Академический Документы

Профессиональный Документы

Культура Документы

NSF Final Report

Загружено:

ricardoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

NSF Final Report

Загружено:

ricardoАвторское право:

Доступные форматы

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Send to:

Neogen Corporation

620 Lesher Place

Lansing, Michigan 48912

Result: COMPLETE

Customer Name:

Location of Testing:

Description:

Test Type:

Job Number:

Report Date: 13-July-2015

Neogen Corporation

NSF Ann Arbor

Sanitation Sampler Assay Protocol - Real World Study

Test Only

J-00175137

Project Number:

10009584

NSF Corporate:

C0245040

Project Manager:

J. Vantine

Executive Summary:

Neogen Corporation contracted the Applied Research Center at NSF International to perform comparison

performance testing of Neogens ATP system, AccuPoint Advanced, against four other commercially available

systems. The recovery efficiencies and consistency of each system were evaluated against an ATP standard

solution and orange juice at different dilutions inoculated onto stainless steel carriers. This study utilized several

methods to determine the effectiveness of each system. Both a directly pipetted ATP standard solution and

commodity onto swab surfaces and surface swabbing of stainless steel coupons were employed with the test

systems.

Neogens AccuPoint Advanced ATP system consistently yielded the highest percent recoveries and the most

consistent readings of the target analytes, when compared to the other four test systems.

ATP devices are utilized to detect the presence of bacteria and organic/food residue on surfaces. ATP has been

incorporated as a key monitoring parameter for the food, beverage and healthcare industries. It is essential that

these devices provide precise and consistent readings so that the hygiene practices of these industries can be

accurately evaluated.

Thank you for having your product tested by NSF International.

Please contact your Project Manager if you have any questions or concerns pertaining to this report.

Digitally signed by Dr. Robert Donofrio /jv

DN: cn=Dr. Robert Donofrio /jv, o=NSF

International, ou=Director - Applied Research

Center, email=Donofrio@NSF.ORG, c=US

Date: 2015.07.13 10:21:51 -04'00'

Report Authorization:____________________________________________

Robert Donofrio Director, Applied Research Center

FI20150713100356

J-00175137

Page 1 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Scope of Test Report

Adenosine triphosphate (ATP) is a compound found in every living cell and can be used as an indicator to

determine if a surface was properly sanitized. ATP hygiene monitoring systems have been used in the food

production industry for over twenty years. The systems are used in facilities to measure the cleaning

effectiveness, removal/reduction of ATP, on food contact surfaces. Our study attempts to mirror typical field

usage by looking at the recovery of each system of ATP standards and commodity from a common surface

(stainless steel.)

Multiple manufactures produce monitoring systems to detect ATP. The following systems were selected to be

tested in this study.

Neogen AccuPoint Advanced ATP Surface Samplers (Lot 216036)

3M Clean-Trace Surface ATP (Lot 1222C)

Hygiena UltraSnap (Lot 02515)

Charm PocketSwab Plus (Lot 4031315A-01)

Biocontrol LIGHTNING MVP ICON ATP Surface Sampling Device (Lot 042915-01)

Neogen Corporation provided its system and the reference standard ATP, all other devices were purchased

independently through normal commercial channels by NSF International.

Each system was tested using 4 differing approaches. Details provided in Methodology.

Section 1: ATP standard solutions were pipetted directly onto sample swabs. Data obtained here was used as a

reference for the calculation of ATP recovery in sections 2 and 3. (Data recorded under NSF J-00170817)

Section 2: ATP standards were deposited over a 4x4 stainless steel surfaces and the above referenced

monitoring systems were used to sample the entire surface under a real world approach*.

FI20150713100356

J-00175137

Page 2 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Section 3: ATP was recovered from a concentrated spot randomly located on 4x4 stainless steel surface

utilizing all 5 test systems detailed above with a real world swabbing approach. In the real world, residue is not

homogeneously distributed across a surface after cleaning. The spot test attempted to recreate this phenomenon by

randomly placing a small, invisible dot of ATP on the stainless steel surfaces to determine the extent and

consistency of each systems ability to locate and accurately identify its presence. 10 replicates of each test were

completed on a single test day for each reader.

Section 4: Orange juice was used as a standard commodity to measure the detection ability of each of the test

units. Orange juice was deposited over a 4x4 stainless steel surface that was sampled utilizing all 5 test systems

detailed above with a real world swabbing approach.. 10 replicates of each test were completed on a single test

day for each reader.

The following series of dilutions were tested:

1:1000(1partorangejuiceto999partssterilewater),

1:5000(1partorangejuiceto4999partssterilewater)and

1:10000(1partorangejuiceto9999partssterilewater).

*Real world approach is defined wherein each 4X4 surface was sampled in a cross-hatch pattern with five

seconds in each direction. This measurement was adapted to replicate real-world operation of these systems that

most often occurs between tightly scheduled production runs where sampling speed is important.

Methodology

These following methods were derived from document Sanitation Sampler Assay Protocol, provided by Brent

Steiner and Ron Sarver of Neogen Biochemistry Laboratory on December 30, 2014. (See Addendum B for

complete text)

FI20150713100356

J-00175137

Page 3 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Recovery Evaluation Protocols

Evaluations of the sanitation systems were conducted in 4 sections. Section 1 involved the addition of ATP

standard solutions directly to sample swabs. Section 2 evaluated the recovery of ATP deposited over a 4x4

stainless steel surface. Section 3 evaluated the recovery of a concentrated spot of ATP randomly located on a

4x4 stainless steel surface and Section 4 involved assessing the recovery of orange juice (commodity testing)

deposited over a 4x4 stainless steel surface. Each section is described in detail below. Adenosine 5triphosphate disodium salt hydrate (ATP) reference standards were prepared and provided by Neogen Corporation

for use during these studies.

Section 1. The goal of this experimental section was to determine the Relative Light Unit (RLU) response for

each of the 5 test systems that corresponded to standard ATP solutions added directly to the sampling system. For

each sanitation system, 20 uL of each ATP standard (0, 12.5, 25.0, and 100 femtomoles of ATP) was pipetted

directly onto the sample swab or pad of the sanitation system. Immediately following addition of the ATP

standard to the sample pad or swab the instructions for the system were followed and the sampler was read on the

appropriate luminescence reader. Each ATP concentration including a blank (sterile water) was tested 25 times

using 25 different samplers. The ATP solutions were labeled by nanomolar concentration and 20 L of the 5.00,

1.25 and 0.625 nM solutions of ATP or sterile water result in the following femtomoles of ATP on the sample pad

or swab, 100, 25.0, 12.5 and 0 femtomoles, respectively. Results for the 100 femtomole solution are reported in

Table 1. The calculated mean RLU response for the 100 femtomole solution was used as a reference for

calculating ATP recovery for the experiments performed in Sections 2 and 3.

Section 2. The goal of this experimental section was to determine the efficiency of the five test systems in

recovering an ATP standard that had been evenly spread across a stainless steel carrier. The surface recovery of

ATP or commodities was determined by using a 4x4 stainless steel plate. The initial cleanliness of the stainless

steel plates was important to monitor and the testing was conducted in a laminar flow hood equipped with a UV

lamp. Prior to each round of testing the stainless steel plates were cleaned and sterilized using a UV lamp with a

twenty minute exposure. Between experiments the stainless steel plates were cleaned using 10% Contrad 70 in

water, then rinsed with sterile water, washed again with isopropanol and then air dried.

FI20150713100356

J-00175137

Page 4 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Sterile water and isopropanol used for cleaning was dispensed from a spray bottle which was sterilized using a

UV lamp (20 minute exposure) and 10% Contrad 70 in water. Periodically a 4x4 plate was checked for

cleanliness using an AccuPoint sampler to ensure the reading was at background levels (below 25 RLU).

100 femtomoles of ATP was spread over the 4x4 surface and air dried for 1 hour at room temperature (1825C) to measure the amount of ATP that could be recovered utilizing each monitoring system. This was

accomplished by pipetting 20 L of a 5.0 nM ATP solution onto the stainless steel surface. The tip of a pipette

was used to distribute the solution over the surface. Ten 4x4 stainless steel squares were covered with 100

femtomoles of ATP for each sanitation system. After the ATP was deposited homogenously across and dried, the

surface was sampled using the sanitation system sampler in the manner recommended by the manufacturers

instructions. The amount of ATP was recovered was determined by comparing the mean response from the

surface recovery to the mean response obtained in Section1. Results are reported in Table 2.

Section 3. The goal of this experimental section was to determine the efficiency of the five test systems in

recovering an ATP standard that had been spot inoculated at a random location on a stainless steel carrier. A 20L

of the 5.0 nM ATP solution (100 femtomoles) was pipetted at a random spot on a 4x4 stainless steel surface to

determine the recovery capability of each monitoring system. The spot was allowed to dry for 1 hour and the plate

was sampled according to the manufacturers sampling instructions. This was repeated 10 times for each sanitation

monitoring system to determine the mean response, standard deviation and the coefficient of variation (CV) for

the recovered ATP from the surface. The percentage recovered from the surface was determined by comparing the

mean response from the surface spot recovery to the mean response obtained in Section 1. Results are reported in

Table 3.

Section 4. The goal of this experimental section was to determine the efficiency and detection limit of the five test

systems in recovering a standard commodity, orange juice, which had been evenly spread across a stainless steel

carrier. This experiment was designed to replicate a typical situation that would be encountered in the field. For

this evaluation, 10mL of orange juice was diluted 1:1000 (1 part orange juice to 999 parts sterile water), 1:5000 (1

part orange juice to 4999 parts sterile water), and 1:10000 (1 part orange juice to 9999 parts sterile water).

FI20150713100356

J-00175137

Page 5 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Surfaces for each dilution level were prepared by dispensing 50 L of a given dilution level across the surface of

a 4x4 section of stainless steel plate and allowing the samples to dry for 1 hour before sampling the surface

according to the prescribed method for each brand of system. Ten surfaces were prepared and sampled at each

dilution for each brand of sanitation systems. The mean, standard deviation and coefficient of variation was

determined for each dilution and each brand of sanitation sampler.

To determine recovery, 50 L of each orange juice dilution was pipetted directly onto the swab or sample pad and

the response measured using each brand of sanitation system. This was repeated ten times to determine the mean

response for directly pipetting the orange juice dilution onto the sampler. The percentage recovered from the

surface was determined by comparing the mean response from the surface recovery to the mean response obtained

from directly pipetting 50 L onto the samplers. Results are reported in Table 4.

FI20150713100356

J-00175137

Page 6 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Results and Discussion

A comparative evaluation of the ability of five commercial ATP monitoring systems to accurately report ATP

levels from stainless steel surfaces was performed. The studies examined the difference in recovery of ATP

standards when applied in a homogenous manner across the carrier as well as to a random spot contamination.

The study also assessed the ability of the five ATP monitoring systems to detect a standard commodity food,

orange juice, which was applied to carriers in varying concentrations. The results of the study are presented in

Appendix A.

During Section 1 of this study, the RLU (Relative Light Unit) outputs for the five test systems were observed

when ATP standards were directly introduced onto the swabs/sample pads. The mean RLU output was calculated

for 25 replicates and reported in Table 1. Table 1 contains the RLU observations for all five systems tested at the

100 femtomole ATP concentrations. The RLU data generated in Section 1 for was used as a reference for

calculating ATP recovery in Sections 2 and 3.

Section 2 of the study utilized stainless steel coupons prepared with the 100 femtomole of the reference ATP

standard as the sample. The surface was sampled using the monitoring systems operational instructions but

utilizing a real world approach to the exposure time of the swab contact on the sample surface. A standard run /

return pattern was used over the sample coupon on 2 axis/sides. Each side had the timed exposure of swab to

surface of 5 seconds making the entire exposure 10 seconds. This timeframe is relevant to compare the results of a

lab study to a real world, situational use of the monitoring system. The percent of ATP recovered was determined

by comparing the mean response from the surface recovery to the mean response of direct swab inoculation

observed in Section 1. Table 2 contains the results for the Section2 study. The two monitoring systems that had

the highest percent ATP recovery from the stainless steel surfaces were the Charm PocketSwab Plus (28.91%)

and the Neogen AccuPoint Advanced system (27.84%). The Neogen AccuPoint Advanced system also displayed

the lowest percent coefficient of variance (21.11%), indicating that it achieved the most consistent (least variable)

readings.

Section 3 involved assessing the ATP recovery efficiencies from stainless steel coupons with a random spot of 5.0

nM ATP solution of 100 femtomoles dried on it. The surfaces of 10 replicant coupons were sampled utilizing the

FI20150713100356

J-00175137

Page 7 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

real world situational sampling method utilizing each of the 5 monitoring systems to determine the mean response

of each unit.

The percentage recovery was calculated by comparing the mean response from the surface spot recovery to the

mean response of direct swab inoculation observed in Section 1. The results for Section 3 can be found in Table 3.

The Neogen AccuPoint Advanced had the highest percentage recovery of all 5 monitoring systems at 40.50%

recovery of the ATP solution from the unit surface. The Neogen AccuPoint Advanced system exhibited a percent

ATP recovery that was 2xs greater than the next most efficient monitoring system. The Neogen Accupoint

system exhibited the greatest consistency in readings (with a CV of 21.11%), indicating that the system is very

precise. The next closest system was BioControl MVP system at 17.93% recovery.

In Section 4 the experimental protocol was designed to mimic real world contamination scenarios. This study

involved contaminating stainless steel surfaces with orange juice at 3 dilutions: 1:1,000, 1:5,000 and 1:10,000.

RLU reference values for each dilution were first generated by direct inoculation onto the ATP monitoring system

swabs. Recovery sampling using a real world approach, as previously described, was performed on

homogenously inoculated stainless steel surfaces. The percentage recovered from each surface was determined

by comparing the RLU of the surface reading with the RLUs observed from direct swab inoculation. Table 4

provides the results for the RLUs observed from direct inoculation (4a), RLUs from stainless steel recovery (4b)

and calculated percent ATP recovery (4c). Once again, the Neogen AccuPoint Advanced had the highest

observed percentage recovery of all 5 monitoring systems. For each of the orange juice dilutions evaluated, the

percent recovery of ATP by the Neogen AccuPoint Advanced was significantly higher than that of the other four

ATP monitoring systems evaluated. Once again, the Neogen Accupoint system proved to be the most consistent

of the devices evaluated (with a CV of 40.58%). The next closest system for recovery at 1:1000 and 1:5000

dilution factors was BioControl MVP. For the 1:10000 dilution factor the 2nd highest recovery was the 3M

CleanTrace.

FI20150713100356

J-00175137

Page 8 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Scope of Work

Scope of work authorized: April 30th, 2015

No revisions were affected.

Disclosure of Deviations

On 5/08/2015 the stainless steel coupon cleaning was validated by 2 Neogen AP swab readings. The readings

were below the 25 RLU background thresholds (4 RLU, 11 RLU) and testing proceeded for the 10 replicate

samples of the AccupPoint 3.04, EnSure and MVP readers. However, each of the three readers had 1 or 2 outlier

samples indicating coupon contamination. Outlier is defined as a sample with an RLU value outside the range

observed when pipetting the orange juice directly on the swab.) After this day of testing, coupons were re-cleaned,

sampled for cleanliness (0 RLU, 0 RLU), and re-tested. Summary of results reported in Table 4 are the data

recovered on the retest date.

Contract Detail Clarification

NSF International and Neogen Corporation entered into a contractual relationship in February 2015. This

document, drafted by NSF International, is the Terms and Conditions for Testing, Audit and Evaluation Services.

Per section 11 of this agreement NSF authorizes Neogen to use select data charts/ graphs from this study in

publications. NSF requires that a draft of the usage be reviewed with the ARC program office / NSF Marketing

for final feedback and authorization to print.

FI20150713100356

J-00175137

Page 9 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Appendix A

Result Tables

FI20150713100356

J-00175137

Page 10 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

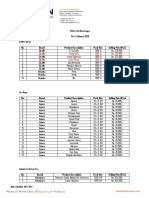

Table 1. Mean RLU response of five ATP monitoring systems against an ATP standard of 100 femtomoles.

ATP standard solutions were pipetted directly onto sample swabs. Mean was taken of 25 replicates (n=25) and

reported. Data obtained was used as a reference for the calculation of ATP recovery in Sections 2 and 3, Tables 2

and 3 respectively. (Data recorded under NSF J-00170817)

Reader

Neogen

AccuPoint 3.04

3M

NG

Hygiena

EnSure

Charm

NovaLUM

BioControl

MVP

AccuPoint

Advanced

CleanTrace

UltraSnap

PocketSwab Plus

Lightning

593.32

871.56

206.64

29,809.04

594.12

Sampler

Mean RLU

FI20150713100356

J-00175137

Page 11 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Table 2. Recovery of ATP standards from a homogenously contaminated stainless steel surface. A 100

femtomole ATP standard solution was homogenously deposited over a 4x4 stainless steel surface. The surface

was then sampled with the referenced monitoring systems utilizing a real world approach swabbing technique (5

seconds in one direction, and then swabbing 5 more seconds perpendicular to the first). The mean RLU was

calculated of 10 replicates (n=10) and reported. To calculate percent ATP recovery, the direct inoculation mean

RLU recovery values (Table 1) were used as a reference.

Reader

FI20150713100356

3M

Hygiena

Charm

BioControl

NG

EnSure

UltraSnap

NovaLUM

MVP

PocketSwab

Plus

Lightning

AccuPoint

Advanced

CleanTrace

Average

165.2

62.8

31.1

8,618.10

123.7

Std Dev

34.87

20.08

18.62

5,236.99

47.34

%CV

21.11%

31.98%

59.86%

60.77%

38.27%

Average

27.84%

7.21%

15.05%

28.91%

20.82%

Samplers

Mean RLU

Recovered

from

Surface

% ATP

Recovery

from

Surface

Neogen

AccuPoint

3.04

J-00175137

Page 12 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

%Recovery

35

30

25

20

%Recovery

15

10

5

0

Neogen

3M

Hygenia

Charm

Biocontrol

Figure 1: provides a pictorial representation of Table 2: Recovery of ATP standards from a homogenously

contaminated stainless steel surface.

%CoefficientVariance

70.00%

60.00%

50.00%

40.00%

%CoefficientVariance

30.00%

20.00%

10.00%

0.00%

Neogen

3M

Hygenia

Charm

Biocontrol

Figure 2: provides a pictorial representation of Table 2. Coefficient of Variance (%) was calculated and lowest %

indicates the most consistent (least variable) readings.

FI20150713100356

J-00175137

Page 13 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Table 3. Recovery of an ATP standard from a single contamination spot on stainless steel surfaces. A 100

femtomole ATP standard solution was deposited randomly as a drop on a 4x4 stainless steel surface. The

surface was then sampled with the referenced monitoring systems utilizing a real world swabbing approach

technique (5 seconds in one direction, and then swabbing 5 more seconds perpendicular to the first). The mean

RLU was calculated of 10 replicates (n=10) and reported. To calculate percent ATP recovery, the direct

inoculation mean RLU recovery values (Table 1) were used as a reference.

Reader

FI20150713100356

3M

Hygiena

Charm

BioControl

NG

EnSure

UltraSnap

NovaLUM

MVP

PocketSwab

Plus

Lightning

AccuPoint

Advanced

CleanTrace

Average

240.3

71.3

20

3,435.40

106.5

Std Dev

97.51

45.34

13.25

2,900.68

88.79

%CV

40.58%

63.58%

66.25%

84.43%

83.37%

Average

40.50%

8.18%

9.68%

11.52%

17.93%

Samplers

Mean RLU

Recovered

from

Surface

% ATP

Recovery

from

Surface

Neogen

AccuPoint

3.04

J-00175137

Page 14 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

%Recovery

45

40

35

30

25

%Recovery

20

15

10

5

0

Neogen

3M

Hygenia

Charm

Biocontrol

Figure 3: provides a pictorial representation of Table 3: Recovery of an ATP standard from a single

contamination spot on stainless steel surfaces.

%Recovery

45

40

35

30

25

%Recovery

20

15

10

5

0

Neogen

3M

Hygenia

Charm

Biocontrol

Figure 4: provides a pictorial representation of Table 3: Recovery of an ATP standard from a single

contamination spot on stainless steel surfaces. Coefficient of Variance (%) was calculated and lowest %

indicates the most consistent (least variable) readings. Table 4. Recovery of ATP from stainless steel surfaces

inoculated with varying concentrations of orange juice. Orange juice was selected as an ATP source since it is

a standard commodity product. Three dilutions of orange juice were utilized: 1:1,000, 1:5,000 and 1:10,000.

FI20150713100356

J-00175137

Page 15 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Table 4a. RLU values observed when the dilutions were amended directly to the ATP monitoring systems

sample pad/swab. These RLU values were used as a reference for the calculation of percent ATP recovery in

Table 4c. The average RLU reading from 10 replicates (n=10) is reported.

Mean RLU for Recovery of Orange Juice Pipetted onto the Sample Pad/ Swab

Samplers

Average

Orange

Juice

Dilution

1:1000

Neogen

AP

Advanced

1,783.4

3M

CleanTrace

3,629.1

Hygiena

UltraSnap

639.6

Charm

PocketSwab

Plus

145,735.9

BioControl

Lightning

2,071.9

Average

1:5000

418.5

832.6

165.6

34,517.6

582.4

Average

1:10000

90.7

217.5

34.0

6,394.1

139.9

FI20150713100356

J-00175137

Page 16 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Table 4b. RLU values observed from sampling 4x4 stainless steel surfaces amended with three dilutions of

orange juice. Percent recovery was calculated by dividing the mean RLU values below (homogenous stainless

steel coupon inoculation) by the mean RLU values in Table 4a (direct swab inoculation).

The dilutions were applied homogenously and the surfaces were sampled utilizing with a real world swabbing

approach (5 seconds in one direction, and then swabbing 5 more seconds perpendicular to the first). The average

RLU reading from 10 replicates (n=10) is reported.

Recovery of Orange Juice from 4"x4" Stainless Steel

Neogen AP

Advanced

3M

CleanTrace

Hygiena

UltraSnap

Charm

PocketSwab

Plus

BioControl

Lightning

553.3

71.4

65.7

14,468.30

271

31.03%

1.97%

10.27%

9.93%

13.08%

%CV

33.1%

74.3%

37.2%

47.6%

55.3%

Average

119.8

48.2

27.9

2,115.40

148.1

28.63%

5.79%

16.85%

6.13%

25.43%

46.7%

32.0%

43.3%

36.5%

38.8%

14

26.6

14.4

10.5

15.44%

12.23%

0.00%

0.23%

7.51%

146.7

111.52

NA

316.2

31.2

Samplers

Orange Juice

Dilution

Average

% ATP

Recovery

% ATP

Recovery

1:1,000

1:5,000

%CV

Average

% ATP

Recovery

%CV

FI20150713100356

1:10,000

J-00175137

Page 17 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Table 5: Stainless steel coupon cleaning readings were completed each test date by 2 Neogen AP Advanced

swabs of 2 representative coupons. All readings were at 0 RLU on days that data was reported from. Data

recorded on 5/8/2015 was dismissed due to outlier readings and repeated.

5/8/2015

5/11/2015

5/12/2015

5/13/2015

5/14/2015

5/15/2015

5/19/2015

5/20/2015

5/21/2015

5/22/2015

FI20150713100356

RLU

Replicate 1 Replicate 2

4

11

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

J-00175137

Page 18 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Appendix B

Sanitation Sampler Assay Protocol

FI20150713100356

J-00175137

Page 19 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

Sanitation Sampler Assay Protocol

Neogen Biochemistry Laboratory

Brent Steiner and Ron Sarver

December 30, 2014

Materials

The ATP Sanitation readers used for this study should include Neogen AccuPoint v3.03, 3M Clean-Trace NG

ATP Illuminator, Charm Novalum, Hygiena Ensure and BioControl MVPICON. Readers should be turned on

and warmed up to room temperature (18-23C) according to the manufacturers instruction. Sanitation

monitoring samplers should include AccuPoint Advanced ATP Surface Samplers, 3M Clean-Trace Surface ATP,

Hygiena UltraSnap, Charm PocketSwab Plus and Biocontrol LIGHTNING MVP ICON ATP Surface Sampling

Device. Samplers also should be allowed to equilibrate to room temperature as recommended by the

manufacturer. ATP will be provided by Neogen. Solutions of ATP will be prepared by NSF for the study. If

additional ATP is required, analytical standard grade Adenosine 5-triphosphate disodium salt hydrate (ATP) was

purchased from Sigma Chemical Co., part # FLAAS. ATP was dissolved in 50 mM Tricine buffer, pH 7.75, the

concentration of stock solution 50 M should be verified by UV (ATP 259 = 15.4 x 103 M-1 cm-1) and dilutions at

50.0 nM, 5.00 nM, 1.25 nM and 0.625 nM were prepared. Dilutions of ATP will be held on ice when not stored

in -20C freezer. Pulp-free orange juice will be purchased and diluted in sterile water. Dilutions of orange juice

will be held on ice when not stored in -20C freezer.

Section Protocols

Evaluations of the sanitation systems will be conducted in 4 sections. Section 1 is the addition of ATP standard

solutions directly to sample swabs. Section 2 is recovery of ATP deposited over a 4x4 stainless steel surface.

Section 3 is recovery of a concentrated spot of ATP randomly located on a 4x4 stainless steel surface and

section 4 is recovery of orange juice (commodity testing) from a 4x4 stainless steel surface.

Section 1). For each sanitation system, 20 uL of each ATP standard (0, 12.5, 25.0, and 100 femtomoles of ATP)

is pipetted directly onto the sample swab or pad of the sanitation system. Immediately following addition of the

ATP standard to the sample pad or swab follow the instructions for the system and read the sampler on the

appropriate luminescence reader. Each ATP concentration including a blank (sterile water) is tested 25 times

using 25 different samplers. The ATP solutions are labeled by nanomolar concentration and 20 L of the 5.00,

1.25 and 0.625 nM solutions of ATP or sterile water result in the following femtomoles of ATP on the sample pad

or swab, 100, 25.0, 12.5 and 0 femtomoles, respectively. For each sanitation monitoring system at each ATP

concentration, the mean response is calculated along with the standard deviation and coefficient of variation.

Section 2). For the determination of surface recovery of ATP or commodities, 4x4 stainless steel plates should

be used. The cleanliness of the stainless steel plate is important and testing should be conducted in a laminar flow

hood equipped with a UV lamp. Prior to each round of testing the stainless steel plate should be cleaned and

sterilized using the UV lamp with twenty minutes exposure time. Between experiments the stainless steel plates

should be cleaned using 10% Contrad 70 in water, rinsed with sterile water, washed with isopropanol and air

dried. Sterile water and isopropanol used for cleaning will be dispensed from a spray bottle which has been

sterilized using a UV lamp (20 minutes exposure time) and 10% Contrad 70 in water. Periodically, a 4x4 plate

should be checked for cleanliness using an AccuPoint sampler to ensure the reading is at background (below 25

RLU).

FI20150713100356

J-00175137

Page 20 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

NSF International Applied Research Center

TEST REPORT

789 N. Dixboro Rd. Ann Arbor, MI 48015, USA

1-800.NSF.MARK | +1-734.769.8010 | www.nsf.org

To determine the amount of ATP recovered from a stainless steel surface 100 femtomoles of ATP should be

spread over the 4x4 surface and air dried for 1 hour at room temperature (18-25C). This is accomplished by

pipetting 20 L of a 5.0 nM ATP solution onto the stainless steel surface. The tip of the pipette can be used to

distribute the solution over the surface. Ten 4x4 stainless steel squares should be covered with 100 femtomoles

of ATP for each sanitation system being evaluated. Care should be taken to not spread the solution with

something other than the pipette tip since other materials may remove the deposited ATP from the surface. After

the ATP is deposited and dried, the surface should be sampled using the sanitation system sampler in the manner

recommended by the manufacturer. The amount of ATP recovered is determined by comparing the mean

response from the surface recovery to the mean response obtained in Section 1 from directly pipetting 100

femtomoles of ATP onto the samplers.

Section 3). For recovery of a concentrated dot of ATP randomly spotted on a

4x4 stainless steel surface, 20L of the 5.0 nM ATP solution (100 femtomoles) is pipetted at a random spot on

each plate. The spot is then allowed to dry for 1 hour and the plate sampled according to the sampling method

prescribed by the manufacturer. This is repeated 10 times for each sanitation monitoring system to determine the

mean response, standard deviation and coefficient of variation (CV) for the recovered ATP from the surface. The

percentage recovered from the surface is determined by comparing the mean response from the surface spot

recovery to the mean response obtained in Section 1 from directly pipetting 100 femtomoles of ATP onto the

samplers..

Section 4). Commodity testing with orange juice is completed to determine recovery from a stainless steel surface

and determine the limit of detection in a more typical situation that would be encountered in the field. For this

evaluation, 10mL of orange juice is diluted 1:1000 (1 part orange juice to 999 parts sterile water), 1:5000 (1 part

orange juice to 4999 parts sterile water), and 1:10000 (1 part orange juice to 9999 parts sterile water). Surfaces

for each dilution level were prepared by dispensing 50 L of a given dilution level across the surface of a 4x4

section of stainless steel plate and allowing the samples to dry for 1 hour before sampling the surface according to

the prescribed method for each brand of sampler. Care should be taken to not spread the solution with something

other than the pipette tip since other materials may remove the deposited orange juice from the surface. Ten

surfaces should be prepared and sampled at each dilution for each brand of sanitation systems. The mean,

standard deviation and coefficient of variation should be determined for each dilution and each brand of sanitation

sampler.

To determine recovery, 50 L of each orange juice dilution should be pipetted directly onto the swab or sample

pad and the response measured using each brand of sanitation sampler. This is repeated ten times to determine

the mean response for directly pipetting the orange juice dilution onto the sampler. The percentage recovered

from the surface is determined by comparing the mean response from the surface recovery to the mean response

obtained from directly pipetting 50 L onto the samplers.

FI20150713100356

J-00175137

Page 21 of 21

Written NSF approval is required for reproduction of this report. Only authorized reports in their entirety may be distributed. This report does not

represent authorization to use the NSF Mark. NSF Certification may be confirmed at www.nsf.org. The results of this report relate only to those items

tested.

Вам также может понравиться

- Cytogenetic Laboratory Management: Chromosomal, FISH and Microarray-Based Best Practices and ProceduresОт EverandCytogenetic Laboratory Management: Chromosomal, FISH and Microarray-Based Best Practices and ProceduresОценок пока нет

- NSF Final Report - Real World Study of 5 Commerical ATP SystemsДокумент21 страницаNSF Final Report - Real World Study of 5 Commerical ATP SystemsPier Valentino Ramos RamosОценок пока нет

- Determination of Thiodiglycol in Soil Using Pressurized Fluid Extraction Followed by Single Reaction Monitoring Liquid Chromatography/Tandem Mass Spectrometry (LC/MS/ MS)Документ9 страницDetermination of Thiodiglycol in Soil Using Pressurized Fluid Extraction Followed by Single Reaction Monitoring Liquid Chromatography/Tandem Mass Spectrometry (LC/MS/ MS)Alevj DbОценок пока нет

- Brand Comparison (Silliker)Документ15 страницBrand Comparison (Silliker)heruhartadi02Оценок пока нет

- Standard Test Method For: Designation: E2866 12 (Reapproved 2016)Документ15 страницStandard Test Method For: Designation: E2866 12 (Reapproved 2016)Alevj DbОценок пока нет

- ETV Joint Verification Statement: U.S. Environmental Protection AgencyДокумент8 страницETV Joint Verification Statement: U.S. Environmental Protection AgencyAloysiusHandyОценок пока нет

- Water System Validation ExampleДокумент6 страницWater System Validation Exampledvdynamic1100% (2)

- Laboratory Procedure Manual: Urinary Creatinine Urine Enzymatic by Roche/Hitachi Modular P Chemistry AnalyzerДокумент12 страницLaboratory Procedure Manual: Urinary Creatinine Urine Enzymatic by Roche/Hitachi Modular P Chemistry AnalyzerfebyОценок пока нет

- Assessment of Grease Interceptor Performance PDFДокумент128 страницAssessment of Grease Interceptor Performance PDFvacomanoОценок пока нет

- 04 VP WastewaterДокумент54 страницы04 VP WastewaterJoaquin Dix'sОценок пока нет

- ATP Meter TestДокумент8 страницATP Meter TestDirector ResearchОценок пока нет

- Hach Method 10225 Spadns IIДокумент8 страницHach Method 10225 Spadns IIDavidSargFolgarОценок пока нет

- Mercially Produced Apple Juice ConcentrateДокумент14 страницMercially Produced Apple Juice ConcentrateL Guillermo RuedaОценок пока нет

- Example Small Wastewater Treatment Plant Laboratory Quality ManualДокумент23 страницыExample Small Wastewater Treatment Plant Laboratory Quality ManualFauTahudAmparoОценок пока нет

- Pall Microza Verification ReportДокумент103 страницыPall Microza Verification ReportcysautsОценок пока нет

- E70-07-ASTM-Standard Test Method For PH of Aqueous Solutions With The Glass ElectrodeДокумент8 страницE70-07-ASTM-Standard Test Method For PH of Aqueous Solutions With The Glass Electrodederek vaughnОценок пока нет

- Enhancing SF6 Analysis - CIGREДокумент58 страницEnhancing SF6 Analysis - CIGREJoseph SumpaicoОценок пока нет

- An Application Kit For Multi-Residue Screening of Pesticides Using LC/TOF or Q-TOF With A Pesticide Personal Compound DatabaseДокумент26 страницAn Application Kit For Multi-Residue Screening of Pesticides Using LC/TOF or Q-TOF With A Pesticide Personal Compound DatabaseTu TranОценок пока нет

- 1040 Method Development and Evaluation PDFДокумент3 страницы1040 Method Development and Evaluation PDFTeresa JeriОценок пока нет

- Ogden Lead TestДокумент10 страницOgden Lead TestDave MatthewsОценок пока нет

- Laboratory Procedure Manual: Selenium Serum Atomic Absorption SpectrometryДокумент22 страницыLaboratory Procedure Manual: Selenium Serum Atomic Absorption SpectrometrySeftiyantiОценок пока нет

- Nsf-Ansi-Can 61-2020-20210602150943 (100-163)Документ64 страницыNsf-Ansi-Can 61-2020-20210602150943 (100-163)QT Trái Tim Của GióОценок пока нет

- TPH Using Horiba OCMA 350 PDFДокумент123 страницыTPH Using Horiba OCMA 350 PDFNova RisdiyantoОценок пока нет

- Guidance Manual For Compliance With The Filtration and Disinfection Requirements PDFДокумент580 страницGuidance Manual For Compliance With The Filtration and Disinfection Requirements PDFเดือนห้า หน้าแล้งОценок пока нет

- CS-400 Service ManualДокумент173 страницыCS-400 Service ManualIvan Villena Chuman50% (4)

- Chemical Testing of Hedysarum Alpinum Seeds For The Neurotoxin beta-ODAPДокумент8 страницChemical Testing of Hedysarum Alpinum Seeds For The Neurotoxin beta-ODAPalatnabirdОценок пока нет

- Gas Natural GLNДокумент17 страницGas Natural GLNDavid SantanderОценок пока нет

- 5-Alkaline PhosphataseДокумент7 страниц5-Alkaline PhosphataseAzhar Clinical Laboratory TubeОценок пока нет

- 11-Psa TotalДокумент7 страниц11-Psa TotalprityОценок пока нет

- D 596 - 91 R95 - Rdu5ni1sruqДокумент11 страницD 596 - 91 R95 - Rdu5ni1sruqDaniel Nuñez HernandezОценок пока нет

- Thermo of DesalДокумент98 страницThermo of DesalEric MorganОценок пока нет

- Nuclear Maintenance Applications Center - Effective Grease PracticesДокумент278 страницNuclear Maintenance Applications Center - Effective Grease PracticesAlex Pujol100% (3)

- METHOD 300.0 Determination of Inorganic Anions by Ion ChromatographyДокумент28 страницMETHOD 300.0 Determination of Inorganic Anions by Ion ChromatographyLuis M MolinaОценок пока нет

- Nnaca Sop 304Документ9 страницNnaca Sop 304Somnis VeritasОценок пока нет

- HI White Paper - Understanding The Effects of Selecting A Pump Performance Test Acceptance GradeДокумент17 страницHI White Paper - Understanding The Effects of Selecting A Pump Performance Test Acceptance Gradeashumishra007Оценок пока нет

- Thesis Prposal 15 Feb 16Документ9 страницThesis Prposal 15 Feb 16Al Ghannami Abu NasserОценок пока нет

- Astm D 1977 - 03Документ3 страницыAstm D 1977 - 03phaindikaОценок пока нет

- Efmhaca: Ethiopian Food, Medicine and Healthcare Administration and Control AuthorityДокумент30 страницEfmhaca: Ethiopian Food, Medicine and Healthcare Administration and Control AuthorityAdanech BerhanuОценок пока нет

- USEPA2004 P HinsolidsДокумент6 страницUSEPA2004 P HinsolidsReiger RoyalОценок пока нет

- Nist 3247Документ10 страницNist 3247Tom CarrollОценок пока нет

- Modified Elutrate TestДокумент11 страницModified Elutrate TestMaria ReginaОценок пока нет

- L06uas C Met Arsenic TotalДокумент33 страницыL06uas C Met Arsenic Totallionelmatsuda20Оценок пока нет

- Generic Name: α-L-Fucosidase Kit ( Abbreviated name:AFU Order Information Cat. No. Package sizeДокумент25 страницGeneric Name: α-L-Fucosidase Kit ( Abbreviated name:AFU Order Information Cat. No. Package sizeSharom Zelene Cordova RomanОценок пока нет

- Nova Prime Evaluation PDFДокумент28 страницNova Prime Evaluation PDFLink BuiОценок пока нет

- Proper Validation of Filter Test Stands Is Critical For Product Development ProgramsДокумент4 страницыProper Validation of Filter Test Stands Is Critical For Product Development ProgramsnannidОценок пока нет

- Ginko Biloba NIST LC MS TestДокумент18 страницGinko Biloba NIST LC MS TestMd HossainОценок пока нет

- BUTLER CE TroubleshootingДокумент15 страницBUTLER CE TroubleshootingBobi SylvaticusОценок пока нет

- Scientific & Technical Report: The Essential Guide To Oil Filter Performance Testing StandardsДокумент5 страницScientific & Technical Report: The Essential Guide To Oil Filter Performance Testing StandardsTamrat AssefaОценок пока нет

- Pipeline Leak Detection System PDFДокумент174 страницыPipeline Leak Detection System PDFridanormaОценок пока нет

- Reg A USP 1058 Analytical Instrument QualificationДокумент8 страницReg A USP 1058 Analytical Instrument QualificationRomen MoirangthemОценок пока нет

- Certificate of Analysis: National Institute of Standards & TechnologyДокумент6 страницCertificate of Analysis: National Institute of Standards & TechnologyJosef FaldíkОценок пока нет

- 1040 Method Development and EvaluationДокумент4 страницы1040 Method Development and EvaluationRaposo IreneОценок пока нет

- Ion Chromatographic Method For Dissolved Hexavalent Chromium in Drinking Water, Groundwater, and Industrial Wastewater Effluents: Collaborative StudyДокумент14 страницIon Chromatographic Method For Dissolved Hexavalent Chromium in Drinking Water, Groundwater, and Industrial Wastewater Effluents: Collaborative StudyKhaled KayaliОценок пока нет

- Cholinesterase - ADVIA Chemistry - Rev D DXDCM 09008b838062478c-1369138193191Документ11 страницCholinesterase - ADVIA Chemistry - Rev D DXDCM 09008b838062478c-1369138193191Lee-Ya AchmadОценок пока нет

- Operators WtpinspДокумент2 страницыOperators WtpinspToufeeq Ahmed LatifОценок пока нет

- TR - 113584 - V1 - Using Environmental Solutions To Lubrication at Hydropower Plants - A Hydropower Technology Round - Up Report - Volume 1Документ56 страницTR - 113584 - V1 - Using Environmental Solutions To Lubrication at Hydropower Plants - A Hydropower Technology Round - Up Report - Volume 1emailsepamku gorgomОценок пока нет

- Research Paper - IJPBSДокумент10 страницResearch Paper - IJPBSFarahat AliОценок пока нет

- LDW NSF 419Документ2 страницыLDW NSF 419afumwafupОценок пока нет

- 2014 Veterans Day Restaurant OfferingsДокумент16 страниц2014 Veterans Day Restaurant OfferingsvrtonerОценок пока нет

- Unmsm Examen Inglés-09 Marzo 2019Документ4 страницыUnmsm Examen Inglés-09 Marzo 2019Absalón Barboza CoronadoОценок пока нет

- MathsDim 7 TEДокумент172 страницыMathsDim 7 TEelgransultanОценок пока нет

- EtiquetteДокумент33 страницыEtiquettebathalapalliОценок пока нет

- A1 Progress Test 04Документ9 страницA1 Progress Test 04Mar PerezОценок пока нет

- Consumig Interests: Water, Rum and Coca-ColaДокумент20 страницConsumig Interests: Water, Rum and Coca-ColaDaniel MurilloОценок пока нет

- Portuguese InfluenceДокумент14 страницPortuguese InfluenceSameir Khan100% (1)

- Grammar ModuleДокумент40 страницGrammar ModuleSha ImanОценок пока нет

- Latihan Soal Bahasa InggrisДокумент11 страницLatihan Soal Bahasa Inggrisdoni erikiawanОценок пока нет

- Suikoden 2 CodesДокумент11 страницSuikoden 2 CodesKilroy Vincent SterlingОценок пока нет

- Toffin Semarang Per. March 2016Документ28 страницToffin Semarang Per. March 2016Soesanto TirtoprodjoОценок пока нет

- 169840-436636-1-SM AltuntugДокумент9 страниц169840-436636-1-SM AltuntugDevi MelizarОценок пока нет

- CG Excise Act, 1915Документ34 страницыCG Excise Act, 1915principal bhanuОценок пока нет

- Rules For Lab Bsa 1cДокумент4 страницыRules For Lab Bsa 1cBotzBotzBotzОценок пока нет

- 10 Steps Cheesemaking InfographicДокумент1 страница10 Steps Cheesemaking InfographicSopat BatnaОценок пока нет

- Pancreatitis Case StudyДокумент48 страницPancreatitis Case StudyHanna Joyce100% (6)

- 4 Steps To Heal Leaky Gut and Autoimmune DiseaseДокумент27 страниц4 Steps To Heal Leaky Gut and Autoimmune DiseaseRobert Glen Murrell Jr100% (1)

- Ear InfectionДокумент7 страницEar Infectionbhatti19Оценок пока нет

- New ZealandДокумент14 страницNew ZealanddgarlandОценок пока нет

- Grammar Practices 10 Sample Worksheets-1Документ10 страницGrammar Practices 10 Sample Worksheets-1Azzura LazuardiОценок пока нет

- Mycology LabДокумент11 страницMycology Labnattadeloco100% (1)

- Bizu Trusted Wedding Package 2018Документ8 страницBizu Trusted Wedding Package 2018Gemma Lynne LayugОценок пока нет

- Cocktail Cheat SheetДокумент5 страницCocktail Cheat SheetAnghel AlexandruОценок пока нет

- Grammar WorksheetsДокумент122 страницыGrammar WorksheetsbabucsintaОценок пока нет

- Reinas Catering Equipment Price ListДокумент2 страницыReinas Catering Equipment Price ListPatricia Grace PerezОценок пока нет

- Duxbury Clipper 2011 - 15 - 06Документ44 страницыDuxbury Clipper 2011 - 15 - 06Duxbury ClipperОценок пока нет

- Engle ZaДокумент7 страницEngle ZaAurika ManolakiОценок пока нет

- Ayurvedic Food GuidelinesДокумент6 страницAyurvedic Food GuidelinesTheArtofInspiration100% (1)

- Healthy Snack Recipes The Conscientious EaterДокумент9 страницHealthy Snack Recipes The Conscientious EaterYuznia PutriОценок пока нет

- Starbucks Case StudyДокумент15 страницStarbucks Case StudyNeeraj NamanОценок пока нет