Академический Документы

Профессиональный Документы

Культура Документы

Production Audit Checklist

Загружено:

andruta1978Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Production Audit Checklist

Загружено:

andruta1978Авторское право:

Доступные форматы

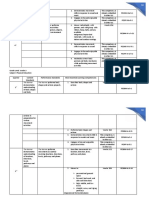

Internal Audit Checklist of Production &

Planning Process

PRODUCTION

Verify the production records such as production slips / memos to ensure that the records are

properly maintained . Also verify the log books of machinery to check the details of production .

Check the production log books.

Check the budgeted production of all the products with the actual result on a monthly / annual

basis. Ascertain the reason for a shortfall in the production if any and comment upon it.

Check the production capacity utilization of all the production plants and enquire in to the

reasons for lower capacity utilization and comment upon it.

Check the system / procedure / method of recording the input and output.

Check whether the Input / Output Norms have been determined of each process of manufacture /

process loss/ wastage (Accounted) losses and the Unaccounted loss and gain.

Check format of the Input and Output statement and ensure that all the relevant data/information

related to the following are shown separately.

o Opening stocks of RM / WIP}.

o Closing stock of RM / WIP . } Total Input

o RM issued.

o Other material issued.

o Accounted losses various types (Norm v/s Actual)

o Finished goods (Norm v/s Actual )

o Unaccounted losses (Norm v/s Actual)

Check the production slips with the entries in the excise record (RG-1).

Comment upon the deviation in the norms set for Input / Output ie Norm v/s actual position.

Check the production schedules to verify whether the production has been carried out as per the

scheduled production.

Check the details in respect of yield - Budgeted yield v/s actual yield in respect of all the

products and enquire in to the reason for lower yield and comment upon it.

PRODUCTION PLANNING AND CONTROL

Study the system / method and the procedure of production planning and the procedure for

the preparation of weekly / monthly / annual production budgets.

Check the status of orders received from the Marketing Department for production of various

products.

Check the machine utilization status report and comment upon the idle time - reason thereof and the

steps to reduce idle time.

Ensure that the log book in respect of all the plant machinery and equipments are kept properly and

up to date. Verify the machine log books and comment on the discrepancies observed .

Check that there is a proper lay out for free flow of materials.

Ensure that the actual production is carried out as per Production Planning and comment upon the

deviation from the production planning figures.

Carry out a study of machine efficiency and utilization to ensure that the machine are utilized as

per the laid standards of efficiency and utilization.

Вам также может понравиться

- Maintenance Department Audit ChecklistДокумент2 страницыMaintenance Department Audit ChecklistSchwihdi Zak78% (23)

- Internal Audit Checklist - PurchaseДокумент2 страницыInternal Audit Checklist - PurchaseSachin Ramdurg89% (9)

- Internal Audit Checklist 22716Документ34 страницыInternal Audit Checklist 22716mrugeshj95% (19)

- ISO 9001:2015 Internal Audit Checklist For Manufacturing CompaniesДокумент4 страницыISO 9001:2015 Internal Audit Checklist For Manufacturing Companiesjapv_pas100% (5)

- Audit Checklist For Store DepartmentДокумент431 страницаAudit Checklist For Store Departmentdepardieu197392% (76)

- Production Process Audit ChecklistДокумент2 страницыProduction Process Audit Checklistprofmlocampo100% (5)

- ISO9001-2015 Departmentwise Audit QuestionnaireДокумент15 страницISO9001-2015 Departmentwise Audit QuestionnaireAnonymous jKuXWubR886% (7)

- Internal Audit Checklist - Quality Assurance & Quality ControlДокумент3 страницыInternal Audit Checklist - Quality Assurance & Quality ControlSachin Ramdurg100% (2)

- Process & Product Audit Check SheetДокумент6 страницProcess & Product Audit Check SheetPrakashRai100% (7)

- Accounts Dept Audit ChecklistДокумент3 страницыAccounts Dept Audit Checklistandruta1978100% (4)

- Audit Checklist in Production AreaДокумент5 страницAudit Checklist in Production AreaPrince Moni100% (2)

- Stores and Spare PartsДокумент3 страницыStores and Spare PartsWalid Sonji0% (1)

- Sample Checklist For Admin AuditДокумент4 страницыSample Checklist For Admin AuditShiv Shankar100% (22)

- Internal Audit Checklist of Administration DepartmentДокумент6 страницInternal Audit Checklist of Administration DepartmentRojan ShresthaОценок пока нет

- Manufacturing Process Audit ChecklistДокумент4 страницыManufacturing Process Audit Checklistgksp100% (4)

- Internal Audit Checklist - Packing & DispatchДокумент2 страницыInternal Audit Checklist - Packing & DispatchSachin Ramdurg100% (6)

- Internal Audit Checklist - MaintenanceДокумент2 страницыInternal Audit Checklist - MaintenanceSachin Ramdurg92% (12)

- Internal Audit Checklist - StoresДокумент2 страницыInternal Audit Checklist - StoresSachin Ramdurg75% (4)

- Stores and Spares Audit ChecklistДокумент4 страницыStores and Spares Audit Checklistandruta197840% (5)

- H13 611 PDFДокумент14 страницH13 611 PDFMonchai PhaichitchanОценок пока нет

- Internal Audit Checklist ProductionДокумент9 страницInternal Audit Checklist Productiondhir.ankur100% (2)

- Audit Checklist in Production AreaДокумент5 страницAudit Checklist in Production AreaPrince Moni100% (2)

- Repair Audit ChecklistДокумент2 страницыRepair Audit Checklistandruta1978100% (2)

- I General: Internal Audit ChecklistДокумент32 страницыI General: Internal Audit Checklistlaltamater83% (12)

- 34 Internal Audit ChecklistДокумент31 страница34 Internal Audit ChecklistMudit Kothari100% (3)

- Product & Manufacturing Process Audit Checklist: Part NumberДокумент6 страницProduct & Manufacturing Process Audit Checklist: Part NumberDuy Le100% (4)

- Internal Audit Checklist PRODUCTIONДокумент6 страницInternal Audit Checklist PRODUCTIONRavi Baghel100% (3)

- Internal Audit Dept Wise Check ListДокумент31 страницаInternal Audit Dept Wise Check ListVijay Hemwani100% (2)

- Internal Quality Audit ChecklistДокумент56 страницInternal Quality Audit Checklistronnie santiago100% (4)

- Internal Audit ISO 9001-2008 Checklist 1-20-12Документ43 страницыInternal Audit ISO 9001-2008 Checklist 1-20-12TravisОценок пока нет

- Internal Audit Checklist - QualityДокумент3 страницыInternal Audit Checklist - QualitySachin Ramdurg100% (1)

- Auditing Fixed Assets and Capital Work in ProgressДокумент23 страницыAuditing Fixed Assets and Capital Work in ProgressMM_AKSI87% (15)

- Internal Audit Checklist - Tool ManufacturingДокумент1 страницаInternal Audit Checklist - Tool ManufacturingSachin Ramdurg100% (2)

- Internal Audit Checklist - Top ManagementДокумент1 страницаInternal Audit Checklist - Top ManagementSachin Ramdurg100% (4)

- Internal Audit Checklist For Mechanical Maintenance Department AuditДокумент9 страницInternal Audit Checklist For Mechanical Maintenance Department AuditSandeep Kaundinya100% (1)

- IQA Audit ChecklistДокумент26 страницIQA Audit ChecklistnorlieОценок пока нет

- Audit ChecklistДокумент67 страницAudit ChecklistseawykОценок пока нет

- Repair Audit ChecklistДокумент2 страницыRepair Audit Checklistandruta1978100% (2)

- Business Development Audit ChecklistДокумент2 страницыBusiness Development Audit Checklistandruta197867% (3)

- BackgroundsДокумент13 страницBackgroundsRaMinah100% (8)

- Production Audit ChecklistДокумент1 страницаProduction Audit ChecklistAnton MymrikovОценок пока нет

- Dispatch of Goods and Receipt of Materials Audit ChecklistДокумент3 страницыDispatch of Goods and Receipt of Materials Audit Checklistandruta197850% (2)

- ISO 9001 2008 Audit ChecklistДокумент20 страницISO 9001 2008 Audit ChecklistTorres EnriqueОценок пока нет

- Procedure For Internal AuditsДокумент2 страницыProcedure For Internal AuditsLuke J LandryОценок пока нет

- Supplier Audit ChecklistДокумент21 страницаSupplier Audit ChecklistAnonymous W2gdmMVhoM100% (2)

- Admin Audit ChecklistДокумент7 страницAdmin Audit Checklistandruta1978100% (1)

- Process AuditДокумент15 страницProcess Auditdesurkarb100% (2)

- Internal Audit Checklist PurchaseДокумент4 страницыInternal Audit Checklist Purchasedhir.ankur100% (2)

- Purchase Audit ChecklistДокумент2 страницыPurchase Audit Checklistandruta197850% (2)

- Utilities Audit ChecklistДокумент2 страницыUtilities Audit Checklistandruta1978100% (1)

- Traceability Audit To Suppliers: SQE / SD-Check-listДокумент43 страницыTraceability Audit To Suppliers: SQE / SD-Check-listMarceta BrankicaОценок пока нет

- 2016 Ia Sample ChecklistДокумент5 страниц2016 Ia Sample ChecklistMiss BreedloveОценок пока нет

- Audit Objectives & Risks Work Done With Observations Observations Noted Management's Response ObjectiveДокумент3 страницыAudit Objectives & Risks Work Done With Observations Observations Noted Management's Response Objectiveusmanafzalacca100% (2)

- Internal Audit ProgramДокумент3 страницыInternal Audit ProgramTakogee100% (1)

- Audit of Warehouse and WeighingДокумент49 страницAudit of Warehouse and WeighingGayatri Tiwaskar100% (2)

- Supplier Audit Checklist - ZftvsДокумент3 страницыSupplier Audit Checklist - Zftvsaboo2uОценок пока нет

- General Process Audit QuestionsДокумент8 страницGeneral Process Audit QuestionsTracy TreacherОценок пока нет

- Chapter 10 Production CycleДокумент3 страницыChapter 10 Production CycleZenn Vanrim Lopez100% (1)

- AIS6e.ab - Az Ch07Документ51 страницаAIS6e.ab - Az Ch07Engel Racraquin BristolОценок пока нет

- Ais Conversion CycleДокумент51 страницаAis Conversion CycleAms Penaflor100% (6)

- Production Audit ProgramДокумент3 страницыProduction Audit Programshiuh chyngОценок пока нет

- Production Planning & ControlДокумент38 страницProduction Planning & ControlNaveen KapoorОценок пока нет

- Production Control FormsДокумент12 страницProduction Control Formsshawar69100% (1)

- Production Planning & ControlДокумент12 страницProduction Planning & Controlshawar69Оценок пока нет

- Production Control CheckingДокумент1 страницаProduction Control Checkingrajiv71Оценок пока нет

- Maersk Sustainability Report 2012 PDFДокумент85 страницMaersk Sustainability Report 2012 PDFandruta1978Оценок пока нет

- Article To Risk-AssessmentДокумент9 страницArticle To Risk-Assessmentandruta1978Оценок пока нет

- Calendar 2016Документ1 страницаCalendar 2016andruta1978Оценок пока нет

- Risk and Compliance - ArticleДокумент1 страницаRisk and Compliance - Articleandruta1978Оценок пока нет

- Identification and TraceabilityДокумент6 страницIdentification and Traceabilityandruta1978100% (1)

- Mandatory Records As Per ISO 9001Документ1 страницаMandatory Records As Per ISO 9001andruta1978Оценок пока нет

- Ebook On How To Implement An ISO 9001 QMSДокумент53 страницыEbook On How To Implement An ISO 9001 QMSandruta1978Оценок пока нет

- Admin Audit ChecklistДокумент7 страницAdmin Audit Checklistandruta1978100% (1)

- Utilities Audit ChecklistДокумент2 страницыUtilities Audit Checklistandruta1978100% (1)

- Purchase Audit ChecklistДокумент2 страницыPurchase Audit Checklistandruta197850% (2)

- Outsourcing Audit ChecklistДокумент1 страницаOutsourcing Audit Checklistandruta1978Оценок пока нет

- PR Audit ChecklistДокумент3 страницыPR Audit Checklistandruta1978Оценок пока нет

- Dispatch of Goods and Receipt of Materials Audit ChecklistДокумент3 страницыDispatch of Goods and Receipt of Materials Audit Checklistandruta197850% (2)

- Chiyoda CSR Report - 2006Документ16 страницChiyoda CSR Report - 2006andruta1978100% (1)

- Syllabus: What Is Artificial Intelligence? ProblemsДокумент66 страницSyllabus: What Is Artificial Intelligence? ProblemsUdupiSri groupОценок пока нет

- Battery Guide - 2021Документ27 страницBattery Guide - 2021Mario LaurieОценок пока нет

- Mahesh R Pujar: (Volume3, Issue2)Документ6 страницMahesh R Pujar: (Volume3, Issue2)Ignited MindsОценок пока нет

- Focus Edition From GC: Phosphate Bonded Investments For C&B TechniquesДокумент35 страницFocus Edition From GC: Phosphate Bonded Investments For C&B TechniquesAlexis De Jesus FernandezОценок пока нет

- 52 - JB CHP Trigen - V01Документ33 страницы52 - JB CHP Trigen - V01July E. Maldonado M.Оценок пока нет

- PE MELCs Grade 3Документ4 страницыPE MELCs Grade 3MARISSA BERNALDOОценок пока нет

- COURTESY Reception Good MannersДокумент1 страницаCOURTESY Reception Good MannersGulzina ZhumashevaОценок пока нет

- 2016 IT - Sheilding Guide PDFДокумент40 страниц2016 IT - Sheilding Guide PDFlazarosОценок пока нет

- Csu Cep Professional Dispositions 1Документ6 страницCsu Cep Professional Dispositions 1api-502440235Оценок пока нет

- Siemens Rapidlab 248, 348, 840, 845, 850, 855, 860, 865: Reagents & ControlsДокумент2 страницыSiemens Rapidlab 248, 348, 840, 845, 850, 855, 860, 865: Reagents & ControlsJuan Carlos CrespoОценок пока нет

- Elpodereso Case AnalysisДокумент3 страницыElpodereso Case AnalysisUsama17100% (2)

- WHO Guidelines For Drinking Water: Parameters Standard Limits As Per WHO Guidelines (MG/L)Документ3 страницыWHO Guidelines For Drinking Water: Parameters Standard Limits As Per WHO Guidelines (MG/L)114912Оценок пока нет

- Pantalla MTA 100Документ84 страницыPantalla MTA 100dariocontrolОценок пока нет

- 1995 Biology Paper I Marking SchemeДокумент13 страниц1995 Biology Paper I Marking Schemetramysss100% (2)

- TESTДокумент27 страницTESTLegal CheekОценок пока нет

- Fundamentals of Signal and Power Integrity PDFДокумент46 страницFundamentals of Signal and Power Integrity PDFjaltitiОценок пока нет

- Chinese Paper Cutting Work SheetДокумент4 страницыChinese Paper Cutting Work Sheet黃梓Оценок пока нет

- Komunikasi Sebagai Piranti Kebijakan Bi: Materi SESMABI Mei 2020Документ26 страницKomunikasi Sebagai Piranti Kebijakan Bi: Materi SESMABI Mei 2020syahriniОценок пока нет

- Native VLAN and Default VLANДокумент6 страницNative VLAN and Default VLANAaliyah WinkyОценок пока нет

- Shelly e CommerceДокумент13 страницShelly e CommerceVarun_Arya_8382Оценок пока нет

- Iphone and Ipad Development TU GrazДокумент2 страницыIphone and Ipad Development TU GrazMartinОценок пока нет

- Guidelines For Prescription Drug Marketing in India-OPPIДокумент23 страницыGuidelines For Prescription Drug Marketing in India-OPPINeelesh Bhandari100% (2)

- 레벨 테스트Документ2 страницы레벨 테스트BОценок пока нет

- The Kicker TranscriptionДокумент4 страницыThe Kicker TranscriptionmilesОценок пока нет

- Research 093502Документ8 страницResearch 093502Chrlszjhon Sales SuguitanОценок пока нет

- Final WMS2023 HairdressingДокумент15 страницFinal WMS2023 HairdressingMIRAWATI SAHIBОценок пока нет

- Production of Bioethanol From Empty Fruit Bunch (Efb) of Oil PalmДокумент26 страницProduction of Bioethanol From Empty Fruit Bunch (Efb) of Oil PalmcelestavionaОценок пока нет

- Final Selection Criteria Tunnel Cons TraДокумент32 страницыFinal Selection Criteria Tunnel Cons TraMd Mobshshir NayeemОценок пока нет