Академический Документы

Профессиональный Документы

Культура Документы

D8 ADVANCE Pre-Installation Guide

Загружено:

Ariel Gaston AgusОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

D8 ADVANCE Pre-Installation Guide

Загружено:

Ariel Gaston AgusАвторское право:

Доступные форматы

Bruker AXS

D8 ADVANCE

X-ray Diffractometer

Pre-installation Guide

(North America)

System Requirements

The following specifications are general system

requirements. Use this information to make an initial

decision on the suitability of your proposed site. Refer to

later sections of this Pre-installation Guide for more

details.

Power (pages 4 - 5)

Purpose

This Pre-installation Guide will aid you and any required

personnel in site preparation prior to installation of the

D8 ADVANCE X-ray diffractometer.

Read these instructions carefully and thoroughly to

prepare for the installation of your D8 ADVANCE. Proper

site planning will ensure optimum efficiency,

maintenance access, proper instrument performance,

and avoidance of unnecessary delays during installation.

Responsibility

The customer is responsible for making certain that the

basic site requirements for the D8 ADVANCE are

fulfilled. These instructions are to be followed by the

customer and by personally contracted tradespeople,

except where otherwise noted.

When the basic site requirements are fulfilled, it is the

customers responsibility to complete the attached Preinstallation Checklist and return it to Bruker AXS via fax.

System

208-240V, 60Hz, 1-phase, 40A

Computer/peripherals

100-120V, 60Hz, 1-phase, 15A

Haskris R100C water

recirculator

208-240V, 60Hz (isolated),

1-phase, 15A

Cooling Capacity

3850W (13125 btu/hr) or greater

Temperature

50-68F 2F (10-20C 1C)

Pressure

60-90 psi (4-6 bar)

Quantity*

6 gal (23 L)

*Quantity specified is for Haskris R100C. Use distilled water.

Communications (Figure 2 and Table 5)

Optional RJ-11 line near system for voice connection

Ethernet network connection (Table 5)

Table 1.

Pre-installation Overview

1 of 9

M88-E04046

18 February 2009

D8 ADVANCE Dimensions

D8 ADVANCE Dimensions

D8 ADVANCE

dimensions

and weight

Shipping Dimensions

Height

82.5 (209.5 cm)

Width

55.1 (140.0 cm)

Depth

49.4 (125.5 cm)

Weight

approx. 1190 lbs

(540 kg)

Floor load

capacity

146.9 lbs/ft2 (717.0 kg/m2) minimum. The floor

should be level and as rigid as possible to avoid

vibration.

Doorway

clearance

required

Largest sub-assembly

(unboxed/uncrated), if

mounted parts are

removed

36.0 (91.4 cm)

27.5 (70.0 cm)

minimum

Although the

instrument has

wheels, it should be

accessible from all

sides for proper

servicing and airflow.

Wall-to rear of

instrument

clearance

Table 2.

The D8 ADVANCE shipment includes two large boxes

from Bruker AXS factories (Table 3). To account for

variation in box size, maximum dimensions are given in

the Table. Additional small boxes may arrive with the

shipment, given the configuration of the system.

Base Box (on pallet)

Top Box (on pallet)

Height

58.3 (148 cm)

44.5 (113 cm)

Width

57.1 (145 cm)

43.3 (110 cm)

Depth

66.1 (168 cm)

55.1 (140 cm)

Weight

1030 lbs (467 kg)

710 lbs (322 kg)

Table 3.

Maximum dimensions of instrument boxes from factory

Actual instrument dimensions, weights, and clearances

33.3" (84.7 cm)

(enclosure rear removed*)

55.1" (140.0 cm)

46.7" (118.7 cm)

Side View

46.0"

(116.8 cm)

43.6"

(111 cm)

Front View

(light bar

removed*)

82.5"

(209.5 cm)

3.1"

(8 cm)

35.1"

(89.2 cm)

33.7" (85.6 cm)

(front and rear panels removed*)

Dolly - 2.4"

(6.0 cm)

46.3" (117.7 cm)

(side panels removed*)

*NOTE: Dimensions with portions temporarily removed for transportation

Figure 1. D8 ADVANCE dimensions

2

M88-E04046

Environmental Considerations

Environmental Considerations

Room/Instrument

Requirements

Optimal room temperature

75.2F (24.0C)

Room operation-range temperature

57.2 - 93.2F (14.0 - 34.0C)

Maximum temperature gradient

1.8F (1C) per hour for highest stability of measuring values

Relative humidity

20%-80%, non-condensing

Heat dissipation to the air by the

diffractometer (with temperature stabilizer,

electronics measuring, X-ray generator, and

vacuum pump).

1.0 kW (3412 btu/hr) maximum

Dissipated heat must be removed by a ventilation or air conditioning system. Cooling air

should flow around the instrument without restriction. If possible, locate the air conditioning

and heating ducts so that their airflow is not aimed directly at the instrument.

This configuration assumes that an external

water recirculator is installed in a separate

room.

NOTE: We recommend a clean, dust-free environment.

Static electricity elimination (to avoid adverse

effects on instrument electronics)

Any carpeting in the area should be of a conductive variety. If the area is carpeted with nonconductive carpet, we recommend that you place anti-static mats over the conventional

carpeting in the area around the instrument.

Table 4.

Environmental considerations

External water recirculator

(Haskris R100C)

28' (8.5 m) maximum

cable distance between

instrument and computer.

Allow for routing of cables

along baseboards.

27.5"

(70 cm)

Generator

Electronics

RJ-45 jack

for internet

connection

(optional)

RJ-11 jack

for voice

connection

(optional)

27.5"

(70 cm)

27.5"

(70 cm)

Minimum

clearance

Table (not factory-supplied)

NOTE: For plumbing and electrical details,

see the other Figures and Tables in

this Pre-installation Guide.

Figure 2. Typical D8 ADVANCE floor plan

3

M88-E04046

Communications

Communications

Electrical Power

See Table 6 for power requirements for the D8

Connection

Connector

Purpose

Telephone

(optional)

RJ-11

Voice connection near

instrument

RJ-45 (Ethernet)

Remote diagnosis over

the internet

Internet

connection

Table 5.

Communications: connections

We strongly recommend that you install a telephone

connection (for voice communications) near the

instrument.

NOTE: Bruker AXS Remote Diagnosis features are now

available over the internet (i.e., WebEx). Check

with your IT administrator to find out how

Remote Diagnosis may affect your IT policy.

ADVANCE (including the computer and peripherals).

Note the lengths of the various cables.

On the wall behind the instrument, connect power

from the building mains to a plug-type wall outlet or

to a direct-wired circuit breaker/disconnect box, so

that power to the instrument can be interrupted if

necessary.

NOTE: Outlet and plug not factory-supplied.

NOTE: If the power line voltage at your site fluctuates

outside the values in Table 6, a compatible line

voltage conditioner or regulator may be

necessary. Check with your sites electrical

coordinator.

Wire the room air conditioner and any external

pumps to a different electrical circuit than that used

for the instrument. High starting currents from their

motors may adversely affect line voltage stability.

Additionally, provide a separate electrical power circuit for the Haskris water recirculator (if purchased).

208 VAC, 40A

Circuit breaker, disconnect box, or

outlet for plug (not factory-supplied).

Secure to wall.

208 VAC, 15A

(isolated from system)

Haskris

R100C

water

recirculator

110 VAC, 15A

Ground cable

(factory-supplied)

six-outlet power strip

(included)

Generator

Electronics

Figure 3. D8 ADVANCE electrical connections

4

M88-E04046

Electrical Power

Instrument

(left side)

Electronics & Generator

Cable to

chassis ground

(factory-supplied)

3-conductor, 8-gauge

power cable (factory-supplied).

Cable is 20 feet (6.1 m) long,

4 feet (1.5 m) of which are

enclosed inside the instrument.

Fuse or

breaker

40 A (2)

Electrical Box

House Power

208 VAC

L1

L2

Earth Ground

Figure 4. D8 ADVANCE electrical connections (schematic)

Component

Current rating

Voltage and frequency

Power cable lengths

D8 ADVANCE diffractometer

unit

40A

208-240V, 60Hz, 1-phase

8-gauge, 3-conductor power cable

(factory-supplied), about 15 ft (4.6 m)*

Computer and peripherals

15A

100-120V, 60Hz, 1-phase

6 ft (1.8 m)**

Data cables: about 28 ft (8.5 m)

External water recirculator,

Haskris R100C

15A

208-240V, 60Hz, 1-phase

About 8 ft (2.4 m)***

* Customer supplies plug to match wall receptacle (if used).

** Factory-supplied 6-position AC outlet strip (110V).

*** For the recommended Haskris model (R100C), customer supplies plug to match wall receptacle (if used).

If fuses are used, use slow-blow fuses.

Table 6.

D8 ADVANCE electrical specifications

5

M88-E04046

Cooling Requirements

Cooling Requirements

Cooling capacity

when water source

is 65F (18C):

3850W (13125 btu/hr)

Water pump

capacity

3.7 gal/min (14.1 L/min)

Water reservoir

volume

6 gal (23 L)

Temperature

stability

2F (1.1C)

Refrigerant

R134a

Unit weight

325 lbs (148 kg)

(approximate shipping

weight without water in

the tank)

Unit dimensions

31H 21W 29D

(79 cm 53 cm 74 cm)

Coolant required

Clean, potable, distilled

water. Do not use

deionized water.

When temp. is:

65F (18C)

75F (24C)

85F (29C)

Flow rate required is:

1.0 gal/min (3.8 L/min)

1.5 gal/min (5.7 L/min)

3.1 gal/min (11.8 L/min)

Minimum required

pressure differential

from condenser

water inlet to outlet:

25 psi (1.7 bar)

During installation, the Bruker AXS Field Service

Engineer will connect factory-supplied 1/2 (12mm)

inside diameter hoses between the Haskris R100C and

piping, and then between the piping and instrument (the

unit and instrument having customer-supplied barbed

fittings). The Engineer will then fasten the water hoses

to the barbed fittings with hose clamps.

Maximum pressure

differential from

condenser water

inlet to outlet:

60 psi (4.1 bar)

Maximum

condenser water

inlet pressure:

125 psi (8.6 bar)

NOTE: The Haskris R100C needs supply water and a

drain to remove heat that it emits. However, it

keeps water consumption to a minimum using a

water valve that opens and closes as required.

Must be installed in

a clean, indoor

environment. If

possible, install the

Haskris in a

separate room to

minimize noise and

heat emission.

We recommend access to

the:

TOP for routine

maintenance, such as

changing water in the

reservoir.

FRONT for visibility of

controls and readouts.

ONE SIDE for convenient

servicing should a spare

part be required.

An external cooling-water system is required to

dissipate heat produced by the D8 ADVANCE. The

cooling-water system must be fed with a closed-circuit

cooling system.

To minimize difficulties with cooling water (e.g.,

suspended solids, low pressure, and extreme water

temperature variations), we recommend installing a

Haskris R100C closed-circuit water recirculator as

shown in Figures 5 and 6. Other cooling system

arrangements are not recommended as they will

inevitably fail to minimize the aforementioned difficulties

and result in cooling problems.

Technical

features

NOTE: If you do not wish to install a Haskris closedcircuit water recirculator, contact Bruker AXS for

more information.

CAUTION

The X-ray tubes warranty does not cover damage

resulting from improper cooling water.

Install two 3/4 copper lines, each maximum length of

48 ft (15m), with a shut-off valve near each end of each

pipe. Install 1/2 barbed fittings (not supplied) at each

end of the pipes. These copper lines are intended for

transporting the cooling water over long distances. The

barbed fittings at the end of the pipes will connect to the

short, factory-supplied hoses attached to the instrument.

NOTE: To protect the Haskris R100C, ensure that the

water is free of suspended matter. Also, ensure

that water hardness does not exceed 300 mg/

liter CaO, while remaining at neutral pH (7).

Condenser

cooling water

requirements

Location

Table 7.

Haskris R100C recirculator specifications

6

M88-E04046

Cooling Requirements

Haskris Model R100C

TECHNICAL SPECIFICATIONS

1. Power Requirements: 208/230V-1-60Hz

2. F.L.A. Rating: 9.9A

3. Recommended Fuse Size: 15A (time delay)

Water Level

Indicator

Note:

Supply and return connections are

1/2" Hand Valves with 1/2" Hose Barbs.

Unit ON/OFF

Switch

65

FULL

MENU

2.25"

Flowmeter

SUPPLY

Power

Indicator

31.0"

(78.7 cm)

RETURN

Water Temp

Control & Display

DEPTH = 29.0"

(73.7 cm)

POWER CORD (7 ft., no plug furnished)

24"

21"

Ventilation grille

18.5"

2.5"

2.5"

3"

City Water "IN"

3/8" FPT Brass

City Water "OUT"

3/8" FPT Brass

Leveling Legs

(adjustable from 1/2" To 2")

21.0"

(53.3 cm)

FRONT

VIEW

REAR

VIEW

NOT DRAWN

TO SCALE

NOT DRAWN

TO SCALE

Figure 5. Haskris R100C recirculator specifications

Water supply

Haskris

R100C

Drain

Reinforced industrial water hose

Return from

instrument

Supply to

instrument

3/4" copper tubing

Shut-off valves (wall-mounted)

1/2" barbed fitting

NOTE: 25 (7.6 m) of water hose comes

with the Haskris R100C.

Generator

Electronics

65 (20.0 m) of usable water

hose comes with the D8

ADVANCE.

Figure 6. Cooling water with the Haskris R100C closed-circuit water recirculator

7

M88-E04046

Plumbing Requirements

Plumbing Requirements

Material supplied with D8

ADVANCE

Tubing/hose ID sizes for

barbed fittings

Tubing/hose lengths

Counter tube gas

(P10for MBraun positionsensitive detector only)

Inlet: Black Viton tubing

0.125 (0.32cm)

23 ft (7m)

Outlet: Blue polymer tubing

0.25 (0.64cm)

23 ft (7m)

Helium

Blue Polymer tubing

0.125 (0.32cm)

23 ft (7m)

Cooling water hoses

Pressure water hose

0.5 (1.27cm)

65 ft (20.0m)

Vacuum exhaust*

Plastic hose

0.5 (1.27cm)

17 ft (5.2m)

* Mist elimination is installed; exhausting vacuum is an option. You must provide an outlet for the vacuum exhaust (see Figure 2).

Table 8.

Tubing and hose sizes for supplied barbed fittings on D8 ADVANCE and Haskris R100C water recirculator

Gas Specifications

Position-sensitive Detector Gas Supply

(optionalfor MBraun PSD only)

Helium Supply (optional)

For equipment with a helium or nitrogen flush option

If an MBraun PSD (position-sensitive detector) is

used with the D8 ADVANCE, install a P10 gas cylinder and regulator as noted in Table 9.

Install a cylinder of gas with a two-stage regulator

(for the flow counter) as noted in Table 9. We recommend indoor installation of the gas cylinder.

(required for liquid or loose powder analysis), install a

helium or nitrogen cylinder with a two-stage regulator as noted in Table 9.

Secure the cylinder with a mounting support to avoid

accidental tipping.

Ensure that the cylinder is securely mounted to avoid

tipping. Observe all safety regulations for flammable

gases. We recommend that you keep a reserve cylinder.

Install as short a line as possible from the gas cylin-

der to the instrument. Use factory-supplied Viton tubing (length as noted in Table 8). If your supply line

must exceed the supplied length, use oxygen-free

(high-purity) copper or stainless-steel piping. Ensure

that the lines are clean and free of water, solvents,

and particulate matter. Avoid exposing the gas lines

to extreme temperatures (such as heating vents).

Operate the flow counters only with a commercial-

grade mixture of P10 gas (i.e., 90% Argon, 10%

methane, impurities less than 0.5% by volume).

Gas

Cylinder/Regulator

(not factory-supplied)

P10

Compressed-gas cylinder with T-size

cylinder filling pressure, 2900 psi (180

bar), with regulator such as AGA model

SGVHPT272B-350 or equivalent.*

Helium or nitrogen

(optional; use if

ordered)

Compressed-gas cylinder with T-size

cylinder filling pressure, 2900 psi (180

bar), with regulator such as AGA model

SGVHPT270B-580 or equivalent.*

* Securely mount the cylinders to a wall or table. Observe safety

regulations for all flammable gases.

Table 9.

Gas specifications

Install a separate exhaust line leading to an outside

discharge for the spent gas.

8

M88-E04046

Final Check

Final Check

When the System Arrives

You, the customer, are responsible for meeting all

applicable building and safety codes. Once the preinstallation utilities are connected, get certification (from

an approved authority) that the installation meets all

local building and safety codes.

When the system arrives, check it for damage with

When all pre-installation work is finished, complete the

attached D8 ADVANCE Pre-installation Checklist and fax

it to Bruker AXS.

Fax:

1 (608) 276-9162 or 1 (608) 276-3015

the delivery driver. Contact the carriers office and

Bruker AXS immediately if you find any damage.

Compare the packing list (i.e., the number of boxes

received) with your order invoice and contact Bruker

AXS if you find any discrepancies.

Move boxes or crates to the installation site (if possi-

ble) to facilitate timely installation. Wait until a Bruker

AXS Field Service Engineer opens the boxes to

check their contents against your invoice. Do not

open or uncrate any boxes.

If uncrating is required, call Bruker AXS for authoriza-

Also, contact the Bruker AXS Service Department by

telephone to confirm that your site is ready for

installation.

Tel:

1 (800) 234-XRAY [9729] or 1 (608) 276-3087

tion at 1 (800) 234-XRAY [9729] extension 3087. If

you are authorized to uncrate the shipment, save all

packing material until the Bruker AXS Field Service

Engineer completes the installation.

Installation must be performed by a Bruker AXS Field

Service Engineer.

Save all packing materials for the system until the

Upon receiving confirmation that your site is ready,

Bruker AXS personnel will schedule the instrument

installation.

Bruker AXS Field Service Engineer has completed

the installation.

NOTE: Installation of the system typically requires three

to four working days. Optional attachments

require additional time for installation and

testing.

Bruker BioSciences

Bruker AXS Inc.

40 Manning Road

Billerica, MA USA

5465 East Cheryl Parkway

Madison, WI 53711-5373 USA

Phone +1 (978) 663-3660

Fax: +1 (978) 667-5993

Phone +1 (800) 234-XRAY [9729]

Fax +1 (608) 276-3006

E-mail: info@bruker-biosciences.com

www.bruker-biosciences.com

E-mail: info@bruker-axs.com

www.bruker-axs.com

This page intentionally left blank

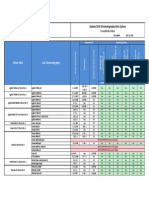

D8 ADVANCE Pre-installation Checklist

D8 ADVANCE Pre-installation Checklist

Please complete the checklist below and fax it to the Bruker AXS Service Department:

FAX

FROM:

TO:

Contact Name

Phone

Company/Organization

Fax

Bruker AXS,

Attn: Service Dept.

1 (608) 276-9162 or

1 (608) 276-3015

Component

YES/NO

Value/remark

Initial/date

Room Location

Floor load capacity exceeds 146.9 lbs/ft2 (717.0 kg/m2)

(see Table 2)

Room height exceeds 82.5 (209.5 cm) (see Table 2)

Floor space for D8 ADVANCE free of equipment and clean (see

Figures 1 and 2, Table 2)

Doors and hallways from loading dock to location have adequate

clearance for moving the D8 ADVANCE in its shipping crates;

freight elevator available (see Table 3)

Clearance on all sides of uncrated unit exceeds 27.5 (70.0 cm)

(see Figure 2, Table 2)

Computer table within 13.0 (4.0 m) of instrument

Environment (see Table 4)

System is not exposed to direct sunlight

Temperature between 57.2 - 93.2F (14.0 - 34.0C)

Temperature gradient less than 1.8F (1C) per hour

Heat removal capacity exceeds 1.0 kW (3412 btu/hr)

Relative humidity between 20% - 80%, no condensation

Carpeted rooms: anti-static carpeting or mats installed

Communications (see page 4)

Optional voice line (near instrument)

Internet connection for remote diagnostics

Electrical Power (see Figure 4, Table 6)

208 VAC, 60 Hz 3 Hz, 40A (D8 ADVANCE)

208 VAC, 60 Hz 3 Hz, 15A (Haskris R100C)

110 VAC, 60 Hz 3 Hz, 15A (Computer and peripherals)

1 of 3

M88-E04046

D8 ADVANCE Pre-installation Checklist

Component

YES/NO

Value/remark

Initial/date

All electrical power for the system must be isolated from circuits

that have high starting currents (e.g., air conditioners, pumps,

furnaces)

Electrical connection of instrument to mains power supply is

provided with automatic circuit breakers for all phases

It is possible to disconnect the D8 ADVANCE completely from the

mains power supply, using either a labeled switch or a circuit

breaker located near the system

Power cable connected directly to switchboard

Socket outlet according to DIN49462, VDE 0623, IEC 309-1

(Approved plug connector supplied by customer)

Cooling Requirements (see page 6)

Closed cooling system (Haskris R100C recommended)

(see Figures 2 and 6)

Plumbing/piping complete

(for recommended Haskris unit)

Customer-supplied cooling system (not recommended)

The Haskris R100C water recirculator meets the cooling water requirements of the system. If you provide your own water supply, it must

meet the following requirements.

Flow rate greater than 1 gal/min (3.6 L/min). Recommended rate:

1.1 gal/min (4.0 L/min)

Pressure 60-110 psi (4-7.5 bar) and pressure-free drain

Temperature 59-68F (15-20C). Room temperature must be high

enough to avoid condensation.

Bruker AXS recommends the use of distilled or reverse osmosis (RO) water for cooling the X-ray tube and generator. Use of deionized water

is NOT recommended. If building water is used, it must meet the following requirements.

Hardness less than:

300mg/L CaO, or

30 CaO (German scale), or

53.7 CaO (French scale), or

37.5 CaO (UK scale)

pH of 7.0 1

Adequate filtering to remove suspended solids (50 m)

Plumbing Requirements (see page 8)

Distance to water supply less than 26 (8 m), less than 48 (15 m)

if Haskris used

Shutoff valves installed on both lines (not required if discharging

into drain)

Elevation difference between Haskris and instrument less than 20

(6 m)

NW hose barb fittings for supply and return of cooling water

Supply Gases (the optional helium mode requires helium gas cylinders and regulators, not factory-supplied) (see

Tables 9 and 8, Figure 2)

2 of 3

M88-E04046

D8 ADVANCE Pre-installation Checklist

Component

YES/NO

Value/remark

Initial/date

P10 Gas (for MBraun PSD only):

Commercial-grade P10 gas (90% Argon, 10% methane, less than

0.5% impurities by volume) in T-size gas cylinder, e.g., 50 L, 200

bar (2900 psi)

Cylinder/regulator securely mounted to wall within 6 (2 m) of the

D8 ADVANCE

If mounted further away than the supplied hose length, correct

tubing/piping line installed (see Table 8)

Local safety requirements for flammable gases fulfilled

Exhaust gas vents to the outside, or a fume hood is present

(if mandated by local safety requirements)

Helium Gas (if applicable):

Cylinder/regulator securely mounted to wall within 6 (2 m) of the

D8 ADVANCE

If mounted farther away than the supplied hose length, correct

tubing/piping line installed (see Table 8)

Vacuum

Exhaust to outside (optional)

Final Check

All local safety codes are met

Fax a copy of this form to: Bruker AXS, Attention: Service

Department 1 (608) 276-9162

Call for installation: 1 (800) 234-XRAY [9729] extension 3087

When system arrives: Check packing crates for shipping damage. If there is damage, contact your Carriers Office and Bruker AXS. Compare

the packing list (the number of boxes) with your invoice. If possible, move boxes (crates) to installation site or storage area.

Do not open crates or boxes. If uncrating is required, call Bruker AXS for authorization at 1 (800) 234-XRAY [9729] extension 3087.

If authorized to uncrate, save all packing material until the Bruker AXS Field Service Engineer completes installation.

3 of 3

Bruker BioSciences

Bruker AXS Inc.

40 Manning Road

Billerica, MA USA

5465 East Cheryl Parkway

Madison, WI 53711-5373 USA

Phone +1 (978) 663-3660

Fax: +1 (978) 667-5993

Phone +1 (800) 234-XRAY [9729]

Fax +1 (608) 276-3006

E-mail: info@bruker-biosciences.com

www.bruker-biosciences.com

E-mail: info@bruker-axs.com

www.bruker-axs.com

Вам также может понравиться

- Asc-9800 SM Zesn-2004 e PDFДокумент32 страницыAsc-9800 SM Zesn-2004 e PDFKhalid ZghearОценок пока нет

- ICPMS-2030: Pre-Installation RequirementsДокумент17 страницICPMS-2030: Pre-Installation Requirementspilar100% (1)

- Application Report DMA 80 Evo Coal USREV061019Документ4 страницыApplication Report DMA 80 Evo Coal USREV061019Roni GustiwaОценок пока нет

- Gas Chromatography Driver Pack: Galaxie 2010 Chromatography Data SystemДокумент3 страницыGas Chromatography Driver Pack: Galaxie 2010 Chromatography Data SystemmardonioandradeОценок пока нет

- Lc-10ad Im Rev0ocДокумент128 страницLc-10ad Im Rev0ocHồ Việt HùngОценок пока нет

- 7820A GC Illustrated Parts BreakdownДокумент102 страницы7820A GC Illustrated Parts BreakdownRuy Santana Jr.Оценок пока нет

- ELAN Improvements Service Training RevBДокумент19 страницELAN Improvements Service Training RevBJOSE ABADОценок пока нет

- Tips & Techniques, MAXI-44, Rev02Документ9 страницTips & Techniques, MAXI-44, Rev02AntWonxxxОценок пока нет

- Fluorospectrometer RF-20A:20Axs Prominence User ManualДокумент352 страницыFluorospectrometer RF-20A:20Axs Prominence User ManualChristos Georgiou100% (1)

- Ethos900 ManualДокумент80 страницEthos900 ManualAndres FalmacelОценок пока нет

- MA180-005 subPUR-duoPUR User ManualДокумент34 страницыMA180-005 subPUR-duoPUR User ManualDiana Putri SofyanОценок пока нет

- ETHOS One Rev 00-2010 PDFДокумент14 страницETHOS One Rev 00-2010 PDFAlida MatousekОценок пока нет

- MA 3000 NIC 600 2233 01 Simplified Operation ManualДокумент10 страницMA 3000 NIC 600 2233 01 Simplified Operation ManualPaul PlimОценок пока нет

- User Manual: Fibertec™ M6 1020/1021Документ84 страницыUser Manual: Fibertec™ M6 1020/1021osklav100% (1)

- AAiCE ICE 3300 Lock Out Spec V2Документ4 страницыAAiCE ICE 3300 Lock Out Spec V2aljonОценок пока нет

- Bruker 430 GC User Manual PDFДокумент2 страницыBruker 430 GC User Manual PDFOsama AhmedОценок пока нет

- GDE NexION 1000 2000 ICP MS Preparing Your Lab 012773 01Документ9 страницGDE NexION 1000 2000 ICP MS Preparing Your Lab 012773 01СтепанОценок пока нет

- GC2014 MAnual Usuario PDFДокумент318 страницGC2014 MAnual Usuario PDFJHON ALEXANDER BEDOYA BUILESОценок пока нет

- ThermoregulationДокумент64 страницыThermoregulationapi-3703371Оценок пока нет

- LC-20A ProminenceДокумент40 страницLC-20A Prominencemian allОценок пока нет

- GBC 01-1005-00 SavantAA Software Operation ManualДокумент64 страницыGBC 01-1005-00 SavantAA Software Operation Manualngobaochan100% (1)

- Clear Choice: TurbomatrixДокумент10 страницClear Choice: TurbomatrixSaleh HamadanyОценок пока нет

- Thermo Easy NLC Service Manual PDFДокумент364 страницыThermo Easy NLC Service Manual PDFrajeeshОценок пока нет

- SMRM TutorialДокумент30 страницSMRM Tutorialyoussef elaskary100% (2)

- NIR - Multivariate Calibration - 3rd Edition 2014Документ12 страницNIR - Multivariate Calibration - 3rd Edition 2014Ingeniero Alfonzo Díaz GuzmánОценок пока нет

- DGU-403 DGU-405: Instruction ManualДокумент30 страницDGU-403 DGU-405: Instruction ManualCrystal LinОценок пока нет

- 9291 6306 PDFДокумент202 страницы9291 6306 PDFsorinavramescuОценок пока нет

- SOP For Milestone Microwave DigestionДокумент11 страницSOP For Milestone Microwave Digestionapi-26966403Оценок пока нет

- The Filtration Spectrum: Relative Size of Common MaterialsДокумент1 страницаThe Filtration Spectrum: Relative Size of Common MaterialsartsonmОценок пока нет

- Agilent 240FS PDFДокумент6 страницAgilent 240FS PDFValentino Budi PratamaОценок пока нет

- UV-1800 System ManualДокумент99 страницUV-1800 System ManualSharif HossenОценок пока нет

- GCMS-QP2010Ultra - SE User'sGuide (Ver2.6) PDFДокумент378 страницGCMS-QP2010Ultra - SE User'sGuide (Ver2.6) PDFnguyenvietanhbtОценок пока нет

- Varian DS-102 202 302 402 602 Instruction ManualДокумент71 страницаVarian DS-102 202 302 402 602 Instruction ManualHumbertoОценок пока нет

- Hydride Vapor Generator: For Shimadzu Atomic Absorption SpectrophotometerДокумент23 страницыHydride Vapor Generator: For Shimadzu Atomic Absorption SpectrophotometerKhalid Zghear100% (2)

- Agilent 7890B Gas ChromatographДокумент24 страницыAgilent 7890B Gas ChromatographFernando González FloresОценок пока нет

- GC Liners InsertsДокумент4 страницыGC Liners InsertsmagicianchemistОценок пока нет

- Fertiliser Quality Control LaboratoryДокумент1 страницаFertiliser Quality Control LaboratoryAnil Nargotra100% (1)

- G10&G10S Product Family Service ManualДокумент135 страницG10&G10S Product Family Service ManualPranish Pradhan100% (1)

- User Manual 06/2013 Edition 2: © HACH Company, 2012, 2013. All Rights Reserved. Printed in GermanyДокумент156 страницUser Manual 06/2013 Edition 2: © HACH Company, 2012, 2013. All Rights Reserved. Printed in GermanyFlorin Neacsu100% (1)

- Certificate of Analysis: OFN EI Checkout Standard 1 PG/ LДокумент1 страницаCertificate of Analysis: OFN EI Checkout Standard 1 PG/ LYony Jhontan Guerreros IñigoОценок пока нет

- UV-1800 Operation ManuyalДокумент453 страницыUV-1800 Operation Manuyalmahadev1907Оценок пока нет

- Separadoe MagneticoДокумент4 страницыSeparadoe MagneticowilsonОценок пока нет

- And Techniques: Ethos Series Ethos SeriesДокумент55 страницAnd Techniques: Ethos Series Ethos SeriesevalenciaОценок пока нет

- ALC PK110 Service SectionДокумент30 страницALC PK110 Service SectionHary John Tsivery Rakotonjak'sParowОценок пока нет

- 7683 ServiceДокумент33 страницы7683 ServiceMarine JolieОценок пока нет

- Operation Manual Spectro UV-2602Документ24 страницыOperation Manual Spectro UV-2602Cesar Alfonso Saldivar Montoya100% (1)

- Prominence Pumps PDFДокумент2 страницыProminence Pumps PDFsandОценок пока нет

- 91494711Документ97 страниц91494711vzimak2355Оценок пока нет

- Sedex75 User Manual Revision 7b CompleteДокумент84 страницыSedex75 User Manual Revision 7b CompleteKenny Sharp100% (3)

- MA180-005 SubPUR-duoPUR User ManualДокумент34 страницыMA180-005 SubPUR-duoPUR User ManualSukrisdianto DiantoОценок пока нет

- Agilent 1290 Infinity II LC: Specification CompendiumДокумент38 страницAgilent 1290 Infinity II LC: Specification CompendiumAmarpreet Singh MalhanОценок пока нет

- Shimadzu Spectrophotometer UV1700 & UV1650PCДокумент24 страницыShimadzu Spectrophotometer UV1700 & UV1650PCAldi Igniel100% (1)

- Rheodyne 2-Way SwitchДокумент34 страницыRheodyne 2-Way SwitchOliver Müller100% (1)

- SOLAAR Software Manual 9499 400 30011Документ102 страницыSOLAAR Software Manual 9499 400 30011Ricardo VegaОценок пока нет

- Prominence SIL-20aДокумент4 страницыProminence SIL-20amr_stali2987Оценок пока нет

- 5890 Common Pinouts-SДокумент21 страница5890 Common Pinouts-SBaroto Setyo SuryoОценок пока нет

- Manual 3U Compact PSC0804036x-Fxx V1.0Документ21 страницаManual 3U Compact PSC0804036x-Fxx V1.0ishtiaq3any1Оценок пока нет

- Catrax Fit - Basic ManualДокумент15 страницCatrax Fit - Basic ManualantonypatoОценок пока нет

- Am144fxvajh Aa Submittal 460vhp 042013aДокумент2 страницыAm144fxvajh Aa Submittal 460vhp 042013acyrus188Оценок пока нет

- JVC Chassis Hd52fa97Документ284 страницыJVC Chassis Hd52fa97Billy McLeanОценок пока нет

- K3VL Datasheet 21 03 11Документ56 страницK3VL Datasheet 21 03 11Muhammad AzkaОценок пока нет

- 18-28 Exploded DrawingДокумент2 страницы18-28 Exploded Drawingchanks498Оценок пока нет

- TM5-4930-207-12 Lubricating and Servicing Unit, Power Operated, Trailer Mounted, 23 CFM Compressor, Reciprocating, Gasoline Driven (Henry Spen Model 901765-1) PDFДокумент127 страницTM5-4930-207-12 Lubricating and Servicing Unit, Power Operated, Trailer Mounted, 23 CFM Compressor, Reciprocating, Gasoline Driven (Henry Spen Model 901765-1) PDFdieudecafeОценок пока нет

- Maintain Training FacilitiesДокумент11 страницMaintain Training FacilitiesRichard Jumalon100% (3)

- Mark V Advanced Settings ManualДокумент8 страницMark V Advanced Settings ManualSermed IngenierosОценок пока нет

- Bronze Safety Relief Valves-Models SV5601 SV5708-Technical InformationДокумент5 страницBronze Safety Relief Valves-Models SV5601 SV5708-Technical InformationMarco ChablaОценок пока нет

- Staflux 187: Pressure RegulatorДокумент23 страницыStaflux 187: Pressure RegulatorRadhakrishnan PaulОценок пока нет

- Docs Oilgas Downloads DB Ops PDFДокумент6 страницDocs Oilgas Downloads DB Ops PDFNitul DoleyОценок пока нет

- Bomba Paletas Eaton-VickersДокумент38 страницBomba Paletas Eaton-VickersChristian Ruben Corihuaman SotoОценок пока нет

- Ltb-E1 BLKДокумент190 страницLtb-E1 BLKMichael Læsø50% (2)

- Laserstar Spec SheetДокумент8 страницLaserstar Spec SheetEduardo EnriquezОценок пока нет

- Process Pigging SystemДокумент22 страницыProcess Pigging SystemAKKI KUMARОценок пока нет

- Volume BoosterДокумент8 страницVolume BoosterArun KumarОценок пока нет

- 7000 Series Field Operations Manual PDFДокумент45 страниц7000 Series Field Operations Manual PDFmanzanaОценок пока нет

- Torch - Instructions For UseДокумент1 страницаTorch - Instructions For UseMihaelaBeatriceVladОценок пока нет

- Divertaflo Specification SheetДокумент12 страницDivertaflo Specification SheetWattsОценок пока нет

- Air ProductsДокумент33 страницыAir Products22hubОценок пока нет

- General Operating Procedures: Exp/Gas AbsorptionДокумент4 страницыGeneral Operating Procedures: Exp/Gas AbsorptionSyazwina AziziОценок пока нет

- Astm D 4810 - 2006Документ3 страницыAstm D 4810 - 2006Nag RajОценок пока нет

- Manual DraguerДокумент386 страницManual DraguerAbner Pinaicobo ZalazarОценок пока нет

- Air-Oxygen Blender: Service ManualДокумент34 страницыAir-Oxygen Blender: Service ManualJames de LunaОценок пока нет

- MNL 0172 PDFДокумент42 страницыMNL 0172 PDFUlises Fernandez100% (1)

- HP237Документ20 страницHP237Asif HameedОценок пока нет

- EatonfuelДокумент20 страницEatonfuelmecambОценок пока нет

- Walbro Carburetors - So How Does This Thing Work - HeliFreakДокумент41 страницаWalbro Carburetors - So How Does This Thing Work - HeliFreakcezarus2001Оценок пока нет

- ALT-Series Burner Manual-Ver2.1Документ44 страницыALT-Series Burner Manual-Ver2.1Mahmoud Abd-Elhamid Abu Eyad100% (1)

- Air Sep Oxy GeneratorДокумент101 страницаAir Sep Oxy Generatorlalab1314Оценок пока нет

- Diaphragm Seal Filling GuideДокумент14 страницDiaphragm Seal Filling GuideKrishnaraj DhavalaОценок пока нет

- 2023 Annexure-1 Calibration CylinderДокумент2 страницы2023 Annexure-1 Calibration CylinderShiv Shankar YadavОценок пока нет

- Overhauled Airbrone Pump DAP UserManual022608Документ25 страницOverhauled Airbrone Pump DAP UserManual022608Kamal Jit DhimanОценок пока нет