Академический Документы

Профессиональный Документы

Культура Документы

Novel Robust Control Algorithm of DC Motors

Загружено:

nguyenbahai0 оценок0% нашли этот документ полезным (0 голосов)

81 просмотров2 страницыBa Hai Nguyen, Hai-Bac Ngo, Jee-Hwan Ryu, “Novel Robust Control Algorithm of DC Motors,” The 6th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI 2009), Seoul, Korea, 2009.

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документBa Hai Nguyen, Hai-Bac Ngo, Jee-Hwan Ryu, “Novel Robust Control Algorithm of DC Motors,” The 6th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI 2009), Seoul, Korea, 2009.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

81 просмотров2 страницыNovel Robust Control Algorithm of DC Motors

Загружено:

nguyenbahaiBa Hai Nguyen, Hai-Bac Ngo, Jee-Hwan Ryu, “Novel Robust Control Algorithm of DC Motors,” The 6th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI 2009), Seoul, Korea, 2009.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

The 6th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI 2009)

Novel Robust Control Algorithm of DC Motors

Ba-Hai Nguyen Hai-Bac Ngo Jee-Hwan Ryu

Korea University of Technology Korea University of Technology Korea University of Technology

and Education and Education and Education

nguyenbahai@hocdelam.org ngohaibac@hocdelam.org jhryu@kut.ac.kr

Abstract - In this paper, a novel speed control algorithm of

dc motors is presented. The key contribution here is a

robust controller of motor speed created based on the

reference velocity of system. This velocity reference is

adjusted before the controller to improve the control

performance of the motor speed. Therefore, our proposed

velocity control algorithm for dc motors works with only a

PWM signal. The current control loop can be neglected

while the performance of the system is maintained.

Moreover, after this method is applied, a simpler Fig. 1. Electrical diagram of permanent magnet DC motors

controller as well as a less complex turning method of DC

motor’s velocity could be achieved. Those eliminations By applying the Newton's law and Kirchhoff's law to

make the design process of DC motor control convenient, the dc motor system, we have mathematic equations (1)

and less complex. This proposed control method is and (2) of DC motors.

investigated by both mathematic analysis and

experimental results.

di

V =L + Ri + Ea (1)

Keywords - DC motor control, feedback control algorithm dt

of DC motors, reduced control scheme of dc motor, robust •• •

control of DC motor. J Θ + bΘ =τm (2)

Where V is the supply voltage, i the armature current,

1. Introduction Ea is the back-emf (electromotive force). L and R are

the electric inductance, and electric resistance respectively.

Direct current (DC) motors are widely used in industrial

applications including mechatronics, automobile, robotics, J is the moment of inertia of the rotor, b is the damping

and aerospace systems [1, 2]. In those systems velocity ratio of the mechanical part. The motor torque, τm , is

control is one of the most typical topics of dc motor

control. For example the velocity control of mobile robots,

kt

related to the armature current, i , by a constant factor

CD-ROM, electrical screw driver, computer hard-disk, (In SI units, kt (armature/torque constant) is equal to k e

and so on. (motor/speed constant)). The back emf, e, is related to the

In general, an accurate velocity control scheme requires rotational velocity by the equation (3).

two closed-loops, an inner current control loop [1,3] and

an outer velocity control loop. In this paper, a novel robust τ m = kt .i (3)

control method of dc motors is presented. Our proposed

velocity control algorithms for dc motors need only a 2.2 Typical velocity control structure for dc motors

simple PWM signal. The current control loop can be Fig 2 illustrated a typical velocity control structure of

removed while the performance of the system is dc motor. The control scheme consists of an inner current

maintained. Moreover, after this method is developed, a control loop. And an outer velocity control loop. The

simpler controller as well as a less complex turning output signal of velocity controller is the input of the

method is possible. current controller. Those two controllers can be designed

independently because the mechanical dynamics of the

2. General velocity control method of dc motors system is usually much slower than the dynamics of the

2.1 DC motor modeling armature circuit.

•

The electrical diagram of the permanent magnet DC

Reference velocity Θ ref is the desired velocity which

motor is shown as Fig. 1. According to the Kirchhoff law,

the electrical equation of DC motors can be expressed as the motor should be achieved after designed time. The

Equation (1). controller found in typical industrial systems is PID

control algorithm. It also can be include fuzzy, neural

network, or adaptive controllers. The current sensor and

The 6th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI 2009)

encoder are usually used as feedback devices in the novel control scheme shown in Fig. 3 is able to provide

system. zero steady-state error.

4. Experiment and result

4.1 Experimental setup

The experiment was set as Fig. 4. A DC maxon

motor was used. The encoder had 4096

pulse/revolution. An PCI board (NI PCI 7356) was

Fig. 2. A typical velocity control structure for dc motor used to connect the DC motor with an user interface

developed in LabVIEW inveronment.

GUI NI PCI 7356 Motor Driver Maxon Motor

3. Novel robust velocity control algorithms

3.1 Overview of proposed velocity control

algorithms

To simplify the velocity control of DC motors, we have

Encoder

proposed a new control scheme shown in Fig. 3. The novel

concept here is the original reference velocity is multiply

with a gain m . The modified reference now becomes the

reference input of the controller. With this modification, Fig. 4. Proposed scheme for motor velocity control

the current control loop can be removed in this control

scheme while steady-state error can be converged to zero.

4.2 Experimental result

The detail analysis of steady-state error and the method to

Fig. 5 shows experimental result of proposed

find the exact value of m are presented in session 3.2.

method. Measured velocity follows reference

velocity with error 7%, and setting time is 2 ms.

ng u yễn bá h ải, la bvi e w t ut orials , la b vi e w

Fig. 3. Proposed scheme for motor velocity control

3.2 Mathematical analysis of the proposed

algorithm

Let consider a P controller for velocity control loop in

typical control scheme in Fig. 2. The closed loop system

can be described as:

•

• K p .G ( s )

Θ = 1+ K .Θ d

p .G ( s ) Fig. 5. Experimental result of proposed control method

K obj

where G ( s ) = is the transfer function of the DC motor

s + Tobj 5. Conclusion

A novel and simple control scheme of motor

K obj and Tobj are constant which relate to motor

velocity was proposed. The steady-state error is proved

parameters. The error is given by: to be converged to zero. Its feasibility was

• • •

1

E ( s ) = Θ d − Θ= .Θ d demonstrated with experimental result.

1 + K p .G ( s )

• d

Ωd References

For a step reference input : Θ ( s ) =

s

s + Tobj Ωd [1] S. C. Won D. J. Lim D. H. Chyung, “D-C motor

We have, E ( s) = . driven robotic manipulator control,” IEEE Decision

s + K p K obj + Tobj s

and Control, Vol. 24, pp. 330-333, 1985.

Therefore, the steady state error e

ss

satisfies: [2] Ba-Hai Nguyen, Jee-Hwan Ryu, “Direct Current

Tobj Measurement Based Steer-By-Wire Systems for

ess = lim e(t ) = lim sE ( s) = .Ω d > 0 Realistic Driving Feeling,”, Proceedings of the IEEE

t →+∞ s→0 K p K obj + Tobj

International Symposium on Industrial Electronics, pp.

The steady-state error can be calculated as followings: 1023-1028, 2009.

Tobj [3] Kenji KANEKO et al., “High Stiffness Torque Control

Ω d − Ω = ess = .Ω d

K p K obj + Tobj for a Geared DC Motor Based on Acceleration

Ωd 1 Controller,” Industrial Electronics, Control and

= =m

Ω Tobj Instrumentation, 1991. Proceedings, vol.1, pp. 849 –

1−

K p K obj + Tobj 854, 1991.

It means we can get the steady state velocity equals to Mathworks, “Manual of Control System Toolbox,”

d 2009.

Ω d if the reference input equals to m.Ω . Therefore, the

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Human Resource Management - Introduction - A Revision Article - A Knol by Narayana RaoДокумент7 страницHuman Resource Management - Introduction - A Revision Article - A Knol by Narayana RaoHimanshu ShuklaОценок пока нет

- Mysuru Royal Institute of Technology. Mandya: Question Bank-1Документ2 страницыMysuru Royal Institute of Technology. Mandya: Question Bank-1chaitragowda213_4732Оценок пока нет

- 3a. Systems Approach To PoliticsДокумент12 страниц3a. Systems Approach To PoliticsOnindya MitraОценок пока нет

- Bsa 32 Chap 3 (Assignment) Orquia, Anndhrea S.Документ3 страницыBsa 32 Chap 3 (Assignment) Orquia, Anndhrea S.Clint Agustin M. RoblesОценок пока нет

- News/procurement-News: WWW - Sbi.co - inДокумент15 страницNews/procurement-News: WWW - Sbi.co - inssat111Оценок пока нет

- Teaching Smart People How To LearnДокумент18 страницTeaching Smart People How To LearnAbhishek KandeyОценок пока нет

- HANA Heroes 1 - EWM Lessons Learned (V2)Документ40 страницHANA Heroes 1 - EWM Lessons Learned (V2)Larissa MaiaОценок пока нет

- Fouzia AnjumДокумент3 страницыFouzia AnjumAbdul SyedОценок пока нет

- 19C Financials WNДокумент60 страниц19C Financials WNbishwabengalitolaОценок пока нет

- Understanding FreeRTOS SVCДокумент11 страницUnderstanding FreeRTOS SVCshafi hasmani0% (1)

- Lucero Flores Resume 2Документ2 страницыLucero Flores Resume 2api-260292914Оценок пока нет

- British Forces in 2nd Battle of AlameinДокумент10 страницBritish Forces in 2nd Battle of AlameinDinko Odak100% (1)

- Title To The ProjectДокумент14 страницTitle To The ProjectJatinChadhaОценок пока нет

- BSNL Project MBA NitishДокумент92 страницыBSNL Project MBA NitishAnkitSingh0% (2)

- Spectrochem Chemindex 2016 17Документ122 страницыSpectrochem Chemindex 2016 17Nivedita Dube0% (1)

- Revamping An Integrated Hydrocracker and Lube Base Oil UnitДокумент5 страницRevamping An Integrated Hydrocracker and Lube Base Oil UnitVyacheslavОценок пока нет

- Raspberry Pi Installing Noobs OSДокумент3 страницыRaspberry Pi Installing Noobs OSEXORCEОценок пока нет

- Bid Submission SheetДокумент3 страницыBid Submission SheetARSE100% (1)

- Event MCQДокумент9 страницEvent MCQpralay ganguly50% (2)

- NammalvarДокумент22 страницыNammalvarPranesh Brisingr100% (1)

- U-Blox Parameters Setting ProtocolsДокумент2 страницыU-Blox Parameters Setting Protocolspedrito perezОценок пока нет

- Layer 3 Managed 8 10G Port Switch Controller: RTL9303-CGДокумент55 страницLayer 3 Managed 8 10G Port Switch Controller: RTL9303-CG박윤지100% (1)

- Literature Review 2500 WordsДокумент6 страницLiterature Review 2500 Wordsvvjrpsbnd100% (1)

- Malinta - Malolos Via Mcarthur Hi-Way: Jeep Bus Time Schedule & Line MapДокумент6 страницMalinta - Malolos Via Mcarthur Hi-Way: Jeep Bus Time Schedule & Line MapMitchie CimorelliОценок пока нет

- Qrqs"1 Xl/Ijj1L Joi?Llt'Lll: Transport Bhawan, 1, Parliament Street New Delhi-110001Документ2 страницыQrqs"1 Xl/Ijj1L Joi?Llt'Lll: Transport Bhawan, 1, Parliament Street New Delhi-110001PrakashKommukuriОценок пока нет

- Bar Q Salaries Part 2Документ5 страницBar Q Salaries Part 2Brigette DomingoОценок пока нет

- BSC IT SyllabusДокумент32 страницыBSC IT Syllabusஜூலியன் சத்தியதாசன்Оценок пока нет

- Compose Testing CheatsheetДокумент1 страницаCompose Testing CheatsheetEstampados SIn ApellidoОценок пока нет

- 3d Mug Tutorial in 3d MaxДокумент5 страниц3d Mug Tutorial in 3d MaxCalvin TejaОценок пока нет

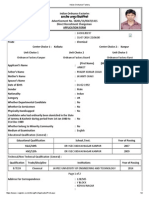

- Indian Ordnance FactoryДокумент2 страницыIndian Ordnance FactoryAniket ChakiОценок пока нет