Академический Документы

Профессиональный Документы

Культура Документы

The Orders To Customers Which Creates Actual Financial Benefit For The Organization

Загружено:

Ramteja Goud KosuriОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

The Orders To Customers Which Creates Actual Financial Benefit For The Organization

Загружено:

Ramteja Goud KosuriАвторское право:

Доступные форматы

Objective

Our main objective is to translate the received work orders into cash by delivering

the orders to customers which creates actual financial benefit for the organization.

ScopeManaging quotations

Sales orders

Invoices and

Receipts.

Pre-requisite/InputsPurchase order

Shipment

Invoice

Process-

STEP 1- There are n number of work orders (1, 2, 3 ..n)

STEP 2- Sum all work orders from 1 to n

STEP 3- Sum all similar Stock keeping Units (SKUs) quantity from various work

orders

STEP 4- Sum all SKUs demand from 1 to n

STEP 5- Check for KANBAN stock availability for each SKU demand

STEP 6- A) If YES then,

Check whether the materials are fully available or partially available or not

available

When materials are fully available then check whether the weight is equal

to 1 truck load or not

If YES then,

Load truck and deliver to the customer

If NO then,

Wait till the other work orders from nearest depots get dispatch ready and

are equivalent to

Minimum one truck load weight

STEP6- B) If NO then,

If the materials are not available then this is the step by step procedure

I)

II)

III)

IV)

V)

VI)

VII)

create the process order for each SKU which would be summation of

multiple work orders

Run Material Requirement Planning(MRP) for each process order

separately

Issue RM, SF & PM from stores as per MRP

Manufacture the products as per process

Pack the products

Segregate orders by depot

Check whether each order weights by depots is equal to 1 truck load

If YES then,

a) Dispatch to depots

If NO then,

B) Check by merging up nearest depots order whether weight equal to

1 truck load or not

If YES then dispatch to depots

If No then repeat step VII until condition (VII a) is fulfilled

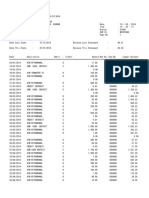

Step by step activities & their responsibilities

S.NO

Decision

/

Executio

n

Department

Activity Performed

by

Activity Description

Sales

Sales managers

Create the work orders and share

to factory

2.

Dispatching

Dispatching

managers

Receive the work orders

3.

Dispatching

Stock managers

Will check the available inventory

4.

Dispatching

Stock managers

Will share the unavailable work

orders to production

5.

Production

Production

managers

Will run the MRP

6.

Production

Production

managers

Request SF,RM & PM from stores as

per MRP

7.

Production

Production heads

8.

Stores

Stock managers

H.O.D will approve the

requirements and make changes

as per requirement.

Will check the stocks availability

9.

Stores

Dispatching

managers

Issue the available materials

10.

Stores

Stock managers

Create the requisition for

unavailable material

11.

Any department

Verification of requisition

12.

Sales

Managers of

particular

department

Sales managers

13.

Dispatching

Dispatching

managers

Receiving the work orders

14.

Dispatching

Dispatching

managers

Segregate orders by depot

15.

Dispatching

Dispatching

managers

Load truck and deliver to

customers

Create PO for entire requisition

Вам также может понравиться

- EWM Best Practise For ShellДокумент22 страницыEWM Best Practise For Shellchiru1010100% (1)

- ERP Module 1Документ16 страницERP Module 1burn121212Оценок пока нет

- Anurag Rana SCM ReportДокумент6 страницAnurag Rana SCM Reportsaket rajОценок пока нет

- 7 Managing Stocks On The FloorДокумент4 страницы7 Managing Stocks On The FloorShankar CОценок пока нет

- IMT SevenElevenJapanДокумент6 страницIMT SevenElevenJapanRahul PandeyОценок пока нет

- 2014+week+8 9P+-+SJs+ +inventory+ Students +slidesДокумент23 страницы2014+week+8 9P+-+SJs+ +inventory+ Students +slideskennedyОценок пока нет

- Inventory Management PDFДокумент49 страницInventory Management PDFVyVyОценок пока нет

- Supply Chain Departments in LAPP India PVT LTD: Order Entry DepartmentДокумент9 страницSupply Chain Departments in LAPP India PVT LTD: Order Entry DepartmentShameem AliОценок пока нет

- InventoriesДокумент8 страницInventoriesAlthon JayОценок пока нет

- SAP WM Interview Questions - 30.10.2019Документ19 страницSAP WM Interview Questions - 30.10.2019Vishnuvardhan ReddyОценок пока нет

- SAP SD Availability Check PDFДокумент17 страницSAP SD Availability Check PDFVinay DhageОценок пока нет

- Quality Management Assignment: Holding Cost Average Unit Holding Cost Per UnitДокумент3 страницыQuality Management Assignment: Holding Cost Average Unit Holding Cost Per UnitPhillip AtkinОценок пока нет

- Batch Management ConfigurationДокумент31 страницаBatch Management ConfigurationRama MoorthyОценок пока нет

- Availability CheckДокумент17 страницAvailability Checkchiarabalsamo96Оценок пока нет

- SIOP (Sales Inventory Operations Planning)Документ31 страницаSIOP (Sales Inventory Operations Planning)Harish GopalanОценок пока нет

- Module 1 Capacity Planning and Line BalancingДокумент2 страницыModule 1 Capacity Planning and Line BalancingJohnathan LavaredsОценок пока нет

- Customer Return in SAP EWMДокумент11 страницCustomer Return in SAP EWMjanipashaОценок пока нет

- Sales and Distribution Q & A: Shipping - ERP Database1Документ7 страницSales and Distribution Q & A: Shipping - ERP Database1Venkata Nelluri PmpОценок пока нет

- SIC PlanningДокумент5 страницSIC Planningadrodriguez523Оценок пока нет

- QNR For SAP SDДокумент5 страницQNR For SAP SDShubham SharmaОценок пока нет

- Akinboboye Omotola D.: Substantial Warehouse ExperienceДокумент4 страницыAkinboboye Omotola D.: Substantial Warehouse ExperienceAkinboboye OmotolaОценок пока нет

- SAP SD Availability CheckДокумент13 страницSAP SD Availability CheckHARIОценок пока нет

- Sap SD Availability Check PDFДокумент17 страницSap SD Availability Check PDFSandip SharmaОценок пока нет

- Group4 ReportДокумент44 страницыGroup4 ReportVera Lúcia Batista SantosОценок пока нет

- CH 06Документ65 страницCH 06Chang Chan Chong0% (1)

- Interview Questions of Production PlanningДокумент7 страницInterview Questions of Production PlanningPriyank Patel0% (1)

- Learning To See - Book SummaryДокумент1 страницаLearning To See - Book Summarysooraj kuteОценок пока нет

- Chapter 6st Aggregation in Supply ChainДокумент54 страницыChapter 6st Aggregation in Supply ChainQuang Vinh TranОценок пока нет

- Difference Between Make To Stock and Make To Order: Sales & DistributionДокумент14 страницDifference Between Make To Stock and Make To Order: Sales & DistributionAnil HiroliОценок пока нет

- Velky Warehouse Case Study Group#4Документ10 страницVelky Warehouse Case Study Group#4Anup John ManiОценок пока нет

- CH 04 - S&OPДокумент15 страницCH 04 - S&OPAwais SadaqatОценок пока нет

- Sap LeДокумент2 страницыSap LeArvind MiraseОценок пока нет

- UNIT-4 (Part-1)Документ15 страницUNIT-4 (Part-1)Vasu PatelОценок пока нет

- Process Sheet: Express Luck Egypt CompanyДокумент19 страницProcess Sheet: Express Luck Egypt Companymohamed abdullahОценок пока нет

- Cma Sir Dawood Vol1 PDFДокумент388 страницCma Sir Dawood Vol1 PDFZari MaviОценок пока нет

- Oracle Inventory Interview QuestionsДокумент42 страницыOracle Inventory Interview QuestionsPritesh Mogane100% (5)

- PP Interview QuestionsДокумент5 страницPP Interview QuestionsPaulo Celso BarbosaОценок пока нет

- QAD Inventory ControlДокумент40 страницQAD Inventory Controlfkjh ijwrОценок пока нет

- MRP Overview ScribdДокумент50 страницMRP Overview Scribdh_kobi76100% (1)

- Understanding The Business Process - Inventory ManagementДокумент8 страницUnderstanding The Business Process - Inventory Managementmoamen.aliОценок пока нет

- Lean Basics: Training ScriptДокумент34 страницыLean Basics: Training ScriptmagudeeshОценок пока нет

- Lean Operations: MRP vs. JitДокумент32 страницыLean Operations: MRP vs. JitSamantha SiauОценок пока нет

- Warehouse Management Final Project ReportДокумент22 страницыWarehouse Management Final Project ReportNainesh KОценок пока нет

- PIS Stores Managment Inventory Control Synopsis)Документ9 страницPIS Stores Managment Inventory Control Synopsis)Vikram AroraОценок пока нет

- Warehousing at Savemart: Group 10 Sec - BДокумент15 страницWarehousing at Savemart: Group 10 Sec - BMandapalli Satish100% (1)

- SAP SD Availability CheckДокумент14 страницSAP SD Availability Checkmanohar rathodОценок пока нет

- Issue of MaterialДокумент1 страницаIssue of MaterialCartoon Kids TVОценок пока нет

- COOP MART QUẬN 7Документ11 страницCOOP MART QUẬN 7ĐẠT NGUYỄN ĐÌNH QUỐCОценок пока нет

- Pengantar Akuntansi 1: SESI - 12Документ18 страницPengantar Akuntansi 1: SESI - 12Sophan SopyanОценок пока нет

- Reverse Subcontracting Process in SAPДокумент3 страницыReverse Subcontracting Process in SAPbandarurp100% (2)

- Inventory Valuation Handbook v1.2Документ24 страницыInventory Valuation Handbook v1.2Dinesh GuptaОценок пока нет

- MRP Lot For LotДокумент43 страницыMRP Lot For LotAmin ShafanezhadОценок пока нет

- ERP - Enterprise Resource PlanningДокумент57 страницERP - Enterprise Resource PlanningdancoxxxОценок пока нет

- Inventory Management - Lecture 3Документ21 страницаInventory Management - Lecture 3AYESHA RASHIDОценок пока нет

- Proposal For WMS Implementation / Stock Correction at NPI: Prepared By: Sanjay K Srivastava, HOD - IT & Digital 26.05.2021Документ12 страницProposal For WMS Implementation / Stock Correction at NPI: Prepared By: Sanjay K Srivastava, HOD - IT & Digital 26.05.2021singhnavin91Оценок пока нет

- InstitutДокумент16 страницInstitutMontassar SrihiОценок пока нет

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyОт EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyРейтинг: 4 из 5 звезд4/5 (6)

- AkДокумент7 страницAkDavid BakcyumОценок пока нет

- MBA - Updated ADNU GSДокумент2 страницыMBA - Updated ADNU GSPhilip Eusebio BitaoОценок пока нет

- Marley Product Catalogue Brochure Grease TrapsДокумент1 страницаMarley Product Catalogue Brochure Grease TrapsKushalKallychurnОценок пока нет

- Minor Project Report Format MCAДокумент11 страницMinor Project Report Format MCAAnurag AroraОценок пока нет

- Chapter 2 A Guide To Using UnixДокумент53 страницыChapter 2 A Guide To Using UnixAntwon KellyОценок пока нет

- Indictment - 17-Cr-00601-EnV Doc 1 Indictment 11-1-17Документ6 страницIndictment - 17-Cr-00601-EnV Doc 1 Indictment 11-1-17C BealeОценок пока нет

- Te 1569 Web PDFДокумент272 страницыTe 1569 Web PDFdavid19890109Оценок пока нет

- An Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)Документ18 страницAn Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)gurumurthy38Оценок пока нет

- Nisha Rough DraftДокумент50 страницNisha Rough DraftbharthanОценок пока нет

- Document 3Документ3 страницыDocument 3AdeleОценок пока нет

- A CMOS Current-Mode Operational Amplifier: Thomas KaulbergДокумент4 страницыA CMOS Current-Mode Operational Amplifier: Thomas KaulbergAbesamis RanmaОценок пока нет

- Item Description RCVD Unit Price Gross Amt Disc % Ta Amount DeptДокумент1 страницаItem Description RCVD Unit Price Gross Amt Disc % Ta Amount DeptGustu LiranОценок пока нет

- Bisleri 2.0Документ59 страницBisleri 2.0Dr Amit Rangnekar100% (4)

- Projects: Term ProjectДокумент2 страницыProjects: Term ProjectCoursePinОценок пока нет

- Simavi - Project Officer PROPOPIДокумент4 страницыSimavi - Project Officer PROPOPIAgus NugrahaОценок пока нет

- Toa Valix Vol 1Документ451 страницаToa Valix Vol 1Joseph Andrei BunadoОценок пока нет

- Analisa RAB Dan INCOME Videotron TrenggalekДокумент2 страницыAnalisa RAB Dan INCOME Videotron TrenggalekMohammad Bagus SaputroОценок пока нет

- Interest Rates and Bond Valuation: All Rights ReservedДокумент22 страницыInterest Rates and Bond Valuation: All Rights ReservedAnonymous f7wV1lQKRОценок пока нет

- Political Positions of Pete ButtigiegДокумент12 страницPolitical Positions of Pete ButtigiegFuzz FuzzОценок пока нет

- Delta PresentationДокумент36 страницDelta Presentationarch_ianОценок пока нет

- SPC Abc Security Agrmnt PDFДокумент6 страницSPC Abc Security Agrmnt PDFChristian Comunity100% (3)

- ArpitResumeISM PDFДокумент1 страницаArpitResumeISM PDFchethan rОценок пока нет

- Department of Labor: 2nd Injury FundДокумент140 страницDepartment of Labor: 2nd Injury FundUSA_DepartmentOfLabor100% (1)

- White Button Mushroom Cultivation ManualДокумент8 страницWhite Button Mushroom Cultivation ManualKhurram Ismail100% (4)

- Bank Statement SampleДокумент6 страницBank Statement SampleRovern Keith Oro CuencaОценок пока нет

- Certification and LettersДокумент6 страницCertification and LettersReimar FerrarenОценок пока нет

- Project Management: Chapter-2Документ26 страницProject Management: Chapter-2Juned BhavayaОценок пока нет

- Product Manual: Panel Mounted ControllerДокумент271 страницаProduct Manual: Panel Mounted ControllerLEONARDO FREITAS COSTAОценок пока нет

- EC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - AДокумент29 страницEC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - AAnonymous bSpP1m8j0n50% (2)

- Outage Analysis of Wireless CommunicationДокумент28 страницOutage Analysis of Wireless CommunicationTarunav SahaОценок пока нет