Академический Документы

Профессиональный Документы

Культура Документы

Anaerobic Digester Covers

Загружено:

Chris QueroИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Anaerobic Digester Covers

Загружено:

Chris QueroАвторское право:

Доступные форматы

WALKER PROCESS EQUIPMENT

Division of McNish Corporation

Anaerobic Digester Covers

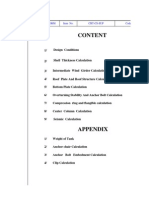

This paper deals with the various types of Digester covers, how they function and where they are used.

There are four basic types of covers: Fixed Cover, Floating Cover, Gasholder Cover, and Combination

Cover.

Fixed Covers

Fixed covers are used in digesters with no

variation in total volume and are often used on the

primary digester in a two-stage system. The

sludge volume can be varied but only by varying

the gas volume at the same time so as to keep the

total volume constant. If gas is to be pressurized

for use, it must also have a companion floating

cover connected by gas lines.

Fixed covers are anchored to the top of the

digester tank and normally there is a static or

constant sludge level. Thus the rim plate only

need be as deep as the tank freeboard plus the

tank operating pressure and an appropriate seal

depth to contain the gas. A typical rim plate depth

might be approximately 2'-6" with 1'-0" freeboard.

A fixed cover has only one steel membrane over

its structural framework.

The advantage to this type of cover is lowest cost.

The disadvantages are: it will not pressurize and

store gas by itself, will not depress scum, and

provides little insulating value.

Floating covers have a minimum rim plate depth since

they float directly on the sludge. This depth is generally

about 3'-0". A floating cover embodies both a ceiling

plate and a roof plate, forming an attic space, in which

are the trusses. Rollers are mounted on the cover roof

to provide for travel.

Floating Cover

Floating Covers float directly on the sludge, allowing

variable sludge levels. However, practically no gas

storage is available and the gas volume is relatively

constant. A floating cover provides for submergence of

scum and again is often applied on the primary digester

in a two-stage system. The floating cover floats on the

liquid surface.

The advantages of this cover are; scum suppression,

good insulation due to the attic space, support trusses

not subject to digester interior corrosive products, and

is very stable. The disadvantages are it is the second

most costly of the four types, and it cannot store gas in

any appreciable amount.

When used with a gasholder it should be ballasted at 2"

water column pressure higher so it "pushes" gas to the

gasholder.

1.0

June 2004

Page 1 of 2

WALKER PROCESS EQUIPMENT

Division of McNish Corporation

Anaerobic Digester Covers

Gas storage is a necessity since most gas burners

will operate on an on-off cycle and in this manner

gasholder serves as a "surge" tank.

Gasholder Cover

Gasholder covers provide for gas storage by riding

on a constant pressure, variable volume gas

bubble. Normally this type of cover is used with a

constant sludge level and this is the most

economical design, and would be applied on a

second stage digester.

As a two-stage digestion system, it is desired that

all digestion occur in the first tank while the second

tank is used for supernatant separation and gas

storage.

The rim plate depth on a gasholder cover is

determined by the required gas storage volume or

travel. Generally, a 5' to 7' deep rim plate is

sufficient for most applications. This cover also

has one steel membrane over its structural

framework.

Rollers and long columns are

provided for cover travel and to maintain stability

throughout its travel range. Note that the ballast is

located at the bottom of the skirt to lower its

metacenter and increase its stability.

The advantages are; it is less costly than any

cover other than the Fixed cover, and that it stores

gas for usage by the boiler or other energy

producer. The disadvantage is that it has little

insulating value.

The advantages are; it has better insulating

qualities than a Gasholder due to existence of an

attic, and the trusses are not exposed to corrosive

interior of digester.

The disadvantage is it is the most costly of all

covers.

Combination Gasholder/Cover

The combination cover is the least understood of

all, and is probably used for the wrong reason in

most instances. In reality, this cover combines

features of the Floating Cover and the Gasholder.

This can be visualized in two manners:

Common Features: The above four sections dealt

with differences between cover types; following

are features commonly used on any digester

cover.

A. A gas dome located at the center of the

cover provides a gas reservoir from which gas

can be withdrawn without also removing

entrained liquid, scum, foam, etc.

1. The combination Gasholder/Cover is a Floating

Cover with a longer skirt, columns, and with the

ballast moved from the attic to the skirt bottom.

2. It is a Gasholder with a ceiling plate added to

the bottom of the truss.

Its use may be the most misunderstood part.

Some specifications require a Gasholder that will

suppress scum and therefore, require a

submerged ceiling plate. But, when gas is stored

(which is the majority of the time), the ceiling plate

is not submerged and therefore not "submerging

scum".

1.0

B. Sampling wells, usually one near the

center, one at about 1/2 radius. These wells

have quick-opening hatches, with seal pipe

extending below liquid, so that samples can

be withdrawn without losing gas.

C. Pressure relief and vacuum-breaker valve,

mounted atop the gas dome for the purpose

of relieving as upon over pressurization, and

allowing atmospheric are to enter if vacuum

exists when cover on corbels. Basically, this

is a safety device, protecting the structure.

June 2004

Page 2 of 2

Вам также может понравиться

- RP32-3 Inspection & Testing of in Service Civil & Mechanical Plant Management PrincipalДокумент7 страницRP32-3 Inspection & Testing of in Service Civil & Mechanical Plant Management PrincipalAlif Rahmat FebriantoОценок пока нет

- Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Документ1 страницаShell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Karthic KeyanОценок пока нет

- Aeration Products PDFДокумент16 страницAeration Products PDFMuhammadObaidullahОценок пока нет

- IIT Hyderabad Faculty Housing Design CalculationsДокумент33 страницыIIT Hyderabad Faculty Housing Design CalculationssmijusОценок пока нет

- Skills: Civil Engineer July 2012-PresentДокумент2 страницыSkills: Civil Engineer July 2012-Presentnirankush rathoreОценок пока нет

- Guideline and Recommendation For The Design of Tank FoundationsДокумент1 страницаGuideline and Recommendation For The Design of Tank FoundationsrabzihОценок пока нет

- ETL Pressure Relief Valves Datasheet PDFДокумент6 страницETL Pressure Relief Valves Datasheet PDFNanasaheb PatilОценок пока нет

- ASMESectionVIIIDivision1 WeldNeckFlangeCalc PDFДокумент8 страницASMESectionVIIIDivision1 WeldNeckFlangeCalc PDFLisa MaloneОценок пока нет

- PMHSA R&D Forum Dent Assessment Methods & Challenges: David Chittick/Millan Sen June 24, 2009Документ7 страницPMHSA R&D Forum Dent Assessment Methods & Challenges: David Chittick/Millan Sen June 24, 2009Hafizul Hisyam Maysih LuzifahОценок пока нет

- Floating Roof TankДокумент2 страницыFloating Roof TankVasant Kumar VarmaОценок пока нет

- Significant Changes in AWWA D100-11Документ6 страницSignificant Changes in AWWA D100-11Leslie Scott100% (4)

- 03 Metal Packing Support PlatesДокумент3 страницы03 Metal Packing Support PlatesypatelsОценок пока нет

- Introduction To Gate Valves and Gate Valve TypesДокумент16 страницIntroduction To Gate Valves and Gate Valve TypesVinay Sharma100% (1)

- 1 Process VesselsДокумент4 страницы1 Process VesselsARIANA NICOLE RELIGIOSOОценок пока нет

- Mandatory Appendix 9Документ2 страницыMandatory Appendix 9Asep DarojatОценок пока нет

- ACI 318-11 Appendix D Changes SummaryДокумент2 страницыACI 318-11 Appendix D Changes SummaryJonathan SchauderОценок пока нет

- Appendix A - Sizing and Capacities of Gas PipingДокумент4 страницыAppendix A - Sizing and Capacities of Gas PipingTohid KarimiОценок пока нет

- Tank Design CalculatorДокумент19 страницTank Design CalculatorSunday PaulОценок пока нет

- Astm F436.04 PDFДокумент6 страницAstm F436.04 PDFWelington Volpatto MoraisОценок пока нет

- CV - Omid KhodadadfarДокумент4 страницыCV - Omid KhodadadfarGurvir SinghОценок пока нет

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeДокумент18 страницeBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xОценок пока нет

- Process Industry Basket StrainersДокумент27 страницProcess Industry Basket StrainersmartinnovelОценок пока нет

- Orifice Plates & AssembliesДокумент12 страницOrifice Plates & AssembliesAjay CОценок пока нет

- CAU2016 Tank PDFДокумент21 страницаCAU2016 Tank PDFJagankumar100% (1)

- F.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellДокумент9 страницF.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellVINOD KAMBLEОценок пока нет

- SP-2069 Specification For Pressure VesselsДокумент68 страницSP-2069 Specification For Pressure Vesselsarjunprasannan7Оценок пока нет

- Piping FabricationДокумент3 страницыPiping FabricationNa100% (2)

- CAESAR II-Applications GuideДокумент302 страницыCAESAR II-Applications GuideTakChi_LamОценок пока нет

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXДокумент1 страницаTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1Оценок пока нет

- Storage Tanks Nozzle Orientation GuideДокумент5 страницStorage Tanks Nozzle Orientation GuideragulОценок пока нет

- Double Wall Tank Installation InstructionsДокумент4 страницыDouble Wall Tank Installation InstructionsalokinstОценок пока нет

- Design and Analysis of Spherical Pressure Vessel UsingДокумент14 страницDesign and Analysis of Spherical Pressure Vessel UsingADitya JenaОценок пока нет

- Application of Bellows Expansion Joints in Piping SystemДокумент5 страницApplication of Bellows Expansion Joints in Piping Systemjlcheefei9258Оценок пока нет

- BPW Company Profile 2013Документ10 страницBPW Company Profile 2013nhiasantariОценок пока нет

- WI06-0260 Calculations For Obround Nozzle ConnectionsДокумент4 страницыWI06-0260 Calculations For Obround Nozzle ConnectionskumarОценок пока нет

- Cone Layout Development by Marking and Calculation Method With Practical ExampleДокумент12 страницCone Layout Development by Marking and Calculation Method With Practical ExampleOkayОценок пока нет

- Design and Analysis of Welded Pressure-Vessel Skirt SupportsДокумент13 страницDesign and Analysis of Welded Pressure-Vessel Skirt SupportsTranLeTrungОценок пока нет

- Garlock Metal - Gaskets TorqueДокумент48 страницGarlock Metal - Gaskets TorqueakenathorОценок пока нет

- Nozzle Loads As Per Shell DEPДокумент4 страницыNozzle Loads As Per Shell DEPSarfaraz KhanОценок пока нет

- Withdrawn NACE Technical ReportsДокумент11 страницWithdrawn NACE Technical ReportspabloОценок пока нет

- Floating Roof DesinДокумент5 страницFloating Roof Desindimdaliak_985662241Оценок пока нет

- ASCE 7-05 Table 15-4-2Документ1 страницаASCE 7-05 Table 15-4-2barouniamineОценок пока нет

- Static Equipment Generator 2019 BrochureДокумент4 страницыStatic Equipment Generator 2019 BrochureDennis RaymondОценок пока нет

- Eng GRP Gui 7011 23Документ20 страницEng GRP Gui 7011 23YOGESH GOPALОценок пока нет

- Flange Leakage Test As Per Asme Boiler & Pressure Vessel CodeДокумент12 страницFlange Leakage Test As Per Asme Boiler & Pressure Vessel CoderssambhiОценок пока нет

- Piping Engineering - Tank Nozzle Loads 1Документ1 страницаPiping Engineering - Tank Nozzle Loads 1Nasrul AdliОценок пока нет

- PED-Design Preliminaries-Mechanical Aspects - MergedДокумент87 страницPED-Design Preliminaries-Mechanical Aspects - Mergedsudhanshu shekharОценок пока нет

- Heat Shrink CoatingДокумент5 страницHeat Shrink CoatingMekhmanОценок пока нет

- HeatExchanger Drawing PDFДокумент7 страницHeatExchanger Drawing PDFssierroОценок пока нет

- Flange Bolt Torque Calculation and Pipe Flange Bolt Torque ChartДокумент6 страницFlange Bolt Torque Calculation and Pipe Flange Bolt Torque ChartArya0% (1)

- Instructed By: Hossein Sadeghi: An Introduction To Welded Tanks For Oil Storage, Api Standard 650Документ287 страницInstructed By: Hossein Sadeghi: An Introduction To Welded Tanks For Oil Storage, Api Standard 650Tania HuqОценок пока нет

- External Floating Roof Tank - WikipediaДокумент2 страницыExternal Floating Roof Tank - WikipediaalphadingОценок пока нет

- Maximum PressureДокумент83 страницыMaximum Pressureanhhung80Оценок пока нет

- Tank Jet MixersДокумент2 страницыTank Jet MixersGabriela Axinte100% (1)

- Simple beam spreadsheetДокумент65 страницSimple beam spreadsheetKrishn DevОценок пока нет

- Sealing Compounds From Project Sales CorpДокумент34 страницыSealing Compounds From Project Sales CorpProject Sales CorpОценок пока нет

- Jack Bolt StandardДокумент2 страницыJack Bolt Standard7761430Оценок пока нет

- Storage Tank SystemsДокумент35 страницStorage Tank Systemskvramanan_1Оценок пока нет

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОт EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОценок пока нет

- 2020-Banjo-Catalog (1)Документ176 страниц2020-Banjo-Catalog (1)Chris QueroОценок пока нет

- A Simplified Method For Assessing The Saturation Efficiency at Full-Scale Dissolved Air Flotation Plant PDFДокумент8 страницA Simplified Method For Assessing The Saturation Efficiency at Full-Scale Dissolved Air Flotation Plant PDFChris QueroОценок пока нет

- Chemical Aspects of Coagulation Using Aluminum Salts I PDFДокумент8 страницChemical Aspects of Coagulation Using Aluminum Salts I PDFChris QueroОценок пока нет

- Chemical Aspects of Coagulation Using Aluminum Salts I PDFДокумент8 страницChemical Aspects of Coagulation Using Aluminum Salts I PDFChris QueroОценок пока нет

- A Model For The Prediction of The Air Composition in Presure Saturator PDFДокумент9 страницA Model For The Prediction of The Air Composition in Presure Saturator PDFChris QueroОценок пока нет

- A Simplified Method For Assessing The Saturation Efficiency at Full-Scale Dissolved Air Flotation Plant PDFДокумент8 страницA Simplified Method For Assessing The Saturation Efficiency at Full-Scale Dissolved Air Flotation Plant PDFChris QueroОценок пока нет

- Adapting Dissolved Air Flotation For The Clarification of SeawaterДокумент5 страницAdapting Dissolved Air Flotation For The Clarification of SeawaterAndreia FalcoОценок пока нет

- A Demonstration Scaling-Up of The Dissolved PDFДокумент8 страницA Demonstration Scaling-Up of The Dissolved PDFChris QueroОценок пока нет

- A KINETIC MODEL FOR DISSOLVED AIR Flotation in Water and Wastewater Treatment PDFДокумент11 страницA KINETIC MODEL FOR DISSOLVED AIR Flotation in Water and Wastewater Treatment PDFChris QueroОценок пока нет

- A Model For The Prediction of The Air Composition in Presure Saturator PDFДокумент9 страницA Model For The Prediction of The Air Composition in Presure Saturator PDFChris QueroОценок пока нет

- Bratby1975 (Saturator Performance) PDFДокумент8 страницBratby1975 (Saturator Performance) PDFChris QueroОценок пока нет

- Aqua - DAF Paper 1 PDFДокумент13 страницAqua - DAF Paper 1 PDFChris QueroОценок пока нет

- Bratby1975 (Saturator Performance) PDFДокумент8 страницBratby1975 (Saturator Performance) PDFChris QueroОценок пока нет

- A Simplified Method For Assessing The Saturation Efficiency at Full-Scale Dissolved Air Flotation Plant PDFДокумент8 страницA Simplified Method For Assessing The Saturation Efficiency at Full-Scale Dissolved Air Flotation Plant PDFChris QueroОценок пока нет

- Aqua - DAF Paper 1 PDFДокумент13 страницAqua - DAF Paper 1 PDFChris QueroОценок пока нет

- A KINETIC MODEL FOR DISSOLVED AIR Flotation in Water and Wastewater Treatment PDFДокумент11 страницA KINETIC MODEL FOR DISSOLVED AIR Flotation in Water and Wastewater Treatment PDFChris QueroОценок пока нет

- Adapting Dissolved Air Flotation For The Clarification of SeawaterДокумент5 страницAdapting Dissolved Air Flotation For The Clarification of SeawaterAndreia FalcoОценок пока нет

- A Demonstration Scaling-Up of The Dissolved PDFДокумент8 страницA Demonstration Scaling-Up of The Dissolved PDFChris QueroОценок пока нет

- Adapting Dissolved Air Flotation For The Clarification of SeawaterДокумент5 страницAdapting Dissolved Air Flotation For The Clarification of SeawaterAndreia FalcoОценок пока нет

- A KINETIC MODEL FOR DISSOLVED AIR Flotation in Water and Wastewater Treatment PDFДокумент11 страницA KINETIC MODEL FOR DISSOLVED AIR Flotation in Water and Wastewater Treatment PDFChris QueroОценок пока нет

- Chemical Aspects of Coagulation Using Aluminum Salts I PDFДокумент8 страницChemical Aspects of Coagulation Using Aluminum Salts I PDFChris QueroОценок пока нет

- Chemical Aspects of Coagulation Using Aluminum Salts I PDFДокумент8 страницChemical Aspects of Coagulation Using Aluminum Salts I PDFChris QueroОценок пока нет

- Bratby1975 (Saturator Performance) PDFДокумент8 страницBratby1975 (Saturator Performance) PDFChris QueroОценок пока нет

- A Model For The Prediction of The Air Composition in Presure Saturator PDFДокумент9 страницA Model For The Prediction of The Air Composition in Presure Saturator PDFChris QueroОценок пока нет

- Aqua - DAF Paper 1 PDFДокумент13 страницAqua - DAF Paper 1 PDFChris QueroОценок пока нет

- Global Trends in Gold Mining Towards Quantifying Environmental PDFДокумент15 страницGlobal Trends in Gold Mining Towards Quantifying Environmental PDFChris QueroОценок пока нет

- A Simplified Method For Assessing The Saturation Efficiency at Full-Scale Dissolved Air Flotation Plant PDFДокумент8 страницA Simplified Method For Assessing The Saturation Efficiency at Full-Scale Dissolved Air Flotation Plant PDFChris QueroОценок пока нет

- Marine organisms' arsenic levels and speciation after contaminationДокумент6 страницMarine organisms' arsenic levels and speciation after contaminationChris QueroОценок пока нет

- A Demonstration Scaling-Up of The Dissolved PDFДокумент8 страницA Demonstration Scaling-Up of The Dissolved PDFChris QueroОценок пока нет

- Cervercia India Puerto Rico Presentacion - WWTP Upgrade L1Документ40 страницCervercia India Puerto Rico Presentacion - WWTP Upgrade L1Chris QueroОценок пока нет

- Industrial Valves Ð Metallic Butterfly Valves: British Standard BS EN 593:1998Документ14 страницIndustrial Valves Ð Metallic Butterfly Valves: British Standard BS EN 593:1998panduranganraghurama100% (1)

- Systellar 180V 40A Solar Charge ControllerДокумент9 страницSystellar 180V 40A Solar Charge ControllerTrevor MendozaОценок пока нет

- 1 - ECC Protocol StackДокумент151 страница1 - ECC Protocol Stacksc159753100% (1)

- Logical Addressing: Faisal Karim ShaikhДокумент69 страницLogical Addressing: Faisal Karim Shaikhsindhu4sindОценок пока нет

- Performance Metrics: - Bandwidth (Throughput) - Latency (Delay) - BandwidthДокумент17 страницPerformance Metrics: - Bandwidth (Throughput) - Latency (Delay) - Bandwidth23wingsОценок пока нет

- GRP ProcedureДокумент42 страницыGRP Proceduremansih45775% (4)

- Exp LG 032778 - 0Документ1 страницаExp LG 032778 - 0sam hadОценок пока нет

- Is 5522 1992Документ9 страницIs 5522 1992manojОценок пока нет

- Aws A5.17 A5.17m-97Документ37 страницAws A5.17 A5.17m-97Islam SahafayatОценок пока нет

- Nonfunctional Requirements (System Qualities) Agile Style: by Dean Leffingwell and Ryan Shriver Agile 2010 Orlando, FLДокумент44 страницыNonfunctional Requirements (System Qualities) Agile Style: by Dean Leffingwell and Ryan Shriver Agile 2010 Orlando, FLFernando Carvalho100% (1)

- Emirates Telecommunications Corporation "Etisalat": By: Maha Kanz (CFA)Документ11 страницEmirates Telecommunications Corporation "Etisalat": By: Maha Kanz (CFA)memo ibОценок пока нет

- Service Strategy Itil v3Документ1 страницаService Strategy Itil v3Noshaba MalikОценок пока нет

- FP200 FR Expanding Foam: AbescoДокумент2 страницыFP200 FR Expanding Foam: AbescoIrfan AliОценок пока нет

- AutoCAD: A Brief History of the Popular CAD SoftwareДокумент19 страницAutoCAD: A Brief History of the Popular CAD SoftwareKumaResan SubramaniamОценок пока нет

- LG 42lh40ed (-Sa) 42lh45ed (-SB) Chassis Lj92jДокумент76 страницLG 42lh40ed (-Sa) 42lh45ed (-SB) Chassis Lj92jJose Fco. Aleman Arriaga100% (1)

- FAQ - FactoryTalk Historian SE CollectivesДокумент2 страницыFAQ - FactoryTalk Historian SE CollectivesjaysonlkhОценок пока нет

- Project Management and The Aspects of Quality Management - An Integrative ApproachДокумент7 страницProject Management and The Aspects of Quality Management - An Integrative Approachabel asratОценок пока нет

- 1303287208Документ27 страниц1303287208Anurag JainОценок пока нет

- Cooling Coil Spec ###Документ2 страницыCooling Coil Spec ###PeterWangОценок пока нет

- Buildings Department Approved Materisla List CDBSFДокумент47 страницBuildings Department Approved Materisla List CDBSFPaulSwinbankОценок пока нет

- BS en 12101-8-2011Документ42 страницыBS en 12101-8-2011L LОценок пока нет

- CEH Exam Part-1Документ19 страницCEH Exam Part-1Abdullah AlrimawiОценок пока нет

- Company Profile NKN 2017Документ11 страницCompany Profile NKN 2017anzaniОценок пока нет

- PP Service Master CONNECT v8 UK PDFДокумент9 страницPP Service Master CONNECT v8 UK PDFAjay KrishnaОценок пока нет

- C-Band Vsat Equipment Options (On Nss10 Formerly Amc-12) : Option 1 (Idirect Platform - Tdma)Документ4 страницыC-Band Vsat Equipment Options (On Nss10 Formerly Amc-12) : Option 1 (Idirect Platform - Tdma)Patrick Cee AnekweОценок пока нет

- Explanatory Note To Ed Decision 2022-021-r-1Документ9 страницExplanatory Note To Ed Decision 2022-021-r-1corticalisОценок пока нет

- Strategic Analysis Abd Choice in Single or Dominant Product BusinessesДокумент65 страницStrategic Analysis Abd Choice in Single or Dominant Product BusinessesicollinsonОценок пока нет

- UPSentry Smart 2000 For Windows (En)Документ42 страницыUPSentry Smart 2000 For Windows (En)babisoОценок пока нет

- Dimension I MiДокумент8 страницDimension I Miismet mehmetiОценок пока нет

- SAP R/3 Forecasting Module GuideДокумент34 страницыSAP R/3 Forecasting Module GuideAjitabh SinghОценок пока нет