Академический Документы

Профессиональный Документы

Культура Документы

Optimization Problems

Загружено:

neftАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Optimization Problems

Загружено:

neftАвторское право:

Доступные форматы

ChE class and home problems

The object of this column is to enhance our readers collections of interesting and novel problems in chemical

engineering. We request problems that can be used to motivate student learning by presenting a particular principle

in a new light, can be assigned as novel home problems, are suited for a collaborative learning environment, or demonstrate a cutting-edge application or principle. Manuscripts should not exceed 14 double-spaced pages and should

be accompanied by the originals of any figures or photographs. Please submit them to Dr. Daina Briedis (e-mail:

briedis@egr.msu.edu), Department of Chemical Engineering and Materials Science, Michigan State University, East

Lansing, MI 48824-1226.

OPTIMIZATION PROBLEMS

Brian J. Anderson, Robin S. Hissam, Joseph A. Shaeiwitz, and Richard Turton

West Virginia University Morgantown, WV 26506-6102

ptimization is often considered to be an advanced,

highly mathematical, and sometimes a somewhat

obscure discipline. While it is true that many advanced optimization techniques exist, optimization problems

can be developed that are suitable for undergraduates at all

levels. Two of these problems will be described in this paper,

and many others are available on the web.[1] A pedagogy is

described that requires students to identify the trends of the

components of the objective function and to understand how

trade-offs between these components lead to the existence

of the optimum.

The ability to solve routine optimization problems has

been simplified by advances in computing power over the

last generation. Earlier editions of current design textbooks[2]

presented a sequence of optimization techniques aimed at

minimizing the number of cases that had to be considered

to close in on the optimum. Now, it is possible to perform

optimization calculations involving numerous cases with a

few clicks of a mouse, and an entire chemical process can be

simulated and results exported to a spreadsheet in a matter

of minutes.

Several optimization examples are routinely discussed

in undergraduate textbooks; however, the objective function does not usually involve economics. These examples

include optimum interstage compressor pressure,[3] optimum

insulation thickness,[4] and identifying conditions for the

optimum selectivity.[5] Qualitative representations of the

economic optimum pipe diameter[6] and reflux ratio[7] are

also available. Other examples of optimization problems

are available, but these do not involve an economic objective function.[8-10] The problems presented here all involve

an economic objective function.

TYPES OF PROBLEMS

Three types of optimization problems are available, and

they are summarized in Table 1. The ones highlighted in italics are discussed in this paper, and the others are available on

the web.[1] The numbers in parenthesis indicate the number

of different versions available for each problem. All of these

have been used successfully in a freshman class designed to

develop computing skills appropriate for an undergraduate

chemical engineering student. Most of these problems would

also be suitable for assignments or projects in unit operations

TABLE 1

Single

Variable

Available Optimization Problems

Multi-variable

Projects

Pipe diameter (2)

Absorber

Generic chemical

process (2)

Reactor/

preheater

(2)

Batch reactor/preheater

Geothermal energy

(2)

Reflux ratio

Staged compressors

Fuel production

from biomass (4)

Brian J. Anderson is the Verl Purdy Faculty Fellow and an assistant professor in

the Department of Chemical Engineering at West Virginia University. His research

experience includes sustainable energy and development, economic modeling

of energy systems, and geothermal energy development as well as molecular

and reservoir modeling.

Joseph A. Shaeiwitz received his B.S. degree from the University of Delaware

and his M.S. and Ph.D. degrees from Carnegie Mellon University. His professional interests are in design, design education, and outcomes assessment. Joe

is a co-author of the text Analysis, Synthesis, and Design of Chemical Processes

(3rd Ed.), published by Prentice Hall in 2009.

Robin S. Hissam received her B.S. and M.S. degrees in materials science and

engineering from Virginia Tech and her Ph.D. in materials science and engineering from the University of Delaware. After a post-doctoral fellowship in chemical

engineering and applied chemistry at the University of Toronto, Robin joined the

Chemical Engineering Department at West Virginia University. Her research is

in production of protein polymers for application in tissue engineering, biomineralization, and biosensors.

Richard Turton, P.E., has taught the senior design course at West Virginia

University for the past 24 years. Prior to this, he spent five years in the design

and construction industry. His main interests are in design education, particulate

processing, and modeling of advanced energy processes. Richard is a co-author

of the text Analysis, Synthesis, and Design of Chemical Processes (3rd Ed.),

published by Prentice Hall in 2009.

144

Copyright ChE Division of ASEE 2011

Chemical Engineering Education

classes or as problem assignments for the portion of a design

class where optimization is taught.

Problem 1: Bioreactor

Background

A liquid-phase, biological reaction is used to produce an

intermediate chemical for use in the pharmaceutical industry. The reaction occurs in a large, well-stirred, isothermal

bioreactor, such that the reactor temperature is identical to

the inlet temperature. Because this chemical is temperature

sensitive, the maximum operating temperature in the reactor

is limited to 65 C by using a heating medium available at this

maximum temperature. The feed material is fed to the reactor

through a heat exchanger that can increase the temperature of

the reactants (contents of the reactor), which in turn increases

the rate of the reaction. This is illustrated in Figure 1. The

time spent in the bioreactor (known as the space time) must

be adjusted to obtain the desired conversion of reactant. As the

temperature in the reactor increases so does the reaction rate,

thereby decreasing the size (and cost) of the reactor required

to give the desired conversion. The problem to be solved is

to determine the optimal value for the single independent

variable; namely, the temperature (Tc,2) at which to maintain

the reactor (preheat the feed). The costs to be considered are

the purchase costs of the reactor and heat exchanger and the

operating cost for the energy to heat the feed.

Problem Statement

It is desired to optimize the preheat temperature for a reactant feed flow of 5,000 gal/h. The feed has the properties

of water ( = 1,000 kg/m3, Cp = 4.18 kJ/kg C) and enters

the heat exchanger at a temperature of 20 C. The reactor

feed is to be heated with a heating medium that is available

at a temperature of 65 C and must leave the heat exchanger

at 30 C. Therefore, the desired reactor inlet temperature is

adjusted by changing the flowrate of the heating medium.

The physical properties of the heating medium are = 920

kg/m3, Cp = 2.2 kJ/kg C.

The reaction rate for this reaction, rA, is given in terms of the

concentration of reactant A (CA) by the following equation:

rA = kCA

(1)

where

3, 500

k s1 = 2.5 exp

T K

vo XA

k (1 X A )

( 2)

Vol. 45, No. 2, Spring 2011

L..-_ _ _

Products

Figure 1. Process flow diagram of the feed preheater

and bioreactor.

The design equation for the heat exchanger is given by:

Q = M c C p,c (Tc ,2 Tc ,1 ) = M h C p,h (Th ,1 Th ,2 ) = UAFTlm ( 4)

where

Tlm =

(T

h ,2

Tc ,1 ) (Th ,1 Tc ,2 )

(T

ln

(T

h ,2

h ,1

Tc ,1 )

(5)

Tc ,2 )

and

F = log-mean temperature correction factor = 0.8 (assume

that this is constant for all cases)

U = overall heat transfer coefficient = 400 W/m2K

The optimum reactor inlet temperature is the one that

minimizes the equivalent annual operating cost (EAOC). The

EAOC is given by

2

EAOC $ / y = PCi $ (A / P, i, n) 1 / y + UC $ / y

(6)

i=1

where PCi are the purchase equipment costs for the heat

exchanger and reactor, UC is the operating (utility) cost for

the heating medium, and (A/P, i, n) is the capital recovery

factor given by

n

(A / P, i, n) =

i(1 + i)

n

(1+ i)

(7 )

For this problem, use i = 7% and n = 12 years.

PCreactor = $17, 000 V 0.85

(8)

where V is the volume of the reactor in m3. The cost of the

heat exchanger is:

(3)

where V is the reactor volume (m ), vo is the volumetric flowrate of fluid into the reactor (m3/s), and XA is the conversion

(assumed to be 80% or 0.8 for this reaction).

3

Reactant Feed

The purchase cost of the reactor is given by:

The design equation for the reactor is given by:

V=

Bioreactor

PCexchanger = $12, 000 A m 2

0.57

(9)

where A is the area of the heat exchanger in m2. The cost of

the heating medium is:

UC $ / h = $5106 Q kJ / h

(10)

145

by the following equation:

The results should be presented as two plots. The first should

show how each term in Eq. (6) changes with Tc,2, and the

second plot should show the EAOC (y-axis) as a function of

Tc,2 (x-axis). The report should contain a physical explanation

of the reason for the trends on these plots.

(11)

3, 500

k s1 = 2.5 exp

T K

(12)

where

Problem 2: Batch Bioreactor

Background

The design equation for the reactor is given by:

A liquid-phase, biological reaction is used to produce an

intermediate chemical for use in the biotech industry. The

reaction occurs in a large, well-stirred, isothermal bioreactor, such that the reactor temperature is identical to the inlet

temperature. Because this chemical is temperature sensitive,

the maximum operating temperature in the reactor is set to

55 C. The feed material is fed to the reactor through a heat

exchanger that increases the temperature of the reactants

(contents of the reactor), which in turn increases the rate of

the reaction. This is illustrated in Figure 2.

t s =

1

1

ln

1

1

XA

k s

(13)

where t is the time spent in the reactor and XA is the fractional

conversion of reactants to products. The amount of product

formed in time t is given as NXA, where N is the number of

moles of reactant fed to the reactor.

The energy balance equation for the heat exchanger is

given by:

Q = M c C p,c (Tc ,2 Tc ,1 ) = M h C p,h (Th ,1 Th ,2 )

(14)

The reactor runs as a batch operation in which the contents

remain in the equipment for a given period of time. The time

spent in the bioreactor must be adjusted to obtain the optimal

conversion of reactant. Because of the fear of contamination

by pathogens and parasitic fungi, the reactor must be cleaned

thoroughly between batch operations. The cleaning time

per batch (tclean) and the cost of cleaning both vary based

on the size of the reactor used.

As the time spent in the reactor increases, the amount

of product also increases but at a decreasing rate. The

problem to be solved is to determine the optimum values

of the two independent variables; namely, the time for the

products to spend in the reactor, or the batch time, and the

reactor size.

rA = kCA

where

M is the mass of fluid to be heated or cooled (kg)

Cp is the specific heat capacity of the fluid (kJ/kg C)

Heat Exchanger

T =30'C

"' 1

T,,=20'C

Reactant Feed

~ ::>

J' T" =55"C

Bioreactor

T" , 65T

Products

For this problem, it is assumed that only standard size

vessels are available (1,000, 5,000, or 10,000 gallons), and Figure 2. Process flow diagram of feed preheater and bioreactor.

that the costs of the feed are fixed. Therefore, the

1,000,000

costs that vary are the revenues from sales, the

reactor cost, and the cost for cleaning.

900,000

Problem Statement

It is desired to optimize the production of

product from the reactor. The feed has the

properties of water ( = 1,000 kg/m3, Cp =

4.18 kJ/kg C) and enters the heat exchanger at

a temperature of 20 C. The reactor feed is to

be heated with a heating medium that is available at a temperature of 65 C and must leave

the heat exchanger at 30 C. The desired reactor

inlet temperature is fixed at 55 C. The physical

properties of the heating medium are = 920

kg/m3, Cp = 2.2 kJ/kg C.

The reaction rate for this reaction, -rA, is given

in terms of the concentration of reactant A (CA)

146

800,000

~

u

<

w

700,000

'"

600,000

500,000

400,000

20

30

40

50

60

70

Reactor Feed Temperature (' C)

Figure 3. Optimization plot for Example 1.

Chemical Engineering Education

T is the temperature (C)

1 and 2 refer to inlet and outlet conditions, respectively.

h and c refer to the hot and cold stream, respectively.

The optimal reactor configuration is the one that minimizes the equivalent

annual operating cost (EAOC). The EAOC is given by:

2

i=1

i=1

EAOC $ / y = PCi $ (A / P, i, n) 1 / y + UCi $ / y R $ / y

(15)

where PCi are the purchase equipment costs for the heat exchanger and reactor;

UCi are the operating (utility) costs for the heating medium, the cost of the

feed stream, and the cost of cleaning; and R is the revenue from sales of the

product. For this problem, use i = 0.07 and n = 12 years.

The purchase cost of the reactor is given by

PCreactor = $17, 000 V 0.85

(16)

where V is the volume of the reactor in m3. The cost of the heat exchanger may

be taken to be equal to 20% of the cost of the reactor from Eq. (16).

The cost of the heating medium is given by:

UC heating $ / h = 5106 Q kJ / h

(17 )

The ability to solve routine

optimization problems

has been simplified by

advances in computing power

over the last generation.

The final results should be presented as two

plots. The first plot should show how each

term in Eq. (15) changes with the batch time,

t, and the second plot should show the EAOC

(y- axis) as a function of t (x-axis). The report

should contain a physical explanation of the

reason for the trends on these plots.

OPTIMIZATION PROBLEMS

In Problem 1, the optimum reactor feed

temperature is to be determined. There is

a trade-off, which is necessary to obtain

where Q is the heat duty obtained from Eq. (14).

an absolute maximum or minimum in the

The price of the feed is $2/mol, the value of the product is $10/mol, and the

objective function (EAOC) as the decision

molar density (concentration) of both feed and product is 100 mol/m3. The

variable (reactor feed temperature) varies.

cost of cleaning the reactor is given by

In this case, at higher temperatures, it costs

more to heat the reactor feed, but, since the

V

gal

reactor

UCclean $ / cleaning = 1, 000 $ / cleaning 1 + 0.5

(18)

reaction rate increases with temperature, the

1, 000 gal

reactor cost is lower because a smaller reactor is needed. Additionally, at higher reactor

and the time to clean a reactor is

feed temperatures, a larger heat exchanger is

Vreactor gal

needed. Students can develop a spreadsheet

t clean h = 4 h 1 + 0.5

(19)

that varies the reactor inlet temperature and

1, 000 gal

plot the EAOC vs. the reactor inlet temperature. This plot is illustrated in

_ _ ut il ly Co st

I ,OOO,Ooo

Figure 3. They can also plot EAOC

vs. reactor cost, heating medium

900 ,000

React or A nrlJ. lile d Cost

cost, and heat exchanger cost to

He<i Elc h,.., ger A nrlJ alize d

:;: 800,000

see the trends. This is illustrated

"- 700,000

~-'>J.+_---_+--'==~cFO~'======OC---J in Figure 4. The trend for the heat

exchanger clearly illustrates how the

600,000

heat exchanger cost goes to infinity

~

as the reactor feed temperature apSOO,OOO

proaches the heating medium inlet

o

temperature, causing the log-mean

o

temperature driving force to go to

300,000

o

zero and the heat exchanger area to

u

200,000

become infinite. This is an example

of why it is important for students

100,000

to analyze a series of data and understand the trends. It is possible to

20

30

40

50

60

70

solve this entire problem on Excel

Reactor Feed Temperature ("C)

using the Solver tool; however,

much of the understanding/synthesis

Figure 4. Component optimization trends in Problem 1.

1',,---1----+----+-- ___

t, ,"',-i----t-----t-- ___

",

_f-__

___

t---i1'--~y___l--__l--__l--__l

t---t--"'--''''''--c--+---t----1

Vol. 45, No. 2, Spring 2011

147

Since these problems have been used

components lead to the existence of the optimum. That is why

methods, such as using the Excel Solver, are not emphasized,

and making plots to investigate trends is emphasized. Once

the trends are understood, Excel Solver can be used to obtain

a more exact value of the optimum.

successfully in a freshman class for

several years, we believe they can be

used anywhere in the curriculum.

of the problem is lost. We believe that optimization is more

than finding an answer. An understanding of the underlying

trends is essential.

It is also possible to illustrate how changes in operating conditions change the optimum. In a problem similar to Problem

1,[11] if the reaction kinetics are increased (pre-exponential

factor increased to 7.0 and the activation energy reduced to

3300), the optimum temperature shifts down to about 35 C.

Many different versions of this and other problems can be

created by changing some parameters or by changing the

economics. We use different versions of these for different

groups in the same class. During oral presentations, we ask

them to explain why the optima differ.

We have used these problems as part of a freshman class

taken by students who know that they are interested in chemical engineering. Other students take a college-wide programming class. In our class, students are taught computer skills

applicable to chemical engineering, mostly using the advanced

features of Excel in addition to some elementary programming techniques and algorithms. All assignments are based on

industrially relevant chemical engineering problems. Some of

these problems also appear in the optimization chapter of our

textbook.[11] Since these problems have been used successfully

in a freshman class for several years, we believe they can be

used anywhere in the curriculum.

Since all students in chemical engineering do not take the

class in which these problems are assigned, assessment of

their long-term impact is difficult. The freshmen do a good

job on these problems, and they seem to appreciate the actual

chemical engineering application compared to their peers in

the programming class.

In Problem 2, there are two decision variables (bivariate

optimization) due to the batch processing. Therefore, this

Additional optimization problems are available on the

problem in slightly more complex than Problem 1, and it il[1]

web.

It is observed that virtually an infinite source of these

lustrates that there may be more than one decision variable.

problems

could be obtained by manipulating some of the

One decision variable is the reactor volume, which in this

values

given

in these problems.

case is limited to three standard sizes (an arbitrary number),

and the other decision variable is the processing time. The

CONCLUSION

trade-off is that for longer processing times, more product is

Two example optimization problems that are believed to be

made, but fewer batches can be made per year. For a larger

suitable for all levels of chemical engineering students have

reactor, more product can be made per batch, but fewer

been presented. These problems do not require advanced

batches can be made per year due to the longer cleaning

mathematical techniques; they can be solved using typical

time. Although this problem does not include it, the reactor

software used by students and practitioners, such as Excel.

feed temperature could also be varied, as in Problem 1, to

These problems involve an economic objective function with

create a three-variable optimization. In this problem, it turns

out that the optimum is the 10,000 L reactor with a

reaction time of 9.1 h, at about 97% conversion, as

$2,000,000

is illustrated in Figure 5. For higher conversions, the

$1,500,000

additional processing time is long enough to make

the annual product revenue drop. This problem also

$1,000,000

illustrates some of the issues associated with batch

processing to students who might be very used to

e>' $500,000

continuous processes. Figure 5 also illustrates a biu

.

-+-24 h clean

0

~

$variate optimization plot, with the x-axis containing

. . . 14 h clean

~

one decision variable with several curves indicating

_ 6h clean

$(500,000)

the second decision variable.

""\,

DISCUSSION

We believe that an important part of the pedagogy

of optimization is for students to understand the

trends of the components of the objective function

and to understand how trade-offs between these

148

$(1 ,000,000)

$(1 ,500,000)

00

"'"

5.0

10.0

15.0

time{h)

Figure 5. Optimization plot for Example 2.

Chemical Engineering Education

component capital and operating cost terms. An important

part of the pedagogy of these problems is an understanding

of how the trends of the components terms in the objective

function contribute to the trade-off involved in most optimization problems.

REFERENCES

1. <http://www.che.cemr.wvu.edu/publications/projects/index.

php#opt>

2. Peters, M.S., and K.D. Timmerhaus, Plant Design and Economics for

Chemical Engineers, (3rd Ed.), McGraw Hill, New York, 1980, Chapter

10

3. Sandler, S.I., Chemical, Biochemical, and Engineering Thermodynamics (4th Ed.), Wiley, New York, 2006, Chapter 4, Problem 4.21b

4. Geankoplis, C., Transport Processes and Separation Principles (4th

Vol. 45, No. 2, Spring 2011

Ed.), Prentice Hall PTR, Upper Saddle River, NJ, 2003, Chapter 4.3F

5. Fogler, H.S., Elements of Chemical Reaction Engineering (4th Ed.),

Prentice Hall PTR, Upper Saddle River, NJ, 2006, Chapter 6

6. de Nevers, N., Fluid Mechanics for Chemical Engineers (3rd Ed.),

McGraw Hill, New York, 2005, Chapter 6

7. Peters, M.S., K.D. Timmerhaus, and R.E. West, Plant Design and

Economics for Chemical Engineers, (4th Ed.), McGraw Hill, New

York, 2003, Chapter 9

8. Barolo, M., Batch Distillation Optimization Made Easy, Chem. Eng.

Ed., 32(4), 280 (1998)

9. Smart, J., Using the Evolutionary Method to Optimize Gas Absorber

Operation, Chem. Eng. Ed., 38(3), 204 (2004)

10. Mitsos, A., Design Course for Micropower Generation Devices,

Chem. Eng. Ed., 43(3), 201 (2009)

11. Turton, R., R.C. Bailie, W.B. Whiting, and J.A. Shaeiwitz, Analysis,

Synthesis, and Design of Chemical Processes (3rd Ed.), Prentice Hall

PTR, Upper Saddle River, NJ, 2009, Chapter 14 p

149

Вам также может понравиться

- Insights into Chemical Engineering: Selected Papers of P.V. DanckwertsОт EverandInsights into Chemical Engineering: Selected Papers of P.V. DanckwertsОценок пока нет

- Chemical Reactor Control OptimizationДокумент19 страницChemical Reactor Control OptimizationJetulio JetulinoОценок пока нет

- PBRДокумент19 страницPBRdarvyneeОценок пока нет

- State Common Entrance Test CellДокумент78 страницState Common Entrance Test CellMohit JagtapОценок пока нет

- A Major Project Report On Design of Multicomponent Distillation Column by Approximate and Rigorous Method Using MatlabДокумент51 страницаA Major Project Report On Design of Multicomponent Distillation Column by Approximate and Rigorous Method Using MatlabMasood HassanОценок пока нет

- Prediction For Particle Removal Efficiecy of A Reverse Jet ScrubberДокумент14 страницPrediction For Particle Removal Efficiecy of A Reverse Jet ScrubberPablo Andrés Pérez FuentesОценок пока нет

- Distillation Models For SimulationДокумент46 страницDistillation Models For Simulationharipriyasri92Оценок пока нет

- Isobaric Vapor-Liquid Equilibrium For Binary System of Methanol and AcetonitrileДокумент4 страницыIsobaric Vapor-Liquid Equilibrium For Binary System of Methanol and AcetonitrileAlejandra Rodríguez MorenoОценок пока нет

- Evolutionary Computation Strategy For Optimization of An Alkylation ReactionДокумент8 страницEvolutionary Computation Strategy For Optimization of An Alkylation ReactionVinayak PathakОценок пока нет

- VLE Calculations for Distillation DesignДокумент4 страницыVLE Calculations for Distillation Designsandeep lal0% (1)

- Theoretical Models of Chemical ProcessesДокумент18 страницTheoretical Models of Chemical ProcessesSparsh NegiОценок пока нет

- Workshop 01 - Introduction To Process Optimization in Excel® PDFДокумент29 страницWorkshop 01 - Introduction To Process Optimization in Excel® PDFSofiaOrtizОценок пока нет

- 39 Algal Oil Production 1Документ21 страница39 Algal Oil Production 1Sai Srivathsava UdathuОценок пока нет

- Overall Flowsheet Simulation Benzene Cyclohexane TW6Документ7 страницOverall Flowsheet Simulation Benzene Cyclohexane TW6Mitesh ParmarОценок пока нет

- HST Systems - StudentsДокумент106 страницHST Systems - StudentsjohnsonОценок пока нет

- Chemical Engineering - 1999 Section A (75 Marks) ExamДокумент13 страницChemical Engineering - 1999 Section A (75 Marks) ExamAnonymous 8pCXXsОценок пока нет

- Report TemplateДокумент9 страницReport Templatedmscott10Оценок пока нет

- Economics of Chemical PlantsДокумент39 страницEconomics of Chemical PlantsRaiha AmiraОценок пока нет

- New Editions in ProductionДокумент99 страницNew Editions in ProductionJordan ParkerОценок пока нет

- Deep Eutectic Solvents Syntheses, Properties and ApplicationsДокумент39 страницDeep Eutectic Solvents Syntheses, Properties and ApplicationsJulio Cesar Almeida100% (1)

- Contoh Soal CreДокумент11 страницContoh Soal CreMuhammad Irfan SalahuddinОценок пока нет

- dx10 02 3 Gen2factor PDFДокумент18 страницdx10 02 3 Gen2factor PDFELFER OBISPO GAVINOОценок пока нет

- CRE AssignmentДокумент5 страницCRE AssignmentKuldeepChoudharyОценок пока нет

- CN2116 HW11 Solution (XJP - 2012) FinalДокумент9 страницCN2116 HW11 Solution (XJP - 2012) FinalPrimus OngОценок пока нет

- Je000301o PDFДокумент20 страницJe000301o PDFRLОценок пока нет

- Process Modeling Lecture 1Документ41 страницаProcess Modeling Lecture 1Virginia ElenaОценок пока нет

- DK5739 CH4Документ70 страницDK5739 CH4Özer ÖktenОценок пока нет

- L13 Equilibrium ConversionДокумент21 страницаL13 Equilibrium ConversionLukas EstivaresОценок пока нет

- Solved - Chapter 3 Problem 77RE Solution - Probability and Statistics For Engineers and Scientists 9th EditionДокумент4 страницыSolved - Chapter 3 Problem 77RE Solution - Probability and Statistics For Engineers and Scientists 9th EditionJaleel AhmedОценок пока нет

- Thus, This Term Actually Means A in A Constant-Volume System The Measure of Reaction Rate of Component I BecomesДокумент23 страницыThus, This Term Actually Means A in A Constant-Volume System The Measure of Reaction Rate of Component I Becomesalice Annabelle100% (1)

- Chap 4. Design of ReactorДокумент15 страницChap 4. Design of ReactorAli AhsanОценок пока нет

- Report Rafael Damar ArjanggiДокумент28 страницReport Rafael Damar ArjanggiRafael DamarОценок пока нет

- Approximate Shortcut Methods For Multicomponent DistillationДокумент44 страницыApproximate Shortcut Methods For Multicomponent DistillationShamsMohd100% (1)

- Batch and Semibatch Reactors Guide: Isothermal Batch Reactor Models and ExamplesДокумент44 страницыBatch and Semibatch Reactors Guide: Isothermal Batch Reactor Models and ExamplesManoaki100% (1)

- Numerical Simulation of A Pressure Swing Adsorption PDFДокумент12 страницNumerical Simulation of A Pressure Swing Adsorption PDFGustavo PalaciosОценок пока нет

- Gas Scrubber Level ControlДокумент2 страницыGas Scrubber Level ControlMehdi Hajd KacemОценок пока нет

- Process Synthesis (Process Creation)Документ32 страницыProcess Synthesis (Process Creation)Göksu KutluОценок пока нет

- Lect 6 - Accident and Loss StatisticsДокумент44 страницыLect 6 - Accident and Loss StatisticsEthan MuddОценок пока нет

- Energy Engineering Lab Manual (WEC)Документ74 страницыEnergy Engineering Lab Manual (WEC)haseebОценок пока нет

- LECTURE - 04 - CDB 3044 - Conceptual Process Design - Synthesis of Reaction System (II)Документ36 страницLECTURE - 04 - CDB 3044 - Conceptual Process Design - Synthesis of Reaction System (II)Ong Jia YeeОценок пока нет

- Integrated Approach To Chemical Process Flowsheet Synthesis - by A. AlqahtaniДокумент335 страницIntegrated Approach To Chemical Process Flowsheet Synthesis - by A. AlqahtanilucianoОценок пока нет

- SITI SOLEHAH BINTI OMAR (2015834112) /EH224 7A1 Heuristics of ReactorДокумент2 страницыSITI SOLEHAH BINTI OMAR (2015834112) /EH224 7A1 Heuristics of ReactorSolehah OmarОценок пока нет

- Advanced Reaction - Lecture 1Документ39 страницAdvanced Reaction - Lecture 1nahomОценок пока нет

- (Marko Zlokarnik) Scale-Up in Chemical EngineeringДокумент9 страниц(Marko Zlokarnik) Scale-Up in Chemical EngineeringakilaprabuОценок пока нет

- Energy Conservation in DistillationДокумент4 страницыEnergy Conservation in DistillationRajat WadhwaniОценок пока нет

- 6 Multicomponent Distillation Shortcut Method - CompleteДокумент30 страниц6 Multicomponent Distillation Shortcut Method - CompleteFadilla RahmiОценок пока нет

- Graphical solution of equilibrium and energy balance equationsДокумент24 страницыGraphical solution of equilibrium and energy balance equationsblackbeauty14100% (1)

- SO2 Oxidation over Pt Catalyst RateДокумент1 страницаSO2 Oxidation over Pt Catalyst RateMainul Haque0% (1)

- Process Design of Distillation ColumnДокумент22 страницыProcess Design of Distillation ColumnUzair WahidОценок пока нет

- PETERS, M. S. (1991) - Plant Design and Economics For Chemical Engineers (4th Ed.)Документ4 страницыPETERS, M. S. (1991) - Plant Design and Economics For Chemical Engineers (4th Ed.)Isabel Rincon100% (1)

- Lab Report R3 Batch ReactorДокумент9 страницLab Report R3 Batch Reactorzy_yf0% (1)

- Distillation Sequencing OptimizationДокумент36 страницDistillation Sequencing OptimizationHasnin ArifianiОценок пока нет

- 37 - 4 - Washington DC - 08-92 - 1855 PDFДокумент9 страниц37 - 4 - Washington DC - 08-92 - 1855 PDFMohamadMostafaviОценок пока нет

- TEG-Dehydration Mass and Energy BalanceДокумент137 страницTEG-Dehydration Mass and Energy BalanceIgnatius Adriel WijayaОценок пока нет

- CHEMICAL REACTION ENGINEERINGДокумент10 страницCHEMICAL REACTION ENGINEERINGtacoОценок пока нет

- CRE Lab ManualДокумент32 страницыCRE Lab ManualAABID SHAIK100% (1)

- Chapter-7 Emparical Relation For Free ConvectionДокумент20 страницChapter-7 Emparical Relation For Free ConvectionJohnnyОценок пока нет

- Optimization Problems Paper FinalДокумент14 страницOptimization Problems Paper FinalEnrique GalindoОценок пока нет

- Optimization ProblemsДокумент6 страницOptimization ProblemsLupis UwUrОценок пока нет

- Solar Drying TechnologyДокумент640 страницSolar Drying Technology11751175100% (1)

- Algebraic Topology A Computational Approach - Kaczynski - Mischaikow - MrozekДокумент219 страницAlgebraic Topology A Computational Approach - Kaczynski - Mischaikow - MrozektamthientaiОценок пока нет

- Nonlinear Control and FilteringДокумент755 страницNonlinear Control and FilteringneftОценок пока нет

- Solar Drying TechnologyДокумент640 страницSolar Drying Technology11751175100% (1)

- Exothermic CSTRs Just How Stable Are The Mutiple Steady StatesДокумент6 страницExothermic CSTRs Just How Stable Are The Mutiple Steady StatesneftОценок пока нет

- Calculation of Vapor-Liquid Equilibria From Infinite-Dilution Excess Enthalpy Data Using The Wilson or NRTL EquationДокумент12 страницCalculation of Vapor-Liquid Equilibria From Infinite-Dilution Excess Enthalpy Data Using The Wilson or NRTL EquationneftОценок пока нет

- A Guidebook To Mechanism in Organic Chemistry - Peter Sykes PDFДокумент424 страницыA Guidebook To Mechanism in Organic Chemistry - Peter Sykes PDFSantosh Parvatikar90% (10)

- SlopeДокумент3 страницыSlopeneftОценок пока нет

- Geographic Diferences in ObesityДокумент7 страницGeographic Diferences in ObesityneftОценок пока нет

- Algebraic Topology From A Homotopical Viewpoint - SPringerДокумент505 страницAlgebraic Topology From A Homotopical Viewpoint - SPringerneft100% (1)

- Mecanica Berkeley Physics Course Vol 1Документ503 страницыMecanica Berkeley Physics Course Vol 1elmimo123100% (3)

- Lewis MathesonДокумент5 страницLewis Mathesonneft100% (1)

- In Situstudy of The Self Accommodating Process During The Martensitic Transformation of A Cu ZN AlДокумент13 страницIn Situstudy of The Self Accommodating Process During The Martensitic Transformation of A Cu ZN AlneftОценок пока нет

- Luyben 2011Документ6 страницLuyben 2011Camilo SernaОценок пока нет

- Petroleum Economics and Engineering, 3rd EdДокумент466 страницPetroleum Economics and Engineering, 3rd Edneft94% (16)

- Basics of Polymers Fabrication and Processing TechnologyДокумент108 страницBasics of Polymers Fabrication and Processing TechnologyneftОценок пока нет

- Anomalous Results ArticleДокумент6 страницAnomalous Results ArticleneftОценок пока нет

- Use of Dynamic Simulation To ConvergeДокумент8 страницUse of Dynamic Simulation To ConvergeneftОценок пока нет

- Fibonacci Search For Optimal Feed LocationДокумент14 страницFibonacci Search For Optimal Feed LocationneftОценок пока нет

- Kinetic Study On The Acid Hydrolysis of Cenchrus Ciliaris Particles For The Production of Xylose and Other MonosaccharidesДокумент10 страницKinetic Study On The Acid Hydrolysis of Cenchrus Ciliaris Particles For The Production of Xylose and Other MonosaccharidesneftОценок пока нет

- Benzophenone/THF StillДокумент3 страницыBenzophenone/THF Stillbloggsjoe1970Оценок пока нет

- 10.8 Special Polar GraphsДокумент16 страниц10.8 Special Polar GraphsIlias NihaОценок пока нет

- RC Beam Deflection and Stress AnalysisДокумент4 страницыRC Beam Deflection and Stress AnalysisMaxОценок пока нет

- Quarter3 Week4 ClimateДокумент11 страницQuarter3 Week4 ClimateJohn EdselОценок пока нет

- Excel ShortcutsДокумент21 страницаExcel Shortcutsrushishinde9797Оценок пока нет

- Ivy Bridge PDFДокумент25 страницIvy Bridge PDFDương Tấn QuốcОценок пока нет

- Suunto Core UserguideДокумент58 страницSuunto Core UserguidePriyo AkuntomoОценок пока нет

- Structural Soils Engineer's Quick Reference GuideДокумент64 страницыStructural Soils Engineer's Quick Reference GuideGreg McNamaraОценок пока нет

- Hibbeler D14 e CH 12 P 23Документ2 страницыHibbeler D14 e CH 12 P 23Mona fabrigarОценок пока нет

- Classification of The Concha Type Microtia and Their New Suitable Tratment Strategies Without Autogenous Costal Cartilage GraftingДокумент7 страницClassification of The Concha Type Microtia and Their New Suitable Tratment Strategies Without Autogenous Costal Cartilage Graftingromina paz morales camposОценок пока нет

- METAL CLUSTER COMPLEXESДокумент13 страницMETAL CLUSTER COMPLEXESKeybateОценок пока нет

- Introduction To Music Theory: Inversions of ChordsДокумент3 страницыIntroduction To Music Theory: Inversions of Chordsnaveenmanuel8879Оценок пока нет

- Vesda Arrange Fire Alarm SystemДокумент1 страницаVesda Arrange Fire Alarm SystemGaurav Kumar SharmaОценок пока нет

- 9th-Implementing Lockout Function With IEC61850 PDFДокумент11 страниц9th-Implementing Lockout Function With IEC61850 PDFBharath SaiОценок пока нет

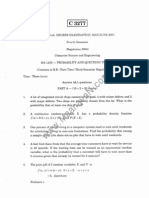

- PQT MJ07Документ6 страницPQT MJ07Raguraman BalajiОценок пока нет

- Transformer X - R CalculationДокумент2 страницыTransformer X - R CalculationTharindu WimalasekaraОценок пока нет

- MT Slides Logistics (14 NovДокумент24 страницыMT Slides Logistics (14 NovRyan Tw ChoumingОценок пока нет

- J Gen Physiol-1952-Hershey-39-56Документ18 страницJ Gen Physiol-1952-Hershey-39-56api-277839406Оценок пока нет

- CH1 The Foundations - Logic and ProofsДокумент106 страницCH1 The Foundations - Logic and ProofsMOHAMED BACHARОценок пока нет

- Well CompletionДокумент26 страницWell Completionnitesh kumarОценок пока нет

- Final Physics GCSE-EOU AssessmentДокумент4 страницыFinal Physics GCSE-EOU AssessmentBehram QureshiОценок пока нет

- HE Drilling JarsДокумент32 страницыHE Drilling Jarsmr_heeraОценок пока нет

- Survey Whole Circle BearingДокумент19 страницSurvey Whole Circle BearingVin GaragiОценок пока нет

- Periodic TableДокумент1 страницаPeriodic TableChemist MookaОценок пока нет

- JqueryДокумент11 страницJqueryShreyas GuduriОценок пока нет

- 24Документ3 страницы24sdssdОценок пока нет

- Johannes KeplerДокумент25 страницJohannes KeplersigitОценок пока нет

- Product Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Документ5 страницProduct Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Tanmoy DuttaОценок пока нет

- Queries With TableДокумент14 страницQueries With TableAkhileshОценок пока нет

- Aimo 2019 Trial g6Документ6 страницAimo 2019 Trial g6Jomar EjedioОценок пока нет