Академический Документы

Профессиональный Документы

Культура Документы

GMAW Transfer Modes

Загружено:

tuna610 оценок0% нашли этот документ полезным (0 голосов)

98 просмотров3 страницыDocument describes the different gases and current settings required to reach specific transfer modes.

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документDocument describes the different gases and current settings required to reach specific transfer modes.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

98 просмотров3 страницыGMAW Transfer Modes

Загружено:

tuna61Document describes the different gases and current settings required to reach specific transfer modes.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

2-9.

Common GMAW Shielding Gases

This is a general chart for common gases and where they are used. Many different combinations (mixtures) of shielding gases have been developed over the years.

Gas

Spray Arc

Steel

Short

Circuiting

Steel

Spray Arc

Short

Stainless Steel Circuiting

Stainless

Steel

Argon

Horizontal5

Argon + 1% O2

Flat &

Fillet

Argon + 2% O2

Flat & Horizontal5

Fillet

Argon + 5% O2

Flat & Horizontal5

Fillet

Argon + 8%

CO2

Flat & Horizontal5

Fillet

All Positions

Argon + 25%

CO2

Flat & Horizontal1

Fillet

All Positions

Argon + 50%

CO2

CO2

Flat &

Fillet

Spray Arc

Aluminum

Short

Circuiting

Aluminum

All Positions5

All Positions

Horizontal5

Flat & Horizontal5

Fillet

All Positions

Flat & Horizontal1

Fillet

All Positions

Helium

All Positions2

Argon +

Helium

All Positions2

Tri-Mix4

1

2

3

Globular Transfer

Heavy Thicknesses

Single Pass Welding Only

All Positions

4

5

90% HE + 7-1/2% AR + 2-1/2% CO2

Also for GMAW-P, All Positions

SECTION 3 MODES OF GMAW TRANSFER

. GMAW transfer mode is determined by variables such as shielding gas type, arc voltage, arc current, diameter of electrode and wire feed speed.

3-1. Short Circuit Transfer

1

Short Circuit Transfer

Short circuit transfer refers to the

welding wire actually short circuiting (touching) the base metal between 90 - 200 times per second.

With short circuit transfer, wire feed

speeds, voltages, and deposition

rates are usually lower than with other types of metal transfer such as

spray transfer. This makes short circuit transfer very versatile allowing

the welder to weld on thin or thick

metals in any position.

Limitations of short circuit transfer:

S A relatively low deposition rate

S Lack of fusion on thicker metals

S More spatter

. Short circuit transfer usually has

a crackling (bacon frying) sound

when a good condition exists.

Short Circuit Cycle

A - Electrode is short circuited to

base metal. No arc, and current

is flowing through electrode

wire and base metal.

B - Resistance increases in electrode wire causing it to heat,

melt and neck down.

C - Electrode wire separates from

weld puddle, creating an arc.

Small portion of electrode wire

is deposited which forms a

weld puddle.

D - Arc length and load voltage are

at maximum. Heat of arc is flattening the puddle and increasing the diameter tip of electrode.

E - Wire feed speed overcomes

heat of arc and wire

approaches base metal again.

F - Arc is off and the short circuit

cycle starts again.

Page 13

3-2. Globular Transfer

1

Globular Transfer

Globular transfer refers to the state of

transfer between short-circuiting and

spray arc transfer. Large globs of

wire are expelled off the end of the

electrode wire and enter the weld

puddle.

Globular transfer can result when

welding parameters such as voltage,

amperage and wire feed speed are

somewhat higher than the settings

for short circuit transfer.

Limitations of globular transfer:

S Presence of spatter

S Less desirable weld appearance

than spray arc transfer

S Welding is limited to flat positions

and horizontally fillet welds

S Welding is limited to metal 1/8 inch

(3 mm)or thicker

3-3. Spray Arc Transfer

1

Spray Arc Transfer

Spray arc transfer sprays a stream

of tiny molten droplets across the

arc, from the electrode wire to the

base metal.

Spray arc transfer uses relatively

high voltage, wire feed speed and

amperage values, compared to short

circuit transfer.

. To achieve a true spray transfer,

an argon-rich shielding gas must

be used.

When proper parameters are used,

the spray arc transfer produces a

characteristic humming or buzzing

sound.

Advantages of spray arc transfer:

S High deposition

S Good fusion and penetration

S Good bead appearance

S Capability of using larger diameter

wires

S Presence of very little spatter

Limitations of spray arc transfer:

S Used only on material 1/8 inch

(3 mm) and thicker (hand held)

S Limited to flat and horizontal fillet

weld position (except for some spray

transfer on aluminum)

S Good fit-up is always required as

there is no open root capability

Вам также может понравиться

- How Does A Blueprint Work?Документ5 страницHow Does A Blueprint Work?Eumieh Jane AlfonsoОценок пока нет

- 3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingДокумент96 страниц3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingAditya KumarОценок пока нет

- Mig WireДокумент10 страницMig WireSathishkumar SrinivasanОценок пока нет

- Consumables For MIG MAG & FCAWДокумент46 страницConsumables For MIG MAG & FCAWaravindanОценок пока нет

- Welding Technology & Inspection MethodДокумент80 страницWelding Technology & Inspection MethodVivek Satapathy100% (1)

- 13 Mig & Mag WeldingДокумент24 страницы13 Mig & Mag WeldingMohamed BencharifОценок пока нет

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesОт EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesОценок пока нет

- Gmaw Thumb RuleДокумент68 страницGmaw Thumb Rule0502raviОценок пока нет

- Modern PetrochemicalsДокумент179 страницModern PetrochemicalsHani Kirmani100% (9)

- ALC 10029C AlcoTec Technical GuideДокумент20 страницALC 10029C AlcoTec Technical Guidetuna61Оценок пока нет

- 500 Technical Questions Safety&Fire-1Документ26 страниц500 Technical Questions Safety&Fire-1Saad GhouriОценок пока нет

- 12 Tig WeldingДокумент8 страниц12 Tig WeldingSampath KumarОценок пока нет

- Modes of Metal TransferДокумент7 страницModes of Metal TransfershruthiОценок пока нет

- Tig RwtiДокумент39 страницTig RwtiSaptarshi PalОценок пока нет

- Welding ProcessДокумент42 страницыWelding ProcessPankaj KumbhareОценок пока нет

- Infobasic ProgrammingДокумент10 страницInfobasic Programmingjaved73bdОценок пока нет

- Welding PresentationДокумент48 страницWelding Presentationedu_canete100% (2)

- SA-6 Press KitДокумент53 страницыSA-6 Press KitBob Andrepont100% (1)

- Introduction To GMAWДокумент63 страницыIntroduction To GMAWRumman Ul AhsanОценок пока нет

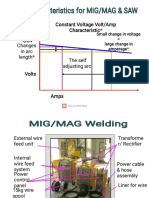

- Constant Voltage Volt/Amp Characteristic: Changes in Arc Length The Self Adjusting ArcДокумент35 страницConstant Voltage Volt/Amp Characteristic: Changes in Arc Length The Self Adjusting Arcpatel ketanОценок пока нет

- Welding BasicsДокумент37 страницWelding BasicsSnehal DeshmukhОценок пока нет

- Chapter9 GMAW FCAW WeldingДокумент17 страницChapter9 GMAW FCAW Weldingrusf123Оценок пока нет

- Joining Copper Nickel AlloysДокумент9 страницJoining Copper Nickel AlloyshboodhaiОценок пока нет

- Lean Thinking Redefines O&M PracticesДокумент10 страницLean Thinking Redefines O&M PracticesAsel Juárez ViteОценок пока нет

- Gas Tungsten Arc WeldingДокумент9 страницGas Tungsten Arc Weldingweldingking1100% (1)

- Navsea S9074 - 278 Part1Документ80 страницNavsea S9074 - 278 Part1tuna61Оценок пока нет

- b-737 - Rev 59 PDFДокумент402 страницыb-737 - Rev 59 PDFCatevario NegroОценок пока нет

- Welding of Copper and Its AlloysДокумент30 страницWelding of Copper and Its Alloysaj87_goswami100% (2)

- GMAWДокумент55 страницGMAWsalunkheclОценок пока нет

- Welding SymbolsДокумент21 страницаWelding Symbolstuna61Оценок пока нет

- Mig WeldДокумент47 страницMig Weldravindra_jivaniОценок пока нет

- Gmaw & Fcaw-MsmeДокумент73 страницыGmaw & Fcaw-MsmemilindОценок пока нет

- Modes of Gmaw TransferДокумент5 страницModes of Gmaw TransfershruthiОценок пока нет

- 3-Gas Metal Arc Welding (GMAW)Документ13 страниц3-Gas Metal Arc Welding (GMAW)abastosuaptОценок пока нет

- Gas Metal Arc WeldingДокумент16 страницGas Metal Arc WeldingAizad IzzuddinОценок пока нет

- MIG Welding: Process CharacteristicsДокумент4 страницыMIG Welding: Process Characteristicstek_surinderОценок пока нет

- IntroДокумент3 страницыIntroMUHAMMAD AFIQ IQWAN KAMARUL BADRINОценок пока нет

- GMAWДокумент7 страницGMAWmostafaОценок пока нет

- Proceso de Soldadura Gmaw. Presentado Por: Fatima Del Rosario Choquehunaca Cutipa Fatima Docente: Ing Larico Grupo: Lunes 2-4Pm 1. ObjetivosДокумент8 страницProceso de Soldadura Gmaw. Presentado Por: Fatima Del Rosario Choquehunaca Cutipa Fatima Docente: Ing Larico Grupo: Lunes 2-4Pm 1. ObjetivosBel BarretoОценок пока нет

- GMAW (CO2) Welding CourseДокумент129 страницGMAW (CO2) Welding Courseanon_554333607Оценок пока нет

- Basic Mig Welding ProcessДокумент4 страницыBasic Mig Welding Processamiter84Оценок пока нет

- Shielding Gases ACM Vs CO2Документ34 страницыShielding Gases ACM Vs CO2ukavathekar100% (2)

- Welding Rods Welding Rods: Manual Metal Arc Welding (MMA)Документ6 страницWelding Rods Welding Rods: Manual Metal Arc Welding (MMA)CT0011Оценок пока нет

- Types of Arc WeldingДокумент20 страницTypes of Arc WeldingEhigiator JosephОценок пока нет

- GtawДокумент11 страницGtawsaravanans1891Оценок пока нет

- CSWIP Day 3Документ35 страницCSWIP Day 3Mehman NasibovОценок пока нет

- Welding ParametersДокумент34 страницыWelding ParametersmilindОценок пока нет

- Arc 2Документ59 страницArc 2May FadlОценок пока нет

- MIG Welding Tech.Документ3 страницыMIG Welding Tech.HoangОценок пока нет

- 4 GmawДокумент41 страница4 GmawPutra Daha PratamaОценок пока нет

- CSWIP Day3Документ35 страницCSWIP Day3rac mediaОценок пока нет

- Welding TerminologiesДокумент11 страницWelding TerminologiesPankajabhangОценок пока нет

- Cswip Section 13 Mig Mag WeldingДокумент23 страницыCswip Section 13 Mig Mag WeldingNsidibe Michael EtimОценок пока нет

- Gas Metal Arc WeldingДокумент16 страницGas Metal Arc WeldingIhsan1991 YusoffОценок пока нет

- Welding Processes - Arc: Solid Wire MIG WeldingДокумент4 страницыWelding Processes - Arc: Solid Wire MIG WeldingMehmet SoysalОценок пока нет

- Mig Mag Saw CswipДокумент35 страницMig Mag Saw CswipHamza DhariwalОценок пока нет

- Gas Tungsten Arc WeldingДокумент14 страницGas Tungsten Arc WeldingKhaled FatnassiОценок пока нет

- Metal Transfer Modes: Short Circuit Surface TensionДокумент3 страницыMetal Transfer Modes: Short Circuit Surface TensionRaman GuptaОценок пока нет

- Metal Inert Gas WeldingДокумент4 страницыMetal Inert Gas WeldingINfo WTCSОценок пока нет

- The Principle of Tungsten Inert Gas TIG Welding ProcessДокумент7 страницThe Principle of Tungsten Inert Gas TIG Welding ProcessWill TohallinoОценок пока нет

- SMAWДокумент8 страницSMAWmostafaОценок пока нет

- Gas Metal Arc WeldingДокумент52 страницыGas Metal Arc WeldingBalakumarОценок пока нет

- Lecture 4Документ65 страницLecture 4Ishtiaq AhmedОценок пока нет

- Weldintg HudanДокумент11 страницWeldintg HudanbotobotoakbarОценок пока нет

- Tips and Techniques For GtawДокумент5 страницTips and Techniques For GtawRavi ChandranОценок пока нет

- Physical Electronics: Handbook of Vacuum PhysicsОт EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckОценок пока нет

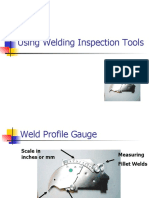

- Using Welding Inspection ToolsДокумент9 страницUsing Welding Inspection Toolstuna61Оценок пока нет

- Pushstick Template PDFДокумент2 страницыPushstick Template PDFtuna61Оценок пока нет

- Hastelloy C-2000 Welding Data: General InformationДокумент1 страницаHastelloy C-2000 Welding Data: General Informationtuna61Оценок пока нет

- Nuance Power PDF Trial: Corner CupboardДокумент26 страницNuance Power PDF Trial: Corner Cupboardtuna61Оценок пока нет

- User Inputs Cost Outputs: Fillet Weld Cost Analysis ToolДокумент2 страницыUser Inputs Cost Outputs: Fillet Weld Cost Analysis Tooltuna61Оценок пока нет

- Variation of Groove Design For WeldingДокумент10 страницVariation of Groove Design For Weldingtuna61Оценок пока нет

- Top Tips For Passing STДокумент1 страницаTop Tips For Passing STtuna61Оценок пока нет

- Test PlateДокумент1 страницаTest Platetuna61Оценок пока нет

- Welding Symbols: Understanding Welding Symbols Terms and Definitions by Mohammed Haroon JaveedДокумент21 страницаWelding Symbols: Understanding Welding Symbols Terms and Definitions by Mohammed Haroon Javeedtuna61Оценок пока нет

- Gama Dimat Catalog Be17Документ16 страницGama Dimat Catalog Be17ELMIR ADILОценок пока нет

- B200S-LF Low Freq Sounder Base Install 56-4151-003R-06-10Документ4 страницыB200S-LF Low Freq Sounder Base Install 56-4151-003R-06-10George P ReynoldsОценок пока нет

- Hitide 2i (BP)Документ4 страницыHitide 2i (BP)Biju_PottayilОценок пока нет

- Tutorial Sheet 7Документ2 страницыTutorial Sheet 7Muhammad NidzwanОценок пока нет

- Welder and Welding Operator Qualification Test Record (Asme Ix Code)Документ1 страницаWelder and Welding Operator Qualification Test Record (Asme Ix Code)Neil TaneoОценок пока нет

- Assign Chap 8Документ3 страницыAssign Chap 8nishedhОценок пока нет

- Drive Test AnalysisДокумент47 страницDrive Test Analysis3a9aОценок пока нет

- Bricks ComparisonДокумент13 страницBricks ComparisonMd. Numan HossainОценок пока нет

- Shell Spirax S6 Txme: Performance, Features & BenefitsДокумент2 страницыShell Spirax S6 Txme: Performance, Features & BenefitsAbdelhadi HoussinОценок пока нет

- K.analysis of The Articulated Robotic Arm (TITLE DEFENCE)Документ22 страницыK.analysis of The Articulated Robotic Arm (TITLE DEFENCE)sky4sterОценок пока нет

- Astm A182 f22 Class 3Документ3 страницыAstm A182 f22 Class 3VõTạОценок пока нет

- Delta Manual 3064Документ2 страницыDelta Manual 3064Nebojša MićićОценок пока нет

- Stanley 46 InstructionsДокумент2 страницыStanley 46 Instructionsj_abendstern4688Оценок пока нет

- Yale PD2, C85, D85Документ28 страницYale PD2, C85, D85LGWILDCAT73Оценок пока нет

- Iv2906 Iveco Ad380t42h 6x4Документ2 страницыIv2906 Iveco Ad380t42h 6x4أبو خالد الأثرىОценок пока нет

- Datasheet Joint Isolant 4'' #300 PDFДокумент1 страницаDatasheet Joint Isolant 4'' #300 PDFseifОценок пока нет

- Service Manual: Model Code - Kib19Bp3-CmgДокумент11 страницService Manual: Model Code - Kib19Bp3-Cmgpravin jadavОценок пока нет

- Instruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 AДокумент32 страницыInstruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 AYunisОценок пока нет

- How To Use Volatility - v2Документ65 страницHow To Use Volatility - v2John SedoskiОценок пока нет

- L3 - Hardening Soil Models in PlaxisДокумент33 страницыL3 - Hardening Soil Models in PlaxisOng Tai BoonОценок пока нет

- DMPCДокумент49 страницDMPCiprassandyОценок пока нет

- Samsung E1272 EN PDFДокумент2 страницыSamsung E1272 EN PDFmuhammad aslamОценок пока нет

- February 2016Документ104 страницыFebruary 2016Cleaner MagazineОценок пока нет