Академический Документы

Профессиональный Документы

Культура Документы

THS016 - Magnetic Refrigeration System

Загружено:

Hemanta dhakalАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

THS016 - Magnetic Refrigeration System

Загружено:

Hemanta dhakalАвторское право:

Доступные форматы

Magnetic Refrigeration System

Tahirhussain and Pratapdawadi

Department of Mechanical Engineering,

Reva Institute of Technology and Management

Address

tahirhussain199@yahoo.com

idawadpratap@gmail.com

AbstractThis is a concise review of possibilities and prospects for

magnetic refrigeration system over conventional vapour

compression refrigeration system.Modern society largely

depends on readily available refrigeration methods. Till now,

the conventional vapour compression refrigerators have been

mainly used for refrigeration applications. Nonetheless, the

conventional refrigerators based on gas compression and

expansion are not very efficient. The ultimate goal of this

technology would be to develop a standard refrigerator for

home use. The use of magnetic refrigeration has the potential

to reduce operating andmaintenance costs when compared to

the conventional method of compressor-basedrefrigeration.

Similarly its efficiency is exorbitantly high, i.e. efficiency

almost equal to that of Carnot Cycle. By eliminating the high

capital cost of the compressor and the high cost ofelectricity to

operate the compressor, magnetic refrigeration can efficiently

(andeconomically) replace compressor-based refrigeration

technology.

KeywordsBrayton Cycle, Coefficient of Performance, MagnetoCaloric Effect, Lanthanide-series, Gadolinium

I.

INTRODUCTION

Refrigeration can be defined simply as the

process of removing heat from a body to

maintain the temperature of the body below

that of that of its surrounding.

The science of refrigeration utilizes several

methods for providing low

temperatures.Everybody is familiar with the

vapour compression cycle, which is to date the

most popular cycle, used for refrigeration, both

for industrial & commercial purpose.Most cooling

equipment uses a vapour compression cycle, which relies

on the physical phenomenon of increasing the pressure of a

vapour to raise the condensing temperature at which it

releases heat and, subsequently, lowering the pressure of

the vapour to decrease the temperature at which it boils and

absorbs heat.However there are various

limitations in using vapour compression

system.

The major drawback of the vapour

compression system is that it requires a

compressor to compressor to compress a large

volume of refrigerant vapour which requires a

large power for its operation. In addition, it has

poor COP as compared with the Carnot cycle,

environmental hazards like Global warming,

limit to the lowest temperature reached as its

drawbacks. Hence we have to continuously

look for alternative methods for refrigeration.

On the other hand, refrigeration cycles or heat pumping

devices can be based on a range of physical phenomena

besides the vapour compression cycle, including a range of

gas compressionExpansion cycles, including:

The reverse Brayton, Stirling, and thermo-acoustic

cycles;

Peltier (thermoelectric) devices;

A recuperated liquid compression-expansion cycle (the

Malone cycle);

Shape memory alloy heat pumps;

Elastomeric compression-expansion cycles; and

Magnetic refrigeration cycles.

With respect to the coefficient of performance (COP),

i.e. the ratio of the heat pumped to the work input, the

idealized Carnot cycle represents the thermodynamic

maximum COP for pumping heat from a low-temperature

heat source to ahigher temperature heat sink. Thus, when

seeking an efficient refrigeration cycle, cycles whose ideal

embodiment match or closely approach the Carnot limit are

clearly desirable.

A large research is going on nonconventional refrigeration systems to produce

very low temperatures which include Thermoelectric refrigeration, Pulse tube refrigeration,

Vortex tube refrigeration etc. Magnetic

Refrigerationis one of such techniques, which

promises to be of practical importance. Even

though the concept is still into research, 20

years down the line we can expect it to be

widely used.

The study of magnetic refrigeration was started with

thediscovery of magneto caloric effect (MCE) 132 years

ago. It was first discovered by Warburg in 1881. Research

today is focused on improvements of magneto-caloric

materials, magnets and an optimal design of magnetic

refrigerator devices for room temperature applications.

In this study, the concept of magneto-caloric effect is

explained. The development of the magnetic material,

magnetic refrigeration cycles, magnetic field and the

refrigerator of room temperature magnetic refrigeration is

introduced. Finally some typical room temperature

magnetic refrigeration prototypes are reviewed and showed

the best magneto-caloric effect materials are presented and

some important points for room temperature applications of

magnetic refrigeration technologies are given.

gadolinium, silicon, and germanium are more efficient at

room temperature.

III.

II.

PRINCIPLE BEHIND MAGNETIC

REFRIGERATION

Magnetic refrigeration is based on the "MagnetoCaloric Effect"; the ability of some metals to heat when

magnetized and cool when removed from the magnetic

field. Using these materials as refrigerants provides an

environmentally friendly alternative to the volatile liquid

chemicals, such as chlorofluorocarbons and hydrochlorofluorocarbons, which are used in traditional vapourcycle cooling.

A. MAGNETO-CALORIC EFFECT

Magneto-caloric effect is defined as the response of a

solid to an appliedmagnetic field which is apparent as a

change in its temperature. This effect is obeyedby all

transitionmetals and lanthanide-series elements. When a

magnetic field isapplied, these metals, known as ferromagnets, tend to heat up. As heat is applied, the magnetic

moments align. When the field is removed, the ferromagnet cools down asthe magnetic moments become

randomly oriented. When a strong magnetic field is applied

to the magneto-caloric material, themagnetic moments of

its atoms become aligned, making the system more

ordered.When the strong magnetic field is removed, the

party is forced to cool down.The magnetic moments return

to their random directions, entropy increases and

thematerial cools. Upon the removal of a magnetic field

from a material, the resultingreduction in magnetic spin

alignment represents an increase in the material's

spinentropy (delta S). If the field reduction is performed

adiabatically so that the totalentropy change is zero, then

the increased spin entropy is offset by an equal decreasein

lattice entropy, as reflected by a decrease in the temperature

of the material. Thisdelta T is called the magneto-caloric

effect.

B. GADOLINIUM AND ITS ALLOYS

Since the discovery of the magneto-caloric effect in pure

iron by E. Warburg in 1881, it has been measured

experimentally on many magnetic metals and

compounds.Gadolinium, a rare-earth metal, exhibits one of

the largest known magneto-caloric effects. It was used as

the refrigerant for many of the early magnetic refrigeration

designs. The problem with using pure gadolinium as the

refrigerant material is that it does not exhibit a strong

magneto-caloric effect at room temperature. More recently,

however, it has been discovered that arc-melted alloys of

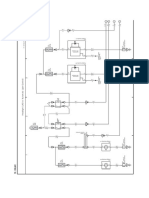

MAGNETIC REFRIGERATION

SYSTEM

With this background of the principal behind the system,

let's take a look at the schematic diagram of the theoretical

magnetic refrigeration system & its vapour compression

counterpart.

The conventional vapour compression system makes use

of a compressor, two heat exchangers- evaporator &

condenser, a throttling device. The refrigerant picks up heat

from the space to be refrigerated in the evaporator where it

is converted into vapour state. This vapour then passes

through the compressor where its pressure &temperature is

increased. Refrigerant then gives out its heat in a condenser

& gets converted into a liquid. The throttling device is used

to reduce the pressure of the refrigerant to the evaporator

pressure.

As compared with this the magnetic system does away

with the compressor. Instead it makes use of magnets,

either permanent or superconducting, to effect a change in

magnetic field. The CFC or HFC refrigerant in the

conventional system is replaced by a working substance i.e.

a magneto-caloric material. The two heat exchangers are

off course still present to affect heat exchange between

working material & a heat transfer fluid.

As before, in the cold heat exchanger the working

substance picks up heat from the space to be refrigerated.

Then the working substance is brought into a strong

magnetic field or it is magnetised so that due to magnetocaloric effect its temperature is increased. Working

substance then gives out its heat to the heat transfer fluid in

a hot heat exchanger. The magnetic field is then reduced,

thereby decreasing its temperature again using the

magneto-caloric effect, so that it can pick up heat in a cold

heat exchanger.

In the conventional system compressor is used to

increase mainly the temperature of the refrigerant so that it

can exchange heat with the atmospheric air. The throttling

device is used to reduce this pressure to evaporator level. In

the magnetic system this is achieved by making use

magneto-caloric effect. Thus the system can do away with

both compressor & throttling device.

point of view, the new system comes as a good substitute

for the conventional system.

IV.

HEAT FLOW SYSTEM

The heat transfer fluid for the magnetic refrigeration

system is aliquid alcohol-water mixture. The mixture used

in the design consists of 60 % ethanol and 40 % water. This

mixture has a freezing point of 40F, assuring that the

mixture does not freeze at the set operating temperatures.

This heat transfer fluid is cheaper than traditional

refrigerants and also eliminates the environmental damage

produced from these refrigerants.

Fig.1. Vapour Compression System

Fig.2. Magnetic Refrigeration System

For comparison purpose the temperature limits for both

systems are taken assame. As can be seen from the chart

the compression process in a vapour compression is never

isentropic. An isentropic process is believed to be the most

efficient path for carrying out any process. This is because

entropy is a property of the system, which measures the

disorder in a system. Thus higher the amount of disorder in

a system more will be its entropy. For higher efficiency we

need minimum disorder in system i.e. minimum entropy.

To have minimum entropy it is necessary to carry out a

process in a reversible manner i.e. the system must be able

to be restored to its original state by an infinitesimal change

in its parameter. Under these conditions, the entropy

generation, which is the sum of entropy of the system &

entropy of the universe, is zero. During compression

process in a vapour compression system there are much

irreversibilities involved like friction, heat exchange of the

hot refrigerant with the surrounding air, which increases the

entropy of the system. Consequently, the process is not the

most efficient process & energy is wasted. As compared

with this in a magnetic system the process of increasing

temperature of the working substance is completely

reversible, since magneto-caloric effect is entirely

reversible. This is because bringing the material out of the

magnetic field can lower the temperature of the magnetocaloric salt. As a result of this the entropy generation

during both processes 1-2 & 3-4 is zero. Thus, the cycle

approaches the Carnot cycle, which is believed to be the

most efficient cycle.As a result of this, even from C.O.P.

Fig.3. Cycle of magnetic refrigeration

The process flow diagram for the magnetic refrigeration

system is shown in fig.3. The fluid first passes through the

hot heat exchanger, which uses air totransfer heat to the

atmosphere. The fluid then passes through the copper

platesattached to the non-magnetized cooler magnetocaloric beds and loses heat. A fan blows air past this cold

fluid into the freezer to keep the freezer temperature at

approximately 0F. The heat transfer fluid then gets heated

up to 80F as it passes through the copper plates adjoined

by the magnetized warmer magneto-caloric beds, where it

continues to cycle around the loop. However, the magnetocaloric beds simultaneously move up and down, into and

out of the magnetic field. The second position of the beds is

shown in Figure 5. The temperature of the refrigerator

section is kept around 39F.

The temperature of the fluid throughout the cycle ranges

from 12F to 80F. The heat transfer fluid at

approximately 70F gets cooled to 12F by the nonmagnetized cold set of beds. This cooled fluid is then sent

to the cold heat exchanger, E-102, where it absorbs the

excess heat from the freezer. This fluid leaves the freezer at

0F. The warm fluid then flows through the opposite

magnetized set of beds, where it is heated up to 80F. This

hot stream is now cooled by room temperature air in the

hot heat exchanger, E-101, to 70F. The cycle then repeats

itself every three seconds after the beds have switched

positions. Copper tubing is used throughout the loop and in

the two heat exchangers.

The two sets of beds, B-101 and B-102, contain the small

spheres of magneto-caloric material. The beds are

alternated in and out of the magnetic field using a chain

and sprocket drive shaft. The drive shaft rotates the beds

back and forth while still keeping them in contact with the

heat transfer plates.

V.

CHALLENGES AHEAD FOR MAGNETIC

REFRIGERATION

Despite all its promise, magnetic refrigeration technology

still has hurdles to overcome if it is to ever give

conventional vapour-based technology a run for the money.

A few of these hurdles are as follows: Small Temperature Spans:- When it comes to a

small temperature span, such asthe range of

temperature in cooling a home or car, the

conventional refrigeration still leads the race.

Size Of The System:- An important consideration

in applications as domesticrefrigerators, car airconditioners is the size of the system. The first

successfulmagnetic refrigerator developed by

Ames lab & ACA makes use of

superconductingmagnet, which makes the system

bulky & big in size. Though the permanent

magnetvariety has been developed, it is still under

testing & the presence of big sized bulkymagnets

makes the system size quite big.

Cost Of The System:- With all the cost saving in

running a magnetic system, thecapital cost of a

magnetic refrigeration system promises to be quite

high. Thus, thesystem may prove to be costly.

Secondly the system has to really

deliverperformance under actual condition similar

to test condition. Otherwise thistechnology will

lose its important advantage of cost saving.

High Reliability Of The Conventional System:Besides the above the otherchallenge faced by the

technology are the high reliability & popularity

due towidespread use of vapour compression

systems. Vapour compression systems havebeen in

use for many years now & have proved to be most

popular method ofrefrigeration

Magneticrefrigeration systems will have to prove

that they are really reliable under normal use.

Thus in future the extensive use of magnetic

systems will be subject to howwell the technology

can sustain growth in various technical areas such

as magnets, magneto-caloric materials, heat

exchangers & other circuitry.

VI.

AREAS OF APPLICATION

With all its promise we can hope to see the use of magnetic

refrigeration systems in the following applications: Liquefaction Of Gases such as Hydrogen,

Nitrogen etc.,

Re-liquefaction of helium in hospital MRI

(magnetic resonance imaging) ,

Large Scale refrigeration applications such as

food-storage,

Industrial air-conditioning applications such as

large restaurants, large shoppingcomplex,

commercial establishments, hospitals etc.,

Industries with specific temperature applications

such as paper pulp industry cloth mills, food

industries, cassette industry etc.,

Low temperature applications such as Cryogenics,

Commercial applications such as household

refrigerator,

Automobile applications such as car airconditioners especially Electric vehicles.

Besides these the technology has a potential to be of

practical importance in almost all applications of

refrigeration & air-conditioning.

CONCLUSION

Magnetic Refrigeration is a clean, environmentally friendly

technology, which replaces the environmentally hazardous

refrigerants in a vapour compression system with a

magneto-caloric substance & a heat transfer fluid, which

are environmentally friendly. With the ever increasing

concern about environmental hazards it promises to be a

technology of the future. However, before the widespread

use of magnetic refrigerators can begin in both industrial &

commercial application, the technology has to cross a few

technical hurdles & prove it is worth. But it won't be long

before we will see magnetic refrigerators take over from

the conventional vapour compression system in all the

fields of application.

REFERENCES

[1].

Gschneidner, Karl, VitalijPecharsky and Carl Zimm,

Magnetic Cooling for Appliances,

International Appliance Technical Conference

Proceedings,May, 1999.

[2].

[3].

Gschneidner, Karl, VitalijPecharsky and Carl Zimm, New

Materials for MagneticRefrigeration Promise Cost Effective,

Environmentally Sound Air Conditioners,

Refrigerators/Freezers, and Gas Liquefiers, Material

Technology, p. 143, 1997.

Wilkinson, Sophie L. Playing It Cool, Science/Technology,

April 2000.

[4].

[5].

[6].

Gschneidner K.A. Jr, Pecharsky V.K. and Tsokol A.O., 2005,

Recent developments in magneto-caloricmaterials, Institute of

Physics Publishing, Rep. Prog. Phys. 68, p. 1479-1539.

Youtube, www.youtube.com/magneticrefrigeration

"A Course In Refrigeration & Air-conditioning" by

S. C. Arora & S.Domkundwar. Publication:DhanpatRai& Co. (P) Ltd. Seventh Edition.

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Larsen and Toubro RVNL Bid Document Rock Bolts PDFДокумент240 страницLarsen and Toubro RVNL Bid Document Rock Bolts PDFSubhash Kedia100% (1)

- Reference Jica-Chodai Scouring Manual in ThailandДокумент175 страницReference Jica-Chodai Scouring Manual in ThailandSeptinurriandianiОценок пока нет

- GERMAN Embassy ContractДокумент79 страницGERMAN Embassy ContractVE.03 QELОценок пока нет

- BITS Herald Summer Issue 2013Документ23 страницыBITS Herald Summer Issue 2013Bits Herald100% (1)

- What MobileДокумент100 страницWhat MobiledoarraulОценок пока нет

- Laplace MPNI 1150Документ20 страницLaplace MPNI 1150mansyur yadi67% (3)

- Jovan Marjanovic Theory of Gravity MachinesДокумент10 страницJovan Marjanovic Theory of Gravity MachinesWilhelm HartmanОценок пока нет

- CilindarДокумент44 страницыCilindardjoko123Оценок пока нет

- Chap 3 HW AssignmentДокумент3 страницыChap 3 HW AssignmentBren OngОценок пока нет

- Gad Ad2 J10k1020c27a 200a201Документ1 страницаGad Ad2 J10k1020c27a 200a201AbdulОценок пока нет

- Taglio Sez Circ 2Документ3 страницыTaglio Sez Circ 2mariorossi_4Оценок пока нет

- GasesДокумент102 страницыGasesLya EscoteОценок пока нет

- Fuji Xerox cp105b Service Manual PDFДокумент2 страницыFuji Xerox cp105b Service Manual PDFSyaf RoniОценок пока нет

- Doka Large Formwork User ManualДокумент21 страницаDoka Large Formwork User ManualNasir AryaniОценок пока нет

- Overall EWD Vehicle Exterior Rear Fog LightДокумент10 страницOverall EWD Vehicle Exterior Rear Fog Lightgabrielzinho43Оценок пока нет

- Congratulations On The Purchase of Your New Antari Z Series Fog MachineДокумент20 страницCongratulations On The Purchase of Your New Antari Z Series Fog MachineWalter SeidlОценок пока нет

- SPE-184314-MS PVT Analysis: Validity Checks and EOS Tuning Techniques For Retrograde Gas Condensate ReservoirsДокумент12 страницSPE-184314-MS PVT Analysis: Validity Checks and EOS Tuning Techniques For Retrograde Gas Condensate ReservoirshusseinhshОценок пока нет

- 1531 Colibasi H Th1 en Rev 2Документ35 страниц1531 Colibasi H Th1 en Rev 2iahim87Оценок пока нет

- ASSEMBLY AND PARTS ALBUM - Kipor Power Systems - KDE6700TA PDFДокумент2 страницыASSEMBLY AND PARTS ALBUM - Kipor Power Systems - KDE6700TA PDFracsoОценок пока нет

- Toshiba Satellite L650 12Q Laptop ManualДокумент229 страницToshiba Satellite L650 12Q Laptop ManualTasos KachpanisОценок пока нет

- 0108E - Report of Welders-OperatorsДокумент6 страниц0108E - Report of Welders-OperatorsErick AlvarezОценок пока нет

- Cooling Coil SizingДокумент4 страницыCooling Coil SizingRanu JanuarОценок пока нет

- M3 Hull Plate Nesting - SP1Документ50 страницM3 Hull Plate Nesting - SP1Bùi Công Lộc100% (1)

- Manual de Parts ES16D6Документ36 страницManual de Parts ES16D6Eduardo CortezОценок пока нет

- 2019 Centennial ClassДокумент291 страница2019 Centennial ClassGerman Vega0% (2)

- Fastshapes - Sprocket: Typical ApplicationsДокумент23 страницыFastshapes - Sprocket: Typical ApplicationsJimmy MyОценок пока нет

- Screw Conveyor DesignДокумент9 страницScrew Conveyor DesignAJAY1381Оценок пока нет

- Sigmazinc 109 HS: Description Principal CharacteristicsДокумент4 страницыSigmazinc 109 HS: Description Principal CharacteristicsАлексейОценок пока нет

- ENTEC Catálogo GeneralДокумент26 страницENTEC Catálogo GeneralPEDRO RISCOОценок пока нет

- Custom PC Magazine UK January 2013Документ132 страницыCustom PC Magazine UK January 2013Sei LaОценок пока нет