Академический Документы

Профессиональный Документы

Культура Документы

A Specifying Engineer's Guide To Water Treatment - IHS Engineering360

Загружено:

PanosMitsopoulosОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A Specifying Engineer's Guide To Water Treatment - IHS Engineering360

Загружено:

PanosMitsopoulosАвторское право:

Доступные форматы

3/10/2016

A Specifying Engineers Guide to Water Treatment | IHS Engineering360

News &

Analysis

Home

Products &

Suppliers

Standards

Library

Reference

Library

Engineering

Community

News & Analysis

HOME

NEWS & ANALYSIS

INDUSTRIES

ENERGY AND NATURAL RESOURCES

Stay

Informed

Free Registration

Search News & Analysis

GO

ARTICLE

Energy and Natural Resources

A Specifying Engineers Guide to Water Treatment

Upcoming Events

Brad Buecker, Process Specialist, Kiewit Engineering and Design Co.

Mar 10, 2016

Webinar

Finite Element Analysis for the Design,

and Optimization of Electric Machines

09 February 2016

Many requests-for-proposals (RFP) for new combined-cycle power plants contain a flaw. In the majority of cases, it is

apparent that the project developers (and often the owners engineer) do not fully understand the importance of

water treatment and steam generation chemistry. Often, insufficient raw water quality data is provided at the outset.

This makes precise design of the makeup water system difficult or impossible to achieve. Also, in the competitive

business of bid preparation, projects often are awarded to the low bidder without sufficient thought given to whether

the design or equipment offering is satisfactory. Then, after commissioning, and when systems underperform or even

fail, the owner and operators are placed in a severe bind.

Whats more, many RFPs specify out-of-date or discredited chemical treatment programs. A primary example for heat

recovery steam generators (HRSGs) is a continued belief in the need for oxygen scavengers (a more accurate term

is reducing agent) as a feedwater treatment. This article explores some of these specifying issues.

Makeup Water Treatment Design

Fresh water supplies are no longer ubiquitous for power plant makeup. Increasingly, plants have to use treated

municipal wastewater, poor quality groundwater or other less-than-ideal supplies. Raw water quality greatly impacts

the design, and often the sizing or redundancy, of the makeup water treatment system and pre-treatment equipment.

Here are a few of the constituents in raw water that must be accounted for in system design:

The hardness ions, calcium and magnesium (Ca and Mg). These can react with alkalinity and silica in the water

to form scale in reverse osmosis (RO) systems and ion exchange units.

Bicarbonate alkalinity (HCO3 -). As the concentration increases in an RO unit or as temperature increases in a

heat exchanger, alkalinity can react with calcium to form calcium carbonate (CaCO3 ) deposits.

Silica (SiO2 ). Silica chemistry is complex. Silica can form scale, but more often combines with magnesium and

sometimes calcium to form silicate scales. These are very difficult to remove. Silicate scale formation becomes

more pronounced with increasing pH. However, if no hardness ions are present, higher pH will keep SiO2 in

solution. The latter chemistry is the basis for a membrane-based wastewater treatment technology that is

becoming more popular. [1]

Chloride (Cl). Chloride is a notorious pitting agent of stainless steels, especially underneath deposits.

Sulfate (SO4 ). Sulfate will combine with calcium to form deposits, although the solubility of CaSO4 is

considerably higher than CaCO3 . However, the deposits are difficult to remove. Sulfate will also form tenacious

Mar 14, 2016

Hyatt Regency Dallas at Reunion, Dallas,

Texas

2016 Spring Committee on Petroleum

Measurement Standards Meeting

Mar 15, 2016

Webinar

Humidity Measurement Using Chilled

Mirror Technology

Mar 16, 2016

Webinar

A Self-contained Marine Hydraulic

Clutch System with Integrated PTO

Mar 16, 2016

Webinar

Precision Polymer Engineering Ltd.

Webinar

View Full Calendar

scales, particularly in RO systems, with barium and strontium. These metals typically exist in trace quantities in

raw water, but, if present in large enough concentrations, can cause problems.

Iron and manganese (Fe and Mn). These metals exist in a number of valence states. If they enter treatment

systems in dissolved form, they can cause fouling and sometimes corrosion.

Suspended solids can be death to RO membranes and must be removed prior to RO treatment.

As a result, raw water analyses for any new project should include these elements or compounds along with pH, total

dissolved solids (TDS), phosphorus, fluoride, ammonia, oil and grease, and total organic carbon (TOC). Also, for any

system that uses reverse osmosis, silt density index (SDI) tests are a requirement for the RO feed. A single snapshot

analysis set is not sufficient; rather, multiple and historical data are needed.

During large power plant construction in the last century, a common treatment design was clarification/filtration,

followed by ion exchange. While this technology was often effective, problems sometimes arose. Changes in flow,

temperature and other factors caused solids carryover from clarifiers, which, in turn, induced downstream fouling.

Clarifiers were large structures, often circular or cone-shaped, that had broad footprints. A common design criteria

for clarifiers is the rise rate, which is gallons perminute (gpm) of flow divided by the area of the water surface. A

reasonable rise rate for older clarifiers is 1 gpm/ft2 . Modern systems may now be able to achieve rise rates of 25

gpm/ft2 or more in some applications.

A formerly common arrangement for demineralizers was cation-anion-mixed bed ion exchange, although variations

were not infrequent. Regardless, clarification does little or nothing to remove dissolved solids, so the TDS loading on

the cation and anion beds was quite substantial. Resins will quickly exhaust in these conditions, and must be

regenerated regularly with acid (typically sulfuric) and caustic.

For these reasons, makeup water treatment evolved considerably. A common scheme today is micro- or ultrafiltration

(MF, UF) for suspended solids removal, two-pass RO for primary TDS removal, and portable mixed-bed ion exchange

or electrodeionization (EDI) for final polishing. These technologies have greatly improved makeup system reliability

and final water quality, but they are not foolproof. Issues that may arise include:

Excessive surges in suspended solids can foul MF and UF membranes.

Use of cationic polymers for coagulation or flocculation ahead of membrane systems may cause problems, as

the polymers will coat the (typically) negatively-charged membranes.

For MF and UF membranes, the choice of outside-in vs. inside-out flow through the membranes may have

http://insights.globalspec.com/article/2088/a-specifying-engineer-s-guide-to-water-treatment?id=%2D1535727606&uh=a594bd&email=maria%5Fmitsopou

1/3

3/10/2016

A Specifying Engineers Guide to Water Treatment | IHS Engineering360

significant consequences.

Membrane cleaning methods may induce scale formation depending upon the concentration of some impurities

in the dilution water.

Although some vendors claim otherwise, in the authors experience, EDI requires feed from a two-pass RO, not

single-pass RO only.

Now let us examine a steam generation chemistry topic that continues to be misunderstood.

Forget the Oxygen Scavenger

Unlike coal-fired power plants, the condensate/feedwater system of an HRSG does not have feedwater heaters other

than perhaps a deaerating heater. Thus, the entire network from the condenser to the low-pressure evaporator is all

steel, with no copper alloys present. Even so, many HRSG proposals continue to call for oxygen scavenger feed to

the condensate. This chemistry has been discredited as it is known that conditions produced by the reducing agent

help to propagate and induce single-phase flow-accelerated corrosion (FAC).

Single-phase FAC occurs at flow disturbances such as elbows in feedwater piping and economizers, locations

downstream of valves and reducing fittings, attemperator piping, and, most notably for the combined-cycle industry,

in low-pressure evaporators. The effect of single-phase FAC is illustrated in the image.

Wall thinning occurs gradually until the

remaining material at the affected

location can no longer withstand the

process pressure. Catastrophic failure

may occur. Temperature and pH also

influence single-phase FAC, with

maximum corrosion occurring at 300o F

and as pH drops towards and below 9.0.

In an HRSG, flow-accelerated corrosion

is typically maximized in the units lowpressure economizer and evaporator,

with their many short-radius elbows and

temperatures in proximity to 300o F.

However, the corrosion also can occur

in other locations including

intermediate-pressure circuits. Also,

equipment such as deaerators that

experience a mixture of water and steam

may be subject to two-phase FAC.

Continued research is improving the

battle against FAC. For those in the

industry who have grasped that the old

AVT(R) program (ammonia or amine

feed for pH control and reducing agent

feed for oxygen removal and metal

passivation) is no longer valid, the

popular replacement is all-volatile

treatment (oxidizing). With AVT(O), the

small amount of oxygen that enters via

condenser air in-leakage is allowed to

remain, and may be supplemented with

a small, pure oxygen feed. Ammonia (or

in some cases amine) is still ued to

Photo of tube-w all thinning caused by single-phase FAC. Im age source: Chem Treat. elevate the feedwater pH. At feedwaterspecific conductivity below 0.2 S/cm,

this chemistry causes the magnetite layer on carbon steel to become interspersed and overlayed with a stronger,

denser layer of ferric oxide hydrate (FeOOH), which essentially eliminates FAC in those locations. New guidelines

recommend a dissolved oxygen concentration of 5 to 10 parts-per-billion at the LP economizer inlet as lower

concentrations might allow gaps to form in the FeOOH coverage.

References

1. B. Buecker, Lessons Learned from a High Recovery RO-Based ZLD System; CTI Journal, Vol. 35, No. 2,

Summer 2014.

To contact the author of this article, email Engineering360Editors@ihs.com

By posting a comment you confirm that you have read and accept our Posting Rules and our Terms of Use of this site.

0 comments

Sign in

3 people listening

+ Follow

Share

Post comment as...

http://insights.globalspec.com/article/2088/a-specifying-engineer-s-guide-to-water-treatment?id=%2D1535727606&uh=a594bd&email=maria%5Fmitsopou

2/3

3/10/2016

A Specifying Engineers Guide to Water Treatment | IHS Engineering360

Newest | Oldest | Top Comments

ENERGY AND NATURAL RESOURCES

Researchers Say Aliso Canyon Was LargestEver U.S. Methane Leak

FEATURED INFOGRAPHIC

Solar, Gas and Wind Drive 2016 Capacity

Growth

ENERGY AND NATURAL RESOURCES

Dont Neglect Closed Cooling System Water

Treatment

ENERGY AND NATURAL RESOURCES

Turbine Designed to Harvest Ocean Currents

for Power

ENERGY AND NATURAL RESOURCES

Chiller Keeps Oil-Rig Pump Motors Cool in

Test

ENERGY AND NATURAL RESOURCES

Electric generating facilities expect to add more than 26 GW of

utility-scale generating capacity to the power grid during 2016.

Storage Systems Deployed for Grid

Frequency Regulation

ENERGY AND NATURAL RESOURCES

IHS Engineering360

360 Websites

IHS

Editorial Team

Advertising

Datasheets360

IHS Electronics360

IHS.com

Client Services

Privacy Policy

IHS Airport 360

IHS Jane's 360

About IHS

Terms of Use

Site Map

IHS Maritime 360

A-Z Products

Contact Us

Copyright 2016 IHS. All rights reserved. Reproduction in whole or in part without permission is prohibited.

Engineering Newsletter Signup

Get the IHS Engineering360

Specs & Techs Newsletter

Stay up to date on:

Industry news and trends, product announcements,

product applications and the latest innovations.

SUBSCRIBE NOW

http://insights.globalspec.com/article/2088/a-specifying-engineer-s-guide-to-water-treatment?id=%2D1535727606&uh=a594bd&email=maria%5Fmitsopou

3/3

Вам также может понравиться

- Solvay BRICORR® 288 40% Phosphonocarboxylic Acid SaltsДокумент1 страницаSolvay BRICORR® 288 40% Phosphonocarboxylic Acid SaltsarjunanpnОценок пока нет

- Boiler Chemical FormulaДокумент5 страницBoiler Chemical Formulasaif asqalanyОценок пока нет

- BAM-S09-11 Phosphates in Boiler Water - Apr97Документ6 страницBAM-S09-11 Phosphates in Boiler Water - Apr97DhileepОценок пока нет

- Determination of Ca Sequestration ValueДокумент3 страницыDetermination of Ca Sequestration ValueGovindanayagi PattabiramanОценок пока нет

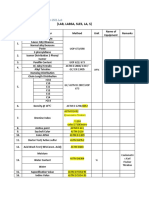

- (Lab, Labsa, Sles, La, S) : No. Test Parameter Method Unit Name of Equipment RemarksДокумент2 страницы(Lab, Labsa, Sles, La, S) : No. Test Parameter Method Unit Name of Equipment RemarksMd Nazim UddinОценок пока нет

- 7 Steps To Boiler Chemical Cleaning and Treatment Selection in Thermal Power PlantДокумент9 страниц7 Steps To Boiler Chemical Cleaning and Treatment Selection in Thermal Power PlantMohamed TallyОценок пока нет

- Applications of Weak Acid Cation Resin in Waste TreatmentДокумент9 страницApplications of Weak Acid Cation Resin in Waste TreatmentSandeep MishraОценок пока нет

- Pass I VationДокумент1 страницаPass I VationSankar100% (1)

- Appendix I 4 IsegenBAR Specialist Studies Risk AssessmentДокумент298 страницAppendix I 4 IsegenBAR Specialist Studies Risk AssessmentMarvvvОценок пока нет

- KCLДокумент3 страницыKCLrahulkotadiya97Оценок пока нет

- Nia CetpДокумент24 страницыNia CetpRahul ParmarОценок пока нет

- Jacobi Tis Aquasorb Raw WaterДокумент15 страницJacobi Tis Aquasorb Raw WaterFarouk Omar100% (1)

- Linear Alkyl BenzeneДокумент9 страницLinear Alkyl BenzeneFouad Achargui100% (1)

- Renoclean Bio Rig WashДокумент2 страницыRenoclean Bio Rig WashMuh yusup100% (1)

- Aminas - ETHANOLAMINAS PDFДокумент6 страницAminas - ETHANOLAMINAS PDFFidel Flores CaricariОценок пока нет

- BWA Belcor 575 Replaces Molybdate USA WF 0Документ2 страницыBWA Belcor 575 Replaces Molybdate USA WF 0dalton2003Оценок пока нет

- LabsaДокумент5 страницLabsaShahbazQureshiОценок пока нет

- Water Chemsitry CourseДокумент44 страницыWater Chemsitry CourseMalik HazaaОценок пока нет

- Organic - New - 2019 Product ProfileДокумент15 страницOrganic - New - 2019 Product Profilevaibhav khodakeОценок пока нет

- MSDS Gengard GN8168Документ11 страницMSDS Gengard GN8168carrspaintsОценок пока нет

- Nouryon. mTA Salt. Electrolysis Salt PDFДокумент3 страницыNouryon. mTA Salt. Electrolysis Salt PDFAbigail HernandezОценок пока нет

- CNA PresentationДокумент27 страницCNA PresentationMayur KhirodeОценок пока нет

- Sodium Silicate PDFДокумент19 страницSodium Silicate PDFnasirtaxila9094Оценок пока нет

- Synopsis Project JocilДокумент16 страницSynopsis Project JocilbhatiaharryjassiОценок пока нет

- DYCOTE E.pdf - DownloadassetДокумент32 страницыDYCOTE E.pdf - DownloadassetJAnottama werdhabudiОценок пока нет

- Acetic Acid Separation Methods: Supervisore: Prof. H. S. GhaziaskarДокумент41 страницаAcetic Acid Separation Methods: Supervisore: Prof. H. S. Ghaziaskarjotas254100% (1)

- Coal Additive PresentationДокумент15 страницCoal Additive PresentationNileshОценок пока нет

- FGC Group LLC - Consulting & Engineering - Products - Thermal Processing Equipment - Activated Carbon Plant PDFДокумент3 страницыFGC Group LLC - Consulting & Engineering - Products - Thermal Processing Equipment - Activated Carbon Plant PDFCleverSeyramKetekuОценок пока нет

- Alpha Olefin SulfonatesДокумент25 страницAlpha Olefin Sulfonatesvnikhar123Оценок пока нет

- Demin Simple Process 7-9-13Документ1 страницаDemin Simple Process 7-9-13kaduxaОценок пока нет

- Material Balance Around Tubular Reactor:: ReactionДокумент7 страницMaterial Balance Around Tubular Reactor:: ReactionAnonymous KsRdWoYtОценок пока нет

- Acid InhibitorДокумент2 страницыAcid Inhibitorglycol_brine_coolant_pcmОценок пока нет

- The Treatment of Cooling Water With Chlorine Dioxide PDFДокумент10 страницThe Treatment of Cooling Water With Chlorine Dioxide PDFMumtaz Ahmed GhummanОценок пока нет

- Technological Result of Decomposition Sodium Aluminate SolutionДокумент10 страницTechnological Result of Decomposition Sodium Aluminate SolutionDragana Dragojlović SmiljanicОценок пока нет

- Fatty AminesДокумент5 страницFatty AminesMehmet AydinОценок пока нет

- Unit 3 Chemical Process Technology II Lesson 1 Nitrogen Industries (M)Документ22 страницыUnit 3 Chemical Process Technology II Lesson 1 Nitrogen Industries (M)Green JeskОценок пока нет

- BP s25 Wwta-DataДокумент20 страницBP s25 Wwta-DatajnmanivannanОценок пока нет

- Cooling Water - PackariousДокумент57 страницCooling Water - PackariousBrett RagonОценок пока нет

- 7 Filming AmineДокумент3 страницы7 Filming Amineengp1922Оценок пока нет

- Water Conditing in IndustryДокумент12 страницWater Conditing in IndustryFarwa MalikОценок пока нет

- Phosphinosuccinic Oligomer (PSO)Документ3 страницыPhosphinosuccinic Oligomer (PSO)mirceablaga86Оценок пока нет

- Gopu Venugopala Reddy Team Labs and Consultants India PDFДокумент22 страницыGopu Venugopala Reddy Team Labs and Consultants India PDFHardik VavdiyaОценок пока нет

- Product Information: Belsperse 164 - High Performance Dispersant For Industrial Water SystemsДокумент2 страницыProduct Information: Belsperse 164 - High Performance Dispersant For Industrial Water SystemsEti SureniОценок пока нет

- SOKALAN - High-Performance Additives For Thermal DesalinationДокумент7 страницSOKALAN - High-Performance Additives For Thermal DesalinationHasbi Ashidiqi P100% (1)

- Water Treatment Brochure PDFДокумент8 страницWater Treatment Brochure PDFmathesis-2Оценок пока нет

- UOP Type AZ-300 Data SheetДокумент1 страницаUOP Type AZ-300 Data SheetAmir RahbariОценок пока нет

- Phosphonates Polymers BROCHUREДокумент2 страницыPhosphonates Polymers BROCHURETunc Tulu CetinkayaОценок пока нет

- Oilfield Chemistry: ProgramДокумент36 страницOilfield Chemistry: ProgramMohamed HassanОценок пока нет

- Phosphinosuccinic Oligomer (PSO)Документ3 страницыPhosphinosuccinic Oligomer (PSO)mirceablaga86Оценок пока нет

- Deposit Control Polymers For Stressed Phosphate-Based Cooling Water SystemsДокумент15 страницDeposit Control Polymers For Stressed Phosphate-Based Cooling Water SystemsJohnОценок пока нет

- Activated Carbon Medicinal Pharmaceutical Processes: For andДокумент14 страницActivated Carbon Medicinal Pharmaceutical Processes: For andArpit jainОценок пока нет

- Sulphite Vs Tannin Oxygen Scavenger TreatmentsДокумент5 страницSulphite Vs Tannin Oxygen Scavenger TreatmentsAhmed Taher100% (1)

- Siloxane DX-1708 and 1709Документ45 страницSiloxane DX-1708 and 1709jones32Оценок пока нет

- Cal TR12x40Документ2 страницыCal TR12x40Herik AziziОценок пока нет

- Manu. Process Flow ChartДокумент2 страницыManu. Process Flow ChartBaljeet Kumar PooniaОценок пока нет

- Liquid Urea-Formaldehyde Resin Manufacturing Industry-217599 - 4Документ65 страницLiquid Urea-Formaldehyde Resin Manufacturing Industry-217599 - 4Sanzar Rahman 1621555030Оценок пока нет

- Thermax Resin Summarized Data Sheet PDFДокумент12 страницThermax Resin Summarized Data Sheet PDFmathesis-2Оценок пока нет

- BBI Webinar Lutropur MSA-XP For DistributionДокумент18 страницBBI Webinar Lutropur MSA-XP For DistributionSeptian Wahyu PriyonoОценок пока нет

- Thermax Chemical Division Brochure PDFДокумент24 страницыThermax Chemical Division Brochure PDFmathesis-2Оценок пока нет

- Store - Catalog Products - NEW - The Dirty War On Syria - Washington, Regime Change and Resistance PDFДокумент4 страницыStore - Catalog Products - NEW - The Dirty War On Syria - Washington, Regime Change and Resistance PDFPanosMitsopoulosОценок пока нет

- How To Calculate Flare Radiation Isopleths - Industrial Professionals - CheresourcesДокумент5 страницHow To Calculate Flare Radiation Isopleths - Industrial Professionals - CheresourcesPanosMitsopoulosОценок пока нет

- Air Quality ModelДокумент30 страницAir Quality ModelPanosMitsopoulosОценок пока нет

- WWW - Engsoft.co - KR - Es Fluegas eДокумент9 страницWWW - Engsoft.co - KR - Es Fluegas ePanosMitsopoulosОценок пока нет

- The Relationship Between Injustice and CrimeДокумент11 страницThe Relationship Between Injustice and CrimePanosMitsopoulosОценок пока нет

- Phsyhopatic CrimeДокумент9 страницPhsyhopatic CrimePanosMitsopoulosОценок пока нет

- A Comparative Analysis of General Strain TheoryДокумент11 страницA Comparative Analysis of General Strain TheoryPanosMitsopoulosОценок пока нет

- In Illinois and New York, The Crime-Fighters Are Criminals - National Review OnlineДокумент10 страницIn Illinois and New York, The Crime-Fighters Are Criminals - National Review OnlinePanosMitsopoulosОценок пока нет

- How To Calculate Flare Radiation Isopleths - Industrial Professionals - CheresourcesДокумент5 страницHow To Calculate Flare Radiation Isopleths - Industrial Professionals - CheresourcesPanosMitsopoulosОценок пока нет

- SUPERGOOD - LSQ - The Model of Dimensional Analysis - VanbrakДокумент16 страницSUPERGOOD - LSQ - The Model of Dimensional Analysis - VanbrakPanosMitsopoulosОценок пока нет

- President John F Kennedy Were Murdered by The Military-SecurityДокумент3 страницыPresident John F Kennedy Were Murdered by The Military-SecurityPanosMitsopoulosОценок пока нет

- Information Warfare - "World War Three, Inside The War Room"Документ4 страницыInformation Warfare - "World War Three, Inside The War Room"PanosMitsopoulosОценок пока нет

- Cover Letter Greeting Errors - Pongo BlogДокумент2 страницыCover Letter Greeting Errors - Pongo BlogPanosMitsopoulosОценок пока нет

- Week Eighteen of The Russian Intervention in Syria - A Dramatic Escalation Appears Imminent - The Unz ReviewДокумент5 страницWeek Eighteen of The Russian Intervention in Syria - A Dramatic Escalation Appears Imminent - The Unz ReviewPanosMitsopoulosОценок пока нет

- The EU, Greece, and All ThatДокумент2 страницыThe EU, Greece, and All ThatPanosMitsopoulosОценок пока нет

- AFT Fathom AmerenMissouriCaseStudyДокумент2 страницыAFT Fathom AmerenMissouriCaseStudypca97Оценок пока нет

- O-2605 Water FireДокумент2 страницыO-2605 Water FirePanosMitsopoulosОценок пока нет

- Brochure06 Usc 07 PDFДокумент2 страницыBrochure06 Usc 07 PDFslawateОценок пока нет

- M 4803Документ1 страницаM 4803PanosMitsopoulosОценок пока нет

- Coalunitcharacteristics2014 SummaryДокумент6 страницCoalunitcharacteristics2014 SummaryPanosMitsopoulosОценок пока нет

- En-548 Doc-Dwg ListДокумент3 страницыEn-548 Doc-Dwg ListPanosMitsopoulosОценок пока нет

- Powerengineering201505-Dl - SOS Gas Turbine EPCДокумент1 страницаPowerengineering201505-Dl - SOS Gas Turbine EPCPanosMitsopoulosОценок пока нет

- Foster Wheeler, Tecnimont Form North America Chemicals Alliance - Hydrocarbon Processing - February 2014Документ2 страницыFoster Wheeler, Tecnimont Form North America Chemicals Alliance - Hydrocarbon Processing - February 2014PanosMitsopoulosОценок пока нет

- Oil&Gas F SasolДокумент2 страницыOil&Gas F SasolPanosMitsopoulosОценок пока нет

- AFT Arrow 4 Data SheetДокумент2 страницыAFT Arrow 4 Data SheetVictor AntonОценок пока нет

- Citgo Reports Fire in Crude Tower at Corpus Refinery - Hydrocarbon Processing - February 2014Документ2 страницыCitgo Reports Fire in Crude Tower at Corpus Refinery - Hydrocarbon Processing - February 2014PanosMitsopoulosОценок пока нет

- PMC Refinery Contract For Foster WheelerДокумент2 страницыPMC Refinery Contract For Foster WheelerPanosMitsopoulosОценок пока нет

- Market Data Book 2015 ProspectusДокумент6 страницMarket Data Book 2015 ProspectusPanosMitsopoulosОценок пока нет

- Foster Wheeler Wins Contract For Pipeline and Power Plant Project in PeruДокумент2 страницыFoster Wheeler Wins Contract For Pipeline and Power Plant Project in PeruPanosMitsopoulosОценок пока нет

- NA ReadingStrategies U5M11L03Документ1 страницаNA ReadingStrategies U5M11L03Lila AlwaerОценок пока нет

- Unilever PakistanДокумент26 страницUnilever PakistanElie Mints100% (3)

- Pipe Freezing StudyДокумент8 страницPipe Freezing StudymirekwaznyОценок пока нет

- University of Ghana: This Paper Contains Two Parts (PART I and PART II) Answer All Questions From Both PARTSДокумент3 страницыUniversity of Ghana: This Paper Contains Two Parts (PART I and PART II) Answer All Questions From Both PARTSPhilip Pearce-PearsonОценок пока нет

- Structure of NABARD Grade AДокумент7 страницStructure of NABARD Grade ARojalin PaniОценок пока нет

- Swiss Army Triplet 1Документ2 страницыSwiss Army Triplet 1johnpwayОценок пока нет

- Exemption in Experience & Turnover CriteriaДокумент4 страницыExemption in Experience & Turnover CriteriaVivek KumarОценок пока нет

- A Method For Prediction of Gas/Gas Ejector PerformanceДокумент6 страницA Method For Prediction of Gas/Gas Ejector PerformancedhavaleshОценок пока нет

- GST RATE LIST - pdf-3Документ6 страницGST RATE LIST - pdf-3Niteesh KumarОценок пока нет

- Hesychasm - A Christian Path of TranscendenceДокумент10 страницHesychasm - A Christian Path of Transcendencebde_gnas100% (1)

- Construction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesДокумент1 страницаConstruction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesrajavelОценок пока нет

- Adolescents' Gender and Their Social Adjustment The Role of The Counsellor in NigeriaДокумент20 страницAdolescents' Gender and Their Social Adjustment The Role of The Counsellor in NigeriaEfosaОценок пока нет

- UpdateJul2007 3julДокумент10 страницUpdateJul2007 3julAnshul SinghОценок пока нет

- Periodic Table Lab AnswersДокумент3 страницыPeriodic Table Lab AnswersIdan LevyОценок пока нет

- (Polish Journal of Sport and Tourism) The Estimation of The RAST Test Usefulness in Monitoring The Anaerobic Capacity of Sprinters in AthleticsДокумент5 страниц(Polish Journal of Sport and Tourism) The Estimation of The RAST Test Usefulness in Monitoring The Anaerobic Capacity of Sprinters in AthleticsAfizieОценок пока нет

- Simple Enzymes Kinetics and Kinetics ModelДокумент14 страницSimple Enzymes Kinetics and Kinetics ModelSidra-tul MuntahaОценок пока нет

- Corrosion Performance of Mild Steel and GalvanizedДокумент18 страницCorrosion Performance of Mild Steel and GalvanizedNarasimha DvlОценок пока нет

- Pre-Paid Customer Churn Prediction Using SPSSДокумент18 страницPre-Paid Customer Churn Prediction Using SPSSabhi1098Оценок пока нет

- Baby DedicationДокумент3 страницыBaby DedicationLouriel Nopal100% (3)

- Review Course 2 (Review On Professional Education Courses)Документ8 страницReview Course 2 (Review On Professional Education Courses)Regie MarcosОценок пока нет

- Group Members: - Muhamad Sahli B Muda - Nurul Hana Balqis Baharom - Napsiah Abdul RahmanДокумент18 страницGroup Members: - Muhamad Sahli B Muda - Nurul Hana Balqis Baharom - Napsiah Abdul RahmanNurul Hana BalqisОценок пока нет

- 835 (Health Care Claim PaymentAdvice) - HIPAA TR3 GuideДокумент306 страниц835 (Health Care Claim PaymentAdvice) - HIPAA TR3 Guideअरूण शर्माОценок пока нет

- DatuinMA (Activity #5 - NSTP 10)Документ2 страницыDatuinMA (Activity #5 - NSTP 10)Marc Alen Porlaje DatuinОценок пока нет

- Ionic Bonding Worksheet - Type 1 PracticeДокумент2 страницыIonic Bonding Worksheet - Type 1 Practicerichwenekylejc o Evaristo100% (6)

- Oral Communication in ContextДокумент19 страницOral Communication in ContextAzory ZelleОценок пока нет

- Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresДокумент39 страницCode of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresIshor ThapaОценок пока нет

- Chrysler CDS System - Bulletin2Документ6 страницChrysler CDS System - Bulletin2Martin Boiani100% (1)

- 2396510-14-8EN - r1 - Service Information and Procedures Class MДокумент2 072 страницы2396510-14-8EN - r1 - Service Information and Procedures Class MJuan Bautista PradoОценок пока нет

- Zillah P. Curato: ObjectiveДокумент1 страницаZillah P. Curato: ObjectiveZillah CuratoОценок пока нет

- (Bruno Bettelheim) Symbolic Wounds Puberty RitesДокумент196 страниц(Bruno Bettelheim) Symbolic Wounds Puberty RitesAmbrose66Оценок пока нет