Академический Документы

Профессиональный Документы

Культура Документы

Precise automated or manual tilting weir gates

Загружено:

sandaldmОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Precise automated or manual tilting weir gates

Загружено:

sandaldmАвторское право:

Доступные форматы

TILTING WEIR GATES

WATERMAN TILTING WEIR GATES

FOR PRECISE AUTOMATED OR

MANUAL LEVEL AND FLOW CONTROL

The tilting weir gate can be totally self-contained

and include fully automated electric motor operation. It is capable of accepting set-point inputs

from user equipment.

The design of the tilting weir hoist is precisely and

thoroughly calculated for each gate. This typically includes:

1.

2.

3.

4.

5.

6.

7.

Cable analysis with a safety factor of 5

Drum diameter of 14 times that of cable

Shaft analysis for beam and torque loading

Bearing requirements

Lift capacity

Torque requirements

Number of turns to open the gate

By incorporating gear reduction actuators, the

size ranges of hoist systems are virtually limitless. The hoist system can be designed to span

the gate structure, thus eliminating the need for

expensive concrete decks and pads for mounting gear reducers or pillow-block bearings.

Waterman Industries

of Egypt

-1-

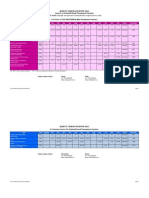

TILTING WEIR GATES

TYPICAL SPECIFICATIONS

GENERAL

The Tilting Weir Gate system shall be furnished as a complete package including gate leaf;

gate hinge; mounting angle; and side seal plates, gate seals; gate operator; and miscellaneous

appurtenances as necessary to place the system in operation to perform its intended

functions.

GATE LEAF

Gate leaf dimensions shall be sufficient to span structure width and provide a water barrier to

depth shown on drawings. The leaf shall consist of a steel frame joined by welding and covered

with a steel sheet face plate. Steel sheets for face plate shall cover the full height of the gate

with no horizontal seams. The face plates shall be joined together and attached to the

structural members by welding.

GATE ARMS

Gate arms for attaching lifting cables shall extend above top of gate.

GATE HINGE

Hinge plates shall be stainless steel conforming to ASTM A240, type 304. The pin shall be

stainless steel in accordance with ASTM 582, Type 303.

MOUNTING ANGLE

The mounting angle shall include stud anchors for embedment in the concrete sill and threaded

bolts for bolting the gate hinges to the mounting angle. The studs for attachment of the gate

hinge to the mounting angle shall be stainless steel conforming to ASTM F-593 Type 304. Cap

nuts and washers shall be 304 stainless steel per ASTM F-594.

SEALS

Seal angles shall be stainless steel and shall be designed to be attached to the leaf gate

structure bay walls on each side of the gate. The seals angles shall have J-seals attached

to the downstream face of the angles so that the J-seals will compress against the sides of

the leaf gates as the gate is brought into the fully closed position.

Hinge Seal shall be a neoprene flap attached on one edge to cover and seal the hinge area.

WIRE DRUM GATE HOISTS

The hoist shall consist of a hoist base, hoist operator, cable drums, drum shaft, cables and

bearing bracket to operate the tilting weir gates. The operators shall be adequate for opening

of the gates to the gate height.

The hoist shall be furnished with steel drum shaft and with two steel drums of the same

diameter attached to the drum shaft. Stainless steel cables and clamps shall be furnished for

field connection to the drums and to the gate. The drum diameter shall not be less than 14 times

the cable diameter.

The manual hoist operator shall consists of a self-locking worm and worm gear, with reduction

spur gears as required, totally enclosed in a cast iron housing. A suitable size handwheel,

Waterman Industries

of Egypt

-2-

TILTING WEIR GATES

TYPICAL SPECIFICATIONS

located approximately 900mm above operating surface, shall be provided to produce the

necessary output torque to raise gate when a maximum 18 kg (40 lb) pull is exerted on the

handwheel rim. The handwheel shall turn counter clockwise to open (lower) gate and the

direction of rotation to open gate shall be marked on handwheel.

MATERIALS

Gate and embedded seal plates

ASTM A 36, DIN 17100 St 37-2

Support brackets, drive shafts and cable drums

ASTM A 36, DIN 17100 St 37-2

Anchor bolts

Type 304 stainless steel bolts.

Finish

Mill finish on all stainless steel surfaces

Epoxy paint on all steel surfaces

Waterman Industries

of Egypt

-3-

Вам также может понравиться

- Specification Series 20 Ss Sluice GateДокумент6 страницSpecification Series 20 Ss Sluice GatepramodtryОценок пока нет

- Sluice GateДокумент2 страницыSluice GateMadusha TisseraОценок пока нет

- AB Valves Manufacturer Industrial Valves EquipmentsДокумент4 страницыAB Valves Manufacturer Industrial Valves EquipmentsRoger Labra LlanoОценок пока нет

- Voith Siemens Hydro Power Generation Micro Turbines Harness Water ResourcesДокумент8 страницVoith Siemens Hydro Power Generation Micro Turbines Harness Water ResourcesAshutosh VashishthaОценок пока нет

- Radial GatesДокумент12 страницRadial GatesCHEL TAKОценок пока нет

- Guide Frame Stop Log 1Документ1 страницаGuide Frame Stop Log 1Ilham PratamaОценок пока нет

- Design of Slide Gate Size 1.6 X 2 MДокумент4 страницыDesign of Slide Gate Size 1.6 X 2 MTarunPatraОценок пока нет

- Hydraulic Design of Hollow Jet Valve-PAP-0152Документ19 страницHydraulic Design of Hollow Jet Valve-PAP-0152laherrans100% (1)

- Waterfront Stoplogs GuideДокумент1 страницаWaterfront Stoplogs GuideiculasiОценок пока нет

- Wetted Rack Length of the Tyrolean WeirДокумент9 страницWetted Rack Length of the Tyrolean Weirzulkifli1220Оценок пока нет

- Sedicon Sluicers As Effective MethodДокумент9 страницSedicon Sluicers As Effective Methodप्रवीण देशारОценок пока нет

- 9 Design of Permanent, Final Linings: EM 1110-2-2901 30 May 97Документ32 страницы9 Design of Permanent, Final Linings: EM 1110-2-2901 30 May 97Prem Singh RawatОценок пока нет

- Expantion Joint (2) : Section 1Документ1 страницаExpantion Joint (2) : Section 1Made Agus BudiarthaОценок пока нет

- Khani Khola - 1 HPP: Design Calculation of Bifurcation Block HorizontalДокумент10 страницKhani Khola - 1 HPP: Design Calculation of Bifurcation Block HorizontalAsmita Koirala100% (1)

- Draft IS 4721Документ10 страницDraft IS 4721rajfabОценок пока нет

- HydromechanicalДокумент31 страницаHydromechanicalJennifer HudsonОценок пока нет

- Howell Bunger Valve 05. HBGR - Text New CoverДокумент4 страницыHowell Bunger Valve 05. HBGR - Text New CovermuazeemKОценок пока нет

- Weir Intake Gate PDFДокумент12 страницWeir Intake Gate PDFIchwan RachmantoОценок пока нет

- 4.2bearing Type ConnectionsДокумент6 страниц4.2bearing Type ConnectionsMani KumarОценок пока нет

- Intake Structures: Group-I 114AR0002 - 114AR0007 - 114AR0026 - 114AR0027 - 114AR0028 - 114AR0030 - 114AR0032Документ22 страницыIntake Structures: Group-I 114AR0002 - 114AR0007 - 114AR0026 - 114AR0027 - 114AR0028 - 114AR0030 - 114AR0032Priyanjita AdhikariОценок пока нет

- Sluice Gate ManufacturerДокумент2 страницыSluice Gate ManufacturerVed PrakashОценок пока нет

- Optimum Design of Penstock For Hydro Projects PDFДокумент12 страницOptimum Design of Penstock For Hydro Projects PDFTharindu Nuwan JayakodyОценок пока нет

- Awwa C200 PDFДокумент6 страницAwwa C200 PDFangel darioОценок пока нет

- Penstocks DesignДокумент36 страницPenstocks DesignTaher Mohiuddin100% (1)

- 330MW Shrinagar Project Technical Data SheetДокумент4 страницы330MW Shrinagar Project Technical Data Sheetsrigirisetty208Оценок пока нет

- Indian Standard Radial GateДокумент8 страницIndian Standard Radial GateMirza FadlulahОценок пока нет

- 01 ST601 Design of Hydraulic Steel Structures (Miter Gates)Документ55 страниц01 ST601 Design of Hydraulic Steel Structures (Miter Gates)JonesОценок пока нет

- Design of a submerged slide gate structureДокумент11 страницDesign of a submerged slide gate structurealiОценок пока нет

- Gates 1Документ30 страницGates 1Caliwan CarlsonОценок пока нет

- Design Criteria For Exposed Hydro Penstocks - Gordon1978 PDFДокумент12 страницDesign Criteria For Exposed Hydro Penstocks - Gordon1978 PDFDavid DelgadoОценок пока нет

- Is 6938Документ13 страницIs 6938Dhanashri Patil100% (1)

- Sluice Gate Presentation1Документ44 страницыSluice Gate Presentation1Nazakat HussainОценок пока нет

- 330MW Shrinagar Hydroelectric Project Penstock Intake DataДокумент2 страницы330MW Shrinagar Hydroelectric Project Penstock Intake Datasrigirisetty208Оценок пока нет

- Draft Tube Theory PDFДокумент3 страницыDraft Tube Theory PDFDeva Raj100% (2)

- Optimizing Hydropower Trashrack Design Saves MoneyДокумент4 страницыOptimizing Hydropower Trashrack Design Saves MoneypicottОценок пока нет

- Spillway Conduit DesignДокумент21 страницаSpillway Conduit DesignBandula PrasadОценок пока нет

- Penstock Thickness CaclДокумент44 страницыPenstock Thickness CaclAnonymous sfkedkym100% (1)

- HDPE Vs GRPДокумент14 страницHDPE Vs GRPMariusОценок пока нет

- Tyrolean Intake Calculation PDFДокумент125 страницTyrolean Intake Calculation PDFAlban100% (1)

- Lime-Dosing Wam Inc Brochure 0114 EDIT PDFДокумент4 страницыLime-Dosing Wam Inc Brochure 0114 EDIT PDFWidiyanto WidiyantiОценок пока нет

- Fet Ci Lecture Notes Prof Quamrul Hassan Design-WeirДокумент53 страницыFet Ci Lecture Notes Prof Quamrul Hassan Design-WeirVEDANT SHARMA 129Оценок пока нет

- Strength Analysis of Penstock Bifurcation Hydropower PlantДокумент12 страницStrength Analysis of Penstock Bifurcation Hydropower PlantJenny Cecilia Ureña ZuriОценок пока нет

- Tyrolean Weir PDFДокумент148 страницTyrolean Weir PDFRex ImperialОценок пока нет

- Hydrodynamic Calculation Howell-Jet ValveДокумент18 страницHydrodynamic Calculation Howell-Jet ValveEng-CalculationsОценок пока нет

- Rodney Hunt Fixed Cone ValvesДокумент5 страницRodney Hunt Fixed Cone ValvesTejender ThakurОценок пока нет

- Design of Hydraulics Structures 89Документ6 страницDesign of Hydraulics Structures 89Jhon Sebastian BolañosОценок пока нет

- Pen StockДокумент59 страницPen StockArpit Agrawal100% (1)

- Design of Hydraulic Structures: B.Tech Civil Credit Hours: 03Документ16 страницDesign of Hydraulic Structures: B.Tech Civil Credit Hours: 03Suleman FaisalОценок пока нет

- Sluice Gate SpecificationДокумент6 страницSluice Gate Specificationramkumar121Оценок пока нет

- Cast Iron Slide Gate SpecificationДокумент12 страницCast Iron Slide Gate SpecificationSohaib Ahmad MushtaqОценок пока нет

- Pinch Valve SpecificationsДокумент7 страницPinch Valve SpecificationsPrakashОценок пока нет

- Sluice Gate ValveДокумент15 страницSluice Gate ValveRinia DurrsakeОценок пока нет

- Vertical Turbine Pumps for Demanding ApplicationsДокумент16 страницVertical Turbine Pumps for Demanding ApplicationsAlex Arma del CarpioОценок пока нет

- Tainter Gate SpecificationДокумент3 страницыTainter Gate SpecificationreviloОценок пока нет

- CraneДокумент19 страницCranedeua2004Оценок пока нет

- Waterman AF-41 Flap GatesДокумент3 страницыWaterman AF-41 Flap GatesIbnuyusoff77Оценок пока нет

- High Mast SpecsДокумент10 страницHigh Mast SpecsBhanu PratapОценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Flood Gate PhotoДокумент6 страницFlood Gate PhotosandaldmОценок пока нет

- Letter UndertakingДокумент1 страницаLetter UndertakingsandaldmОценок пока нет

- Screw Pump Level DrawingДокумент1 страницаScrew Pump Level DrawingsandaldmОценок пока нет

- Attendance Report2Документ1 страницаAttendance Report2sandaldmОценок пока нет

- Progress Photos of Horizontal Conveyor by Adasfa Sdn. BHDДокумент33 страницыProgress Photos of Horizontal Conveyor by Adasfa Sdn. BHDsandaldmОценок пока нет

- Series TF-1: Materials of ConstructionДокумент1 страницаSeries TF-1: Materials of ConstructionsandaldmОценок пока нет

- Pekula Stoplog-Progess PhotosДокумент2 страницыPekula Stoplog-Progess PhotossandaldmОценок пока нет

- ST Training Planner 2012Документ16 страницST Training Planner 2012sandaldmОценок пока нет

- Tanah 205depa Di Pasir Tumbuh - Land For Sale Kelantan - MudahДокумент1 страницаTanah 205depa Di Pasir Tumbuh - Land For Sale Kelantan - MudahsandaldmОценок пока нет

- Terminals of Ecm: For M/TДокумент4 страницыTerminals of Ecm: For M/TTdco SonicoОценок пока нет

- Cyber Dynamic Line UsДокумент8 страницCyber Dynamic Line UsMilan PitovicОценок пока нет

- Spec - LA 11,22,33 KV LA R1 Sep10Документ14 страницSpec - LA 11,22,33 KV LA R1 Sep10Amarjit KulkarniОценок пока нет

- Top Issues List - V2Документ110 страницTop Issues List - V2Lam HoangОценок пока нет

- Trajectory ClusteringДокумент58 страницTrajectory ClusteringPetrick Gonzalez PerezОценок пока нет

- Carrier LDU ManualДокумент123 страницыCarrier LDU Manualdafrie rimbaОценок пока нет

- Electric Current and Ohm's Law - LecturesДокумент21 страницаElectric Current and Ohm's Law - LecturesMuhammad AhmadОценок пока нет

- Eee342 hw3 PDFДокумент2 страницыEee342 hw3 PDFRedion XhepaОценок пока нет

- Fire Safety Equipment SpecificationДокумент12 страницFire Safety Equipment SpecificationRIMEL ASMAОценок пока нет

- Mikom Remote Unit Software ManualДокумент35 страницMikom Remote Unit Software ManualealforaОценок пока нет

- Chap4 Student VersionДокумент39 страницChap4 Student VersionAzrif MoskamОценок пока нет

- Ztree 2 StataДокумент3 страницыZtree 2 StataDaniel Felipe ParraОценок пока нет

- AllProducts catalogGREENHECKДокумент52 страницыAllProducts catalogGREENHECKGenes Macalintal GalleneroОценок пока нет

- R Programming CheatsheetДокумент6 страницR Programming CheatsheetAnand PrasadОценок пока нет

- IWWA Directory-2020-2021Документ72 страницыIWWA Directory-2020-2021venkatesh19701Оценок пока нет

- AT-8600 Series Switch: Hardware ReferenceДокумент30 страницAT-8600 Series Switch: Hardware ReferenceSubbuОценок пока нет

- Linear Loaded Vert 80-40Документ14 страницLinear Loaded Vert 80-40Claudio ChiconОценок пока нет

- A Study On Customer Satisfaction Towards Online Banking ServicesДокумент12 страницA Study On Customer Satisfaction Towards Online Banking ServicesEditor IJTSRD100% (1)

- 9303 Part 1 Vol 1 PDFДокумент99 страниц9303 Part 1 Vol 1 PDFrexthrottleОценок пока нет

- Fix 3Документ12 страницFix 3Eng TrОценок пока нет

- Scientific Management's Influence on Organizational DesignДокумент8 страницScientific Management's Influence on Organizational Designjailekha0% (1)

- Perencanaan Produksi Dan Kebutuhan Material: Modul 4Документ48 страницPerencanaan Produksi Dan Kebutuhan Material: Modul 4Ivanca Earltina Miranda SimanungkalitОценок пока нет

- OSN 6800 Electronic DocumentДокумент159 страницOSN 6800 Electronic DocumentRashid Mahmood SajidОценок пока нет

- Finaldc 2Документ10 страницFinaldc 2Noel BactonОценок пока нет

- Be 2K OEM's Manual: Bernini Design SRL - ItalyДокумент48 страницBe 2K OEM's Manual: Bernini Design SRL - ItalySergio Ricardo IbañezОценок пока нет

- Question BankДокумент3 страницыQuestion BankArshath AbdullahОценок пока нет

- InRoom Tech Data 31010 ApcДокумент92 страницыInRoom Tech Data 31010 ApcRolandoОценок пока нет

- Blast Furnace Cooling System MonitoringДокумент27 страницBlast Furnace Cooling System MonitoringAnil MistryОценок пока нет

- W6 ReadmeДокумент15 страницW6 ReadmewerewОценок пока нет

- Syabas Water ApplicationДокумент7 страницSyabas Water ApplicationKen Chia0% (1)