Академический Документы

Профессиональный Документы

Культура Документы

Siemens Flender 05 Bipex

Загружено:

DhanielАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Siemens Flender 05 Bipex

Загружено:

DhanielАвторское право:

Доступные форматы

9

Siemens AG 2011

Flexible Couplings

BIPEX Series

9/2

Overview

9/2

Benefits

9/2

Application

9/3

Design

9/4

Technical data

9/5

9/5

Type BWN

Selection and ordering data

9/6

9/6

Type BWT

Selection and ordering data

9/7

9/7

Type BNT

Selection and ordering data

9/8

9/8

Spare and wear parts

Selection and ordering data

Siemens MD 10.1 2011

Siemens AG 2011

FLENDER Standard Couplings

Flexible Couplings BIPEX Series

General information

Overview

BIPEX couplings are torsionally flexible with low torsional backlash. They are outstanding for their particularly compact construction. BIPEX couplings link machine shafts.

BIPEX couplings are specially suited for electric motor drives

which are well aligned and have uniform torque loads.

Benefits

BIPEX couplings are suitable for mounting horizontally, vertically

or at any desired angle. The coupling parts can be arranged as

required on the shaft extensions to be connected.

The cam ring is mounted with low backlash and achieves progressive torsional stiffness, i.e. torsional stiffness increases in

proportion to capacity utilization.

The BIPEX coupling is fail-safe, i.e. if the cam ring is worn, the

cast cams of the coupling hub provide for emergency operation.

Application

The BIPEX coupling is available as a catalog standard in 13

sizes with rated torque of between 13.5 Nm and 3700 Nm.

The coupling is suitable for ambient temperatures of between

-30 C and +80 C.

BIPEX couplings are particularly suited for electric motor drives

which have a uniform torque load and are well aligned. BIPEX

couplings are frequently fitted and used in motor bell housings.

9/2

Siemens MD 10.1 2011

Siemens AG 2011

FLENDER Standard Couplings

Flexible Couplings BIPEX Series

General information

Design

G_MD10_XX_00008

BIPEX couplings of types BWN, BWT and BNT each comprise

two hub parts connected by a cam ring of elastomer material.

The couplings are inserted during fitting. The hubs are connected to the respective shafts via Taper clamping bushes or

finished bores with parallel keyway connection.

BIPEX couplings are positive-locking and torsionally flexible

thanks to the polyurethane cam ring. Shaft misalignment will

result in deformation of the cam ring.

Coupling materials:

Hubs: EN-GJL-250

Cam ring: PU 92 ShoreA -30 C to +80 C

Types of BIPEX coupling

Type

BWN

BWT

Type BWN

G_MD10_XX_00009

BNT

The coupling comprises the following:

Cam ring

2 hub parts with identical cams. The hub parts are designed

with a bore and keyway to DIN 6885 or with a taper bore for

mounting a Taper clamping bush.

Fitting the clamping bush connects the hub firmly to the machine

shaft.

In the case of part 4 the Taper clamping bush is inserted from

the machine housing side. If there is insufficient space, the Taper

clamping bush cannot be fitted from this side. Besides space for

fitting the Taper clamping bush, space for the fitting tool (offset

screwdriver) must be taken into consideration. In the case of

part 3 the Taper clamping bush is inserted from the shaft end

face side. The hub must be fitted before the machines to be connected are pushed together.

G_MD10_XX_00010

Type BWT

Description

Coupling as a shaft-to-shaft connection with drilled and

grooved hubs

Coupling as a shaft-shaft connection with Taper clamping

bushes

Coupling as a shaft-shaft connection with drilled and

grooved hubs and a Taper clamping bush

Type BNT

Siemens MD 10.1 2011

9/3

Siemens AG 2011

FLENDER Standard Couplings

Flexible Couplings BIPEX Series

General information

Technical data

Power ratings

Size

Rated

torque

Maximum

torque

Overload

torque

Fatigue

torque

Maximum

speed

TKW

Torsional

stiffness at

50 % capacity

utilization

Assembly

Permissible shaft misalignment at speed n = 1500 rpm 1)

nmax

CTdyn 50 %

Ka

Kr

Kw

rpm

Nm/rad

mm

mm

mm

Degree

Gap

dimension

TKN

TKmax

TKOL

Nm

Nm

Nm

43

13.5

40.5

54

2.7

5000

1160

0.5

0.25

0.08

0.1

53

24

72

96

4.8

5000

2100

0.5

0.25

0.09

0.1

62

42

126

168

8.4

5000

3500

0.5

0.25

0.11

0.1

72

75

225

300

15

5000

6100

0.5

0.25

0.12

0.1

84

130

390

520

26

5000

9600

0.5

0.25

0.14

0.1

97

220

660

880

44

5000

15800

1.0

0.5

0.16

0.1

112

360

1080

1440

72

5000

23100

1.0

0.5

0.19

0.1

127

550

1650

2200

110

5000

37000

1.0

0.5

0.21

0.1

142

800

2400

3200

160

4900

57000

1.0

0.5

0.24

0.1

162

1250

3750

5000

250

4200

85000

1.0

0.5

0.27

0.1

182

1750

5250

7000

350

3800

127000

1.0

0.5

0.30

0.1

202

2650

7950

10600

530

3400

171000

1.0

0.5

0.34

0.1

227

3700

11100

14800

740

3000

285000

2.0

1.0

0.38

0.1

Torsional stiffness and damping

Permitted shaft misalignment

The values stated in the above table apply to a capacity utilization of 50 %, an excitation amplitude of 10 % TKN with the frequency 10 Hz and an ambient temperature of 20 C. Dynamic

torsional stiffness is dependent on load and increases in proportion to capacity utilization. The following table shows the correction factors for different nominal loads.

The permitted shaft misalignment depends on the operating

speed. As the speed increases, lower shaft misalignment values

are permitted. The following table shows the correction factors

for different speeds.

The maximum speed for the respective coupling size and type

must be observed!

CTdyn = CTdyn 50 % FKC

Kperm = K1500 FKV

Capacity utilization TN / TKN

20 % 40 % 50 % 60 %

Correction factor FKC 0.7

0.9

1.0

1.1

70 %

1.25

80 %

1.4

100 %

1.7

The damping coefficient is = 1.4

Furthermore, torsional stiffness and damping depend on the

ambient temperature and the frequency and amplitude of the

torsional vibration excitation. More precise torsional stiffness

and damping parameters on request.

1)

The maximum speed of the respective type must be noted. For further

information on permissible shaft misalignment, please see the operating

instructions.

9/4

Siemens MD 10.1 2011

Speed in rpm

500

1000

Correction factor FKV 1.20

1.10

1500

1.0

3000

0.70

The axial misalignment may occur dynamically at frequencies

up to 10 Hz. For fitting, a maximum gap dimension of

S max. = S + S and a minimum gap dimension of

S min. = S S are permitted.

Shaft misalignments Ka, Kr and Kw may occur simultaneously.

Siemens AG 2011

FLENDER Standard Couplings

Flexible Couplings BIPEX Series

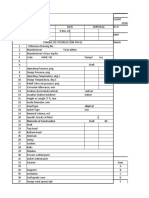

Type BWN

Selection and ordering data

Part 1/2

J2

D3

D2

ND2

J1

DA

ND1

D1

Part 1/2

G_MD10_EN_00011

NL1

Size

43

53

62

72

84

97

112

127

142

162

182

202

227

D1:

S

LG

Dimensions in mm

Bore with keyway to

DIN 6885

D1/D2

DA

ND1/

NL1/

D3

S

ND2

NL2

max.

25

43

43

22

21

12

30

53

50

25

25

14

35

62

58

30

29

16

32

72

54

35

36

18

42

68

130

38

84

64

40

40

21

48

76

220

42

97

72

50

48

24

50

90

360

48

112

82

60

54

27

60

100

550

55

127

94

65

61

27

65

110

800

60

142

100

75

70

31

75

126

1250

65

162

110

80

81

36

80

134

1750

75

182

126

90

90

42

90

152

2650

80

202

134

100

100

48

100

168

3700

90

227

150

110

111

54

110

180

Without finished bore Without order codes for diameter and tolerance

Rated

torque

TKN

Nm

13.5

24

42

75

NL2

Mass moment of

inertia

LG

56

64

76

88

101

124

147

157

181

196

222

248

274

J1/J2

gm2

0.04

0.12

0.26

0.55

0.65

0.8

1.1

1.6

2.2

3.2

4.8

6.0

8.0

10.0

16.0

18.0

26.0

35.0

46.0

55.0

80.0

85.0

110.0

Without finished bore from size 72 for 2nd diameter range D1 Without order codes

With finished bore With order codes for diameter and tolerance (product code without -Z)

D2:

Without finished bore Without order codes for diameter and tolerance

Without finished bore from size 72 for 2nd diameter range D2 Without order codes

With finished bore With order codes for diameter and tolerance (product code without -Z)

Mass moment of inertia J in gm2, 1 gm2 = 0.001 kgm2,

Ordering example:

with reference to one coupling half.

Weight and mass moments of inertia apply to maximum bore

diameters.

Product code

Weight

Order codes for bore

diameters and tolerances

are specified in catalog

m

section 3

kg

2LC0120-0AA -0AA0 0.36

2LC0120-1AA -0AA0 0.62

2LC0120-2AA -0AA0 0.96

2LC0120-3AA -0AA0 1.4

1.6

2LC0120-4AA -0AA0 2.1

2.3

2LC0120-5AA -0AA0 3.3

3.6

2LC0120-6AA -0AA0 5.0

5.8

2LC0120-7AA -0AA0 7.3

7.8

2LC0120-8AA -0AA0 9.8

11.5

2LC0121-0AA -0AA0 13.5

15.5

2LC0121-1AA -0AA0 19.5

22.0

2LC0121-2AA -0AA0 25.0

30.0

2LC0121-3AA -0AA0 40.0

45.0

1

2

9

1

2

9

BIPEX BWN coupling, size 43,

Part 1/2: Bore D1 20H7 mm, with keyway to DIN 6885-1 and

set screw,

Part 1/2: Bore D2 22H7 mm, with keyway to DIN 6885-1 and

set screw.

Product code:

2LC0120-0AA99-0AA0

L0M+M0N

Siemens MD 10.1 2011

9/5

Siemens AG 2011

FLENDER Standard Couplings

Flexible Couplings BIPEX Series

Type BWT

Selection and ordering data

Part 3

Part 4

G_MD10_EN_00012

NL1

Part 3

Part 4

Part 4

D2

ND2

DA

D3

ND1

D1

Part 3

Variant A

Variant B

NL2

S

LG

Variant AB

Coupling parts 3 and 4 can be combined as required.

In the case of part 3, the Taper clamping bush is fitted from the

Size

Taper

clamping

bush

shaft end face side, in the case of part 4 from the shaft shoulder

side.

Dimensions in mm

Variant:

Rated

torque

TKN

Nm

42

75

130

360

800

1750

2650

3700

A

D1:

B

AB

Without Taper clamping bush Without order codes for diameter and tolerance

62

72

84

112

142

182

202

227

D2:

Size

1008

1108

1210

1610

2012

2517

3020

3535

Bore with keyway

to DIN 6885-1

D1/D2 D1/D2

min.

max.

10

25 1)

10

28 1)

11

32

14

42 1)

14

50

16

60

25

75

35

90

Mass

moment

of inertia

DA

ND1 NL1 D3

ND2 NL2

LG

62

72

84

112

142

182

202

227

58

68

76

100

126

126

168

180

16

18

21

27

31

42

48

54

62

64

73

79

97

132

152

134

23

23

26

26

33

45

52

90

29

36

40

54

70

90

100

111

J

gm2

0.22

0.41

0.85

2.70

9.25

27.0

52.5

82.5

Weight and mass moments of inertia apply to maximum bore

diameters.

-0AA0

-0AA0

-0AA0

-0AA0

-0AA0

-0AA0

-0AA0

-0AA0

B

C

D

BIPEX BWT coupling, size 62, variant AB

Part 3: with Taper clamping bush size 1008,

Bore D1 20 mm, with keyway to DIN 6885-1,

Part 4: with Taper clamping bush size 1008,

Bore D2 22 mm, with keyway to DIN 6885-1

and set screw.

Product code:

2LC0120-2AD99-0AA0

L0M+M0N

Maximum bore with shallow keyway, see catalog section 14.

9/6

2LC0120-2A

2LC0120-3A

2LC0120-4A

2LC0120-6A

2LC0120-8A

2LC0121-1A

2LC0121-2A

2LC0121-3A

With Taper clamping bush With order codes for diameter (product code without -Z)

Without Taper clamping bush Without order codes for diameter and tolerance

With Taper clamping bush With order codes for diameter (product code without -Z)

inertia J in gm2, 1 gm2 = 0.001 kgm2,

Ordering example:

Mass moment of

with reference to one coupling half.

1)

Product

code

Order codes for bore

diameters and tolerances

are specified in catalog

section 3

Siemens MD 10.1 2011

1

9

1

9

Weight

m

kg

0.75

1.2

1.5

3.2

6.2

11.3

15.6

30.0

Siemens AG 2011

FLENDER Standard Couplings

Flexible Couplings BIPEX Series

Type BNT

Selection and ordering data

Part 1/2

Part 1/2

Part 4

D2

ND2

D3

DA

ND1

D1

Part 3

G_MD10_EN_00013

NL1

NL2

LG

Variant A

Variant B

Dimension D3, see type BWN.

Size

Rated

torque

TKN

Nm

42

62

72

84

112

142

182

202

227

D1:

D2:

Dimensions in mm

Variant Bore with

Taper

keyway to

clamping

DIN 6885-1 bushes

max.

Size

Bore with

keyway to

DIN 6885-1

D1/D2

DA ND1 ND2 NL1

min. max.

10

25 1) 62 58

58

30

A

35

1008

B

75

A

32

1108

10

28 1) 72 54

68

B

42

68

130

A

38

1210

11

32

84 64

76

B

48

76

360

A

48

1610

14

42 1) 112 82

100

B

60

100

800

A

60

2012

14

50

142 100 126

B

75

126

1750

A

75

2517

16

60

182 126 126

B

90

152

2650

A

80

3020

25

75

202 134 168

B

100

168

3700

A

90

3535

35

90

227 150 180

B

110

180

Without finished bore Without order codes for diameter and tolerance

Mass

moment

of inertia

NL2

23

16

LG J

gm2

69 0.22

35

23

18

76

0.41

40

26

21

87

0.85

60

26

27

113 2.70

75

33

31

139 9.25

90

45

42

177 27.0

100

52

48

200 52.5

110

90

54

254 30.0

With finished bore With order codes for diameter and tolerance (product code without -Z)

Without Taper clamping bush Without order codes for diameter and tolerance

With Taper clamping bush With order codes for diameter (product code without -Z)

moment of inertia J in gm2, 1 gm2 = 0.001 kgm2,

Ordering example:

Mass

with reference to one coupling half.

Weight and mass moments of inertia apply to maximum bore

diameters.

Product code

Weight

Order codes for bore

diameters and tolerances

are specified in catalog

section 3

m

kg

2LC0120-2AE -0AA0 0.9

2LC0120-2AF -0AA0 0.9

2LC0120-3AE -0AA0 1.3

2LC0120-3AF -0AA0 1.4

2LC0120-4AE -0AA0 1.8

2LC0120-4AF -0AA0 1.9

2LC0120-6AE -0AA0 4.1

2LC0120-6AF -0AA0 4.5

2LC0120-8AE -0AA0 8.0

2LC0120-8AF -0AA0 8.9

2LC0121-1AE -0AA0 15.5

2LC0121-1AF -0AA0 16.7

2LC0121-2AE -0AA0 20

2LC0121-2AF -0AA0 23

2LC0121-3AE -0AA0 35

2LC0121-3AF -0AA0 37.5

2

9

1

9

BIPEX BNT coupling, size 62, variant B

Part 1/2: Bore D1 20H7 mm, with keyway to DIN 6885-1 and

set screw,

Part 4: Bore D2 22H7 mm, with keyway to DIN 6885-1 and

set screw.

Product code:

2LC0120-2AF99-0AA0

L0M+M0N

1)

Bores, some with shallow keyway, see catalog section 14.

Siemens MD 10.1 2011

9/7

Siemens AG 2011

FLENDER Standard Couplings

Flexible Couplings BIPEX Series

Spare and wear parts

Selection and ordering data

BIPEX cam ring

Size

Product code

43

53

62

72

84

97

112

127

142

162

182

202

227

2LC0120-0WA00-0AA0

2LC0120-1WA00-0AA0

2LC0120-2WA00-0AA0

2LC0120-3WA00-0AA0

2LC0120-4WA00-0AA0

2LC0120-5WA00-0AA0

2LC0120-6WA00-0AA0

2LC0120-7WA00-0AA0

2LC0120-8WA00-0AA0

2LC0121-0WA00-0AA0

2LC0121-1WA00-0AA0

2LC0121-2WA00-0AA0

2LC0121-3WA00-0AA0

Weight

kg

0.004

0.005

0.008

0.013

0.021

0.034

0.062

0.082

0.14

0.18

0.3

0.4

0.54

The elastomer cam rings are wear parts. The service life

depends on the operating conditions.

9/8

Siemens MD 10.1 2011

Вам также может понравиться

- Dump Valves: DVU SeriesДокумент2 страницыDump Valves: DVU SeriesalopezvillavicencioОценок пока нет

- ASME FiltroДокумент11 страницASME FiltroDenise AGОценок пока нет

- Scope: Plant Buildings For Operation and Storage IP 4-3-1Документ8 страницScope: Plant Buildings For Operation and Storage IP 4-3-1Sixto Gerardo Oña AnaguanoОценок пока нет

- Fdocuments - in - Shell Dep ListДокумент25 страницFdocuments - in - Shell Dep Listdeyanshu7Оценок пока нет

- COMBER Pressofiltro® Filter-Dryer Pharma DesignДокумент2 страницыCOMBER Pressofiltro® Filter-Dryer Pharma Designeino6622Оценок пока нет

- Agitator Design 5 PDF FreeДокумент36 страницAgitator Design 5 PDF FreeMeisam MomeniОценок пока нет

- Catalogue Air Handling Unit DDW Without Frame PDFДокумент27 страницCatalogue Air Handling Unit DDW Without Frame PDFFirman AnriОценок пока нет

- Agitator Details PDFДокумент4 страницыAgitator Details PDFPhượng NguyễnОценок пока нет

- Modco Closures: Operation, Maintenance & Welding InstructionsДокумент7 страницModco Closures: Operation, Maintenance & Welding InstructionsWijayanto BekasiОценок пока нет

- 2007 Dias, Efficient Cooling of Fermentation Vats in Ethanol Production - Part 1Документ8 страниц2007 Dias, Efficient Cooling of Fermentation Vats in Ethanol Production - Part 1roger_shОценок пока нет

- Manual Entry of Properties For 2-Phase VL Mixtures With Aspen EDRДокумент7 страницManual Entry of Properties For 2-Phase VL Mixtures With Aspen EDRMuhammad NaeemОценок пока нет

- LWN Operating Manual of FanДокумент20 страницLWN Operating Manual of FanYogesh Badhe100% (1)

- BR Epv Pres 02Документ20 страницBR Epv Pres 02Mano NegraОценок пока нет

- Annex H (Summary API 650) : 1. MaterialДокумент6 страницAnnex H (Summary API 650) : 1. MaterialnjkasdncjkdОценок пока нет

- Gas Scrubber Level ControlДокумент2 страницыGas Scrubber Level ControlMehdi Hajd KacemОценок пока нет

- Hextran Getting Started GuideДокумент56 страницHextran Getting Started GuideFelix Lara100% (1)

- Danfoss Vex Tes5 Te 20 Sep2011Документ19 страницDanfoss Vex Tes5 Te 20 Sep2011ionut ciobanuОценок пока нет

- Air Cooled Heat ExchangerДокумент1 страницаAir Cooled Heat Exchangermuhammadtayyab_87Оценок пока нет

- Pigging Products: Safe and Effi Cient PiggingДокумент16 страницPigging Products: Safe and Effi Cient PiggingAnonymous qhVGVpОценок пока нет

- Design and Analysis of a Flat Heat PipeДокумент102 страницыDesign and Analysis of a Flat Heat Pipeafic219473Оценок пока нет

- Manufacturing FRP Chemical Storage TanksДокумент4 страницыManufacturing FRP Chemical Storage TanksSunil KumarОценок пока нет

- Electrostatic Desalter Process Data SheetДокумент10 страницElectrostatic Desalter Process Data SheetfedemochileroОценок пока нет

- Installation and Maintenance Manual for Colloidal Mill Type 490 PMBДокумент14 страницInstallation and Maintenance Manual for Colloidal Mill Type 490 PMBMahmoud Abd-Elhamid Abu EyadОценок пока нет

- Hydroheater Auto Manual VersionДокумент45 страницHydroheater Auto Manual VersionVishal Nawalgaria100% (3)

- IR HL Heatless DryerДокумент1 страницаIR HL Heatless DryerYing Kei ChanОценок пока нет

- Flowserve-Ball Valve Technical Manual For AKH3 IOMДокумент23 страницыFlowserve-Ball Valve Technical Manual For AKH3 IOMwholenumberОценок пока нет

- Technical Data: Foam Chambers Model FCДокумент5 страницTechnical Data: Foam Chambers Model FCjhoger2012Оценок пока нет

- NOVEM-NLAHX (HTRI Technology-November 2002) BДокумент21 страницаNOVEM-NLAHX (HTRI Technology-November 2002) Bvsraochemical1979Оценок пока нет

- Microsoft Word - 8100a Flame ArresterДокумент4 страницыMicrosoft Word - 8100a Flame Arresterhasan_676489616100% (1)

- Biocleaner - Manual de Operacion y MantenimientoДокумент9 страницBiocleaner - Manual de Operacion y MantenimientoFabian Ignacio Marquez OsorioОценок пока нет

- AIRTORQUEДокумент20 страницAIRTORQUEPaula MendesОценок пока нет

- Eska Valve ERG-S Series Double Stage Pressure RegulatorДокумент4 страницыEska Valve ERG-S Series Double Stage Pressure RegulatorRONAL QUISPE MAMANIОценок пока нет

- NGL1 V1 Sec 7Документ203 страницыNGL1 V1 Sec 7varatharajan g rОценок пока нет

- Diseño de ProcesoДокумент9 страницDiseño de ProcesotinocamargoОценок пока нет

- Tank Design SpecificationДокумент8 страницTank Design SpecificationRodrigo Gracia100% (1)

- Manual de Pro IIДокумент48 страницManual de Pro IIMiguel Jiménez FloresОценок пока нет

- Odin Elastopipe Eng Oct 2019 PDFДокумент2 страницыOdin Elastopipe Eng Oct 2019 PDFHafidzManaf100% (1)

- PP Lined Pipe PDFДокумент27 страницPP Lined Pipe PDFNILADRI BHATTACHARYYAОценок пока нет

- Types of Heat Exchangers and LMTD Design MethodДокумент70 страницTypes of Heat Exchangers and LMTD Design MethodffownОценок пока нет

- DDG-T-P-03310 Condensate StripperДокумент11 страницDDG-T-P-03310 Condensate StripperCristinaОценок пока нет

- VAL Team Adca: Steam Distribution Manifold MASДокумент4 страницыVAL Team Adca: Steam Distribution Manifold MASEdgar León100% (2)

- Model: 3196 Size: 1.5X3-6 Group: Sti 60Hz RPM: 2453 Stages: 1Документ10 страницModel: 3196 Size: 1.5X3-6 Group: Sti 60Hz RPM: 2453 Stages: 1Weisong D. LeeОценок пока нет

- ASHRAE Standard 55-2010 - ASHRAE-55-2010Документ44 страницыASHRAE Standard 55-2010 - ASHRAE-55-2010AlejandroОценок пока нет

- 503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFДокумент8 страниц503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFsvnaik14Оценок пока нет

- PV EliteДокумент4 страницыPV EliteBruno AguilarОценок пока нет

- Carrier Serie 50TC (15-27.5 Ton) PDFДокумент98 страницCarrier Serie 50TC (15-27.5 Ton) PDFRafael CentenoОценок пока нет

- Masoneilan Valves Spec Data Sheet for Steam and Nitrogen NEW VALVESДокумент5 страницMasoneilan Valves Spec Data Sheet for Steam and Nitrogen NEW VALVESRaulRodriguezОценок пока нет

- Sulsim Integration for Accurate Sulfur Recovery SimulationДокумент23 страницыSulsim Integration for Accurate Sulfur Recovery SimulationSergio Lazarte MercadoОценок пока нет

- DA DX DZ Service Manual RSD6200006r44Документ112 страницDA DX DZ Service Manual RSD6200006r44Wayne BodnarchukОценок пока нет

- Analizadores de Presion de Vapor Analizador RVPДокумент6 страницAnalizadores de Presion de Vapor Analizador RVPLuis OsorioОценок пока нет

- Quick Opening ClosuresДокумент4 страницыQuick Opening ClosuresJuan CarvajalОценок пока нет

- Bulletin 71.4MR108 PDFДокумент20 страницBulletin 71.4MR108 PDFBledarОценок пока нет

- Hoja de Datos de BombaДокумент5 страницHoja de Datos de Bombaluis zambranoОценок пока нет

- Biruk Endale Design On Heat Exchanger-1Документ32 страницыBiruk Endale Design On Heat Exchanger-1nigus gereziherОценок пока нет

- Acoplamientos TSK PDFДокумент4 страницыAcoplamientos TSK PDFBenicio Joaquín Ferrero BrebesОценок пока нет

- Re77502 2004-05Документ20 страницRe77502 2004-05pamururamuОценок пока нет

- Steel MillsДокумент60 страницSteel MillsJulio CarbonettiОценок пока нет

- 23 Cb2000 Ls Varmeca enДокумент10 страниц23 Cb2000 Ls Varmeca enFlying2eagleОценок пока нет

- Couplings SiemensДокумент139 страницCouplings SiemensTài liệu Công ty TNHH Nam TrungОценок пока нет

- Axem Disc DC Servo Motor ManualДокумент12 страницAxem Disc DC Servo Motor ManualjohnysonycumОценок пока нет

- Template Contoh HSE PlanДокумент9 страницTemplate Contoh HSE PlanLusy Gusti EfendiОценок пока нет

- PT Pertamina (Persero) : Safety Data SheetДокумент10 страницPT Pertamina (Persero) : Safety Data SheetFaizal HidayatОценок пока нет

- Fls Ball MillДокумент8 страницFls Ball Millrazen_inОценок пока нет

- WIKA - 213.53 SeriesДокумент2 страницыWIKA - 213.53 SeriesDhanielОценок пока нет

- 6BT5 9Документ2 страницы6BT5 9Dhaniel100% (1)

- NTN Ultage SRB 3030 eДокумент16 страницNTN Ultage SRB 3030 eDhanielОценок пока нет

- XAR 400 (WB 703) EnglischДокумент3 страницыXAR 400 (WB 703) Englischgheoda8926Оценок пока нет

- Template Contoh HSE PlanДокумент9 страницTemplate Contoh HSE PlanLusy Gusti EfendiОценок пока нет

- UNAX Internals: Increased Lining Stability Higher Efficiency Fewer Types of Spare Parts Short Installation TimeДокумент4 страницыUNAX Internals: Increased Lining Stability Higher Efficiency Fewer Types of Spare Parts Short Installation TimeDhanielОценок пока нет

- NTN 5301eДокумент24 страницыNTN 5301eDhanielОценок пока нет

- Brosur Rotex CouplingДокумент1 страницаBrosur Rotex CouplingDhanielОценок пока нет

- Reduct orДокумент20 страницReduct orFlores CesarОценок пока нет

- Everything You Need to Know About A53 Standard PipeДокумент6 страницEverything You Need to Know About A53 Standard PipeRodrigo SandovalОценок пока нет

- Pipe SpecificationДокумент5 страницPipe SpecificationDhanielОценок пока нет

- Plate Heat Ex B120T SwepДокумент2 страницыPlate Heat Ex B120T SwepDhanielОценок пока нет

- Atlas Copco Ga+Xa Technical Kit List 2009Документ12 страницAtlas Copco Ga+Xa Technical Kit List 2009vtichonov50% (4)

- Brazed Plate Heat ExchangersДокумент6 страницBrazed Plate Heat ExchangersDhanielОценок пока нет

- Manual de Partes Atlas CopcoДокумент48 страницManual de Partes Atlas CopcoJose75% (4)

- Din 1.4003Документ2 страницыDin 1.4003Dhaniel100% (1)

- Graviner MK6 Oil Mist DetectorДокумент4 страницыGraviner MK6 Oil Mist DetectorDhanielОценок пока нет

- PTFE (Teflon) : Material PropertiesДокумент2 страницыPTFE (Teflon) : Material PropertiesDhaniel100% (1)

- Rubric 5th GradeДокумент2 страницыRubric 5th GradeAlbert SantosОценок пока нет

- Excess AirДокумент10 страницExcess AirjkaunoОценок пока нет

- 2010 HD Part Cat. LBBДокумент466 страниц2010 HD Part Cat. LBBBuddy ButlerОценок пока нет

- Methods to estimate stakeholder views of sustainabilityДокумент7 страницMethods to estimate stakeholder views of sustainabilityAlireza FatemiОценок пока нет

- Technical Manual - C&C08 Digital Switching System Chapter 2 OverviewДокумент19 страницTechnical Manual - C&C08 Digital Switching System Chapter 2 OverviewSamuel100% (2)

- Technical specifications for JR3 multi-axis force-torque sensor modelsДокумент1 страницаTechnical specifications for JR3 multi-axis force-torque sensor modelsSAN JUAN BAUTISTAОценок пока нет

- GP Rating GSK Exit ExamДокумент108 страницGP Rating GSK Exit ExamMicle VM100% (4)

- Easa Management System Assessment ToolДокумент40 страницEasa Management System Assessment ToolAdam Tudor-danielОценок пока нет

- Crystallizers: Chapter 16 Cost Accounting and Capital Cost EstimationДокумент1 страницаCrystallizers: Chapter 16 Cost Accounting and Capital Cost EstimationDeiver Enrique SampayoОценок пока нет

- Ailunce HD1 Software ManualДокумент33 страницыAilunce HD1 Software ManualMarc LaBarberaОценок пока нет

- A Princess of Mars Part 3Документ4 страницыA Princess of Mars Part 3Sheila Inca100% (1)

- Kalley Ltdn40k221twam Chassis msd6308 SM PDFДокумент49 страницKalley Ltdn40k221twam Chassis msd6308 SM PDFjulio cesar calveteОценок пока нет

- Worksheet 5 Communications and Privacy: Unit 6 CommunicationДокумент3 страницыWorksheet 5 Communications and Privacy: Unit 6 Communicationwh45w45hw54Оценок пока нет

- Trillium Seismometer: User GuideДокумент34 страницыTrillium Seismometer: User GuideDjibril Idé AlphaОценок пока нет

- Google Earth Learning Activity Cuban Missile CrisisДокумент2 страницыGoogle Earth Learning Activity Cuban Missile CrisisseankassОценок пока нет

- Analyze and Design Sewer and Stormwater Systems with SewerGEMSДокумент18 страницAnalyze and Design Sewer and Stormwater Systems with SewerGEMSBoni ClydeОценок пока нет

- Real Estate Broker ReviewerREBLEXДокумент124 страницыReal Estate Broker ReviewerREBLEXMar100% (4)

- Dell Compellent Sc4020 Deploy GuideДокумент184 страницыDell Compellent Sc4020 Deploy Guidetar_py100% (1)

- Marshall Stability Test AnalysisДокумент5 страницMarshall Stability Test AnalysisZick Zickry50% (2)

- UD150L-40E Ope M501-E053GДокумент164 страницыUD150L-40E Ope M501-E053GMahmoud Mady100% (3)

- Equilibruim of Forces and How Three Forces Meet at A PointДокумент32 страницыEquilibruim of Forces and How Three Forces Meet at A PointSherif Yehia Al MaraghyОценок пока нет

- STS Prelim ExamДокумент2 страницыSTS Prelim ExamMychie Lynne MayugaОценок пока нет

- The Dominant Regime Method - Hinloopen and Nijkamp PDFДокумент20 страницThe Dominant Regime Method - Hinloopen and Nijkamp PDFLuiz Felipe GuaycuruОценок пока нет

- Maharashtra Auto Permit Winner ListДокумент148 страницMaharashtra Auto Permit Winner ListSadik Shaikh50% (2)

- 100 Training Games - Kroehnert, GaryДокумент180 страниц100 Training Games - Kroehnert, GarywindsorccОценок пока нет

- Legends and Lairs - Elemental Lore PDFДокумент66 страницLegends and Lairs - Elemental Lore PDFAlexis LoboОценок пока нет

- Hipotension 6Документ16 страницHipotension 6arturo castilloОценок пока нет

- EC GATE 2017 Set I Key SolutionДокумент21 страницаEC GATE 2017 Set I Key SolutionJeevan Sai MaddiОценок пока нет

- Mobile ApplicationДокумент2 страницыMobile Applicationdarebusi1Оценок пока нет

- Computer Networks Transmission Media: Dr. Mohammad AdlyДокумент14 страницComputer Networks Transmission Media: Dr. Mohammad AdlyRichthofen Flies Bf109Оценок пока нет