.1.6 The tests shall be conducted on the prototype Panel at the works of

the manufacturer or at any NABL/Government approved test house

or laboratory in the presence of authorized representative of

DG/EM/RDSO. Contractor shall submit the complete test report

consisting of full details of the tests and test parameters.

6.1.7 On successful completion of the tests prototype approval certificate

shall be issued.

6.1.8 Series manufacture shall start only after issue of prototype approval

by RDSO. Acceptance tests, as per the approved test plan, on the

balance quantity shall be done by the authorized representative of the

Indian Railways as per purchase order.

6.1.9 Six copies of the following test certificates shall be submitted to

the

Purchaser for record:6.1.9.1 Type test certificate as issued by RDSO for the panels.

6.1.9.2 Acceptance test certificate for complete lot of the panels.

6.1.9.3 Routine test certificates for each panels.

6.1.10 Test certificates shall be completed with all the results. Purchasers

approval shall be obtained before dispatch of electrical panels.

6.1.11 Manufacturer shall advise the purchaser one month in advance when

the panels shall be ready for inspection and tests, so that the latters

representatives may be deputed to witness the test(s).

6.1.12 No material shall be shipped or dispatched until inspection and tests,

upto the satisfaction of the purchaser, have been completed.

6.1.13 Notwithstanding the successful completion of the tests as above, the

contractor shall be fully responsible for the satisfactory performance

of the panel as per the specification, without any prejudice to any

claim, right or privilege of the purchaser arising out of use of defective

design, material or manufacturing by the contractor.

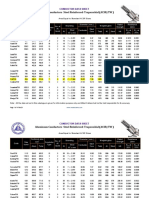

6.2.0 TESTS:

The test plan, including the sampling plan for various rating of panels, shall be got

approved by RDSO before carrying out the test. Following tests shall be carried out

on the panel as a minimum:

S.

No

General Test Conditions

Performance Tests

Temperature-rise

1.1

Type

Test

Routine

Test

Acceptance

Test

Test

Procedure

Sub Clause (

As per IEC

60947-2 )

8.3.2.5

Page 16 of 20

8.3.3.1

8.3.3.2

8.3.3.3

8.3.3.4

Short-circuit

breaking

capacities

Short-time withstand current

(where applicable)

8.3.4

8.3.5

8.3.6

1.9

Performance

of

integrally

fused circuit-breakers

8.3.7

1.1

Mechanical operation

Tripping

limits

and

characteristics

Dielectric properties

HV test on power & control

circuits ( 2.0kV for one

minute )

Earth continuity test with a

low voltage tester

8.4.1

8.4.2

8.4.3

Insulation test with 500V

megger before & after H.V.

test

Gasket test ( as per details

given below

5.1

Shore 00 hardness for type

(Soft) enclosure 40 + 5

Shore 00 hardness for type

(Hard) enclosure 55 + 5

Shore 00 hardness for type

(Outdoor) enclosure 55 + 5

Shore 00 hardness for type

(Silicon) enclosure 55 + 5

1.2

1.3

1.4

1.5

1.6

1.8

1.8

2

3

5.2

5.3

5.4

5.5

5.6

5.7

5.8

Tripping

limits

and

characteristics

Dielectric properties

Operational

performance

capability

Overload performance (where

applicable)

2

3

S

Compression hardness

[N/mm]

at 25% compression 0.02

0.01 /0.03 0.01

at

40%

compression

0.04 0.01 / 0.08 0.01

Min.

tensile

strength

(approximation)0.150.2

N/mm

Min. elongation at break

75%

Max. water absorption 1-

and

ASTM

97

ASTM

97

ASTM

97

ASTM

97

D2240D2240D2240D2240-

DIN 53504

DIN EN

1798

ISO

Page 17 of 20

5.9

5.10

5.11

5.12

5%

Water penetration >2-4 h

Temperature

resistance

30 minutes 180-300C

Max. change of Shore A(00

hardness +/- 20%

Max. change of tensile strength

+/- 20% after heat ageing

5.13

Heat ageing (168 hrs @ 100200deg C)

5.14

Compression set [%]

Measurement after 24h and

50%

compression,

at

corresponding temperature

at T @ 70C = 10

at T @ -40C = 10

Confirmed

continuous

temperature [C]

@ - 40 to 80C

5.15

6

6.1

6.2

6.3

6.4

6.5

7

7.1

7.2

7.3

ASTM D224097

DIN53504

DIN EN ISO

1798

DIN 53572

AA-TL03-A 4

Bus-Bar Support and Main

Bus-Bar Test ( as per details

given below)

Temperature rise limits ace.

chapter

Dielectric

properties

ace.

Chapter

Short-circuit

withstand

strength ace. chapter

Effectiveness

of protective

circuit ace. chapter

Clearances

and

creepage

distances ace. chapter

Sub Clause (

As per IEC

60439-1 )

8.2. 1

8.2.2

8.2.3

8.2.4

Paint Test ( as per details

given below)

Flexibility(Mandrel

5/8mm dia.

bend)

Cupping test 4mm

Adhesion test (Scratch hatch)

test

Impact resistance TEX

7.4

7.5

Impact resistance Glossy/SG

Din EN ISO

1519/

IS

13871

Din EN ISO

1520

DIN EN ISO

2409

(ASTM

D

2794-69)/ IS

13871

(ASTM

D

2794-69)

Page 18 of 20

7.6

7.7

7.8

Corrosion resistance

Thickness

Tests on Primer

ASTM B-117,

Annex C of IS

2075,DIN

50961

IS 13871

IS 2075

6.2.2 Tests on Cable Entry Sealing System6.2.2.1 Following shall constitute the type tests

1. Water Ingress Test

2. Pull Test

1

Water Ingress Test

i) OBJECTIVE: To determine the water tightness of the Cable Transit System

when subjected to spray of water.

ii) TEST EQUIPMENT: A holding arrangement / fixture of sufficient dimension

to house the Cable Transit System.

iii) INITIAL EXAMINATION: The Cable Transit System shall be assembled with

all its components like modules, stay plates, wedge etc. and a continuous

cable passing through its any module.

iv) CONDITIONING: The cable transit system in its assembled condition shall be

secured at holding arrangement / fixture. The water shall be sprayed with a

pressure of 12.5 l/min and the distance between nozzle & test item shall be

2.5m to 3.0 m. at a normal room temperature. This test shall meet the

requirement as per IEC 60529.

v) DURATION: The test to be done for a 3 min in all direction.

vi) FINAL EXAMINATION: The Cable Transit System shall be examined

externally for any abnormality. The Cable Transit System shall be visually

examined at other side of system for any ingress of water.

vii) ACCEPTANCE: The Cable Transit System will be declared to have passed the

water ingress test in case there is no water vapour presents other side of the

transit system.

2

i)

Pull Test

OBJECTIVE: To check the strength and holding of the cable by module

inside the Cable Transit System.

ii) TEST EQUIPMENT: A holding arrangement / fixture of sufficient dimension

to house the Cable Transit System.

iii) METHOD: The Cable Transit System

should be assembled with a long

length of cable so that it can be pulled to the required force of 80N to check

the strength of module inside the Transit System.

Page 19 of 20

iv) ACCEPTANCE: The cable transit system will be declared to have passed the

pull test in case there is no movement of cables or modules.

6.2.2.2 Following test shall be done to carryout the acceptance of the product.

1) Visual Examination- The Cable Sealing System shall be examined

physically for the workmanship and the design

technology employed. It

shall be checked for any

flaws defects, cracks visible to naked eye

2) Manufacturers Identity & Dimensional Range- Cable Sealing System shall

be examined visually to check the manufacturers trademark. The location

of the trademark on the system shall be matched with the concerned

drawing of system. Each module shall be visually checked for the range of

diameters of cables it can hold & shall be verified by printed dimensional

range mention on each module.

3) Compression of System - The Cable Sealing System shall be examined

visually to check the proper compression of modules. The rays of light

shall not be come through system/ modules.

4) System Configuration - The Cable Sealing System shall be examined

visually to check configuration of modules with frame/system.

Configuration shall be verified with concerned drawing and BOM of

system.

5) Dimensional Test - Each Module is printed with dimensional range

showing the minimum & maximum cable diameters it can hold. The

Module

shall be verified by placing the cables falls under that

dimensional range.

6.3.0 OTHER REQUIREMENTS

Only after approval of the original drawings incorporating changes, if any, as a

result of the prototype tests and clear written approval of the results of the tests on

the prototype is communicated by the Purchaser/DG (EM), RDSO, Lucknow, to the

successful tenderer/manufacturer, shall he take up bulk manufacture of the

panels. In no circumstances shall materials other than those approved in the

design/drawings and/or during the prototype testing be used for bulk manufacture

on the plea that they had been obtained prior to the approval of the prototype.

7.0

DRAWINGS:

Drawing in triplicate incorporating the detailed dimensional cross-sectional

drawing of the panels following particulars shall be submitted with the tender for

the purpose of preliminary study. After award of the contract the successful

tenderer shall be required to submit reproducible copies of final drawings for the

panels ordered.

8.0 IDENTIFICATION AND MARKING

One name plate giving description of the MCC shall be affixed prominently on the

top of the MCC. Details will be furnished latter. The nameplates for individual

feeders shall carry the general information as mentioned below.

Page 20 of 20

Feeder No.

Equipment ref. no. & description

Rating

For spares feeder blank labels shall be provided.

9.0 WARRANTY:

The panels must be guaranteed for satisfactory operation for a period of 12 months

from the date of commissioning.

10.0 INFRINGEMENT OF PATENT RIGHTS

Indian Railways shall not be responsible for infringement of patent rights arising

due to similarity in design, manufacturing process, use of similar components in

the design & development of this item and any other factor not mentioned herein

which may cause such a dispute. The entire responsibility to settle any such

disputes/matters lies with the manufacturer/ supplier.

11.0 SCHEDULE OF GUARANTEED PARAMETERS

The following information shall be given by the tenderer in addition to any other

relevant data:S. No.

1

2

3

4

5

6

7

Description

IP Tests

Surface preparation & treatment test

Short circuit test

Bus-bar rating

Factory Acceptance

Third Party Inspection

Main Bus-Bar and Bus-Bar Support

Certificate

Yes

Yes

Yes

Yes

No

Yes

Yes

Test

Yes

No

No

No

Yes

Yes

Yes

Вам также может понравиться

- Newton Interviews - Tookie AngusДокумент12 страницNewton Interviews - Tookie AngusPeter BellОценок пока нет

- Ti SPC Ohe Inscom 1070Документ23 страницыTi SPC Ohe Inscom 1070hardeepsingh_08Оценок пока нет

- Corus - A Corrosion Protection GuideДокумент6 страницCorus - A Corrosion Protection GuideBellana SirishОценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Patel, Anita - Super Indian Snack and Street Food Recipes PDFДокумент117 страницPatel, Anita - Super Indian Snack and Street Food Recipes PDFBella ImèneОценок пока нет

- APTRANSCO Spec - 11KV Polymer Insulators (C&T) RevisedДокумент13 страницAPTRANSCO Spec - 11KV Polymer Insulators (C&T) RevisedAshutosh SharmaОценок пока нет

- 15 TMSS 02 R0Документ0 страниц15 TMSS 02 R0renjithas2005Оценок пока нет

- Techinical Specification of Polymer 11 KV & 33 KV Pin InsulatorДокумент14 страницTechinical Specification of Polymer 11 KV & 33 KV Pin InsulatordamlanОценок пока нет

- Ti SPC Ohe Inscom 107Документ44 страницыTi SPC Ohe Inscom 107mukeshhОценок пока нет

- PAL Polyurethane Panel Spec 31102008Документ4 страницыPAL Polyurethane Panel Spec 31102008Mohd Fahmie Bin MustapaОценок пока нет

- Medium Voltage Composite InsulatorsДокумент14 страницMedium Voltage Composite Insulatorsdeepthik27Оценок пока нет

- Is 2551Документ44 страницыIs 2551sankaractecheeeОценок пока нет

- 09875Документ10 страниц09875sethu1091Оценок пока нет

- Connector Product Locations: GermanyДокумент56 страницConnector Product Locations: Germanywww.erwer9Оценок пока нет

- EP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..Документ14 страницEP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..dimaomarОценок пока нет

- GRP Enclosures For PAckage SubstationДокумент12 страницGRP Enclosures For PAckage SubstationjoseОценок пока нет

- 11kv CablesДокумент46 страниц11kv CablesS.k. RathОценок пока нет

- TROSTEN Mechanical Specification - AHUДокумент6 страницTROSTEN Mechanical Specification - AHUBalaji JenarthananОценок пока нет

- Catalogue Long RodДокумент10 страницCatalogue Long RodTravis WoodОценок пока нет

- En PyrotenaxSystem2000 DS H57049 Tcm432 26219Документ5 страницEn PyrotenaxSystem2000 DS H57049 Tcm432 26219thanna9783Оценок пока нет

- Technical Specification - FilterДокумент15 страницTechnical Specification - FilterMurli RamchandranОценок пока нет

- Product Data Sheet: Product: Ks1000 SF EcosafeДокумент4 страницыProduct Data Sheet: Product: Ks1000 SF EcosafeSamuel RICEANОценок пока нет

- Thermazone Foilboard Insulation DatasheetДокумент3 страницыThermazone Foilboard Insulation DatasheetSuthirak SumranОценок пока нет

- Arc Insulations BrochureДокумент5 страницArc Insulations BrochureacompositesОценок пока нет

- Exhibit B-30 InsulationДокумент7 страницExhibit B-30 Insulationsethu1091Оценок пока нет

- Tech. Specification For Dry Typ. Dist - TransformerДокумент8 страницTech. Specification For Dry Typ. Dist - TransformerPramod B.Wankhade0% (1)

- Metco 402 10-007Документ10 страницMetco 402 10-007JSH100100% (2)

- 08 - 1 Section VIII Composite Longrod Insulator, Rev-0 (July'2022) - 1Документ27 страниц08 - 1 Section VIII Composite Longrod Insulator, Rev-0 (July'2022) - 1Jash PancholiОценок пока нет

- Insulation SpecДокумент16 страницInsulation Specsandesh100% (1)

- Crime HQ BoqДокумент42 страницыCrime HQ BoqNitish YadavОценок пока нет

- Section-Viii: Composite Long Rod InsulatorДокумент33 страницыSection-Viii: Composite Long Rod Insulatorsaravanan jОценок пока нет

- 80080-TCH-0000-SP-003 - SIGNED-Coating ProcedureДокумент7 страниц80080-TCH-0000-SP-003 - SIGNED-Coating ProcedurePaul NieОценок пока нет

- RO4000 Laminates Data SheetДокумент4 страницыRO4000 Laminates Data SheetJavier De La VegaОценок пока нет

- Tica SpecДокумент29 страницTica SpecCong ThanhОценок пока нет

- ZTT Spec SheetДокумент8 страницZTT Spec SheetEnzo del PradoОценок пока нет

- Air Handling Units 39HQMДокумент8 страницAir Handling Units 39HQMAhmadОценок пока нет

- Fresh Air Handling Units 39HQMДокумент10 страницFresh Air Handling Units 39HQMAhmadОценок пока нет

- Sectional TankДокумент4 страницыSectional TankGT2013Оценок пока нет

- Lanka Electricity Company (Private) Limited: Outdoor Current TransformerДокумент11 страницLanka Electricity Company (Private) Limited: Outdoor Current Transformerkavish malakaОценок пока нет

- Recotec Rotafil enДокумент16 страницRecotec Rotafil enJordan RileyОценок пока нет

- Cam LockДокумент7 страницCam LockBrant AkkanОценок пока нет

- Vulcoferran 2190Документ2 страницыVulcoferran 2190iran13620% (1)

- 01 Appd SPSCLT Piller Drawings 28-04-2010Документ41 страница01 Appd SPSCLT Piller Drawings 28-04-2010cayunk7145Оценок пока нет

- 0.9. OPGW - Tech - Discription For OPGWДокумент12 страниц0.9. OPGW - Tech - Discription For OPGWgiorgis072Оценок пока нет

- GPT 1-3 PGE Tech SpecificationsДокумент4 страницыGPT 1-3 PGE Tech SpecificationsEhtisham AndrAbiОценок пока нет

- CEILCOTE 505 Coroline.Документ2 страницыCEILCOTE 505 Coroline.stuart3962Оценок пока нет

- مواصفات كابلات 33 ك.فДокумент12 страницمواصفات كابلات 33 ك.فAhmed EzzatОценок пока нет

- Complaince Statement - 01 - CMS AF-TDCS050404523 - R04Документ7 страницComplaince Statement - 01 - CMS AF-TDCS050404523 - R04Arun CDОценок пока нет

- FPR SpecificationsДокумент15 страницFPR SpecificationsHector Manuel Leon JimenezОценок пока нет

- VORTEX Powder Coating For Conductor Insulation of Transformer WindingsДокумент4 страницыVORTEX Powder Coating For Conductor Insulation of Transformer WindingsYogesh ChadawatОценок пока нет

- Pyro Mi Specifiers GuideДокумент12 страницPyro Mi Specifiers Guideashley_moseley1918Оценок пока нет

- Disc InsulatorsДокумент6 страницDisc Insulatorsdaniel_sa2011Оценок пока нет

- Piping Equipment IsolationДокумент14 страницPiping Equipment IsolationLữ Hành ShutoОценок пока нет

- Specification For Polymer Pin InsulatorДокумент9 страницSpecification For Polymer Pin InsulatorBinay PaudyalОценок пока нет

- Isocop Rev 07-11-2012 - ENGLДокумент15 страницIsocop Rev 07-11-2012 - ENGLAlexandru RucareanuОценок пока нет

- Tarecpir Project Spec Inst GuideДокумент64 страницыTarecpir Project Spec Inst GuideFaizal YaacobОценок пока нет

- P 8-96 Disc Porcelain InsulatorsДокумент14 страницP 8-96 Disc Porcelain InsulatorsSyed Oon Haider ZaidiОценок пока нет

- 9Документ25 страниц9pcelisОценок пока нет

- Pikotek Vcs Tech SpecsДокумент2 страницыPikotek Vcs Tech SpecsBaskar KannaiahОценок пока нет

- Ceramic Materials for Energy Applications VIОт EverandCeramic Materials for Energy Applications VIHua-Tay LinОценок пока нет

- Spot Welding Interview Success: An Introduction to Spot WeldingОт EverandSpot Welding Interview Success: An Introduction to Spot WeldingОценок пока нет

- Re Voltage StabilityДокумент27 страницRe Voltage StabilityTravis WoodОценок пока нет

- Effect of Grading Ring On Voltage Distribution of ArrestorsДокумент7 страницEffect of Grading Ring On Voltage Distribution of ArrestorsTravis WoodОценок пока нет

- Anandaram BaruaДокумент1 страницаAnandaram BaruaTravis WoodОценок пока нет

- Aluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Документ4 страницыAluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Travis WoodОценок пока нет

- Gear Design For Quiet Reduction GearДокумент8 страницGear Design For Quiet Reduction GearTravis WoodОценок пока нет

- 1363 Bolts and Nut Standard PDFДокумент7 страниц1363 Bolts and Nut Standard PDFTravis WoodОценок пока нет

- April Is The Cruellest MonthДокумент1 страницаApril Is The Cruellest MonthTravis WoodОценок пока нет

- KSEB Technical SPec PDFДокумент279 страницKSEB Technical SPec PDFTravis WoodОценок пока нет

- Double Sampling-Wha It Means PDFДокумент17 страницDouble Sampling-Wha It Means PDFTravis WoodОценок пока нет

- Ceramic Manufacturing PDFДокумент41 страницаCeramic Manufacturing PDFTravis WoodОценок пока нет

- Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135Документ6 страницEnhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135Travis WoodОценок пока нет

- Overhead Conductor Installation Guide: Recommended PracticesДокумент20 страницOverhead Conductor Installation Guide: Recommended Practicesvjs270385Оценок пока нет

- Study of Single and Double Sampling PlansДокумент14 страницStudy of Single and Double Sampling PlansTravis WoodОценок пока нет

- Unidirectional Corona RingДокумент2 страницыUnidirectional Corona RingTravis WoodОценок пока нет

- 3 Sec-III-Hardware Fittings & AccessoriesДокумент49 страниц3 Sec-III-Hardware Fittings & AccessoriesTravis WoodОценок пока нет

- Innovative Adhesive For Sandwich SystemsДокумент20 страницInnovative Adhesive For Sandwich SystemsTravis WoodОценок пока нет

- Transformer Factory Assembly Area LayoutДокумент55 страницTransformer Factory Assembly Area LayoutTravis Wood100% (2)

- Ehv Disconnectors For Smart GridДокумент2 страницыEhv Disconnectors For Smart GridTravis WoodОценок пока нет

- En 10204-2004 Metallic Products - Types of Inspection DocumentsДокумент10 страницEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosОценок пока нет

- CT Grounding To Avoid Nuisance TrippingДокумент2 страницыCT Grounding To Avoid Nuisance TrippingTravis WoodОценок пока нет

- Spacer Damper IssuesДокумент5 страницSpacer Damper IssuesTravis WoodОценок пока нет

- Fretting Fatigue in Overhead ConductorsДокумент16 страницFretting Fatigue in Overhead ConductorsTravis WoodОценок пока нет

- SPEED Continuous Panels Plants Design IssuesДокумент18 страницSPEED Continuous Panels Plants Design IssuesTravis WoodОценок пока нет

- SPEED Continuous Panels Plants Design IssuesДокумент18 страницSPEED Continuous Panels Plants Design IssuesTravis WoodОценок пока нет

- An Introduction To Conway's Games and NumbersДокумент30 страницAn Introduction To Conway's Games and NumbersSilentSparrow98Оценок пока нет

- ElectricalДокумент34 страницыElectricalTravis WoodОценок пока нет

- Mud Architecture: I J I R S E TДокумент6 страницMud Architecture: I J I R S E TJazzОценок пока нет

- Anil Agarwal: Research: Mud As A Traditional Building MaterialДокумент10 страницAnil Agarwal: Research: Mud As A Traditional Building MaterialTravis WoodОценок пока нет

- Bolt InterlocksДокумент5 страницBolt InterlocksTravis WoodОценок пока нет

- CB Spec SvenskaДокумент44 страницыCB Spec SvenskaTravis WoodОценок пока нет

- Unit 2 - CT2Документ45 страницUnit 2 - CT2Jagrit DusejaОценок пока нет

- Papr114 SpectralДокумент4 страницыPapr114 Spectrallilivaca28Оценок пока нет

- Samyung SI-30 ManualДокумент2 страницыSamyung SI-30 ManualYan Naing0% (1)

- Hebrew and TamilДокумент98 страницHebrew and TamilSreshta JustinОценок пока нет

- Industrial TYROLITc 21Документ611 страницIndustrial TYROLITc 21kamilОценок пока нет

- New Magic Grammar TE3BДокумент34 страницыNew Magic Grammar TE3BYume ZhuОценок пока нет

- Bravo Petroleum ProfileДокумент8 страницBravo Petroleum ProfileJacob Thom ZiwahwaОценок пока нет

- Genmega G2500Документ103 страницыGenmega G2500tchindaforentОценок пока нет

- Concrete Tunnel Design and Calculation Spreadsheet Based On AASHTO and ACIДокумент3 страницыConcrete Tunnel Design and Calculation Spreadsheet Based On AASHTO and ACIFirat PulatОценок пока нет

- Booster Mock Test For NEETДокумент15 страницBooster Mock Test For NEETDrОценок пока нет

- Chemical Engineering Refresher CourseДокумент7 страницChemical Engineering Refresher CourseAstra BeckettОценок пока нет

- REE0913ra LegazpiДокумент6 страницREE0913ra LegazpiScoopBoyОценок пока нет

- Pediatric Airway ManagementДокумент2 страницыPediatric Airway ManagementSilvy AmaliaОценок пока нет

- Rangtong Shentong ViewДокумент19 страницRangtong Shentong Viewlongjim31100% (1)

- NarcolepsyДокумент12 страницNarcolepsyapi-489712369Оценок пока нет

- Aspire 7535 ManualДокумент220 страницAspire 7535 ManualinklabsОценок пока нет

- Detector de Fum Si Temperatura Apollo XP95-55000-885Документ2 страницыDetector de Fum Si Temperatura Apollo XP95-55000-885dorobantu_alexandruОценок пока нет

- Candaza, HM Pe4l Reaction PaperДокумент5 страницCandaza, HM Pe4l Reaction Papermaria isabel candazaОценок пока нет

- Hopf 6870 - 1101Документ58 страницHopf 6870 - 1101macakafkaОценок пока нет

- Morning Star Cafe Menu Revised 08-14-2019 On Line Menu 1Документ2 страницыMorning Star Cafe Menu Revised 08-14-2019 On Line Menu 1api-471935951Оценок пока нет

- English: Third Quarter - Module 3Документ12 страницEnglish: Third Quarter - Module 3Anna Agravante-SulitОценок пока нет

- Subcontracting Process in Production - SAP BlogsДокумент12 страницSubcontracting Process in Production - SAP Blogsprasanna0788Оценок пока нет

- A Ongc HRM Summer ProjectДокумент58 страницA Ongc HRM Summer ProjectAmit SunsaraОценок пока нет

- Drugs and Tinnitus - Neil Bauman PHD - April '09Документ2 страницыDrugs and Tinnitus - Neil Bauman PHD - April '09DownTheTheRabbitHole108Оценок пока нет

- Unit 1 - Theoretical Framework PDFДокумент67 страницUnit 1 - Theoretical Framework PDFMeli EujaniánОценок пока нет

- Method Statement For Boom Barrier Installation (Rev00) ELV2Документ38 страницMethod Statement For Boom Barrier Installation (Rev00) ELV2balajiОценок пока нет

- Iec 62031 PDFДокумент16 страницIec 62031 PDFAlbertoОценок пока нет

- The Interrelationship Between Fashion andДокумент17 страницThe Interrelationship Between Fashion andpushpak navandarОценок пока нет