Академический Документы

Профессиональный Документы

Культура Документы

Ijetae 0315 83

Загружено:

Ruchit Kumar SharmaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ijetae 0315 83

Загружено:

Ruchit Kumar SharmaАвторское право:

Доступные форматы

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 5, Issue 3, March 2015)

Electricity Free Refrigeration System using Domestic LPG

Design of Energy Saving Refrigerator

Nikam S.D.1, Dargude S. B.2, Dhanagar V. L.3, Patharwat A. A.4, Khandare R. S.5, Bhane A. B.6

1,2,3,4

5,6

Student at Department of Mechanical Engineering, University of Pune, SND COE & RC, Yeola, Dist. Nasik, India.

Asst.Professor, Department of Mechanical Engineering, University of Pune, SND COE& RC, Yeola, Dist. Nasik, India.

When we think about refrigerator we only remember

refrigeration in kitchen, but actually divided in three types

in which each type having their own type of functioning.

One which used in Industrial purpose called as Industrial

refrigerator.Which used as food processing, chemical

processing & cold storage. Industrial refrigeration, which

frequently uses ammonia refrigeration to maintain

temperature, is necessary for computer, foodstuffs, blood,

vaccines, and quite a few other goods that must maintain a

constant and steady temperature at all times. Temperatures

matters in industrial refrigeration companies to pay

attention at all times. Domestic refrigerant consumes 17500

metric tons of traditional refrigerant as CFC, HFC and

which contribute high ozone depletion potential (ODP) and

Global warming potential (GWP). Good progress is being

made with the phase out of CFC 22 from new equipment

manufacture by replacing LPG since it possesses an

environmentally friendly nature with no ODP. LPG is

expected to results in comparable product efficiencies

based on its characteristics. Therefore, this two types of

refrigerants (LPG and CFC 22) to be examined using a

modified domestic refrigerator in term of their performance

characteristics parameters such as pressure and temperature

at specified location at the refrigerator and the safety

requirements while conducting the experiment. By

performing the tests on new system, it is indicate that the

successful of using LPG as an alternative refrigerant to

replace CFC 22 in domestic refrigerators is possible by

getting LPG.

AbstractElectricity free refrigerator system throughout

which we can make refrigeration system in electricity less

areas. There are so many areas in India where electricity not

available. So in that areas to preserve food, medicine, meat the

electricity refrigeration must be required. LPG (Liquefied

Petroleum Gas) is the combination of propane, isobutene and

highest amount of butane with 56.4%.The use of LPG for

refrigeration purpose can be environment friendly since it has

no ozone depletion potential (ODP). In

these

electricity

refrigerator system we have to use LPG as refrigerant because

of it having low boiling point property and it also have high

pressure. When high pressure LPG passed through the

capillary tubes because of small internal diameter the

pressure of LPG dropped suddenly due to isentropic cycle.

While changing property of LPG from liquid to gas latent

heat of refrigerant increased, and temperature will be

dropped and it acts as a refrigerant predominately.

Keywords LPG Refrigeration, LPG, Capillary tube,

Evaporator, COP, VCR, Refrigerating Effect.

I. INTRODUCTION

According to the Indian Government, the refrigerator is

the 3rd heaviest consumer of power amongst household

appliances. It is one of the few appliances that is running

365 days a year, increasing the importance, whenever

possible, to have an eco-friendly refrigerator in your

household. A new eco-friendly refrigerator in 2006 was

estimated to consume 481 kilowatt hours per year. The

energy consumption of refrigerators has improved steadily

year over year.It works on the principle that during the

conversion of LPG into gaseous form the expansion will be

take place. Due to this expansion in LPG gas the pressure

will drops. And the volume will be increase this will be

result into dropped in temperature and it acts as refrigerant.

According to second law of thermodynamics, this process

can only be performed with the aid of some external work.

It is thus obvious, that supply of power (say electrical

motor) is regularly required to drive a refrigerator. The

substance which works in a heat pump to extract heat from

a cold body and to deliver it to a hot body is called

refrigerant.

II. LITERATURE SURVEY

The refrigeration system is known to the man, since the

middle nineteenth century. The scientist, of the time,

developed a few stray machines to achieve some pleasure.

But it paved the way by inviting the attention of scientist

for proper studies and research. They were able to build a

reasonably reliable machine by the end of nineteenth

century for the refrigeration jobs. But with the advent of

efficient rotary compressors and gas turbines, the science of

refrigeration reached its present height.

456

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 5, Issue 3, March 2015)

Hebrews, Greeks, and Romans placed large amounts of

snow into storage pits dug into the ground and insulated

with wood and straw. The ancient Egyptians filled earthen

jars with boiled water and put them their roofs, thus

exposing the jars to the nights cool air. In India,

evaporating cooling was employed. When a liquid

vaporizes rapidly, it expands quickly. The rising molecules

of vapor abruptly increase their kinetic energy and this

increase is drawn from the immediate surroundings of the

vapor. These surroundings are therefore cooled. The

intermediate stage in the history of cooling foods was to

add chemicals like sodium nitrate or potassium nitrate to

water causing the temperature to fall. Cooling wine via

above method was recorded in 1550, as were the words to

refrigerate.Cooling drinks came into vogue by 1600 in

France. Instead of cooling water at night, people rotate

long-necked bottles in water in which salt petre had been

dissolved. This solution could be used to produce very low

temperature and to make ice. By the end of the 17 Century,

iced liquors and frozen juices were popular in French

society. The first known artificial refrigeration was

demonstrated by William Cullen at the University of

Glasgow in 1748.Beginning in the 1840, refrigerated cars

were used to transport milk and butter. By 1860,

refrigerated transport was limited to mostly seafood and

dairy products. The refrigerated railroad car was patented

by J.B.Sutherland of Detroit; Michigan in 1867. He

designed an insulated car with ice bunkers in each end. Air

came in on the top, passed through the bunkers, and

circulated through the car by gravity, controlled by the use

of hanging flaps that created differences in air temperature.

Brewing was the first activity in the northern states to use

mechanical refrigeration extensively, beginning with an

absorption machine used by S.Liebmanns Sons Brewing

Company in Brooklyn, New York in 1870.commercial

refrigeration was primarily directed at breweries in the

1870 and 1891,nearly every brewery was equipped with

refrigerating machines. Natural ice supply became an

industry unto itself. By 1879, there were 35commercial ice

plants in America, more than 200 a decade later, and 2,000

by 1909. No pond was safe from scraping for ice

production, not even Thoreaus Walden Pond, where 1,000

tons of ice was extracted each day in 1847.However, as

time went on, ice, as a refrigeration agent, became health

problem. Says Bern Nagengast, co-author of Heat and

Cold: Mastering the Great Indoors (published by the

American Society of Heating, Refrigeration and Airconditioning Engineers), Good sources were harder and

harder to find. By the 1890s, natural ice became a problem

because of pollution and sewage dumping. Signs of a

problem were first evident in the brewing industry.

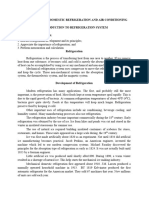

III. CONSTRUCTION & WORKING

The basic idea behind LPG refrigeration is to use the

evaporation of a LPG to absorb heat. LPG is stored in

cylinders at pressure at about 80 psi. We lowering this

pressure to pressure of 1 psi so that the heat absorbed

adiabatically and cooling is obtained on surrounding.

The simple mechanism of the LPG refrigeration working

is shown in figure.

Fig. 3.1 Circuit diagram of LPG refrigerator

LPG is stored in the LPG cylinder under high pressure.

When the gas tank of regulators is opened then

high pressure LPG passes in gas pipe. This LPG is going

by high pressure gas pipe in capillary tube.

High pressure LPG is converted in low pressure at

capillary tube with enthalpy remains constant.

After capillary tube, low pressure LPG is passed through

evaporator. LPG is converted into low pressure and

temperature vapor from and passing through the evaporator

which absorbs heat from the chamber. Thus the camber

becomes cools down. Thus we can achieve cooling effect

in refrigerator.

After passing through the evaporator low pressure LPG

is passed through pipe by burner. And we can uses the low

pressure of LPG is burning processes.

In this project instead of compressor a recompressed

LPG cylinder is used. The compressed gas in cylinder is

expands adiabatically while using for cooking purpose or

combusting, as result of its adiabatic expansion a

refrigeration cycle takes place. Causes cooling of

surrounding.

Construction Features:

A. LPG Gas Cylinder

LPG is Liquefied Petroleum Gas. This is general

description of Propane (C3H8) and Butane (C4H10), either

stored separately or together as a mix. This is because these

gases can be liquefied at a normal temperature by

application of a moderate pressure increases, or at normal

pressure by application of LPG using refrigeration.

457

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 5, Issue 3, March 2015)

LPG is used as a fuel for domestic, industrial,

horticultural, agricultural, cooking, heating and drying

processes. LPG can be used as an automotive fuel or

as propellant for aerosol, in addition to other specialist

applications. LPG can also be used to provide lighting

through the use of pressure lantern. LPG is Liquefied

Petroleum Gas. This is general description of Propane

(C3H8) and Butane (C4H10), either stored separately or

together as a mix. This is because these gases can be

liquefied at a normal temperature by application of a

moderate pressure increases, or at normal pressure by

application of LPG using refrigeration. LPG is used as a

fuel for domestic, industrial, horticultural, agricultural,

cooking, heating and drying processes. LPG can be used as

an automotive fuel or as propellant for aerosol, in addition

to other specialist applications. LPG can also be used to

provide lighting through the use of pressure lantern.

Fig.3.3 Capillary Tube

C. Evaporator

The evaporators are another important parts of the

refrigeration systems. It through the evaporators that the

cooling effect is produced in the refrigeration system.

Fig. 3.4 Evaporator

It is in the evaporators when the actual cooling effect

takes place in the refrigeration systems. For many people

the evaporator is the main part of the refrigeration system,

consider other part as less useful. The evaporators are heat

exchanger surface that transfer the heat from the substance

to be cooled to the refrigerant, thus removing the heat from

the from the substance. Theevaporators are used for wide

variety of diverse application in refrigeration and hence the

available in wide variety of shape, sizes and designs. They

are also classified in different manner depending on the

method of feeding the refrigerant, construction of the

evaporator, direction of air circulation around the

evaporator, application and also the refrigerant control. In

the domestic refrigerators the evaporators are commonly

known as freezers since the ice is made in these

compartment. In the evaporators the refrigerant enters at

very low pressure and temperature after passing through

the capillary tube. This refrigerant absorbs the heat from

the substance that is to be cooled so the refrigerant gets

heated while the substance gets cooled. Even after cooling

the substance the temperature of the refrigerant leaving the

evaporator is less than the substance.

Fig 3.2 LPG Gas Cylinder

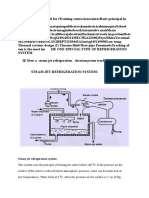

B. Capillary Tube

The capillary tube is the commonly used throttling

device in the domestic refrigeration. The capillary tube is a

copper tube of very small internal diameter. It is of very

long length and it is coiled to several turns so that it would

occupy less space. The internal diameter of the capillary

tube used for the refrigeration applications varies from 0.5

to 2.28 mm(0.020 to 0.09 inch). The capillary tube is

shown in picture. When the refrigerant enters in the

capillary tube, its pressure drops down suddenly due to

very small diameter. The decrease in pressure of the

refrigerant through the capillary depends on the diameter of

capillary and the length of capillary. Smaller is the

diameter and more is the length of capillary more is the

drop in pressure of the refrigerant as it passes through it.

458

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 5, Issue 3, March 2015)

In the large refrigeration plants the evaporator is used for

chilling water. In such cases shell and tube type of heat

exchanger are used as the evaporators.

D. Pressure Gauge

Many techniques have been developed for the

measurement of pressure and vacuums. Instruments used to

measure pressure are called pressure gauges or vacuum

gauges.

Fig. 3.5 High Pressure pipes.

Wide range of pipes.

All pipes are pressure tested to 100 M Pa (14,500

psi) over recommended working pressure.

IV. DESIGN CONSIDERATION

There are many requirements that need to be met to

produce a product that is both feasible and optimal. There

are also some constraints, both geometric and engineering

that also need to be satisfied. The following list describes

these requirements and constraints:

Fig. 3.4 Stainless steel pressure gauge

A manometer could also referring to a pressure

measuring instrument, usually limited to measuring

pressures near to atmospheric. The term manometer is often

used to refer specifically to liquid column hydrostatic

instruments.

Catering to the requirements of to power and allied

Industry, we offer quality array of stainless steel,

weatherproof pressure gauges. Renowned for offering

resistance in corrosive environments and modes, these find

wide application in power generation, pollution control

equipment, chemicals and petrochemicals and also

exploration. These gauges are available in 63mm, 100mm,

and 150mm sizes and can be customized as per client.

Refrigeration capacity: This is the main requirement

and the overall objective of the device and must be

suitable to meet the different cooling loads.

Inexpensive and affordable: This product must be

able to make a profit and be desirable.

Safe to user and environmentally friendly: Safety is

always a very important aspect whenever there is a

consumer product.

Economical: The product economical and the

products for this design must be cheaply available.

Reliable: It is important to have a product that is

reliable and this requirement will affect the normal

bicycling process and must be easy to use.

Manufacturability: In order to make anything

economical, it needs to be manufacturability, hence

the important of having a product that can be made

easily and cheaply.

Aesthetically pleasing: This is not a requirement that

needs to be taken heavily, but the design should

always have nice look about it, because looks will

persuade the consumer.

E. High Pressure Pipes

The range of high pressure pipes covers most application

where there is a requirement to transfer gas at high

pressure. They consist of a steel pipe with steel ball fitted

to both ends. Two swiveling connection nipples press these

balls against the seating of the connecting hole and thus

sealing against gas leakage.

459

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 5, Issue 3, March 2015)

Modular: Having a device that can be adapted to

existing refrigerators is essential to be added to the

existing ones so that its easier to adopt. This also can

reduce other types of manufacturing costs.

Advantages :

1. No moving parts.

2. No vibration or noise on small system.

3. Small systems can operate without electricity using

only heat, large systems require power for chemical

pumps

4. Can make use of waste heat

Limitations :

1. Potential refrigerant leaks.

2. Operates under limited vibration and orientations.

3. Complicated and difficult to service and repair.

4. Stalls in a hot ambient

5. Very bulky.

6. Poor efficiency

Using the sophisticated data and instruments the relevant

refrigeration system will be develop practically. In this

project the capillary tube is more suitable throttling device

in LPG refrigeration system.

This system is cheaper in initial as well as running cost.

It does not require an external energy sources to run the

system and no moving part in the system so maintenance is

also very low. We also conclude that, we try the burnt to

the exhaust LPG, as we daily do but also the refrigeration is

obtained which is inherent process takes place daily. In this

system this refrigeration is amplified remarkably and a

cheaper and eco-friendly method is developed. This system

most suitable for hotel, industries, refinery, chemical

industries where consumption of LPG is very high.

REFERENCES

[1]

[2]

V. CONCLUSION

[3]

[4]

The project Analysis and performance of domestic

refrigerator using LPG as refrigerant is based on the

principle of adiabatic expansion of a refrigerant (In this

case LPG) from 80 psi to 10 psi so that thermodynamically

it absorbs heat from surrounding and cooling may done.

Expected cooling is predicted up to range of 20 to 50

degrees.

[5]

[6]

460

S. J. Cleg, Thermodynamic analysis of LPG as refrigerant for

industrial refrigeration and transportation, Institute of Transport

Studies, University of Leeds, Working paper of 471, 1996.

Dr. IqbalHusain, Analysis of VCR and VAR systems using organic

refrigerants, CRC press, Taylor and Francis Group, USA, 2012.

Text book of refrigeration and air conditioning by Domkundwar.

Catalogue of Gas Authority of India on Properties of combustible

gases for industrial purpose.

www.wikipedia.com/refrigeration

www.scribd.com/lpgrefrigerent

Вам также может понравиться

- LPG Refrigeration ProposalДокумент11 страницLPG Refrigeration ProposalRahul100% (1)

- Project On LPG Refrigerator Mechanical ProjectДокумент53 страницыProject On LPG Refrigerator Mechanical Projectpatel ketan86% (69)

- Absorption Chiller Rev3 (MSB) 20-9Документ96 страницAbsorption Chiller Rev3 (MSB) 20-9norshakeela100% (3)

- DESIGN AND FABRICATION OF IMPROVE PERFORMANCE IN DEEP FREEZER Ijariie3833Документ7 страницDESIGN AND FABRICATION OF IMPROVE PERFORMANCE IN DEEP FREEZER Ijariie3833EzekielОценок пока нет

- Electricity Free Refrigeration System Using Domestic LPG Design of Energy Saving RefrigeratorДокумент5 страницElectricity Free Refrigeration System Using Domestic LPG Design of Energy Saving RefrigeratorHarsha KОценок пока нет

- Historical Applications: Ice HarvestingДокумент13 страницHistorical Applications: Ice HarvestingPushpendra KumarОценок пока нет

- Domestic Refrigerator and Water Cooler ProjectДокумент25 страницDomestic Refrigerator and Water Cooler ProjectAniket Kalore88% (8)

- Low Cost of Refrigeration System Using LPGДокумент13 страницLow Cost of Refrigeration System Using LPGArsh GillОценок пока нет

- Chapter 1Документ57 страницChapter 1Satyam JhaОценок пока нет

- RefrigerationДокумент21 страницаRefrigerationAdeel iqbalОценок пока нет

- IJCTER Scientific Journal Impact Fabrication of Hot and Cold Water DispenserДокумент6 страницIJCTER Scientific Journal Impact Fabrication of Hot and Cold Water Dispensersentot ali basahОценок пока нет

- Zero Cost Refrigeration SystemДокумент48 страницZero Cost Refrigeration SystemKritisundar GarnayakОценок пока нет

- LPG Water Cooling SystemДокумент46 страницLPG Water Cooling SystemLaxman Deshmukh33% (3)

- Refrigaration With LPGДокумент3 страницыRefrigaration With LPGSSSОценок пока нет

- MODULE 1 Introduction To Refrigeration SystemДокумент9 страницMODULE 1 Introduction To Refrigeration SystemBembem DelfinОценок пока нет

- Term Paper: Refrigertaor vs. Heat PumpДокумент24 страницыTerm Paper: Refrigertaor vs. Heat PumpHoney BhatiaОценок пока нет

- RefrigerationДокумент52 страницыRefrigerationSreejith VaneryОценок пока нет

- Ass 4Документ6 страницAss 4Nick's CreationОценок пока нет

- Refrigeration & Air Conditioning IntroДокумент30 страницRefrigeration & Air Conditioning IntroJANANI MОценок пока нет

- Karthik Keshav Bhuvan J Surya Ravishankar R V Ruthu: Done byДокумент17 страницKarthik Keshav Bhuvan J Surya Ravishankar R V Ruthu: Done bySurya RSОценок пока нет

- Absorption Refrigerator Uses Heat Source for Cooling Without CompressorДокумент5 страницAbsorption Refrigerator Uses Heat Source for Cooling Without CompressorThanveer Ahmed SОценок пока нет

- IntroductionДокумент4 страницыIntroductionDevan SanmugamОценок пока нет

- Refrigeration CycleДокумент19 страницRefrigeration CycleCherryl De Asis-PanesОценок пока нет

- ICE PLANT ProjectДокумент53 страницыICE PLANT ProjectSandeep MagapuОценок пока нет

- Lesson1 and Lesson 2Документ10 страницLesson1 and Lesson 2Gerlan Madrid MingoОценок пока нет

- LPG Refrigerator A Literature ReviewДокумент4 страницыLPG Refrigerator A Literature Reviewafdtlgezo100% (1)

- Refrigeration System Research PaperДокумент6 страницRefrigeration System Research Paperoabmzrznd100% (1)

- Refrigeration Paper in IJSER FormatДокумент14 страницRefrigeration Paper in IJSER Formattitto84886Оценок пока нет

- 2009 10 Otti Solarcooling PalermoДокумент6 страниц2009 10 Otti Solarcooling PalermoKelvinVelasquezPascualОценок пока нет

- Literature ReviewДокумент11 страницLiterature ReviewAsif RahmanОценок пока нет

- Performansi Mesin Pendingin Tipe Chiller Untuk Cold Storage Dan IndoorДокумент8 страницPerformansi Mesin Pendingin Tipe Chiller Untuk Cold Storage Dan IndoorMamad ParidОценок пока нет

- Thermally Insulated Heat PumpДокумент20 страницThermally Insulated Heat Pumpoke chuksОценок пока нет

- Refrigeration Process in Oil and Gas IndustryДокумент20 страницRefrigeration Process in Oil and Gas IndustrysanjayОценок пока нет

- Adsorption RefrigerationДокумент22 страницыAdsorption RefrigerationVijay Krishnan100% (1)

- REFRIGERATORДокумент11 страницREFRIGERATORHacker ManОценок пока нет

- Ch-1 RAC PDFДокумент17 страницCh-1 RAC PDFMuhammad Noman Khan100% (1)

- Module 1 PDFДокумент56 страницModule 1 PDFAli khanОценок пока нет

- Design of LPG Used Refrigeration System Using Nozzle ExpansionДокумент8 страницDesign of LPG Used Refrigeration System Using Nozzle ExpansionBharath HariОценок пока нет

- Advantages and Disadvantages of Using Absorption Chillers ToДокумент4 страницыAdvantages and Disadvantages of Using Absorption Chillers Toأحمد صلاحОценок пока нет

- Geo Source Heat Pump HandbookДокумент89 страницGeo Source Heat Pump Handbookapi-26532647100% (2)

- Final IplДокумент16 страницFinal IplSurya RSОценок пока нет

- About RefrigeratorДокумент3 страницыAbout RefrigeratorRieza AldioОценок пока нет

- Module 4Документ29 страницModule 4YUG VARSHNEYОценок пока нет

- Steam Jet Refrigeration SystemДокумент7 страницSteam Jet Refrigeration SystembbaytlОценок пока нет

- 3200077-Waste Heat Recovery System For LPG StoveДокумент2 страницы3200077-Waste Heat Recovery System For LPG StoveFrances EstoceОценок пока нет

- History of Refrigeration and the Refrigeration ProcessДокумент17 страницHistory of Refrigeration and the Refrigeration Processsohaib992Оценок пока нет

- Steam Jet Refrigeration SystemДокумент7 страницSteam Jet Refrigeration SystembbaytlОценок пока нет

- Steam jet refrigeration systemДокумент7 страницSteam jet refrigeration systembbaytlОценок пока нет

- History and Application of RefrigerationДокумент18 страницHistory and Application of RefrigerationKanwarnain SinghОценок пока нет

- Thesis Diri Thesis NgadtoДокумент24 страницыThesis Diri Thesis NgadtoKhiet LaRosaОценок пока нет

- Industrial Training Final ReportДокумент22 страницыIndustrial Training Final ReportAkash MarkhaleОценок пока нет

- Heat Pump For Heating and Cooling Water For Aquacultural ProductionДокумент4 страницыHeat Pump For Heating and Cooling Water For Aquacultural ProductionJoao MinhoОценок пока нет

- Research PaperДокумент9 страницResearch Paperdhanushsai1218Оценок пока нет

- Steam jet refrigeration systemДокумент7 страницSteam jet refrigeration systembbaytlОценок пока нет

- R & Ac 1Документ38 страницR & Ac 1ahsanОценок пока нет

- EME Notes RefrigerationДокумент7 страницEME Notes RefrigerationedhanaaОценок пока нет

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОт EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОценок пока нет

- An Introduction to Thermogeology: Ground Source Heating and CoolingОт EverandAn Introduction to Thermogeology: Ground Source Heating and CoolingОценок пока нет

- Aquaponics in Winter: How to Heat Your Aquaponic Garden in Cold ClimateОт EverandAquaponics in Winter: How to Heat Your Aquaponic Garden in Cold ClimateОценок пока нет

- The Gist of NCERT General Science PDFДокумент148 страницThe Gist of NCERT General Science PDFSatyajitSahooОценок пока нет

- P18 Probability in The CourtroomДокумент14 страницP18 Probability in The CourtroomYehiaОценок пока нет

- Open Problems in The Mathematics of Data ScienceДокумент152 страницыOpen Problems in The Mathematics of Data Sciencecan dagidirОценок пока нет

- What Is Radar and Its FunctionДокумент3 страницыWhat Is Radar and Its FunctionJean Maya DiscayaОценок пока нет

- Electrical Plant Load AnalysisДокумент36 страницElectrical Plant Load AnalysisJesus EspinozaОценок пока нет

- Maporillal Vs DeliciasДокумент14 страницMaporillal Vs DeliciasJessica RiveraОценок пока нет

- Synopsis On Mobile TrackingДокумент11 страницSynopsis On Mobile Trackingcooolhoney885Оценок пока нет

- Fire Strength Performance ofДокумент3 страницыFire Strength Performance ofMarimuthu KannimuthuОценок пока нет

- Limiting Reagents 1Документ17 страницLimiting Reagents 1Aldrin Jay Patungan100% (1)

- A Review On Promethee and Analytic Hierarchy Process With Its ApplicationДокумент7 страницA Review On Promethee and Analytic Hierarchy Process With Its Applicationkherrouf YOUNESОценок пока нет

- Reinforcement Detailing in BeamsДокумент9 страницReinforcement Detailing in Beamssaheed tijaniОценок пока нет

- Answer: 60% Answer: Geography 55%: Harmonic Mean-Is Good at Handling Large OutliersДокумент2 страницыAnswer: 60% Answer: Geography 55%: Harmonic Mean-Is Good at Handling Large Outliersroshia maeОценок пока нет

- SAP Table BufferingДокумент31 страницаSAP Table Bufferingashok_oleti100% (3)

- Foundations On Friction Creep Piles in Soft ClaysДокумент11 страницFoundations On Friction Creep Piles in Soft ClaysGhaith M. SalihОценок пока нет

- Kotlin Programs - StudentsДокумент74 страницыKotlin Programs - Studentsgandem gowhithОценок пока нет

- 01 New StaffДокумент9 страниц01 New StaffCIS AdminОценок пока нет

- Flex-Shaft Attachment Instructions Model 225: WarningДокумент1 страницаFlex-Shaft Attachment Instructions Model 225: WarningFernando Lopez Lago100% (1)

- QFD PresentationДокумент75 страницQFD PresentationBhushan Verma100% (3)

- Hypothesis TestingДокумент2 страницыHypothesis TestingNerish PlazaОценок пока нет

- Module 11A-09 Turbine Aeroplane Aerodynamics, Structures and SystemsДокумент133 страницыModule 11A-09 Turbine Aeroplane Aerodynamics, Structures and SystemsИлларион ПанасенкоОценок пока нет

- Driver MC34152Документ4 страницыDriver MC34152William RamírezОценок пока нет

- Fundamental of Database: Madda Walabu University College of Computing Department of Information TechnologyДокумент46 страницFundamental of Database: Madda Walabu University College of Computing Department of Information TechnologychalaОценок пока нет

- 7-3 IP Board Part (SMPS Part) : 7 Block DiagramsДокумент8 страниц7-3 IP Board Part (SMPS Part) : 7 Block DiagramsSonu KumarОценок пока нет

- Arduino Library For The AM2302 Humidity and Temperature SensorДокумент2 страницыArduino Library For The AM2302 Humidity and Temperature SensorMallickarjunaОценок пока нет

- Scan Path DesignДокумент54 страницыScan Path DesignGowtham HariОценок пока нет

- Seamless Steel Tubes and Pipes For BoilersДокумент20 страницSeamless Steel Tubes and Pipes For BoilersABChungBAОценок пока нет

- Discussion Exp 2 Chm674Документ4 страницыDiscussion Exp 2 Chm674Eva Lizwina MatinОценок пока нет

- Openscape Business V2: How To Configure Sip Trunk For Netfone HungaryДокумент14 страницOpenscape Business V2: How To Configure Sip Trunk For Netfone HungaryBelahreche MohamedОценок пока нет

- EE6010-High Voltage Direct Current TransmissionДокумент12 страницEE6010-High Voltage Direct Current Transmissionabish abish0% (1)

- 2024 Quiz Bee Math 7Документ1 страница2024 Quiz Bee Math 7Jabez Magda GenorgaОценок пока нет