Академический Документы

Профессиональный Документы

Культура Документы

PV Array Emulator For Testing Commercial PV Inverters

Загружено:

ĐứcTrọngИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PV Array Emulator For Testing Commercial PV Inverters

Загружено:

ĐứcTrọngАвторское право:

Доступные форматы

http://dx.doi.org/10.5755/j01.eee.19.10.

5899

ELEKTRONIKA IR ELEKTROTECHNIKA, ISSN 1392-1215, VOL. 19, NO. 10, 2013

PV Array Emulator for Testing Commercial PV

Inverters

C. Roncero-Clemente1, E. Romero-Cadaval1, V. M. Minambres1, M. A. Guerrero-Martinez1,

J. Gallardo-Lozano1

1

Power Electrical and Electronic Systems Research Group (PE&ES),

Elvas Avenue, University Campus. School of Industrial Engineering of Badajoz. 06006 Spain

croncero@peandes.unex.es

temperature (T).

This fact obliges that every commercial PV inverter must

be tested under different conditions. For high power testing

applications a DC power supply is hard to find and certainly

a PV array could not be available.

There are some commercial PV array emulators but they

present limitations in the output power and also in the

number of points of the I-V panel curve reproduction.

Several prototypes developed by researchers can be found in

the literature [6][10]. In [6] a DC power supply is

programmed according to a PV model which increases the

accuracy of the I-V curve but the same power level

limitation level appears when the MPPT efficiency is tested.

Other works [7][9] use different DC/DC converter

topologies to obtain the I-V curves but the influence of

temperature and solar irradiance is not taken into account in

some of them. In other cases, the used model to emulate the

I-V curve requires some parameters which are not provided

by manufacturers in the PV panel datasheet being difficult

their use [10].

The main goal of this paper is to show a regenerative PV

array emulator for high power application in order to test PV

inverters. Every kind of PV panels could be emulated by a

PV model which only uses parameters provided in

datasheets. The power conversion is done by a three-phase

synchronous rectifier which allows demanding sinusoidal

currents from the grid which are synchronized with the

voltage at the point of common coupling (PCC) increasing

the power quality. This emulator can be used to evaluate the

performance of PV inverters and the efficiency of MPPT

algorithms under different conditions of W and T.

1AbstractThis paper is devoted to the design and

construction of a photovoltaic array emulator for high power

applications in order to analyze and evaluate all kind of

commercial photovoltaic inverters. To validate the proposed

photovoltaic emulator experimentally, a rapid prototyping tool

based on xPC Target of Matlab/Simulink has been used,

providing a real-time testing environment. The proposed

emulator has been used to test the performance and maximum

power point tracking algorithm efficiency of a commercial

photovoltaic inverter by programming the desired conditions

of temperature and irradiance.

Index TermsPhotovoltaic systems, inverters, energy

efficiency, Matlab.

I. INTRODUCTION

Nowadays, the power electrical system scenario is quite

different in comparison with the traditional configuration

[1]-[2]. Several factors, such as an electrical consumption

increase, the electrical market liberalization, the need to

reduce CO2 emission, and the new technological

development are boosting the distributed generation (GD).

Renewable distributed energy resources are becoming

more and more popular (wind turbines, photovoltaic (PV)

plants, fuel cells, microturbines, etc) [3]. Many of them can

only output DC voltage so an inverter interface has to be

used.

PV generation plants have increased a lot over the last

years, taking an important role towards a sustainable energy

system. The performance of PV panels and PV inverters and

also their maintenance are keys in the pay-back time and the

profitability of grid-connected PV plants.

Several control algorithms are involved in PV inverters,

for instance: maximum power point tracker (MPPT) [4],

anti-islanding algorithm and reactive power compensation

ability. The efficiency of these algorithms must to be

assured in order to carry out their roles being essential in the

overall performance [5].

Due to the high cost of the solar panels, the maximum

power point (MPP) operation is necessary to maximize the

output power in different conditions of irradiance (W) and

II. PV ARRAY EMULATOR TOPOLOGY

In order to achieve PV array emulation, an electronic

converter working as a rectifier has been used. AC/DC

family of converters constitutes the interface circuit between

the electrical grid and the DC loads. With the ever increase

of power quality requirements at the point of common

coupling (PCC), these converters are nowadays required to

achieve different task such as: provide high input power

factor, low current distortion [11] and fixed output voltage.

Synchronous rectifier allows demanding sinusoidalcurrents

from the grid which are synchronized with the voltage at the

PCC. Fig. 1 shows the topology used in the PV array

emulator.

Manuscript received May 21, 2013; accepted July 14, 2013.

This research was supported by Ministerio de Economa y

Competitividad, Fondos FEDER, Junta de Extremadura, Consejera

de Empleo, Empresa e Innovacin and Fondo Social Europeo. The work

has been developed under the Project SIDER (TEC2010-19242-C03) and

the grant BES-2011-043390.

71

ELEKTRONIKA IR ELEKTROTECHNIKA, ISSN 1392-1215, VOL. 19, NO. 10, 2013

Fig. 1. Photovoltaic array emulator topology.

The electronic converter controlled to emulate the PV

array is the Semikron SEMISTACK SKS 230F B8CI 190

V12. The commercial PV inverter to be tested is connected

to the DC-link of the PV array emulator.

array model. By this way, the reference DC link voltage

(V*DC) is generated according to the I-V curve.

In order to generate the reference current (i*s) to be

demanded from the grid by the PV emulator, a proportionalintegral (PI) controller calculates the reference RMS current

(I*s,RMS) (control variable) depending on the DC voltage

error. The peak value of the reference current is multiplied

by three unitary waveforms synchronized with the voltage

(vpcc) at the PCC. These waveforms are provided by an

adjustable synchronous reference frame (ASRF) [12].

III. CONTROL STRATEGY. REFERENCE GENERATION

In this section the whole control strategy to generate the

references of the PV array emulator are explained. The

control strategy block diagram is depicted in Fig. 2.

d

iDC

v pcc

v pcc

T

*

VDC

*

I s,rms

B. PV array model

In order to reproduce the typical curve of a PV panel, a

PV model has been employed.

This model, explained in detail in [13], is based on the IV exponential curve defined by the information provided by

the manufacturers in datasheets. I-V curves obtained in the

simulation of the panel Shell SP 150-P in different

conditions of W and T are shown in Fig. 3(a) and Fig. 3(b).

The parameters of this commercial panel have been used to

emulate the PV array during experimental tests.

v dpcc

d

V pcc

,RMS

i*s

*

I s,rms

vDC

Fig. 2. Control strategy block diagram of the PV array emulator.

A. PV Array Emulator Control Strategy

The measured DC-link current (idc) is the input of the PV

a)

5

Current (A)

4

60C

50C

40C

30C

20C

3

2

1

0

0

10

15

20

25

Voltage (V)

30

35

b)

Fig. 3. a) I-V curves in different irradiance conditions. b) I-V curves in different temperature conditions.

72

40

45

ELEKTRONIKA IR ELEKTROTECHNIKA, ISSN 1392-1215, VOL. 19, NO. 10, 2013

real-time testing environment is depicted in Fig. 5.

The real time environment built for rapid prototyping is

based on xPC Target from Matlab/Simulink. The PV model,

control strategy and current controller have been

implemented on the host PC (which runs Matlab/Simulink,

Real-Time Workshop and xPC Target toolbox). xPC Target

operates with the code generated by a C compiler from the

Simulink models in order to develop the real-time target

application. Target application can be executed in real time

once it is downloaded in the target PC from the host PC

through TCP/IP. The target PC is equipped with data

acquisition Cards (DAQs). The measurements are carried

out with hall effect sensors to measure the DC-link current

and the demanded current from the grid and voltage sensors

to capture the DC-link voltage and voltages at PCC.

To evaluate the performance of a commercial PV inverter,

the power quality analyzer Fluke 435 Series II has been

connected to the power stage, which allows measuring the

PV inverter performance.

IV. CURRENT CONTROLLER. REFERENCE TRACKING

A hysteresis band Fig. 4 has been used as current

controller in the PV array emulator to track the demanded

reference current. This technique compares the reference

current with the measured current and depending of the sign

of the error the switching signals of the IGBTs are

generated.

a)

VI. MPPT STATIC EVALUATION

In order to evaluate commercial PV inverter efficiency,

the MPPT algorithm must be evaluated. The efficiency of

this algorithm and it proper operation are essentials to inject

the maximum amount of energy produced by the PV panels.

The MPPT efficiency is calculated as follows (1)

MPPT

Ppv

PMPP

100,

(1)

where Ppv and PMPP are the theoretical power of the PV array

and the power at the MPP respectively determined it by the

commercial PV inverter.

To analyze the static efficiency of a commercial inverter,

an experimental test has been carried out. The different

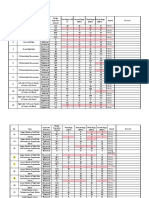

parameters used during experimental tests are shown in

Table I.

b)

Fig. 4. a) Hysteresis band block diagram. b) Switching signal generation.

V. PV ARRAY EMULATOR EXPERIMENTAL SETUP

A block diagram of the experimental prototype and the

Fig. 5. Block diagram of the experimental test setup.

73

ELEKTRONIKA IR ELEKTROTECHNIKA, ISSN 1392-1215, VOL. 19, NO. 10, 2013

between current and voltage is demonstrated. In Fig. 7 we

can see DC-link voltage and current when the MPP is

achieved by the commercial inverter.

According to the theoretical parameters of the PV panel

Shell SP 150-P provided by manufacturers at MPP and the

PV array configuration, the MPP static efficiency is 98 %.

TABLE I. USED PARAMETERS IN EXPERIMENTAL TESTS.

Parameter

Description

Value

Stage

np

Number of panel in

parallel

Array

configuration

ns

Number of panel in series

12

Isc

Short-circuit current (A)

4.8

Voc

Open circuit voltage (V)

43.4

Vmpp

Voltage at MPP (V)

34

Impp

Current at MPP (A)

4.41

Temperature (C)

25

Irradiance (W/m )

1000

Vs

RMS voltage at PCC

400

Electrical grid

Lf

Filter inductance (mH)

6.2

C1,C2

DC-link capacitors (mF)

28.2

Passive

elements

fw

Switching frequency (kHz)

12

PV panel

parameters.

Shell SP 150P

VII. MPPT DYNAMIC EVALUATION

In order to analyze the dynamic MPPT efficiency and the

required time to reach the MPP in variable conditions of

irradiance, different irradiance profiles have been

implemented.

First of all, the time since the MPP algorithm start to

work when the commercial inverter is connected to the

electrical grid till the MPP is reached has been analyzed.

This evolution is shown in Fig. 8. The time that the

commercial inverter requires to achieve the MPP is 9

seconds.

Also, a step in the irradiance from 1000 W/m2 to

700 W/m2 and to 1000 W/m2 again has been done. The

response of the MPP algorithm is depicted in Fig. 9. The

time to reach the new MPP is 150 ms.

Conditions

The commercial PV inverter that has been studied is the

SMA Sunny Mini Central 6000TL. Figure 6 shows the

voltage at the PCC and the demanded current (phase A) by

the PV emulator and the proper synchronization in phase

Fig. 6. Voltage at PCC and demanded current (phase A).

Fig. 7. PV voltage and PV current.

74

ELEKTRONIKA IR ELEKTROTECHNIKA, ISSN 1392-1215, VOL. 19, NO. 10, 2013

IX. CONCLUSIONS

A PV array emulator has been proposed and validated in

this paper. It reproduces any PV panel and array association

with a high level of accuracy by only using the information

provided by manufacturers of PV panels in datasheet.

It device is suitable for testing commercial PV inverter at

high power level. Also, it is possible to program any

irradiance and temperature profiles which allow evaluating

MPP tracking algorithm efficiency and power energy

conversion performances.

REFERENCES

[1]

[2]

Fig. 8. PV voltage and PV current evolution when the commercial inverter

searchs the MPP.

[3]

[4]

[5]

[6]

[7]

Fig. 9. PV voltage and PV current during irradiance steps.

VIII. PERFORMANCE EVALUATION

[8]

To calculate the performance of the energy conversion on

the DC-link power and the AC output power the power

quality analyzer Fluke 435 Series II has been connected to

the power stage. This equipment has the capability of

evaluating the

power

inverter

performance.

It

simultaneously measure AC output power and DC input

power for power electronics system.

The obtained performance at rated power of the inverter

SMA Sunny Mini Central 6000TL is 92.87 % as Fig. 10

shows.

[9]

[10]

[11]

[12]

[13]

Fig. 10. Calculated performance by the power quality analyzer Fluke 435

Series II of the tested commercial inverter.

75

International Energy Agency. Photovoltaic Power Systems

Programme, [Online]. Available: http://www.iea-pvps.org. Statistic

Reports, 2011.

A.Andrijanovits, H.Hoimoja, D. Vinnikov, Comparative review of

long-term energy storage technologies for renewable energy systems,

Electronics and

Electrical

Engineering

(Elektronika

ir

Elektrotechnika), no. 2, pp. 2126, 2012.

V. Salas, E. Olias, Overview of the Photovoltaic Technology Status

and Perspective in Spain, Renewable and Sustainable Energy

Reviews, vol. 13, pp. 10491057, 2009. [Online]. Available:

http://dx.doi.org/10.1016/j.rser.2008.03.011

D. Vasarevicius, R. Martavicius, M. Pitukis, Application of artificial

neural network for maximum power point tracking of photovoltaic

panels, Electronics and Electrical Engineering (Elektronika ir

Elektrotechnika), no 10, pp. 6568. 2012.

F. Baumgarther, H. Schmidt, B. Burger, R. Brundlinger, H. Haberlin

and M. Zehner, Status and relevance of the dc voltage dependency of

the inverter efficiency, in 22nd European Photovoltaic Solar Energy

Conf. and Exhibition, no. Session 4Do.4.6, 37 Sept. 2007.

M. Valentini, A. Raducu, D. Sera, R.Teodorescu, PV inverter test

setup for European efficiency, static and dynamic MPPT efficiency

evaluation, Optimization of Electrical and Electronic Equipment,

2008. OPTIM 2008. 11th Int. Conf, 2224 May 2008, pp. 433438.

J. M. Enrique, E. Duran, M. Sidrach de Cardona, J. M Andujar, M. A.

Bohorquez, J. Carretero, A new approach to obtain I-V and P-V

curves of photovoltaic modules by using DC/DC converters, Rec.

IEEE Photovoltaic Specialist Conf., 2005, pp. 17691722.

E. Duran, J. M. Enrique, M. A Bohorquez, M. Sidrach de Cardona, J.

E. Carretero, J. M. Andujar, A new application of the coupledinductors SEPIC converter to obtain I-V and P-V curves of

photovoltaic modules. 2005 EPE Conf., 1114 Sept. 2005, pp P.1-P10.

M. C. Di Piazza, C. Serporta, G. Vitale, A DC/DC Converter Based

Circuit Model for a Solar Photovoltaic, 21th European Photovoltaic

Solar Energy Conf. and Exhibition, 48 Sept. 2006, Dresden,

Germany, pp. 27262731.

M. Cirrincione, M. C. Di Piazza, G. Marsala, M. Pucci, G. Vitale,

Real time simulation of renewable sources by model-based control

of DC/DC converters, Industrial Electronics, 2008. ISIE 2008. IEEE

Int. Symposium, pp. 15481555, June 30 2008-July 2 2008.

B. M. Wilamowski, J. D. Irwin, The Industrial Electronics

Handbook. Power Electronics and Motor Drives. Second Edition.

2011.

M. I. Milans-Montero, E. Romero-Cadaval, V. M. Minambres, F.

Barrero-Gonzalez, Novel Method for Synchronization to Disturbed

Three-phase and Single-phase Systems, IEEE Int. Symposium on

Industrial Electronics, 2007, pp. 860865.

C. Roncero-Clemente, E. Romero-Cadaval, P. Roncero-Sanchez, E.

Gonzalez-Romera, Comparison of Two Power Flow Control

Strategies for Photovoltaic Inverters. 38th Annual Conf. of the IEEE

Industrial Electronics Socienty IECON 2012. Montreal, Canada, pp.

51495154.

Вам также может понравиться

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorОт EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorОценок пока нет

- Pscad PV THDДокумент6 страницPscad PV THDRavishankar KankaleОценок пока нет

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlОт EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlРейтинг: 5 из 5 звезд5/5 (1)

- Investigation of Three-Phase Grid-Connected Inverter For Photovoltaic ApplicationДокумент6 страницInvestigation of Three-Phase Grid-Connected Inverter For Photovoltaic ApplicationAmran MaulanaОценок пока нет

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsОт EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsОценок пока нет

- Design and Implementation of A Digitally Controlled Standalone Photovoltaic Power SupplyДокумент0 страницDesign and Implementation of A Digitally Controlled Standalone Photovoltaic Power SupplyMarco LiguoriОценок пока нет

- Methods For The Optimal Design of Grid-Connected PV InvertersДокумент11 страницMethods For The Optimal Design of Grid-Connected PV InvertersAmmar IshaquiОценок пока нет

- CIRED2011 1190 FinalДокумент4 страницыCIRED2011 1190 FinalAtul ChauhanОценок пока нет

- Modeling and Control of DC-DC Boost Converter Using K-Factor Control For MPPT of Solar PV SystemДокумент6 страницModeling and Control of DC-DC Boost Converter Using K-Factor Control For MPPT of Solar PV SystemHoang ManhОценок пока нет

- Development of A MATLABSimulink Model of A Single-Phase Grid-Connected Photovoltaic System-IwQДокумент8 страницDevelopment of A MATLABSimulink Model of A Single-Phase Grid-Connected Photovoltaic System-IwQSaddam HussainОценок пока нет

- Design Simulation For A 3 Phase Grid Connected PV Inverter in Simulink PDFДокумент9 страницDesign Simulation For A 3 Phase Grid Connected PV Inverter in Simulink PDFNguyen KhoaОценок пока нет

- Development of A MATLAB/Simulink Model of A Single-Phase Grid-Connected Photovoltaic SystemДокумент8 страницDevelopment of A MATLAB/Simulink Model of A Single-Phase Grid-Connected Photovoltaic SystemMohamed NabilОценок пока нет

- SynopsisДокумент8 страницSynopsismanu thomasОценок пока нет

- PV InverterДокумент16 страницPV Inverterramalingam sОценок пока нет

- One-Cycle-Controlled Single-Phase Inverter For Grid Connected PV SystemДокумент8 страницOne-Cycle-Controlled Single-Phase Inverter For Grid Connected PV SystemVIJAYPUTRAОценок пока нет

- Control of PEM Fuel Cell Distributed Generation SystemsДокумент10 страницControl of PEM Fuel Cell Distributed Generation SystemsRushikeshKatkarОценок пока нет

- Elk 21 2 1 1105 29Документ8 страницElk 21 2 1 1105 29tinhmaixatoi2006Оценок пока нет

- A Novel Topology and Control Strategy For Maximum Power Point Trackers and Multi-String Grid-Connected PV InvertersДокумент6 страницA Novel Topology and Control Strategy For Maximum Power Point Trackers and Multi-String Grid-Connected PV Inverterswalidghoneim1970Оценок пока нет

- Midterm Report: in Electrical EngineeringДокумент11 страницMidterm Report: in Electrical Engineeringdr.Sabita shresthaОценок пока нет

- Modeling and Circuit-Based Simulation of Photovoltaic ArraysДокумент11 страницModeling and Circuit-Based Simulation of Photovoltaic ArraysnavidelecОценок пока нет

- 16 IJTPE Issue45 Vol12 No4 Dec2020 pp103 108Документ6 страниц16 IJTPE Issue45 Vol12 No4 Dec2020 pp103 108azeygpchОценок пока нет

- Adaptive PID Interleaved3Документ3 страницыAdaptive PID Interleaved3Hattab MakerОценок пока нет

- Research PaperДокумент17 страницResearch PaperShubham MishraОценок пока нет

- Control H BridgeДокумент5 страницControl H BridgeFahad Al-shammeriОценок пока нет

- PWM Based Passive Power Factor CorrectionДокумент4 страницыPWM Based Passive Power Factor CorrectionijaertОценок пока нет

- Modelling and Simulation: Wind Turbine GeneratorДокумент7 страницModelling and Simulation: Wind Turbine GeneratorEléctrico IngenieríaОценок пока нет

- Modeling of Grid Connected Hybrid Wind/Pv Generation System Using MatlabДокумент5 страницModeling of Grid Connected Hybrid Wind/Pv Generation System Using MatlabSABIR KHANОценок пока нет

- Modeling and Simulation of PV Array and Its Performance Enhancement Using MPPT (P&O) TechniqueДокумент8 страницModeling and Simulation of PV Array and Its Performance Enhancement Using MPPT (P&O) Techniqueeditor9891Оценок пока нет

- Sumanth 9Документ13 страницSumanth 9Chenchu TnvОценок пока нет

- Psat Wind FactДокумент6 страницPsat Wind FactSandeep KumarОценок пока нет

- PQ and PV Control of Photovoltaic GeneratorsДокумент8 страницPQ and PV Control of Photovoltaic GeneratorsBreno NunesОценок пока нет

- (Doi 10.1109/ICMCS.2011.5945712) Amatoul, Fatima Zahra Lamchich, Moulay Tahar Outzourhit, Abdel - (IEEE 2011 International Conference On Multimedia Computing and Systems (ICMCS) - Ouarzazate, MorДокумент6 страниц(Doi 10.1109/ICMCS.2011.5945712) Amatoul, Fatima Zahra Lamchich, Moulay Tahar Outzourhit, Abdel - (IEEE 2011 International Conference On Multimedia Computing and Systems (ICMCS) - Ouarzazate, MorDiego Quintana ValenzuelaОценок пока нет

- Nadiathul Raihana BT IsmailДокумент24 страницыNadiathul Raihana BT IsmailBinu SbОценок пока нет

- Adaptive P&O MPPT Technique For Photovoltaic Buck-Boost Converter SystemДокумент5 страницAdaptive P&O MPPT Technique For Photovoltaic Buck-Boost Converter SystemFajar MaulanaОценок пока нет

- Incremental Conductance MPPT Method For PV Systems-LibreДокумент3 страницыIncremental Conductance MPPT Method For PV Systems-LibreRushikeshKatkarОценок пока нет

- Voltage Dip's Mitigation During PV-Grid-Connection Using STATCOMДокумент7 страницVoltage Dip's Mitigation During PV-Grid-Connection Using STATCOMMohammedSaeedОценок пока нет

- Hindawi Publishidng CorporationДокумент27 страницHindawi Publishidng CorporationAtul ChauhanОценок пока нет

- Survey of CascadeДокумент10 страницSurvey of Cascadesumiths32Оценок пока нет

- DC DC ConvertersДокумент4 страницыDC DC Convertersmurthy237Оценок пока нет

- Cascadwed MultiДокумент14 страницCascadwed Multisandeepbabu28Оценок пока нет

- Simulation Model Developed For A Small-Scale PV System in Distribution NetworksДокумент6 страницSimulation Model Developed For A Small-Scale PV System in Distribution NetworksJota EseОценок пока нет

- Emtp Based SimultorДокумент4 страницыEmtp Based SimultorrudoljersonОценок пока нет

- Reduced Switches Count of Five Level H-Bridge Inverter With Integrated Boost Converter in Solar PV SystemДокумент12 страницReduced Switches Count of Five Level H-Bridge Inverter With Integrated Boost Converter in Solar PV SystemIJRASETPublicationsОценок пока нет

- JIMMA UNIVERSITY ReviewДокумент19 страницJIMMA UNIVERSITY Reviewgadisa fayeraОценок пока нет

- Control of Hybrid System Using Multi-Input Inverter and Maximum Power Point TrackingДокумент8 страницControl of Hybrid System Using Multi-Input Inverter and Maximum Power Point TrackingInternational Organization of Scientific Research (IOSR)Оценок пока нет

- Simulation of Non-Isolated Bidirectional DC - DC Converter For Battery Charging and Discharging of PV Battery Stand Alone System Supplying DC LoadДокумент12 страницSimulation of Non-Isolated Bidirectional DC - DC Converter For Battery Charging and Discharging of PV Battery Stand Alone System Supplying DC LoadGaurav PranamiОценок пока нет

- Irjet V4i4113Документ4 страницыIrjet V4i4113sambit dasОценок пока нет

- A Single-Stage Three-Phase Grid-Connected Photovoltaic System With Modified MPPT Method and Reactive Power CompensationДокумент6 страницA Single-Stage Three-Phase Grid-Connected Photovoltaic System With Modified MPPT Method and Reactive Power Compensationsandeepbabu28Оценок пока нет

- Grid-Tied System Modelling: and Why: PV HOWДокумент4 страницыGrid-Tied System Modelling: and Why: PV HOWAnonymous MjOqh7mОценок пока нет

- Analysis and Implementation of An Improved FlybackДокумент17 страницAnalysis and Implementation of An Improved FlybackReddyKvmОценок пока нет

- 3 DacДокумент7 страниц3 DacAde safitraОценок пока нет

- A Maximum Power Point Tracking System With Parallel Connection For PV Stand-Alone ApplicationsДокумент10 страницA Maximum Power Point Tracking System With Parallel Connection For PV Stand-Alone ApplicationsJidhin JayanОценок пока нет

- PSCAD EMTDC Based Modeling and AnalysisДокумент10 страницPSCAD EMTDC Based Modeling and Analysisuma.bhuvanОценок пока нет

- Maximum Power Point Tracking of Coupled Interleaved Boost Converter Supplied SystemДокумент10 страницMaximum Power Point Tracking of Coupled Interleaved Boost Converter Supplied SystemRaveendhra IitrОценок пока нет

- Matlab Simulink As Simulation Tool For Wind Generation Systems Based On Doubly Fed Induction MachinesДокумент22 страницыMatlab Simulink As Simulation Tool For Wind Generation Systems Based On Doubly Fed Induction MachinesAchraf BourassОценок пока нет

- Design of Photovoltaic System Using Buck-Boost Converter Based On MPPT With PID ControllerДокумент9 страницDesign of Photovoltaic System Using Buck-Boost Converter Based On MPPT With PID ControllerL CHОценок пока нет

- Grid Interactive PV System With Harmonic and Reactive Power Compensation Features Using A Novel Fuzzy Logic Based MPPTДокумент6 страницGrid Interactive PV System With Harmonic and Reactive Power Compensation Features Using A Novel Fuzzy Logic Based MPPTvinay kumarОценок пока нет

- STATCOMДокумент7 страницSTATCOMALPHONCEОценок пока нет

- Improved Single Stage Grid Connected Solar PV System Using Multilevel InverterДокумент6 страницImproved Single Stage Grid Connected Solar PV System Using Multilevel InverterFaruq FaruqОценок пока нет

- Final Journal PEE OldДокумент8 страницFinal Journal PEE OldNikunj AgarwalОценок пока нет

- Discussion Lab 2Документ2 страницыDiscussion Lab 2nazrin0% (1)

- Devi Ever Diy Info Manual, Aw Heck YesДокумент20 страницDevi Ever Diy Info Manual, Aw Heck YesRiley Smith75% (4)

- Proeceedings of Geotechnical Advancement in Hong Kong Since 1970s, 15 May 2007, Hong KongДокумент313 страницProeceedings of Geotechnical Advancement in Hong Kong Since 1970s, 15 May 2007, Hong KongcheewingyuenОценок пока нет

- Ansi Aga B109 1 2000Документ43 страницыAnsi Aga B109 1 2000Ihab El-SaftawiОценок пока нет

- Simulation Exercise Manual HandbookДокумент44 страницыSimulation Exercise Manual HandbookMayte Gz100% (1)

- Cobra-5: Power Brush SystemДокумент12 страницCobra-5: Power Brush SystemJuan Carlos CarrilloОценок пока нет

- Acct Statement XX6669 23062023Документ66 страницAcct Statement XX6669 23062023Suraj KoratkarОценок пока нет

- Copia de FORMATO AmefДокумент2 страницыCopia de FORMATO AmefDavid SaucedoОценок пока нет

- Literature MyДокумент5 страницLiterature MysandipparekhОценок пока нет

- Business - 29 Aug 2014Документ146 страницBusiness - 29 Aug 2014Iftikhar AhmedОценок пока нет

- VCSEL Technology v1Документ17 страницVCSEL Technology v1Vaibhav MathurОценок пока нет

- Expansion Indicator Boiler #1Документ6 страницExpansion Indicator Boiler #1Muhammad AbyОценок пока нет

- Buku Program Kopo 18Документ20 страницBuku Program Kopo 18Mieza Binti YusoffОценок пока нет

- DD FC Basix ConfДокумент18 страницDD FC Basix ConfwstanzlОценок пока нет

- Unit Plan: Economics Educated: Submitted By: Nancy Vargas-CisnerosДокумент4 страницыUnit Plan: Economics Educated: Submitted By: Nancy Vargas-CisnerosNancy VargasОценок пока нет

- Nob - Data Center - DammamДокумент1 страницаNob - Data Center - DammamImthiyazAliAhamedHОценок пока нет

- Stm32 Mcu FamilyДокумент12 страницStm32 Mcu FamilyriverajluizОценок пока нет

- Autohex Ii BMW: Beyond The Edge of ImpossibleДокумент2 страницыAutohex Ii BMW: Beyond The Edge of ImpossibleJuank MrtОценок пока нет

- Manual de Estudiante Mitel 3300Документ466 страницManual de Estudiante Mitel 3300Romeo VelasquezОценок пока нет

- Collapsible Steering ColumnДокумент2 страницыCollapsible Steering ColumnKrishna KumarОценок пока нет

- Amca - 201 Fans and SystemsДокумент80 страницAmca - 201 Fans and SystemsenricoОценок пока нет

- K13 High-Flex Waterproofing SlurryДокумент3 страницыK13 High-Flex Waterproofing SlurryAmila SampathОценок пока нет

- IT Audit Exercise 2Документ1 страницаIT Audit Exercise 2wirdinaОценок пока нет

- ANDROID Workshop MaheshДокумент72 страницыANDROID Workshop MaheshPradeepCool100% (2)

- Boq IДокумент7 страницBoq IAmolОценок пока нет

- Seagoing Tug "Mhan Aung-3": Ministry of TransportДокумент2 страницыSeagoing Tug "Mhan Aung-3": Ministry of TransportnyaungzinОценок пока нет

- Muhammad ALI Azmi: Contact +62 812 1944 5086 Komplek Poin Mas Blok F-2 No. 20B, Depok, Jawa BaratДокумент1 страницаMuhammad ALI Azmi: Contact +62 812 1944 5086 Komplek Poin Mas Blok F-2 No. 20B, Depok, Jawa BaratanggaraОценок пока нет

- Influence of Nano - Sized Powder Content On Physical Properties of Waste Acid Refractory BrickДокумент19 страницInfluence of Nano - Sized Powder Content On Physical Properties of Waste Acid Refractory BrickamnajamОценок пока нет

- The Age of Exploration/Age of Discovery: Countries InvolvedДокумент6 страницThe Age of Exploration/Age of Discovery: Countries InvolvedRocky RayoОценок пока нет

- English Core 2005Документ5 страницEnglish Core 2005thiripura sundariОценок пока нет

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialОт EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeОт EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeРейтинг: 4.5 из 5 звезд4.5/5 (9)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosОт EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosРейтинг: 5 из 5 звезд5/5 (1)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesОт EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesРейтинг: 5 из 5 звезд5/5 (1)

- Complete Electronics Self-Teaching Guide with ProjectsОт EverandComplete Electronics Self-Teaching Guide with ProjectsРейтинг: 3 из 5 звезд3/5 (2)

- Analog Design and Simulation Using OrCAD Capture and PSpiceОт EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceОценок пока нет

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)От EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)Оценок пока нет

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonОт EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonРейтинг: 5 из 5 звезд5/5 (2)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesОт EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesРейтинг: 5 из 5 звезд5/5 (1)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsОт EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsРейтинг: 3.5 из 5 звезд3.5/5 (2)

- The Long Hangover: Putin's New Russia and the Ghosts of the PastОт EverandThe Long Hangover: Putin's New Russia and the Ghosts of the PastРейтинг: 4.5 из 5 звезд4.5/5 (76)

- Practical Electronics for Inventors, Fourth EditionОт EverandPractical Electronics for Inventors, Fourth EditionРейтинг: 4 из 5 звезд4/5 (3)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)От EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Рейтинг: 4.5 из 5 звезд4.5/5 (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionОт EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionРейтинг: 4.5 из 5 звезд4.5/5 (543)

- Teach Yourself Electricity and Electronics, 6th EditionОт EverandTeach Yourself Electricity and Electronics, 6th EditionРейтинг: 3.5 из 5 звезд3.5/5 (15)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsОт EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovОценок пока нет