Академический Документы

Профессиональный Документы

Культура Документы

Us 4956194

Загружено:

patelpiyushbАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Us 4956194

Загружено:

patelpiyushbАвторское право:

Доступные форматы

United States Patent 119]

[11] Patent Number:

[45] Date of Patent:

Gos

54

[ 1

METHOD FOR ACCELERATIN THE

AGING 0F DWI-Es

.

[76] Invmm"

4,956,194

Sep. 11, 1990

FOREIGN PATENT DOCUMENTS

2459)

13" 6" 43 Cass St" spnng?eld'

5/1987

Fed. Rep. of Germany .... .. 426/592

1-157372 6/1989 Japan ................................. .. 426/592

M' 01104

464618 11/1975 U.S.S.R. ............................ .. 426/592

[21] And No: 483341

Primary Examiner-Carolyn Paden

[22] Filed:

Attorney, Agent, or FirmH. Jay Spiegel

Feb. 21, 1990

[51]

1m. 01.5 ............................................. .. c1211 1/22

[52]

US. Cl. ................................... .. 426/592; 426/489

[58] Field 61 Search ............. .. 426/592, 494, 425, 489,

Q6/3303 330A 429 431, 11, 15

-~

[56]

ABSTRACT

.

The Presem_m". relates}? a PM? math.

for accelerating the aging of dlstlllates. In the mventlve

method, the addition of a tree bark either m a crushed

Refmllm Cited ,

form or as an extract is added to the distillate during the

us PATENT DOCUMENTS

aging of the distillate in wooden barrels. Additonally,

Re. 21,589 10/1940 Krebs ................................ .. 426/425

2,088,585 8/1937 Chambers

2,119,234

[57]

426/238

.apple ngtmd9ay$s be added t: mam the

fgmg Pmcess' y

_ mg

e, mP,n 5 an_ as?

5/1938

Krebs . . . . . . . . .

. . . . . .. 426/11

1118 fr a Predetcfmmed Pemd of tune, the mvemlve

2,132,435 10/1938

1161mm . . . . . .

. . . .. 426/592

method produces distillates that have comparable'quali

2,196,193 4/1940 Chambers ..

426/238

gel: - ~ - - ,

2,417,505

4,210,676

... ..

. . . ..

3/1947 Krebs _ ' . ' n

. . _ " 426L592

7/1980 Dlidar ....................... .. 426/238

4,350,708 9/1982 Ruiz de Palacios

4,576,824

3/1986

ties to distillates that have been seasoned for 12 years. A

variety of types of tree barks may be utilized in the

-~--

mgfntlve method, mcludmg the bark from oak and

W w "ces

426/592

Gubiev .............................. .. 4267592

16 Claims, No Drawings

4,956,194

be made and the extract added to the distillate during

aging.

METHOD FOR ACCELERATING THE AGING OF

DISTILLATES

(c) The accelerated aging process using these tree

barks may be utilized with various types of distillates,

BACKGROUND OF THE INVENTION

5 including grain distillates, wine distillates or fruit distil

lates. Additionally, the inventive process may be prac

The present invention relates to an improved method

ticed on distillates having no aging performed thereon

for accelerating the aging of distillates. Heretofore,

or distillates that have been aged for a short period of

alcoholic distillates such as whiskey have been aged in

time.

oak barrels or casks over long periods of time. During

this aging time, the distillate reacts within the oak barrel 0 Accordingly, it is a ?rst object of the present inven

tion to provide an improved method for accelerating

to produce a higher quality distillate. The wooden bar

the aging of distillates.

rels are usually stored in warehouses at a constant tem

It is a further object of the present invention to pro

perature, which signi?cantly increases the cost of the

?nal product. Given the long length of the aging period

vide a method of aging of distillates using a tree bark to

and the costs incurred, various methods and devices

accelerate the aging process.

have been developed to speed up the aging process.

It is a yet further object of the present invention to

However, Applicant is unaware of any prior art pro

provide a method wherein the tree bark may be added

cesses that teach or fairly suggest all of the features of

directly to the distillate or may be added indirectly to

the present invention including using a tree bark to

the distillate in an extract form.

20

accelerate the aging process.

It is still a yet further object of the present invention

The following United States patents are known to

to provide a method for accelerated aging of distillates

Applicant:

that may be practiced upon a wide variety of distillates,

US. Pat. No. 2,119,234 to Krebs, et al. teaches a

unaged and aged.

method of accelerating the aging process for whiskey

These and other objects, aspects and features of the

and is seen to include the addition of oakwood shavings 25 present invention will be better understood from the

during the maturation process. Of course, the Krebs, et

following speci?c description of the preferred embodi

al. patent is different from that of the present invention

ments.

in that there is no suggestion of using a tree bark to

accelerate the aging process.

SPECIFIC DESCRIPTION OF THE PREFERRED

EMBODIMENTS

In the distillation process of various types of liquors, _

a vital step to produce a palatable product includes the

aging or maturation step. In this step, the distillate is

35 normally put into a wooden barrel and is aged over a

U.S. Pat. No. 4,350,708 to Ruiz de Palacios teaches a 30

method of accelerating the aging of liqueurs by the

addition of an extract produced from oakwood shavings

to the distillate during the aging process. Again, the

teachings of this patent do not include any suggestion to

add a tree bark to a distillate during the maturation

process.

US. Pat. No. 4,173,656 to Duggins teaches a method

for aging liquor similar to the aforementioned patents,

wherein particles of charred oakwood are added to the

period of years to produce a smooth, high quality distil

late that may be consumed. In the prior art, methods

have been employed to accelerate this aging process

because of the extended length of time involved as well

liqueur to accelerate the aging process. The teachings of 40 as the economic costs. In one method, it has been pro

posed to add oakwood shavings or particles into the

this patent fail to suggest the addition of a tree bark or

wooden barrels to accelerate the aging process. It is to

this type of acceleration process that Applicants inven

tion is drawn. Applicant would like to incorporate by

U.S. Pat. Nos. 2,207 to Oliver and 6,130 to Hopkins

are only generally related to the method of distilling 45 reference the teachings contained in the book Chemis

an apple concentrate to the distillate during the process

of aging.

liquors.

SUMMARY OF THE INVENTION

The present invention relates to an improved method

try of Cognac by Lafon, published in Paris by Bailliere

in 1973 and 1978, which more-fully explains the aging

process of distillates including the specific chemistry

for accelerating the aging of distillates. The present

invention includes the following interrelated aspects

involved.

Applicant has discovered that the aging process for

distillates may be accelerated by the addition of the bark

and features:

of trees to distillates that are to be aged or have been

aged for a short period of time in wooden barrels. Addi

(a) In a first aspect, the method for accelerating the

tionally, Applicant has discovered that the aging pro

aging of distillates includes the step of the addition of a

tree bark to a distillate during the aging of the distillate 55 cess is accelerated by the addition of an apple concen-_

trate along with the tree bark during the aging process.

in a wooden barrel. A preferred tree bark may include

As will be described hereinafter, the addition of tree

bark from oak trees or the bark from willow trees. In

bark and apple concentrate to unrecti?ed distillates and

addition to the tree bark, a quantity of apple concentrate

may be added to the distillate to further accelerate the

aging process. The addition of these components to an

unrecti?ed distillate and aging this distillate for a period

of approximately one year has been shown to produce a

distillate comparable in taste and quality to a distillate

that has been aged for approximately twelve years.

aging the mixture for about one year results in a distil

late that has the same qualities as a distillate that has

been aged in wooden barrels for about twelve years.

A preferred tree bark for the inventive process in

cludes bark from oak trees or willow trees. Since most

of the aging of distillates is now performed in oakwood

(b) The addition of the tree bark may be done in a 65 barrels, the addition of oak bark provides components

direct method whereby the tree bark is crushed and

that are similar to the components that are provided in

added directly to the wooden barrel during the aging

process. Alternatively, an extract of the tree bark may

the aging process from the oakwood barrels. The wil

low bark also has similar components as the oakwood,

4,956,194

with additional compounds that will be described here

inafter.

Regarding the bark from oak trees, Applicant has

discovered that certain tree barks provide better aging

characteristics than others. One type of tree bark useful

in the accelerated aging process may include oak bark

from the branches of young oak trees. It has been found

that branches 5-6 centimeters in thickness from 2-4

year-old oak trees may be especially adaptable for the

inventive process. It should be noted that the bark from

branches of young oak trees should be dried in prepara

tion for the aging process. If a drying step is necessary

prior to adding the bark to the distillate, the drying

temperature should not exceed 100 degrees Fahrenheit.

A second type of oak bark that is adaptable to the

aging process may include the bark from oak tree

trunks. This type of bark is best derived from oak trees

to about 2 liters of apple juice concentrate per liter of

distillate to be aged.

In the actual aging process, the tree bark and apple

concentrate may be added in different ways. In a first

method, the tree bark may be crushed and added di

rectly to the barrel with the apple concentrate. The

crushed tree bark may be placed in a fabric such as

chiffon or gauze and then put into the barrel. In this

method, the contact between the distillate and the wood

barrel should be at least about 20 cm2 of wood barrel

surface area to liter of distillate. If the area of contact is

less than 20 cmz/l, it is necessary to place in the barrel

an appropriate amount of pieces of oak wood taken

from old barrels that are no longer used for aging.

In the second method, an extract of the tree bark may

be produced and the then formed extract added to the

distillate for the aging process. The extract may be

made in the following manner. A recti?ed rye spirit or

that range in age from 80 to 300 years old.

It should be noted that when using tree bark from any

unrecti?ed spirit for the production of whiskey or wine

source for the inventive accelerated aging process, bark 20 distillate of strength 47% by volume of alcohol-94

proof in a quantity of about 700 liters should be used to

having a contamination, mildew or signs or decay

should not be used. In comparing barks from oakwood

infuse 100 kg of the crushed oak bark. The mixture

trees, it has been shown that when a solution has been

should then be stirred or the distillate should circulate

prepared from crushed bark, the solutions derived from

through the bark for 7 hours a day. After six days, this

bark containing evidence of decay, mildew or ligni?ca 25 ?rst extract should be poured into an oakwood vat. The

tion had a perceptable bitterness in taste as compared to

solutions derived from bark without such types of con

tamination.

same crushed oak bark should then be again infused

with spirit or wine distillate in the quantity of 450 liters

Concerning the addition of the apple concentrate to

the distillate during the aging process, the apple concen

ture should then be stirred or circulated as described

30 above for 7 hours a day. After 14 days, this second

trate may be derived from conventional methods that

are well known in the art, such methods not intended to

extract should be poured into the oakwood vat and

mixed with the first extract. This process should yield a

of strength, 70% volume alcoholl40 proof. This mix

be an aspect of the present invention. A preferred apple

total of approximately 1,000 liters of extract having a

strength of approximately 55% volume alcohol --1 l0

include sour apples. In particular, a sour apple variety 35 proof. In making this extract, recti?ed potato or grain

spirits may be used as the distillate. After the extract has

cultivated in Poland, i.e., Antonowka, has been uti

to be used as a source for the apple concentrate may

lized in the aging process. Of course, other sour apples

been made, it may be stored in oakwood vessels to

such as Granny Smith or McIntosh may be used as the

improve the quality.

source of the apple concentrate.

In the method of using an extract in the aging process,

The addition of the apple concentrate to the distillate 40 a surface area contact of about 60 cm2 of wood barrel

during the aging process introduces the apple acid

which is similar to the type present in oak trees and

oakwood and which assists in respiration during the

aging process. Typically, 100 grams of apple juice con

surface area per liter of distillate being aged should be

maintained. In the method of using an extract, old oak

. tains approximately 88 to 90 grams of water with the 45

wood barrels (previously used) must be used. This

method is used normally when the barrel capacity for

the aging process is less than 500 liters. When larger

. remaining extract (mass) containing the sugars, acids,

barrels are used, the direct method using a crushed oak

solids, etc. from the apple juice. In the inventive pro

cess, normal apple juice is not sufficient in concentra

tion to produce the desired apple acids necessary to

bark addition to the distillate is preferred.

The method of the present invention may be prac

ticed on distillates such as unrecti?ed grain spirits made

render the addition of apple concentrate to the process 50 of rye or barley, wine distillates, or fruit distillates.

effective. A preferred concentration of the apple juice

Furthermore, the accelerated aging process may be

for addition to the distillate ranges from about 65-68%

practiced on unrecti?ed fresh distillates or distillates

by weight, i.e., 68 grams of extract per 100 grams of

that have been aged two, three or five years. In either

concentrate or about six times the concentration of a

case, the accelerated aging process produces an end

typical'apple juice. Apple concentrates having this per 55 product comparable to products aged some ten to

centage by weight contain about at least 4% by weight

twelve years with only approximately three months to

of acid content. This amount of apple acid corresponds

about one year of aging.

generally to the amount of acid formed in the distillates

In the actual process of maturing or aging distillates,

made by the traditional aging of distillates in barrel

the distillates extract from the oakwood barrels tanning

having a capacity of 250-500 liters within l0-l2 years.

agents, lignins and hemicellulose. Typically, the dry

Apple concentrate also introduces into the spirits a

oakwood would contain about 45% cellulose, 25%

sugar, i.e., fructose, which is one of the main sugars

hemicellulose, about 23% lignin, and up to about 15%

found in aged spirits. It should be noted that one skilled

extract substances with tanning agents. On the other

in the art could readily obtain the preferred concentra

hand, the oak bark may contain up to about 20% cellu

tion of apple juice by merely concentrating or diluting 65 lose, up to about 17.5% hemicellulose, up to about 49%

an apple juice concentrate of any known concentration.

lignin, and up to about 30% extract substances with

The amount of apple juice concentrate added to the

tanning agents. When comparing the oakwood to the

distillates may vary, but a preferred amount ranges up

oak bark, it is apparent that the oak bark may have

4,956,194

nearly twice the content of tanning agents, lignin and

months. An extract based upon the crushed oak bark

from a tree trunk using 95% alcohol caused the forma

extract substances. To demonstrate this difference, the

tion of lignin aromatic compounds only after ten days.

Regarding the fatty acids, the fatty acids which are

same method of producing an extract of oak bark was

used for both oakwood chips and crushed oak bark.

After evaporating the extract from the oakwood chips,

a dry mass of 3.681 g/l was obtained and evaporating

normally contained in the distillate, C5C14 as well as

their esters, are normally transformed by mildew en

zymes into ketones. It is likely that the ketones shall

occur to a larger extent and more quickly through aging

in distillates with the addition of oak bark and apple

concentrates due to the action of the already existing

oxidized compounds and enzymes toward the existing

main fatty acids. This acceleration in the aging process

the extract derived from the oak bark, a dry mass of

7.3975 g/l was obtained. Additionally, the oakwood

extract contained 2.2 g/l of tanning agents, whereas the

oak bark extract contained 4.45 g/l of tanning agents.

As can be seen from this comparison, the oak bark ex

tract is seen to contain twice the amount of tanning

agents and dry mass as the oak tree extract.

has been con?rmed by practical application, wherein

During the maturation process, the transformation of

the accelerated aging process of the present invention

the tanning agents, lignin and fatty acids in the distillate

produce compounds which give the distillate the bou

quet necessary to produce a high quality product. This

transformation is aided by molds and fungi that origi

pa 5 has shown the same transformation of the fatty acids

nate on the oakwood barrels or the oak bark. The same

kind of mildew found on the oakwood barrels is present

on the oak bark. The enzymes associated with this mil

dew retain part of their activity even when the alcohol '

content of 140 proof distillate is used during the aging

process.

after only one year as compared to the traditional aging

process of approximately twelve years. As is apparent,

the increased lignin amount found in the oak bark con

tributes to the quicker formation of the aromatic vanil

lin compounds that contribute to the enhancement of

the ?avor of the distillate.

Several experiments have been conducted showing

the comparisons between distillates aged according to

the improved accelerated aging process as compared to

distillates aged in oakwood barrels according to prior

Regarding the tanning agents found in oakwood and 25

art methods. The ?rst series of experiments used oak

oak bark, these tannins include the tannins of gallic acid,

bark derived from 5-6 cm thick branches of 2-4-year

catechol acid, etc. This is an inde?nite group of tanning

agents containing gallotannins and flobotannins as well

old oak trees. Using the direct addition method, 8.5 kg

of this oak bark was mixed with 1,000 liters of 140 proof

as products of their decay. Among the characteristic

non-tannic components associated with the aging pro 30 distillate and 2 liters of apple juice having a mass con

centration of 68% by weight. The contact of the distil

cess there is found cyclic alcohol-quercit and quercitron

late in the wood barrel was approximately 20 cmz/l.

belonging to the type of Vitamin P. These compounds

This experiment employed unrecti?ed rye spirit, the

may be found in spirits that have been aged in oakwood

same spirit that was used during aging in oak barrels

barrels for many years. Comparing the oakwood to the

oak bark, the oakwood generally contains more com

having a capacity of 250-500 liters at an average tem

plex compounds. For example, in oak bark there is gal

perature of approximately 57 F. The samples accord

ing to the present inventive method had undergone

lic acid, and in oakwood there is m-2-gallic acid. The

m-2-gallic acid is of a tannin type with its esters and

glicosides being stringent and bitter tasting substances.

Only hydrolysis and oxidation of m-2-gallic acid gives

the gallic acid which has a gentle and pleasant taste.

During many years of seasoning of oakwood in the

open air, the m-2-gallic acid divides itself into two parti

cles of gallic acid by the enzymes emitted by the various

approximately one year of aging at a temperature of

approximately'68 F. and the organoleptic estimation

40 showed that this method was equivalent to the effect of

aging the distillate for twelve years in 250-500 liter

barrels at an average annual temperature of 57 F. The

taste of the samples from the inventive method was

better than that of the 12-year-old aged distillate. In the

mildews associated with the oakwood or bark, i.e., as 45 l2-year-old age distillate, the odor of ethyl acetate ester

perqulis niger. The fact that the simpler compounds

already exist in the oak bark reduces in time the lengthy

aging process for distillates in oakwood, wherein the

more complex compounds found in oak trees must be

broken down by oxidation and hydrolysis.

Furthermore, the lignin that occurs in oak bark is also

and acetic aldehyde was predominating. The samples of

the inventive process were more abundant in less vola

tile odors due to the oak bark. The physical and chemi

cal properties, i.e., acid content, content of dry mass,

50 sugars and others, corresponds to about 14 to 20 years

of aged distillate in oakwood barrels at an average tem

in simpler fragments than the oakwood lignin. The

products of the degradation of the oakwood lignin are

perature of 57 F.

was subject to an extraction with 100% alcohol and was

aged conventionally for 12 years.

Using the same oak bark, and the indirect method of

the inventive process, approximately 95-100 liters of

formed in a biochemical way on the outer surface of the

barrel which then penetrate through the layers of wood, 55 oak bark extract should be mixed with 1,000 liters of

distillate and 2 liters of apple concentrate with the same

wherein they encounter the spirit compounds. The con

concentration as aforementioned. The aging of this

tent of the lignin in the oak and willow bark is approxi

mixture should be carried out in old oakwood barrels of

mately twice that which is contained in the oakwood.

250-500 liter capacity for approximately one year at an

During the spirit aging process, the lignin gives off

annual average temperature of 68 F. The quality of this

aromatic compounds of the vanillin type. In comparing

aged distillate should be equivalent to that of a distillate

the different amounts of lignin, an oakwood sawdust

seen to give off lignin aromatic compounds of the vanil

lin type and vanillin itself after four years. In compari

The inventive method using the same type of oak

bark was also utilized with 120-140 proof distillates

son, an extract based upon crushed oak bark from the 65 which were two years, three years, and ?ve years old.

branches of two-to-four-year-old oak trees using alco

The addition of 60 liters to Z-year-old distillate, 50 liters

hol of 95% concentration caused the formation of lignin

aromatic compounds of the vanillin type after only two

to 3-year-old distillate, and 40 liters to S-year-old distil

late of the oak bark extract and 2 liters of apple concen

4,956,194

trate to 1,000 liters of the aforementioned distillate pro

duced a ready product after only three months of sea

soning. In this method, whiskey, brandy, calvados, or

natural plum-vodka types may be used. Additionally,

the color may be corrected by the use of caramel and

the smell may be strengthened by adding approximately

0.5 liters of vanilla extract which contains 0.05 kg of

vanilla per liter for every 1,000 liters of distillate.

As is well known in the art, the color and smell of

distillates may be altered, if necessary, by adding cara

mel and a vanilla extract. The method of making of

vanilla extract is well known in the art and is not consid

ered an aspect of the present invention. Using the pres

ent inventive process, it is possible to avoid the addition

of these compounds to distillates and still produce a

high quality distillate."

Using the oak bark from 80-300-year-old oak tree

trunks, and the direct addition method, only approxi

mately 5 kg of crushed oak bark and 2 liters of apple

concentrate for every 1,000 liters of 140 proof distillates

are needed. Using a contact with the wood of 20 cm2

raw materials as obtained from trees grown in Poland.

Oakwood from oak trees grown in Poland is of light

color. There may occur some small differences while

using oak bark from trees grown in the United States,

but with the suggested amounts, the effects should not

be signi?cant to change the results as described herein

above.

One of the advantages of an accelerated maturation

process is the bene?t in the economics associated with

the production of the distillate. During the maturation

process, the strength and volume of the distillate are

diminished. The losses for a year generally range in the

amounts of 1% of strength and 3% of volume. Conse

quently, a distillate that is aged for 10 years would have '

a signi?cant amount of loss of strength and volume.

These losses are re?ected in the price of the as-pro

duced product. With the accelerated aging process,

these losses in strength and volume are greatly reduced,

and consequently re?ect in a favorable economic effect.

Additionally, the decreased aging time also results in

less sediments in the form of precipitated iron and cop

per because the tanning agents are already in oxidized

form prior to the beginning of the aging process.

per liter, the distillate is stirred several times during the

approximately one year seasoning period. After the

one-year aging period, the distillate is comparable to

It should also be noted that the tree bark does not

distillate aged for approximately 12 years.

25

contain

any compounds that are hazardous to human

Using the indirect method and the oak bark from the

health. In fact, oak bark has been used to bake bread and

80-300-year-old oak trees, 45 liters of oak bark extract

as a source of tea in past years. The willow bark, Cortex

and 2 liters of apple concentrate are added to 1,000 liters

Salicis, containing salicylic acid, has been the aspirin

of 120 proof spirit. After one year of aging at an annual

average temperature of 68 F. in old barrels having a 30 of our ancestors.

As such, an invention has been disclosed in terms of a

capacity of 250-500 liters, the distillate obtained is com

preferred embodiment thereof which ful?lls each and

parable to distillates aged for approximately 12 years.

every one of the objects of the invention as set forth

Using the same oak bark as described above, i.e.

hereinabove and provides a new and improved method

80-300-year-old oak trees, bark extracts of amounts 20,

for accelerating the aging of distillates having great

25 and 30 liters and 2 liters of apple concentrate were

added to 1,000 liters of 5-year, 3-year and 2-year-old

120-140 proof distillates, respectively. After three

months of seasoning, there should be obtained a product

of distillate comparable in quality to that of distillates

aged for 12 years.

In a further mode, the bark of willow trees which

were about 50 years old was used. The willow bark

should be taken from tree trunk lower parts, 2-3 cm

thick. In the direct method, utilizing a wood surface

contact of approximately 20 cmz/l, approximately 9 kg

novelty and utility.

Of course, various changes, modi?cations and alter

ations in the teachings of the present invention may be

- contemplated by those skilled in the art without depart

ing from the intended spirit and scope thereof. As such,

it is intended that the present invention only be limited

by the terms of the appended claims.

I claim:

1. A method of accelerating the aging of distillates in

wooden barrels comprising the steps of:

of the crushed willow tree bark, and 2 liters of the apple

juice concentrate of 68% by weight mass concentration

were added to 1,000 liters of 140 proof distillate. The

(a) adding a distillate to a wooden barrel;

(b) adding an amount of tree bark in a suf?cient quan

distillate with the willow bark mixed therein was stirred

(c) aging said mixture of distillate and oak bark for a

several times during the one year of aging period. After 50

one year of aging at a temperature of approximately 68

period of time;

(d) whereby said distillate a?er said aging step ap

tity to accelerate the aging of said distillate; and

F., the obtained distillate was equivalent to a distillate

proximates the taste and quality of a distillate aged

aged for 12 years.

In using the indirect method, a willow bark extract

2. The method of claim 1, wherein said tree bark

10 to 12 years without an addition of a tree bark.

was made as described hereinabove, and approximately 55 comprises oak bark.

3. The method of claim 2, wherein said oak bark

100 liters of extract and 2 liters of apple concentrate

comprises crushed oak bark.

were added to 1,000 liters of 120 proof distillate. After

4. The method of claim 2, wherein said oak bark

one year of aging at a temperature of approximately 68

comprises an extract of oak bark.

F. in old barrels having a capacity of 250-500 liters, the

5. The method of claim 1, further comprising adding

obtained distillate was comparable to a distillate aged 60

a concentrate of apple juice to said distillate prior to

for 12 years. A willow bark extract was added in

said aging step.

amounts of 50, 60 and 70 liters of extract along with 2

liters of apple concentrate to 1,000 liters of 5-year-old,

6. The method of claim 5, wherein said concentrate of

3-year-old, and 2-year-old distillates respectively. After

apple juice has a mass concentration of approximately

3 months of seasoning, a ready product of distillate was 65 65 to 68% by weight.

obtained.

7. The method of claim 3, wherein said amount of

The speci?ed quantities of oak bark and willow bark

crushed oak bark comprises up to about 8.5 kg of oak

are generally considered to be optimum values for the

bark per 1000 liters of said distillate.

4,956,194

10

9 .

of concentrate of apple juice per 1,000 liters of said

distillate.

13. The invention of claim 8, wherein said willow tree

8. The method of claim 4, wherein said amount of oak

bark extract comprises up to about 100 liters of said

extract per 1000 liters of said distillate.

9. The invention of claim 1, wherein said tree bark

comprises willow tree bark.

10. The method of claim 1, wherein said distillate is

bark comprises crushed willow tree bark.

14. The invention of claim 8, wherein said willow tree

bark comprises an extract of willow tree bark.

15. The invention of claim 12, wherein said crushed

willow tree bark comprises up to about 9 kg of crushed

willow tree bark per 1000 liters of said distillate.

16. The method of claim 1, wherein said period of

time ranges between about 2 months and about one

selected from the group comprising grain distillates,

wine distillates and fruit distillates.

11. The method of claim 1, wherein said distillate

comprises an unaged distillate or an aged distillate.

12. The method of claim 1, wherein said amount of

concentrate of apple juice comprises up to about 2 liters

year.

*

15

20

25

30

35

50

55

65

Вам также может понравиться

- Ultramarine Blue - India To PakistanДокумент2 страницыUltramarine Blue - India To PakistanpatelpiyushbОценок пока нет

- Ultramarine Blue - India To Pakistan - 13-07-2019Документ11 страницUltramarine Blue - India To Pakistan - 13-07-2019patelpiyushbОценок пока нет

- DS DN Tai DubaiДокумент337 страницDS DN Tai DubaiMasih Ur Rahman33% (3)

- List of Saudi Importers of Food Products: Sl. No. Name of Importer Address Phone/ Fax E-Mail/ WebsiteДокумент34 страницыList of Saudi Importers of Food Products: Sl. No. Name of Importer Address Phone/ Fax E-Mail/ WebsiteGiri Kanyakumari74% (54)

- Malawian Importers VililiДокумент16 страницMalawian Importers VililipatelpiyushbОценок пока нет

- Company Name Location P.O.Box Tele FAX Email Website: Lorenzo Advertising Entertainment ProductionДокумент4 страницыCompany Name Location P.O.Box Tele FAX Email Website: Lorenzo Advertising Entertainment ProductionpatelpiyushbОценок пока нет

- General Traders South AfricaДокумент47 страницGeneral Traders South AfricapatelpiyushbОценок пока нет

- 3Документ109 страниц3Bala MuruganОценок пока нет

- Thiland Cosmetics Suppliers ListДокумент76 страницThiland Cosmetics Suppliers Listyandan27400272% (18)

- Thiland Cosmetics Suppliers ListДокумент76 страницThiland Cosmetics Suppliers Listyandan27400272% (18)

- Australian Importers of Grocery ProductsДокумент4 страницыAustralian Importers of Grocery ProductsSanjay KoriОценок пока нет

- Malawian Importers VililiДокумент16 страницMalawian Importers VililiSiba Prasad100% (4)

- Fluidization of Marine Mud by WavesДокумент2 страницыFluidization of Marine Mud by WavespatelpiyushbОценок пока нет

- EP0860498A1Документ14 страницEP0860498A1patelpiyushbОценок пока нет

- Patent CN102925326A - Preparation Method of Powder White Spirit - Google PatentsДокумент3 страницыPatent CN102925326A - Preparation Method of Powder White Spirit - Google PatentspatelpiyushbОценок пока нет

- Brand Id 19&product Line Id 343&search Type PL&template 1Документ1 страницаBrand Id 19&product Line Id 343&search Type PL&template 1patelpiyushbОценок пока нет

- Alcohol Powder - Wikipedia, The Free EncyclopediaДокумент4 страницыAlcohol Powder - Wikipedia, The Free EncyclopediapatelpiyushbОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0092636 A1Документ5 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0092636 A1patelpiyushbОценок пока нет

- Lysol Brand III Disinfectant All Purpose Cleaner 4 in 1 US EnglishДокумент7 страницLysol Brand III Disinfectant All Purpose Cleaner 4 in 1 US EnglishpatelpiyushbОценок пока нет

- Us 5173318Документ13 страницUs 5173318patelpiyushbОценок пока нет

- From Helical Starch Inclusion Complexes To Supramolecular Starch AssembliesДокумент4 страницыFrom Helical Starch Inclusion Complexes To Supramolecular Starch AssembliespatelpiyushbОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2009/0068308 A1Документ3 страницыUnited States: (12) Patent Application Publication (10) Pub. No.: US 2009/0068308 A1patelpiyushbОценок пока нет

- SuperPad2 Flytouch3 Tim Rom TipsДокумент4 страницыSuperPad2 Flytouch3 Tim Rom TipspatelpiyushbОценок пока нет

- Brand Id 19&product Line Id 343&search Type PL&template 1Документ1 страницаBrand Id 19&product Line Id 343&search Type PL&template 1patelpiyushbОценок пока нет

- Hostapur Sas 60Документ8 страницHostapur Sas 60betun2011Оценок пока нет

- Brand Id 19&product Line Id 331&search Type PL&template 1Документ1 страницаBrand Id 19&product Line Id 331&search Type PL&template 1patelpiyushbОценок пока нет

- LYSOL Brand Multi Surface Cleaner Complete Clean Pourable US EnglishДокумент7 страницLYSOL Brand Multi Surface Cleaner Complete Clean Pourable US EnglishpatelpiyushbОценок пока нет

- Lysol® All Purpose Cleaner - Trigger - Orange: Material Safety Data SheetsДокумент1 страницаLysol® All Purpose Cleaner - Trigger - Orange: Material Safety Data SheetspatelpiyushbОценок пока нет

- Lysol® All Purpose Cleaner - Pourable - Island Berries: Material Safety Data SheetsДокумент1 страницаLysol® All Purpose Cleaner - Pourable - Island Berries: Material Safety Data SheetspatelpiyushbОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- 2004 Bordeu Proposal For A Standardized Set of Sensory Terms For Pisco A Young Muscat Wine DistillateДокумент5 страниц2004 Bordeu Proposal For A Standardized Set of Sensory Terms For Pisco A Young Muscat Wine DistillateJaime LaquiОценок пока нет

- LiqourДокумент12 страницLiqourOswinda GomesОценок пока нет

- Jameson Information Grain To GlassДокумент9 страницJameson Information Grain To GlassMilen PeninОценок пока нет

- Palmento Sicilian Wine OdesseyДокумент308 страницPalmento Sicilian Wine Odesseyaniruddha behalОценок пока нет

- Temporary BridgeДокумент10 страницTemporary BridgeAnish TayadeОценок пока нет

- Old British Beers PDFДокумент31 страницаOld British Beers PDFjavijavier100% (1)

- Net Equipment List v4.0Документ60 страницNet Equipment List v4.0I_NiemandОценок пока нет

- Fermentation TechniquesДокумент24 страницыFermentation Techniqueskashaf aslamОценок пока нет

- Kubota Tractor B3300su Aus Workshop ManualДокумент23 страницыKubota Tractor B3300su Aus Workshop Manualbrianwong090198pni100% (22)

- Production and history of Scotch and Irish whiskiesДокумент32 страницыProduction and history of Scotch and Irish whiskiesTaurai ChiwanzaОценок пока нет

- WP Brochure - 1023Документ12 страницWP Brochure - 1023JohnRykerОценок пока нет

- David DobbinsДокумент3 страницыDavid DobbinsNitish PrasadОценок пока нет

- Part Des Anges (En) PDFДокумент9 страницPart Des Anges (En) PDFSão Paulo GourmetОценок пока нет

- X13 - Crown of Ancient GloryДокумент70 страницX13 - Crown of Ancient GloryPaolo Allara100% (2)

- Cask of Amontillado Vocab WorksheetДокумент2 страницыCask of Amontillado Vocab WorksheetMean SoriyaОценок пока нет

- ESM503 Fall2010 HW2Документ3 страницыESM503 Fall2010 HW2Ahmed ZidanОценок пока нет

- The Fun Knowledge Encyclopedia Volume 2 The Crazy Stories Behind The World S Most Interesting Facts (Trivia Bill S General Knowledge) Bill O Neill LAK PublishingДокумент288 страницThe Fun Knowledge Encyclopedia Volume 2 The Crazy Stories Behind The World S Most Interesting Facts (Trivia Bill S General Knowledge) Bill O Neill LAK PublishingPhani RajОценок пока нет

- Distilleria Washington Inc vs Honorable Court of Appeals and La Tondena DistillersДокумент1 страницаDistilleria Washington Inc vs Honorable Court of Appeals and La Tondena DistillersCalebОценок пока нет

- Catalogue Fermentation Storage VesselsДокумент5 страницCatalogue Fermentation Storage VesselsandapandistaОценок пока нет

- Hollandus - Mineral WorksДокумент51 страницаHollandus - Mineral Workstravellerfellow100% (1)

- Distilleria Washington VS CaДокумент11 страницDistilleria Washington VS CaJAMОценок пока нет

- The Lincoln Story Book by Williams, Henry LlewellynДокумент157 страницThe Lincoln Story Book by Williams, Henry LlewellynGutenberg.orgОценок пока нет

- Understanding WhiskeyДокумент3 страницыUnderstanding Whiskeysechd100% (12)

- 1000 Best Bartenders Recipes - MalestromДокумент576 страниц1000 Best Bartenders Recipes - MalestromRahul ShrivastavaОценок пока нет

- Ms Assignment 1Документ9 страницMs Assignment 1Marcus Goh100% (1)

- Alligations MixturesДокумент18 страницAlligations MixturesVedant PatneОценок пока нет

- Rum's Guide to Styles, Aging & RecommendationsДокумент15 страницRum's Guide to Styles, Aging & RecommendationsRichard Zhu100% (1)

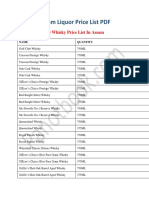

- Assam Liquor Price List PDFДокумент7 страницAssam Liquor Price List PDFBeatrix WanwanОценок пока нет

- Layout and Evaluation of Clavey Winery FacilityДокумент44 страницыLayout and Evaluation of Clavey Winery FacilityNebojša Perišić100% (1)

- Aging of Whiskey Spirits in Barrels of Non Traditional VolumeДокумент117 страницAging of Whiskey Spirits in Barrels of Non Traditional VolumeJeremyОценок пока нет