Академический Документы

Профессиональный Документы

Культура Документы

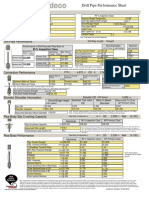

DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)

Загружено:

Johann ZabaletaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)

Загружено:

Johann ZabaletaАвторское право:

Доступные форматы

Drill Pipe Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

Note: Unbalanced Connection, Pin weak (Connection ID should be smaller or OD smaller).

Drill Pipe Configuration

Pipe Body OD

Pipe Body Wall Thickness

Pipe Body Grade

Drill Pipe Length

Connection

Tool Joint OD

Tool Joint ID

Pin Tong

Box Tong

(in)

(in)

(in)

(in)

(in)

(in)

80 % Inspection Class

Nominal Weight Designation

19.50

(ft) 31.9

Drill Pipe Approximate Length

(in) 3/32 Raised

SmoothEdge Height

(psi) 120,000

Tool Joint SMYS

Upset Type

IEU

(in) 5.125

Max Upset OD (DTE)

Friction Factor

1.0

5.000

0.362

X-95

Range2

XT50

6.625

3.938

10

15

Note: Tong space may include hardfacing.

Drill-Pipe Length

Drill Pipe Performance

Best Estimates

Performance of Drill Pipe with Pipe Body at

(without Coating)

80 % Inspection Class

Applied Make-up

Torque

Max Tension

Operational

Torque (ft-lbs)

(lbs)

(ft-lbs)

Maximum MUT

39,600

Minimum MUT

33,200

Tension Only

Combined Loading

Tension Only

Combined Loading

0

37,600

394,600

154,600

0

29,700

394,600

270,800

Drill Pipe Adjusted Weight

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

23.26

0.36

(Bbls/ft) 0.0085

(gal/ft) 0.72

(Bbls/ft) 0.0172

(in) 3.813

XT50

6.625

Applied Make-up

Tension at Shoulder

Torque

Separation

(ft-lbs)

39,600

33,200

(ft-lbs)

(lbs)

(lbs)

Tensile Limited

918,700

SmoothEdge Height

(in)

(lbs)

3/32 Raised

6.812

1,658,000

Assumed Elevator Bore Diameter

22.45

0.34

0.0082

0.74

0.0175

(lbs/ft)

0.72

0.0171

OD X

(in)

3.938

Tension at Connection

Yield

(lbs)

ID

(in)

120,000

(psi)

Tool Joint Dimensions

Balanced OD

778,100

942,100

(in)

Minimum Tool Joint OD for API

(in)

Premium Class

Minimum Tool Joint OD for

Counterbore

(in)

6.292

6.066

6.066

65,900

942,100

Elevator Shoulder Information

Box OD

Elevator Capacity

(least accurate)

(gal/ft)

Note: The maximum make-up torque should be applied when possible.

Note: To maximize connection operational tensile, a MUT (T4) = 34,000 (ft-lbs) should be applied.

Tool Joint Torsional Strength

Tool Joint Tensile Strength

Nominal

(with Coating)

Note: Oil field barrel equals 42 US gallons.

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

Connection Performance

Maximum Make-up Torque

Minimum Make-up Torque

Range2

(in)

Elevator OD 3/32 Raised

Nominal Tool Joint

Worn to Bevel

OD

Diameter

Worn to Min TJ OD for

API Premium Class

6.625

1,440,200

6.066

826,700

Pipe Body Slip Crushing Capacity

Pipe Body Configuration

Nominal

Assumed Slip Length

Transverse Load Factor (K)

(lbs)

(in)

Pipe Body Performance

350,700

(ft-lbs)

(ft-lbs)

(psi)

(psi)

(in)

(in)

(in)

(in^2)

(in^2)

(in^2)

(in^3)

(in^3)

5 (in) OD

80 % Inspection Class

279,000

Pipe Body Configuration

(lbs)

0.362 (in) Wall

X-95 )

API Premium Class

279,000

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe

Fail in the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference

only. Slip crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in

slips, drill pipe OD and wall variation, and other factors. Consult with the slip manufacturer for additional

information.

16.5

4.2

Nominal

Pipe Tensile Strength

Pipe Torsional Strength

TJ/PipeBody Torsional Ratio

80% Pipe Torsional Strength

Burst

Collapse

Pipe OD

Wall Thickness

Nominal Pipe ID

Cross Sectional Area of Pipe Body

Cross Sectional Area of OD

Cross Sectional Area of ID

Section Modulus

Polar Section Modulus

(in)

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

5.219

Slip Crushing Capacity

6.318

1,096,600

6.812

501,100

52,100

1.26

41,700

12,037

12,026

5.000

0.362

4.276

5.275

19.635

14.360

5.708

11.415

5 (in) OD

80 % Inspection Class

394,600

40,900

1.61

32,700

11,005

8,241

4.855

0.290

4.276

4.154

18.514

14.360

4.476

8.953

0.362 (in) Wall

X-95 )

API Premium Class

394,600

40,900

1.61

32,700

11,005

8,241

4.855

0.290

4.276

4.154

18.514

14.360

4.476

8.953

Note: Nominal Burst

calculated at 87.5% RBW

per API.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear

conditions (remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance

ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to

the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback

Customer Created 02-03-2014

Operational Limits of Drill Pipe

Connection

Pipe Body

XT50

80 % Inspection Class

Tool Joint OD

(in)

6.625

Tool Joint ID

Pipe Body OD

(in)

Wall Thickness (in) 0.362

(in)

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 39,600

Operational Assembly

Torque

Max Tension

(ft-lbs)

0

2,000

4,000

5,900

7,900

9,900

11,900

13,900

15,800

17,800

19,800

21,800

23,800

25,700

27,700

29,700

31,700

33,700

35,600

37,600

(lbs)

394,600

394,100

392,700

390,500

387,200

382,900

377,500

371,100

364,000

355,300

345,300

333,900

320,900

307,000

290,300

271,300

249,300

223,500

194,200

154,600

Pipe Body Grade

Minimum Make-up Torque = 33,200

(ft-lbs)

Operationa Assembly

l Torque

Max Tension

(ft-lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(lbs)

(lbs)

394,600

394,600

918,700

394,600

778,100

394,100

778,100

1,600

394,300

394,300

918,700

778,100

3,100

393,500

393,500

918,700

918,700

390,500

778,100

4,700

392,000

392,000

387,200

778,100

6,300

389,900

389,900

918,700

382,900

778,100

7,800

387,400

387,400

918,700

377,500

778,100

9,400

384,000

384,000

918,700

778,100

11,000

380,100

380,100

918,700

778,100

12,500

375,700

375,700

918,700

778,100

14,100

370,400

370,400

918,700

918,700

371,100

364,000

355,300

345,300

778,100

15,700

364,400

364,400

333,900

778,100

17,200

358,000

358,000

918,700

320,900

778,100

18,800

350,400

350,400

918,700

307,000

778,100

20,300

342,600

342,600

918,700

778,100

21,900

333,300

333,300

918,700

778,100

23,500

323,000

323,000

918,700

312,300

312,300

918,700

918,700

290,300

271,300

249,300

25,000

778,100

223,500

778,100

26,600

299,700

299,700

194,200

778,100

28,200

285,800

285,800

918,700

154,600

778,100

29,700

270,800

270,800

918,700

Operational drilling torque is limited by the Make-up Torque.

(ft-lbs)

Connection

Max Tension

392,700

X-95

Combined Loading for Drill Pipe at

Connection Max

Pipe Body

Max Tension Tension

(lbs)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

3.938

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

33,200

33,900

34,600

35,300

36,000

36,800

37,500

38,200

38,900

39,600

Connection Max

Tension

(lbs)

918,700

938,000

925,800

905,100

884,500

860,800

840,100

819,500

798,800

778,100

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

Connection Wear Table

Connection

XT50

Tool Joint OD

Connection

Wear

Tool

Joint OD

New OD

(in)

6.625

6.574

6.523

6.473

6.422

6.371

6.32

6.269

6.218

6.168

6.117

6.066

Worn OD

(in)

6.625

Tool Joint ID

(in)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

3.938

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

65,900

65,900

65,900

65,900

65,900

65,900

65,900

64,700

62,100

59,500

56,900

54,400

39,600

39,600

39,600

39,600

39,600

39,600

39,600

38,800

37,200

35,700

34,200

32,600

(ft-lbs)

Connection Max

Tension

Min MUT

(lbs)

(lbs)

(ft-lbs)

778,100

773,500

768,700

763,900

758,700

753,300

747,700

763,800

801,000

834,700

867,400

901,900

33,000

913,100

33,000

918,200

33,000

923,700

33,000

929,300

33,000

935,500

33,000

942,100

33,000

935,100

32,400

940,000

31,000

908,200

29,800

881,900

28,500

852,700

27,200

823,300

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

Pipe Body OD

80 % Inspection Class

Pipe Body Torque

(in)

Wall Thickness (in) 0.362

Pipe Body Grade

X-95

3,700

7,400

11,200

14,900

18,600

22,300

26,000

29,700

33,500

37,200

40,800

393,000

388,100

379,500

367,500

351,400

330,800

304,600

271,300

226,300

163,900

26,900

(ft-lbs)

Pipe Body Max

394,600

Tension

(lbs)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

Вам также может понравиться

- Measurement While Drilling: Signal Analysis, Optimization and DesignОт EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignОценок пока нет

- TM 120 Daily and Weekly Inspection and Maintenance TasksДокумент23 страницыTM 120 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoОценок пока нет

- Annular Bops D Bop DL Bop: To Contents PageДокумент6 страницAnnular Bops D Bop DL Bop: To Contents PageJohn Alexander Bonilla AngelОценок пока нет

- Releasing & Circulating OvershotДокумент16 страницReleasing & Circulating OvershotPrime Energy Warehouse-YemenОценок пока нет

- AccumulatorДокумент12 страницAccumulatorNaser Khan100% (1)

- Davis Stage Cementing Collar and Equipment PDFДокумент5 страницDavis Stage Cementing Collar and Equipment PDFPdax FirdausОценок пока нет

- 4200Документ44 страницы4200Hamdi Said100% (1)

- CF Diverter BrochureДокумент2 страницыCF Diverter BrochureRobertok1234Оценок пока нет

- Ttt2b Drillable TlsДокумент26 страницTtt2b Drillable TlsMahmoud Ahmed Ali AbdelrazikОценок пока нет

- Junk Subs (JUNK BASKET)Документ1 страницаJunk Subs (JUNK BASKET)mosli_Оценок пока нет

- TM 120 Commissioning Manual - Rev.01 REVISADOДокумент32 страницыTM 120 Commissioning Manual - Rev.01 REVISADOjaimeОценок пока нет

- Snubbing PDFДокумент134 страницыSnubbing PDFNavin SinghОценок пока нет

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedДокумент8 страницBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightОценок пока нет

- Bowen Fishing Magnets - Instruction ManualДокумент9 страницBowen Fishing Magnets - Instruction Manualmturri100% (1)

- 1PackerSystem PackerAccessories&tools PDFДокумент21 страница1PackerSystem PackerAccessories&tools PDFAnand aashishОценок пока нет

- Seminar Casing FailureДокумент27 страницSeminar Casing FailurehshobeyriОценок пока нет

- Cementing & Casing Accessories Davis-Lynch Equipment CatalogДокумент19 страницCementing & Casing Accessories Davis-Lynch Equipment CatalogfarajОценок пока нет

- Actual Manual de Rig-Up PDFДокумент430 страницActual Manual de Rig-Up PDFJulian TorresОценок пока нет

- F-S Divertor PDFДокумент174 страницыF-S Divertor PDFJohn NorrieОценок пока нет

- Type Z Oil Jars: Instruction Manual 4065Документ24 страницыType Z Oil Jars: Instruction Manual 4065G100% (1)

- RTTS Packer: Technical Data SheetДокумент5 страницRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- 7 Wellhead AccesoriesДокумент7 страниц7 Wellhead AccesoriesafasdgОценок пока нет

- Cameron EB 538 D Rev D2 - Shear Rams - Op & MaintДокумент7 страницCameron EB 538 D Rev D2 - Shear Rams - Op & MaintCanrig RamdeОценок пока нет

- Series 150 Overshots: Instruction Manual 1150Документ25 страницSeries 150 Overshots: Instruction Manual 1150Rares PetreОценок пока нет

- Diverter Manual (Read Only) 29101707Документ158 страницDiverter Manual (Read Only) 29101707adnan0307100% (1)

- Evo-Trieve® EB0 Retrievable Straddle - HalliburtonДокумент2 страницыEvo-Trieve® EB0 Retrievable Straddle - HalliburtonYovaraj KarunakaranОценок пока нет

- Scrugrab 05-03-10 PDFДокумент2 страницыScrugrab 05-03-10 PDFfabisysОценок пока нет

- Prevention, Fishing and Casing Repair - Jim Short - Part 2Документ249 страницPrevention, Fishing and Casing Repair - Jim Short - Part 2MitsúMilagrosToroSayasОценок пока нет

- Ratings Packers PDFДокумент10 страницRatings Packers PDFsabilco13Оценок пока нет

- Casing Packer Setting Tool (CPST) : WL Equipment Guidelines CPSTДокумент9 страницCasing Packer Setting Tool (CPST) : WL Equipment Guidelines CPSTJose Antonio AcostaОценок пока нет

- Pressure Rating For SSII Float EquipmentДокумент2 страницыPressure Rating For SSII Float EquipmentMahmoud Ahmed Ali AbdelrazikОценок пока нет

- 003 Casing & Tubing Hanger PDFДокумент4 страницы003 Casing & Tubing Hanger PDFalaliali88Оценок пока нет

- Hydraquaker: Hydraulic Drilling Jar Delivers High ImpactДокумент4 страницыHydraquaker: Hydraulic Drilling Jar Delivers High ImpactPavin PiromОценок пока нет

- 6.37 Combi Bop ManualДокумент23 страницы6.37 Combi Bop ManualDEATH ASSASSIN GAMERОценок пока нет

- Cup Tester Torque ValuesДокумент3 страницыCup Tester Torque ValuesDorin Radu100% (1)

- IRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Документ68 страницIRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Tanyawat Sahsakmontri100% (2)

- Fishing ToolsДокумент10 страницFishing Toolsdanarkurniadi123Оценок пока нет

- Bop Test Info PDFДокумент18 страницBop Test Info PDFjairaso2950Оценок пока нет

- OMNI Roller ReamerДокумент2 страницыOMNI Roller ReamerCaptain NematollahiОценок пока нет

- 02 - FIP CT M PC 10.2 2009feb11 ExtДокумент4 страницы02 - FIP CT M PC 10.2 2009feb11 ExtKarla HernandezОценок пока нет

- 59 PSL Wireline Basic Manual Rev2Документ128 страниц59 PSL Wireline Basic Manual Rev2Tebengz ShakespearОценок пока нет

- 21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Документ28 страниц21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Mehdi SoltaniОценок пока нет

- Mill Washover ShoesДокумент2 страницыMill Washover ShoesEdwin MP100% (1)

- T3 Annulars BOP Operators Manual 7022 PDFДокумент28 страницT3 Annulars BOP Operators Manual 7022 PDFJohn Jairo Simanca100% (2)

- Study of Dies and InsertsДокумент14 страницStudy of Dies and InsertstraidenОценок пока нет

- Effective Hydrostatic Tubing Bailer for Sand and Junk RecoveryДокумент1 страницаEffective Hydrostatic Tubing Bailer for Sand and Junk RecoveryHassan KhalidОценок пока нет

- Handling ToolsДокумент33 страницыHandling ToolsDaladier LozanoОценок пока нет

- Maintain Annular BOP EfficiencyДокумент21 страницаMaintain Annular BOP EfficiencyDavid GonzalezОценок пока нет

- Reverse Circulating Junk BasketДокумент7 страницReverse Circulating Junk BasketLove KumarОценок пока нет

- Bowen Reverse Circulation Junk Baskets: Instruction ManualДокумент15 страницBowen Reverse Circulation Junk Baskets: Instruction ManualCristian PopaОценок пока нет

- Low Force Shear Ram Test Results SummaryДокумент2 страницыLow Force Shear Ram Test Results SummaryBala KrishnanОценок пока нет

- PART II (Intermediate & Advanced Wireline Course)Документ465 страницPART II (Intermediate & Advanced Wireline Course)Hedi ChhidiОценок пока нет

- Drill Pipe Design FundamentalsДокумент7 страницDrill Pipe Design FundamentalsNaser KhanОценок пока нет

- 13.62 5K Model 7022 Manual PDFДокумент30 страниц13.62 5K Model 7022 Manual PDFPato GonzalezОценок пока нет

- Downhole PDFДокумент84 страницыDownhole PDFVictor MartinezОценок пока нет

- Soft Torque System (Paper) - OME Paper 112Документ18 страницSoft Torque System (Paper) - OME Paper 112Odion Ikhajiagbe100% (1)

- Plug Setting Tool and Junk Basket: Purpose of The ServiceДокумент15 страницPlug Setting Tool and Junk Basket: Purpose of The Servicerobin2806Оценок пока нет

- Section 5 - Milling Tools & Washover EquipДокумент22 страницыSection 5 - Milling Tools & Washover EquipMichèle SpiteriОценок пока нет

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyДокумент1 страницаPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaОценок пока нет

- Blanking Chart XT - XT-M Pin 1d68Документ2 страницыBlanking Chart XT - XT-M Pin 1d68Johann ZabaletaОценок пока нет

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BДокумент3 страницы3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- 5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Документ3 страницы5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Johann ZabaletaОценок пока нет

- 5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Документ3 страницы5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Johann ZabaletaОценок пока нет

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BДокумент3 страницы3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- For Reference Only: Drill Pipe Performance Characteristics ©Документ3 страницыFor Reference Only: Drill Pipe Performance Characteristics ©doploveОценок пока нет

- 5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Документ3 страницы5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Johann ZabaletaОценок пока нет

- 5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Документ3 страницы5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Johann ZabaletaОценок пока нет

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BДокумент3 страницы3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- Grant Prideco Rotary Shoulder HandbookДокумент112 страницGrant Prideco Rotary Shoulder Handbookrlk2806Оценок пока нет

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BДокумент3 страницы3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Документ3 страницыDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaОценок пока нет

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Документ3 страницыDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaОценок пока нет

- Casing Repair-15062015080103Документ16 страницCasing Repair-15062015080103Johann ZabaletaОценок пока нет

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BДокумент3 страницы3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- MatrixДокумент1 страницаMatrixJohann ZabaletaОценок пока нет

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Документ3 страницыDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaОценок пока нет

- EnglishДокумент1 страницаEnglishJohann ZabaletaОценок пока нет

- Tool and Curve Mnemonics for Reeves TechnologiesДокумент47 страницTool and Curve Mnemonics for Reeves TechnologiesJohann ZabaletaОценок пока нет

- Hydrostatic Pressure CalculationДокумент2 страницыHydrostatic Pressure CalculationJohann ZabaletaОценок пока нет

- LDW LogДокумент9 страницLDW LogJohann ZabaletaОценок пока нет

- Estilo IndirectoДокумент2 страницыEstilo IndirectoLelyLealGonzalezОценок пока нет

- MusicДокумент1 страницаMusicJohann ZabaletaОценок пока нет

- ChE212 Implicit Eqn Soln and OptimizationДокумент3 страницыChE212 Implicit Eqn Soln and OptimizationJohann ZabaletaОценок пока нет

- List of Comparative and Superlative AdjectivesДокумент3 страницыList of Comparative and Superlative AdjectivesJohann ZabaletaОценок пока нет

- 6 Chemical FloodingДокумент73 страницы6 Chemical FloodingJohann ZabaletaОценок пока нет

- Lista de Verbos Regulares e Irregulares en InglesДокумент33 страницыLista de Verbos Regulares e Irregulares en InglesAdmirador Bueno67% (21)

- Thermography ReportДокумент9 страницThermography ReportsandrositohangОценок пока нет

- Simple Machines TestДокумент7 страницSimple Machines TestAlyanna CrisologoОценок пока нет

- Service Kit: Single EngineДокумент6 страницService Kit: Single EngineKJ DhimanОценок пока нет

- Z2000 Modulating Zone Comfort System Control PanelДокумент4 страницыZ2000 Modulating Zone Comfort System Control PanelibrahimsirpiОценок пока нет

- OSHA safety standards and engineering reference sheetsДокумент452 страницыOSHA safety standards and engineering reference sheetsobaniceОценок пока нет

- Welding DefectsДокумент4 страницыWelding DefectsSD Recruiters100% (1)

- Caja Transferencia Jeep Grand Cherokee Laredo 1993 4.0LДокумент120 страницCaja Transferencia Jeep Grand Cherokee Laredo 1993 4.0LGermán BustamanteОценок пока нет

- Exploded View of The Suntour Duro DJ E Suspension ForkДокумент1 страницаExploded View of The Suntour Duro DJ E Suspension Forksdjanus0% (1)

- TRIM AND STABILITY CALCULATION SHEET ANALYSISДокумент33 страницыTRIM AND STABILITY CALCULATION SHEET ANALYSISДмитрий ЯрычОценок пока нет

- Design and Analysis of Three Dimensional Structural Analysis of Airfoil To Various Composite MaterialsДокумент4 страницыDesign and Analysis of Three Dimensional Structural Analysis of Airfoil To Various Composite MaterialsSri Tech EngineeringОценок пока нет

- Dead loads and gravity framing designДокумент3 страницыDead loads and gravity framing designYURITZI MARTINEZ CUELLARОценок пока нет

- An Insight of Compacted Graphite Iron (Cgi) Characteristics and Its Production A ReviewДокумент18 страницAn Insight of Compacted Graphite Iron (Cgi) Characteristics and Its Production A ReviewMiguel BrionesОценок пока нет

- IX Exercise Rev 02 PDFДокумент11 страницIX Exercise Rev 02 PDFweerasinghekОценок пока нет

- Parts Manual Current Products I21Документ166 страницParts Manual Current Products I21juancglugoОценок пока нет

- Design and Development of Car Suspension Lower Arm: December 2015Документ8 страницDesign and Development of Car Suspension Lower Arm: December 2015Sami Onur VuralОценок пока нет

- General Catalog 2011: SELCO S.R.LДокумент194 страницыGeneral Catalog 2011: SELCO S.R.LPapp ZsoltОценок пока нет

- Gear TrainsДокумент16 страницGear Trainsraju100% (1)

- Nia Audina Sitanggang CBR Temperature and Heat BMH J 17-18Документ9 страницNia Audina Sitanggang CBR Temperature and Heat BMH J 17-18NIA AUDINA SITANGGANGОценок пока нет

- A Mechanical Engineer S Handbook by ONGC PDFДокумент303 страницыA Mechanical Engineer S Handbook by ONGC PDFshujad77Оценок пока нет

- Short Courses Modelling and Computation of Multiphase FlowsДокумент4 страницыShort Courses Modelling and Computation of Multiphase FlowsKaushik SarkarОценок пока нет

- The Piping Engineering WorldДокумент4 страницыThe Piping Engineering WorldHrishikesh PatilОценок пока нет

- Positioning Strain Gages To Monitor Bending, Axial, Shear, and Torsional LoadsДокумент2 страницыPositioning Strain Gages To Monitor Bending, Axial, Shear, and Torsional LoadsPrakash VasudevanОценок пока нет

- Landing GearДокумент12 страницLanding GearcmpmarinhoОценок пока нет

- TSBДокумент3 страницыTSBnoe dela vegaОценок пока нет

- Altronics DC-CPU IOM 06-1988 PDFДокумент22 страницыAltronics DC-CPU IOM 06-1988 PDFSMcОценок пока нет

- HR2470TДокумент3 страницыHR2470TRosângela O. Santos0% (1)

- BP Heating ManualДокумент44 страницыBP Heating ManualpasabeyОценок пока нет

- Report of Intelligent Braking SystemДокумент29 страницReport of Intelligent Braking SystemHarsh Gaming100% (3)

- Permanent Magnet DC MotorДокумент4 страницыPermanent Magnet DC MotorSourav Kumar100% (1)