Академический Документы

Профессиональный Документы

Культура Документы

Pak Shankar Comment and Gesit Response (Review KHI)

Загружено:

Iqbal Nurrasa Bakti0 оценок0% нашли этот документ полезным (0 голосов)

10 просмотров1 страницаSahnkar coment

Оригинальное название

20150623 Pak Shankar Comment and Gesit Response (Review KHI)

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документSahnkar coment

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

10 просмотров1 страницаPak Shankar Comment and Gesit Response (Review KHI)

Загружено:

Iqbal Nurrasa BaktiSahnkar coment

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

No.

Comment Pak Shankar

Point of Comment

Include the procedure of receipt,

handling and storage of RAW

materials

Please include the anode material

electrochemical capacity and

closed circuit potential to be

check against the supplied

material.

Raw Materials

Will be attached (please find attached file).

Raw Materials

Chemical composition perhaps (Our only one supplier

in Indonesia - PT. Inalum only provide us the

chertificate of chemical composition only. Inalum

never provide the certificate of capacity and closed

circuit potential of Aluminium ingot since these two

testing can be done for Aluminium ingot with this

99.90% Purity. In this 99.90% of Purity, Aluminium is

in passive conditions).

Reference standards with a

chemical composition certified by

an independent party shall be

used for spectrometric analyses of

anode chemical composition.

Raw Materials

Will be Charged (Please see our reply as per item No.

2. We only receive the certificate of chemical

composition only from Inalum and we will re-check

the chemical composition of this Aluminium ingot by

our spectrometer if we order the Aluminium ingot

more than 50 tonnes or as per client's requirements. If

you need the chemical composition certified by

independent party, we will be charged you the cost of

testing. The Aluminum ingot 99.90% purity is in

passive conditions and it cannot be tested for the

electrochemical testing).

Will be Charged (other raw material is Zinc Alloy and

Indium alloy. As same as Aluminum ingot, we only

received the certificate of chemical composition only

for this both alloying. We never re tested the

composition of this alloying since the total

composition of Zinc & Indium in Aluminium anode is

too small, maximum 6% only. If you need the

chemical composition certified by independent party

for this tow alloyings, we will be charged you the cost

of testing).

Also contractor shall retain the

RAW materials samples for

additional chemical analysis or

electrochemical testing.

4

Not only Aluminium, all the RAW

material shall be tested.

Raw Materials

Table 1 and 2 for purity and

chemical composition

respectively

shall be 8 hours

Please include the bending

requirements and procedure for

the anode cores or submit as a

separate document for company

information,

shall be greater than the design

weight

Raw Materials

6

7

10

11

12

13

what about anode core

dimensional tolerances and the

position inspection?

Also,please comply with the crack

acceptance criteria of Section

9.8.3 of ISO 15589:

For PQT: at least two half shell

anodes for each type for PQT shall

be tested.

is this mean each of the anode set

will be trial fitted,

anodes capacities when buried in

seamud should also be tested.

Core Blasting time

Anode Core

Anode Weight

Anode Core

Anode Cracks

Destructive Test

Gesit Response

Comply

Comply eventhough this is not painting/coating work.

The core of anodes are made from plate strip. There

is no bending process in making of anode's core. The

process shall be "rolling" by using our roller machine

in our workshop. We will put one section in our MPS

for this rolling of plate strip.

We refer to NACE Standard, SP 0492, minimum 97%

and the total not to be less than total contract weight.

If the minimum of a single units bracelet anode less

then 97%, we will reject it.

Will be implemented on destructive test and at trial fit

testing.

Comply, all criteria refer to ISO 15589 Section 9.8.3.

Comply as per your requirement, we will do the DT on

1 set (2 half shell) for every type of bracelet anodes.

Trial Fit

Yes, trial fit shall be conducted 100%.

Wet test

Ussually, we do the anode's perfomance testing

(capacity & potential) only in sea water with ambient

temperature. We can do the testing of anode's

perfomance testing (capacity & potential) buried in

sea mud and this is need the special equipment and

special environment. We will charge the cost for this

testing.

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Daily Progres 22 AprilДокумент2 страницыDaily Progres 22 AprilIqbal Nurrasa Bakti100% (3)

- Contoh 2Документ5 страницContoh 2Iqbal Nurrasa BaktiОценок пока нет

- Invitation Letter PQT AEC & CWCДокумент3 страницыInvitation Letter PQT AEC & CWCIqbal Nurrasa BaktiОценок пока нет

- Draft MRR Isolation JointДокумент9 страницDraft MRR Isolation JointIqbal Nurrasa BaktiОценок пока нет

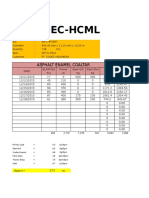

- Cooec-Hcml: Asphalt Enamel CoaltarДокумент3 страницыCooec-Hcml: Asphalt Enamel CoaltarIqbal Nurrasa BaktiОценок пока нет

- Summary Production of Concrete Production: No Sample Production Date Remarks Total ProdДокумент4 страницыSummary Production of Concrete Production: No Sample Production Date Remarks Total ProdIqbal Nurrasa BaktiОценок пока нет

- Receive MaterialДокумент1 страницаReceive MaterialIqbal Nurrasa BaktiОценок пока нет

- Book 1Документ15 страницBook 1Iqbal Nurrasa BaktiОценок пока нет

- DAILY PROGRESS PQT and Production Asphalt Enamel CoatingДокумент1 страницаDAILY PROGRESS PQT and Production Asphalt Enamel CoatingIqbal Nurrasa BaktiОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Astm B 240-07 PDFДокумент4 страницыAstm B 240-07 PDFRamsi AnkziОценок пока нет

- Examples of Semiconductor: 1. IG-NANA Wafers: ApplicationДокумент4 страницыExamples of Semiconductor: 1. IG-NANA Wafers: Applicationaldehyde123Оценок пока нет

- How Much Is Left PDFДокумент9 страницHow Much Is Left PDFElleОценок пока нет

- Comparative Chemistry of B, Al, Ga, In, TLДокумент13 страницComparative Chemistry of B, Al, Ga, In, TLMmadu CcyОценок пока нет

- A Drop-In Lead Free Solder ReplacementДокумент10 страницA Drop-In Lead Free Solder Replacementb0i13rОценок пока нет

- Amendment No. 3 December 2021 TO Is 209: 1992 Zinc Ingot - SpecificationДокумент2 страницыAmendment No. 3 December 2021 TO Is 209: 1992 Zinc Ingot - Specificationvishal.shelareОценок пока нет

- IS-209 For ZN IngotsДокумент6 страницIS-209 For ZN IngotsAnuradhaPatraОценок пока нет

- Unit 3 Lesson 5 Combining Semiconductors Into Phosphors 2017 Teacher'sДокумент34 страницыUnit 3 Lesson 5 Combining Semiconductors Into Phosphors 2017 Teacher'sThomas Cancino LastraОценок пока нет

- ChemistryДокумент1 страницаChemistryIvy JoyceОценок пока нет

- Francescone - Tracing Indium Production To The Mines of The Cerro Rico de PotosíДокумент13 страницFrancescone - Tracing Indium Production To The Mines of The Cerro Rico de PotosíKay FranОценок пока нет

- Lec 20Документ23 страницыLec 20ArunaОценок пока нет

- Endangered Elements - Critical Thinking - tcm18-196054Документ5 страницEndangered Elements - Critical Thinking - tcm18-196054kennyvsspandex100% (1)

- Pure Nickel Special, Nuclear Grade: Never SeezДокумент2 страницыPure Nickel Special, Nuclear Grade: Never SeezsekharsamyОценок пока нет

- Electrochemical Behaviors of Indium PDFДокумент13 страницElectrochemical Behaviors of Indium PDFMaria Shin Yen MendozaОценок пока нет

- Astm F 2191 2013 (Latest)Документ9 страницAstm F 2191 2013 (Latest)akashdruva892100% (1)

- Inorganic Photovoltaics - Planar and Nanostructured DevicesДокумент111 страницInorganic Photovoltaics - Planar and Nanostructured DevicesUdai SinghОценок пока нет

- Indium PDFДокумент3 страницыIndium PDFWwJd HeavenОценок пока нет

- Aluminium Dross Waste - Topics by Science - GovДокумент198 страницAluminium Dross Waste - Topics by Science - GovPramod Reddy TilletiОценок пока нет

- Dictionary of Chemical Formulas - Sonu PDFДокумент60 страницDictionary of Chemical Formulas - Sonu PDFAtulya Singh75% (4)

- NihoniumДокумент21 страницаNihoniumBrandon McguireОценок пока нет

- Vehical Control by Alcohol Detector: BY: DHRUV AGARWAL (12-EEU-014) HEEVAN SHER (12-EEU-020)Документ24 страницыVehical Control by Alcohol Detector: BY: DHRUV AGARWAL (12-EEU-014) HEEVAN SHER (12-EEU-020)Anonymous ytZsBOVОценок пока нет

- Ion Reference SheetДокумент1 страницаIon Reference SheetBrandi Picard SchmitОценок пока нет

- CHEMJUNE2002C4Документ9 страницCHEMJUNE2002C4api-3726022Оценок пока нет

- Treliver-Anglosaxony MiningДокумент28 страницTreliver-Anglosaxony MiningCraftychemistОценок пока нет

- 11 TH P Block MGKДокумент14 страниц11 TH P Block MGKChandrapal RathoreОценок пока нет

- (Gaston Charlot) Qualitative Inorganic Analysis AДокумент376 страниц(Gaston Charlot) Qualitative Inorganic Analysis AFrederik RareОценок пока нет

- Boron FamilyДокумент52 страницыBoron FamilyTol Ralph SabОценок пока нет

- Feasibility Study of Solar-Wind HybridДокумент79 страницFeasibility Study of Solar-Wind Hybridvj4249Оценок пока нет

- Fator de Watson KW Ie50312a018Документ5 страницFator de Watson KW Ie50312a018Luiz Roberto TerronОценок пока нет

- MeissnerДокумент11 страницMeissner12345678Оценок пока нет