Академический Документы

Профессиональный Документы

Культура Документы

Minutes of Meeting: Held at M/S Alshifa Medical Syringes Mfg. Co. Ltd. ON9 TO 11 FEB'08

Загружено:

MohsinShaikhОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Minutes of Meeting: Held at M/S Alshifa Medical Syringes Mfg. Co. Ltd. ON9 TO 11 FEB'08

Загружено:

MohsinShaikhАвторское право:

Доступные форматы

MINUTES OF MEETING

HELD AT M/S ALSHIFA MEDICAL SYRINGES MFG. CO. LTD.

ON 9TH TO 11TH FEB08

M/s Alshifa

Mr. Ibrahim Zimmo

Mr. Farhat CH

M/s Knack Technocrats

Mr. Rohit Darolia

09-02-08

1. Mr. Rohit requested for the electrical load for all the process equipments to

calculate the heat load for HVAC Design. And was submitted by M/s Alshifa.

2. Locations for new machines & existing machine finalized.

3. Meeting held with the structural contractor. It was decided to have service

area just above the injection moulding area between grid A-B (new extension)

4. Mr. Rohit suggested to construct the structure on the basis of 500 Kgs/Sq.M.

load instead of waiting for AHU weight & sizes.

5. Sectional drawing submitted by Mr. Rohit for new extension area between grid

A-B.

6. Revisions in Area Layout

a. Passage & air locks for RM movement from approved RM stores to

dispensing is redesign, as the existing rooms can not be disturbed.

b. Water system will remain at its present location & Die mould shop is

relocated near injection mouldin-1 (grid B-C & 13-15)

c. Lift planned near ink room (grid 7-C) for the movement of moulded

material to the stores in new extension.

d. Existing Air compressors will be shifted out side the building (location

marked in the layout)

10-02-08

1. Layout & Equipment location revised for injection moulding area, as per the

exact site conditions (columns in room)

2. Mr. Rohit checked the existing room dimensions physically and revised the

layout accordingly.

3. Revisions in layout

a. Injection moulding room dimensions revised. Also the equipment

layout revised as per the column locations.

b. Passage P1 adjacent to sterilizer & gamma departments shifted

towards process area by 1.8 mtrs. Dimensions for assembly area

revised accordingly.

c. Existing staircase on grid G is to be removed and new staircase and lift

to be planned.

d. Existing assembly machines & printing machines are relocated in the

new layout.

e. Nitrogen Tank is relocated as it was coming in the passage-P1

4. M/s Alshifa will confirm the orientation of insulin assembly machine with the

manufacturer according to the layout.

5. Meeting held with the HVAC contractor, it was suggested by the contractor

that instead of compressor type chiller we should select absorption type chiller

to save the power consumption. Also the line diagram for AHU is explained by

Mr. Rohit for the classified area.

11-02-08

1. Revised drawing submitted by Mr. Rohit, as per the discussions held on

10-02-08.

2. M/s Alshifa will confirm that the existing columns on grid B and 1-7 can be

shifted by 700 mm to avoid the step in the passage.

3. Meeting held with structural contractor and revised drawing submitted by

Mr. Rohit

4. Mr. Rohit physically checked the locations of existing AHUs. It is decided to

make structure for two or three AHUs above the existing mezzanine area

(Grid 7-9).

5. Meeting held with Mr. Glenn Durham (Agent for Thermax) for the

information about absorption type chillers.

6. Following details area required from Alshifa to design the HVAC system.

a. Existing AHU Capacities (CFM, Tonnage, static pressure etc.)

b. Drawing for Existing AHUs if possible.

c. Existing Ducting Drawings.

d. Existing Chiller capacities.

e. Power consumption for existing utility equipments, cutting mill &

Sterilizer, Gamma.

f.

SECCO details.

7. Bar Chart for submission of drawing is submitted by Mr. Rohit.

Mr. Ibrahim Zimmo

Mr. Farhat CH

Mr. Rohit Darolia

Вам также может понравиться

- Industrial Piping and Equipment Estimating ManualОт EverandIndustrial Piping and Equipment Estimating ManualРейтинг: 5 из 5 звезд5/5 (7)

- Wi-Fi Planning and Design Questionnaire 2.0Документ12 страницWi-Fi Planning and Design Questionnaire 2.0Free Space67% (3)

- CPA Taxation by Ampongan - Principles of TaxationДокумент43 страницыCPA Taxation by Ampongan - Principles of TaxationVictor Tuco100% (1)

- Layer 3 Managed 8 10G Port Switch Controller: RTL9303-CGДокумент55 страницLayer 3 Managed 8 10G Port Switch Controller: RTL9303-CG박윤지100% (1)

- Method Statement For Pile Head BreakingДокумент18 страницMethod Statement For Pile Head BreakingLijo Joseph100% (6)

- Portals/0/WO - RCC - Building Work, Only Labour With Shuttering - SAMPLEДокумент12 страницPortals/0/WO - RCC - Building Work, Only Labour With Shuttering - SAMPLEyogiforyou100% (1)

- Mine Plan Case StudyДокумент23 страницыMine Plan Case Studynear3st1Оценок пока нет

- 2008 Reverse Logistics Strategies For End-Of-life ProductsДокумент22 страницы2008 Reverse Logistics Strategies For End-Of-life ProductsValen Ramirez HОценок пока нет

- Completion Certificate Letter RequestДокумент2 страницыCompletion Certificate Letter RequestJabel Oil Services Technical DPT100% (3)

- EOI-paar Rev2063162815Документ4 страницыEOI-paar Rev2063162815rahul672sweetОценок пока нет

- 140617-Additional HVAC Design ReviewДокумент8 страниц140617-Additional HVAC Design ReviewMd Ashad NasimОценок пока нет

- Minutes of Progress Review Meeting: ParticipantsДокумент3 страницыMinutes of Progress Review Meeting: Participantssivaguruk2Оценок пока нет

- Sr. No. Comments Received From MPPGCL Comments As Per Letter No. 07-02/352, DTD 24.03.2018Документ4 страницыSr. No. Comments Received From MPPGCL Comments As Per Letter No. 07-02/352, DTD 24.03.2018john jacobОценок пока нет

- 1574 03 Vol 2B DS PackageДокумент69 страниц1574 03 Vol 2B DS PackageZahoor AhmedОценок пока нет

- Tajaria Buillding Chiller Maintain 25-2-2014Документ3 страницыTajaria Buillding Chiller Maintain 25-2-2014AmanОценок пока нет

- Moe Transmittal #1resbonse 19jan2012Документ10 страницMoe Transmittal #1resbonse 19jan2012niginpОценок пока нет

- Balance of PlantДокумент5 страницBalance of PlantshringimaheshОценок пока нет

- 2021-03-12 - Special ConditionДокумент11 страниц2021-03-12 - Special ConditionMAULIK RAVALОценок пока нет

- Schematic Rev0 - FinalДокумент8 страницSchematic Rev0 - FinalEslam ElsayedОценок пока нет

- TenderДокумент26 страницTenderShiyas IbrahimОценок пока нет

- Issued Provisional Fire NOC Certificate 1091Документ9 страницIssued Provisional Fire NOC Certificate 1091ram hanumanthaОценок пока нет

- Minutes of Meetings Held On 3rd August 2023Документ4 страницыMinutes of Meetings Held On 3rd August 2023Y Uday BhaskarОценок пока нет

- Full Final Claim StudyДокумент43 страницыFull Final Claim StudyJanet LeeОценок пока нет

- Snapshot 19569Документ6 страницSnapshot 19569FOX 17 News Digital StaffОценок пока нет

- Abbco Conceptual Design ContentsДокумент128 страницAbbco Conceptual Design Contentssbjtcms98Оценок пока нет

- Letter To Poddar GlobalДокумент2 страницыLetter To Poddar GlobaldishkuОценок пока нет

- P91 Repair With NiCrДокумент76 страницP91 Repair With NiCrElias KapaОценок пока нет

- Capital Av 393 CSPR 120914pubДокумент5 страницCapital Av 393 CSPR 120914pubrealhartfordОценок пока нет

- Cold Water Plumbing Design GuideДокумент3 страницыCold Water Plumbing Design GuidejoshuatamОценок пока нет

- Revised Data Roadsbridges1Документ404 страницыRevised Data Roadsbridges1Krishna SinghОценок пока нет

- Technical Requirements, Specifications and Bidding Documents: Dated: 11-14-2016Документ20 страницTechnical Requirements, Specifications and Bidding Documents: Dated: 11-14-2016Savy PhanethОценок пока нет

- Annexure-III: Compliance of General Provisions (Technical) During Construction Phase (To Be Ensured by TL)Документ4 страницыAnnexure-III: Compliance of General Provisions (Technical) During Construction Phase (To Be Ensured by TL)sriОценок пока нет

- Albion Sugar Case PDFДокумент7 страницAlbion Sugar Case PDFAmeeno Pradeep PaulОценок пока нет

- 24 Inch Sirtica Engineering Study DRAFTДокумент24 страницы24 Inch Sirtica Engineering Study DRAFTReggie TuanОценок пока нет

- Revised Data Roadsbridges1Документ538 страницRevised Data Roadsbridges1deepakОценок пока нет

- Standard Data Book For RoadsДокумент1 082 страницыStandard Data Book For RoadsMonjit Gogoi100% (4)

- ZGP Shutdown For Leak ArrestДокумент2 страницыZGP Shutdown For Leak ArrestPazhamalai RajanОценок пока нет

- General Specifications (Civil Works)Документ22 страницыGeneral Specifications (Civil Works)Richard FallegaОценок пока нет

- A Presentation ON Technical Examination OF CHP PackageДокумент28 страницA Presentation ON Technical Examination OF CHP Packagechoudhary.bikash024Оценок пока нет

- Revised Data (Roads&Bridges)Документ409 страницRevised Data (Roads&Bridges)vijayunityОценок пока нет

- Lifetime Extension Against Minimum Downtime and Cost PDFДокумент2 страницыLifetime Extension Against Minimum Downtime and Cost PDFCesar EnochОценок пока нет

- Cinnotech Corporation SMBДокумент9 страницCinnotech Corporation SMBNoel CastilloОценок пока нет

- Construction Staking GuidelinesДокумент3 страницыConstruction Staking GuidelinesMac ShaikОценок пока нет

- Sop EngДокумент8 страницSop EngpaycanachristianОценок пока нет

- Specs For Precast Sub ElementsДокумент11 страницSpecs For Precast Sub ElementsTimothy CruseОценок пока нет

- Ethyleneglycol Plant 2520Location&LayoutДокумент2 страницыEthyleneglycol Plant 2520Location&LayoutThey See Soon EngОценок пока нет

- SSP 500 - Mass Concrete - 9!16!14Документ3 страницыSSP 500 - Mass Concrete - 9!16!14dicky1969Оценок пока нет

- Overview of BHELДокумент8 страницOverview of BHELRahul KashyapОценок пока нет

- Construction of Cover DrainsДокумент4 страницыConstruction of Cover DrainsnaseebОценок пока нет

- Loadability Constratint To Format and UpdateДокумент10 страницLoadability Constratint To Format and Updaterbdubey2020Оценок пока нет

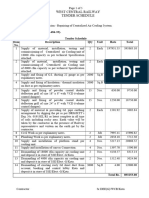

- TTender Schedule EL-50-67-2020-21Документ5 страницTTender Schedule EL-50-67-2020-21kaygupta301102Оценок пока нет

- RAS Pump Valve ReplacementДокумент178 страницRAS Pump Valve ReplacementgeorgedytrasОценок пока нет

- Comments For Generator Shop Drawings Edited by TharangiДокумент2 страницыComments For Generator Shop Drawings Edited by TharangiKrishnasamy SanjeevanОценок пока нет

- Aegis LPG TenderДокумент147 страницAegis LPG TenderKazeem100% (1)

- Testing and Commissioning at Intex Nurmohal (205/3,205/4 Tejgaon, Dhaka)Документ2 страницыTesting and Commissioning at Intex Nurmohal (205/3,205/4 Tejgaon, Dhaka)HabibОценок пока нет

- Site Manager'S Weekly ReportДокумент1 страницаSite Manager'S Weekly ReportMark Nassef NaguibОценок пока нет

- Outstanding IssuesДокумент4 страницыOutstanding IssuesYoga RiKumoroОценок пока нет

- Turn Over ReportДокумент2 страницыTurn Over ReportjdpardoОценок пока нет

- Site Visit ReportДокумент2 страницыSite Visit ReportAqua FiltaОценок пока нет

- Site Manager'S Weekly ReportДокумент2 страницыSite Manager'S Weekly ReportMark Nassef NaguibОценок пока нет

- Request For Hot-Water-Boiler-For-AirportДокумент23 страницыRequest For Hot-Water-Boiler-For-AirportHatem HadiaОценок пока нет

- Boiler Codes Require Updating ToLДокумент9 страницBoiler Codes Require Updating ToLmahmoud_allam3Оценок пока нет

- Published by Technical Services / PSSR For Internal CirculationДокумент33 страницыPublished by Technical Services / PSSR For Internal CirculationVed PrakashОценок пока нет

- Machines, Tools and Methods of Automobile ManufactureОт EverandMachines, Tools and Methods of Automobile ManufactureРейтинг: 4 из 5 звезд4/5 (1)

- Soft Gel MFG ProcedureДокумент4 страницыSoft Gel MFG ProcedureMohsinShaikhОценок пока нет

- Solids Flow Monitor (SFM) :-: January 25, 2016 Mukan, ManishДокумент2 страницыSolids Flow Monitor (SFM) :-: January 25, 2016 Mukan, ManishMohsinShaikhОценок пока нет

- Cleanroom Construction and MaterialsДокумент24 страницыCleanroom Construction and MaterialsMohsinShaikhОценок пока нет

- Cabinet - 1 (Engineers Room) Cabinet - 2 (Engineers Room)Документ13 страницCabinet - 1 (Engineers Room) Cabinet - 2 (Engineers Room)MohsinShaikhОценок пока нет

- Heating Coil in The Main Air Handling UnitДокумент15 страницHeating Coil in The Main Air Handling UnitMohsinShaikh100% (2)

- ASTM E 2500 Standard For Pharma and Biopharma ManufacturingДокумент30 страницASTM E 2500 Standard For Pharma and Biopharma ManufacturingMohsinShaikh100% (2)

- Minutes of Meeting Held At: M/S. Knack Technocrats 0N 16 February 2016Документ2 страницыMinutes of Meeting Held At: M/S. Knack Technocrats 0N 16 February 2016MohsinShaikhОценок пока нет

- Yazid Bin MuawiyaДокумент15 страницYazid Bin MuawiyaMohsinShaikhОценок пока нет

- Approximate Bill of Quantities - Civil: SR. NO. Description Qty. UnitДокумент1 страницаApproximate Bill of Quantities - Civil: SR. NO. Description Qty. UnitMohsinShaikhОценок пока нет

- Are They Going To Destroy The Tomb of The Prophet MohammadДокумент3 страницыAre They Going To Destroy The Tomb of The Prophet MohammadMohsinShaikhОценок пока нет

- Auto CoaterДокумент6 страницAuto CoaterMohsinShaikhОценок пока нет

- Technical Drawing StandardsДокумент28 страницTechnical Drawing StandardsMohsinShaikhОценок пока нет

- AntiДокумент1 страницаAntiMohsinShaikhОценок пока нет

- Various Characteristics of The MahdiДокумент45 страницVarious Characteristics of The MahdiMohsinShaikhОценок пока нет

- Cultural Safety Jesus SantiniДокумент2 страницыCultural Safety Jesus Santinisq4mc4vqckОценок пока нет

- Fine Fragrances After Shave, Eau de Parfum, Eau de Cologne, Eau de Toilette, Parfume Products (9-08)Документ6 страницFine Fragrances After Shave, Eau de Parfum, Eau de Cologne, Eau de Toilette, Parfume Products (9-08)Mustafa BanafaОценок пока нет

- SecuritizationДокумент46 страницSecuritizationHitesh MoreОценок пока нет

- BMW Speakers Install BSW Stage 1 E60 Sedan Logic7Документ13 страницBMW Speakers Install BSW Stage 1 E60 Sedan Logic7StolnicuBogdanОценок пока нет

- High Performance Computing in Power System Applications.: September 1996Документ24 страницыHigh Performance Computing in Power System Applications.: September 1996Ahmed adelОценок пока нет

- Tesco Travel Policy BookletДокумент64 страницыTesco Travel Policy Bookletuser001hОценок пока нет

- MushroomДокумент8 страницMushroomAkshay AhlawatОценок пока нет

- UNIT 6 - Dr. Cemre Erciyes PDFДокумент24 страницыUNIT 6 - Dr. Cemre Erciyes PDFMaries San PedroОценок пока нет

- Group9 SecAДокумент7 страницGroup9 SecAshivendrakadamОценок пока нет

- Blockchain Unit Wise Question BankДокумент3 страницыBlockchain Unit Wise Question BankMeghana50% (4)

- Profile Romblon IslandДокумент10 страницProfile Romblon Islandderella starsОценок пока нет

- Art 3 Sec 2Документ157 страницArt 3 Sec 2KELVINОценок пока нет

- HRM Ass1Документ3 страницыHRM Ass1asdas asfasfasdОценок пока нет

- 1 General: Fig. 1.1 Industrial RobotДокумент40 страниц1 General: Fig. 1.1 Industrial RobotArunОценок пока нет

- Shareholder Agreement 06Документ19 страницShareholder Agreement 06Josmar TelloОценок пока нет

- Past Simple and Continuous - When - While Worksheet - Live WorksheetsДокумент4 страницыPast Simple and Continuous - When - While Worksheet - Live WorksheetsSaraí CaracúnОценок пока нет

- Evaporator EfficiencyДокумент15 страницEvaporator EfficiencySanjaySinghAdhikariОценок пока нет

- Cattle Feed Close Tenders in BikanerДокумент9 страницCattle Feed Close Tenders in BikanerCodm DutyОценок пока нет

- Introduction To Content AnalysisДокумент10 страницIntroduction To Content AnalysisfelixОценок пока нет

- Beneparts Quotation BYBJ192388 20191024Документ1 страницаBeneparts Quotation BYBJ192388 20191024احمد عبدهОценок пока нет

- Oxford Handbooks Online: From Old To New Developmentalism in Latin AmericaДокумент27 страницOxford Handbooks Online: From Old To New Developmentalism in Latin AmericadiegoОценок пока нет

- Accomplishment Report Dictrict Preventive MaintenanceДокумент2 страницыAccomplishment Report Dictrict Preventive MaintenanceZenia CapalacОценок пока нет

- Transport StrikeДокумент9 страницTransport StrikeYsrael Von ArcillaОценок пока нет

- Bsa 32 Chap 3 (Assignment) Orquia, Anndhrea S.Документ3 страницыBsa 32 Chap 3 (Assignment) Orquia, Anndhrea S.Clint Agustin M. RoblesОценок пока нет

- Water Cooled Centrifugal Chiller (150-3000RT)Документ49 страницWater Cooled Centrifugal Chiller (150-3000RT)remigius yudhiОценок пока нет

- Form Ticketing Latihan ContohДокумент29 страницForm Ticketing Latihan ContohASPIN SURYONOОценок пока нет