Академический Документы

Профессиональный Документы

Культура Документы

US4927617 Production of Ammonium Nitrate

Загружено:

Christian MavarezАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

US4927617 Production of Ammonium Nitrate

Загружено:

Christian MavarezАвторское право:

Доступные форматы

I

Umted States Patent [19]

[11] Patent Number:

Villard et a1.

[45]

[54]

4,308,049 12/1981 Mini .................................. .. 423/396

4,699,773 10/1987 Ulrichs et a1. .................... .. 422/113

PROCESS OF PRODUCING

CONCENTRATED SOLUTIONS 0}?

AMMONIUM NITRATE

Date of Patent:

813196 3/1937 France_

both of R0119", France

1029010 5/1953 France.

[73] Assignee: Societe Chimique des Charbonnages

;/

S.A. Paris France

[211

1426746

4/1966

496847 12/1938

Mar. 2, 1987

Field 61' Search ....................................... .. 423/396

[ 1

United Kingdom .............. .. 423/396

1105466 3/1968 United Kingdom .

.............................................. ..

56

tame '

France .

474181 10/1937 United Kingdom .............. .. 423/396

[58]

gran

App]_ NO; 20,770

[22] F11ed:

May 22, 1990

FOREIGN PATENT DOCUMENTS

[75] Inventors: Alexandre Villard; Yves Cotonea,

4,927,617

References Cited

OTHER PUBLICATIONS

Ammnium Nitride Techmbgy, U M- Olevski, PP

193-198, (1978).

Primary ExaminerJohn D011

U'S' PATENT DOCUMENTS

2,551,569 5/1951 Strelzoff ............................ .. 423/396

2,568,901 9/1951 Stengel .............................. .. 423/396

Assistant Examiner-Wayne A. Langel

Attorney, Agent, or Firm-Finnegan, Henderson,

Farabow, Garrett & Dunner

2,618,547 11/1952 Davenport et a1. .

2,755,176 7/1956 Pearce e181. .

[57]

gall?" Jr- 3,238,021 3/1966 Webb et a1.

Process for producing concentrated solutions of ammo

mtrate by neutrallzanon of mtnc acid wlth ammo

3,301,657

ep

ens

1/1967 Dee et a1. .......................... .. 423/396

ABSTRACT

-

ma 1 a P1P: mac r

3,310,371 3/1967 Lutz .

When the global ?ow of reactives corresponds to an

3,362,309 V1968 Tucker '

3399o31 8/1968 McCarthy '

output higher than 150 kg/h/cm2 neutralization is per

formed in the presence of recycled concentrated solu

3,419,378 12/1968

3 464808 9/1969

t.

f

.

.

wh

h

l bal ?

.

mm o ammomum nitrate.

en t e g o

ow 1s

'

3,482,945

3,502,441

Keams .

Keams _

'

higher

than

12/1969 Legal Jr. _

3/ 1970

I'CCYC1111 g

is not necess ary.

Hudson ............................. .. 423/396

3,503,706 3/ 1970 Legal, Jr. .

'

4 Claims, 1 Drawing Sheet

NH3

HNO3

R

NH4NO3

5%

US. Patent

May 22, 1990

NH3

NH4NO3

4,927,617

4,927,617

PROCESS OF PRODUCING CONCENTRATED

SOLUTIONS OF AMMONIUM NITRATE

When the global ?ow of reactives is such that the

production is higher than 150 kg/h/cmZ, it is no longer

necessary to recycle ammonium nitrate solutions. No

smoke is produced. It must however be noted that it is

The present invention relates to a process for produc

advantageous to introduce, on commencing operation,

ing concentrated solutions of ammonium nitrate by

neutralization of nitric acid with ammonia.

The present invention relates to a process for produc

ing concentrated solutions of ammonium nitrate charac

terized in that neutralization is carried out in a pipe

reactor.

The pipe reactor or tubular reactor is a length of pipe

having a rather small diameter and containing no inside

stuf?ng. These tubular reactors have been used for the

manufacture of ammonium phosphates by neutraliza

tion of phosphoric acid with ammonia. The reaction is

quite instantaneous and vaporization of the water con

tained in phosphoric acid takes place. The use of a pipe

reactor for the production of ammonium phosphate has

been described in many patents such as the following:

FR-B 1426746, USA 2618547, USA 2755176, USA

2902342, USA 2977201, USA 3238021, USA 3310371,

USA 3362809, USA 3399031, USA 3419378, USA

3464808, USA 3482945, USA 3503706. The pipe reactor

used is horizontally set or stands at small angle to an

horizontal line. The pipe reactors most generally used

have a diameter ranging between 200 mm and 10 mm

and a length ranging between 1.50 meter and 10 meters.

The ratio length/diameter is usually not below 50. Ac

cording to the present application neutralization of

nitric acid with ammonia is performed with or without

recycling of concentrated solution of ammonium nitrate

as a function of the global flow of reactives. Thus when

the global ?ow of reactives corresponds to an output

lower than 150 kg/h/cmz, the reaction leads to the

formation of an aerosol of droplets or of solids mi

croparticles generating an important cloud of smoke or

fog from which it is very difficult, if not possible, to

a certain quantity of ammonium nitrate solution. Thus,

at that time, the opening of the valves is not instanta

neous and takes about ten seconds during which plenty

of smoke is produced. Furthermore it is preferable to

provide a device for recycling ammonium nitrate solu

tions in order to be able to modify the global flow of the

reactives according to need.

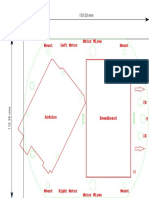

The process of the invention can be carried out in the

following unit.

This unit is essentially characterized by the fact that it

comprises at least a pipe reactor provided with feed

means for introducing reactives (HNO3-NH3), at least

a separator for separating steam from the reaction prod

uct (concentrated aqueous solution of ammonium ni

trate) and optionally recycling means of part of the

reaction product into pipe reactor. The pipe reactor has

feed means for recycled solution.

Other characteristics and advantages of the invention

will be better understood from the following descrip

tion with reference to the accompanying diagrammatic

drawing.

Pipe reactor (R) is provided at one of its ends with

three feed means for NH3, HNO3 and NH3NO3 recy

cled solutions. The feed means are preferably built up in

order to cause a turbulent ?ow. At the other end of the

pipe reactor, a concentrated solution of ammonium

nitrate is discharged and fed into separator (S). At the

bottom part of the separator (S), concentrated solutions

of ammonium nitrate are separated and stored. Part of

these solutions are optionally recycled after neutraliza

tion with NH; fed at (C). Storage tanks (G) may be

heated by inside heating means (V) in order to maintain

separate the desired product. The applicant has found 40 the solutions in a liquid state in case of unit stopping. In

the upper part of separator (S), steam is carried off

injected together with ammonia, into a flow of recycled

following arrow (F). Condensate is discharged at H.

solutions of ammonium nitrate, the pipe reactor product

Preheating of NH3 and HNO3 takes place in heat ex

is an easily separable mixture of droplets of ammonium

changers (ECH1, ECHZ) before introduction in reactor

nitrate solution and steam. Nitric acid is injected in the 45

(R). The amount of NH3 added in storage tank (G) a

presence of a volume of ammonium nitrate ranging

function

of the acidity of the product solutions, which is

between 1 and 5 times the volume of produced ammo

a function of the amount of HNO3 used. An excess of

nium nitrate solution. The lower the global ?ow of

HNO3 is necessary to maintain acidity in the product

reactives, the higher the recycling rate.

that, in such a case, when concentrated nitric acid is

It was already known to react concentrated nitric

acid and ammonia inside a high volume of aqueous

solution of ammonium nitrate. The reactives are in

issuing from the reactor in order to avoid loss of NH3.

The advantages of the process of the present inven

tion are the following:

jected in an apparatus comprising two distinct chambers

connected by vertical tubes. The reactives are intro

small investment cost for the reactor as it is very

duced at the bottom of the lower chamber and the reac 55

tion heat leads to vaporization of the water contained in

a very small inertia of the unit as the amounts of

concentrated nitric acid. This boiling takes place in the

second chamber disposed above the ?rst chamber and

communicating with the latter through vertical tubes. A

phenomenon of thermosiphon makes the product go up 60

risks due to acid nitrate are lowered as the volume of

simple and has a small diameter,

ammonium nitrate solutions circulating are small,

circulating solutions is small.

The following examples illustrate the invention.

EXAMPLE 1 (comparative)

in some vertical tubes and down in others. In this type

In a pipe reactor having a diameter of 15 mm are fed

of apparatus the recycle rate (calculated as the ratio of

per hour:

the volume of recycled ammonium nitrate to the vol

157 liters of 57.5% nitric acid,

ume of produced ammonium nitrate solution) is about

33.5 kg of gaseous ammonia at 20 C.

100/1. Installations using this type of reactor are cum 65

bersome and contain a large volume of a rather danger

A dense smoke is obtained and the test is stopped

ous product maintained at elevated temperatures

after a few minutes. The estimated loss of ammonium

nitrate is about 40%.

(140-l60 C.).

4,927,617

4

EXAMPLE 2

In an unit as illustrated in the annexed ?gure with the

same pipe reactor as in example 1 are fed per hour:

218.4 liters of 57.5% nitric acid at 20 C.,

5

46 kg of gaseous ammonia at 60 C.,

97.5 kg of gaseous ammonia at 58 C.

The output is 518 kg per hour of a weakly acidic

ammonium nitrate solution) having a concentration of

88.3% and a temperature of 148 C.

The total losses of N amount to 0.6%.

We claim:

1000 kg of recycled ammonium nitrate solution hav

1. Process for producing concentrated solutions of

ing a 92% concentration and a temperature of 150

C.

ammonium nitrate which comprises neutralizing nitric

acid with ammonia in a substantially horizontal pipe

reactor containing no packing wherein the global ?ow

having a 91.2% concentration and a temperature of 140

of reactants is less than 150 kg/h/cm2 and a recycled

C. is obtained. The total N losses are 5.8% of the total

?ow of ammonium nitrate solution is present having a

amount of N provided by HNO3 and NH3.

recycling ratio ranging between 1:1 and 5:1.

2. Process according to claim 1 further comprising

EXAMPLE 3

15 supplying reactants (HNO3 and NH3) to said pipe reac

In the same unit as in example 2 are fed per hour:

tor, separating said produced concentrated solution of

373 liters of 57.5% nitric acid at 20 C.,

ammonium nitrate from steam in a separator and recy

76.8 liters of gaseous ammonia at 80 C.,

cling said ammonium nitrate solution from said separa

700 kg of recycled ammonium nitrate solutions hav

tor into said pipe reactor.

ing a concentration of 92% and a temperature of 20

3. Process for producing concentrated solutions of

150 C. in which was introduced at C 1,2 kg of

ammonium nitrate which comprises neutralizing nitric

NH3.

acid with ammonia in a substantially horizontal pipe

The output is 1120 kg/h of a weakly acidic solution

reactor containing no packing wherein the global ?ow

(free acidity 6 g of HNO3 per liter of solution) having a

of reactants is greater than 150 kg/h/cm2 and no recy

concentration of 92.4% and a temperature of 155 C. 25 cling of ammonium nitrate solution is carried out.

The total losses of N amount to 0.15%.

4. Process according to claim 3 further comprising

supplying

reactants (HNO3 and NH3) to said pipe reac

EXAMPLE 4

An output of 1230 kg/h of ammonium nitrate solution

tor, and separating said concentrated solution of ammo

nium nitrate from steam in a separator.

In the same unit as in example 2 are fed per hour:

480 liters of 57.5% nitric acid preheated at 45 C.,

30

35

45

55

65

ll

Вам также может понравиться

- Cost Data Analysis For The Food IindustryДокумент11 страницCost Data Analysis For The Food IindustryChristian MavarezОценок пока нет

- Bulk Material Handling Belt-Conveyor-CatalogДокумент21 страницаBulk Material Handling Belt-Conveyor-CatalogjayОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Feed Mill InfoДокумент33 страницыFeed Mill InfoSapelОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Design and Fabricatino of Liquid Dispensing Machine Using Automatic Control For Engg IndustryДокумент7 страницDesign and Fabricatino of Liquid Dispensing Machine Using Automatic Control For Engg IndustryChristian MavarezОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Heat Sink Design Optimization Using The Thermal Bottleneck ConceptДокумент5 страницHeat Sink Design Optimization Using The Thermal Bottleneck ConceptChristian MavarezОценок пока нет

- Car Top FinalДокумент1 страницаCar Top FinalChristian MavarezОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Cost Standards For A Model Stationary Custom Feed Mill For The MidwestДокумент18 страницCost Standards For A Model Stationary Custom Feed Mill For The MidwestChristian MavarezОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Temperature, Pressure and Time Dependence of LubricantДокумент8 страницThe Temperature, Pressure and Time Dependence of LubricantChristian MavarezОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Isothermal Quenching of Crusher HammersДокумент1 страницаIsothermal Quenching of Crusher HammersChristian MavarezОценок пока нет

- Conveyer Screw Stops Bottles for LabelingДокумент3 страницыConveyer Screw Stops Bottles for LabelingChristian MavarezОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Optimal Sizing of Counterflow Cooler For PelletsДокумент72 страницыOptimal Sizing of Counterflow Cooler For PelletsChristian MavarezОценок пока нет

- Isothermal Quenching of Crusher HammersДокумент1 страницаIsothermal Quenching of Crusher HammersChristian MavarezОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Journal of Kones 2014 No. 4 Vol. - 21 Issn 1231-4005 Mlynarczyk111Документ8 страницJournal of Kones 2014 No. 4 Vol. - 21 Issn 1231-4005 Mlynarczyk111Christian MavarezОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- 3-3 THR - Keith Behnke - Feed Milling Milestones - ANC 2010Документ31 страница3-3 THR - Keith Behnke - Feed Milling Milestones - ANC 2010Christian Mavarez100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- US4927617 Production of Ammonium NitrateДокумент4 страницыUS4927617 Production of Ammonium NitrateChristian MavarezОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Investigating Limits in Naturally Cooled Systems Using FlothermДокумент6 страницInvestigating Limits in Naturally Cooled Systems Using FlothermChristian MavarezОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Mobile Crushing Plant: Rio Tinto Coal Australia Clermont Coal Mine (Australia) Turn-Key ProjectДокумент2 страницыMobile Crushing Plant: Rio Tinto Coal Australia Clermont Coal Mine (Australia) Turn-Key ProjectChristian MavarezОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- Journal of Kones 2014 No. 4 Vol. - 21 Issn 1231-4005 Mlynarczyk111Документ8 страницJournal of Kones 2014 No. 4 Vol. - 21 Issn 1231-4005 Mlynarczyk111Christian MavarezОценок пока нет

- 304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFДокумент16 страниц304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFAndressa EgerОценок пока нет

- Mobile CrushersДокумент8 страницMobile CrushersChristian MavarezОценок пока нет

- Animal Feed Compunding ProcessДокумент41 страницаAnimal Feed Compunding ProcessChristian Mavarez100% (1)

- ATTACHMENT A A Weight of Evidence Assessment of TДокумент67 страницATTACHMENT A A Weight of Evidence Assessment of TChristian MavarezОценок пока нет

- Production Process Analysis On Manufacturing of Hydraulic Gear PumpДокумент17 страницProduction Process Analysis On Manufacturing of Hydraulic Gear PumpChristian MavarezОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 605 05 Industrial Screw ConveyorДокумент1 страница605 05 Industrial Screw ConveyorChristian MavarezОценок пока нет

- 72Документ17 страниц72Christian MavarezОценок пока нет

- Agitated Vessel Heat Transfer Design PDFДокумент3 страницыAgitated Vessel Heat Transfer Design PDFmrariffОценок пока нет

- Common-Cause Failures of Centrifugal PumpsДокумент30 страницCommon-Cause Failures of Centrifugal PumpsingrbarrosОценок пока нет

- Ds Asphalt THF 1214 EngДокумент2 страницыDs Asphalt THF 1214 EngChristian MavarezОценок пока нет

- Cimbria Conveyor In-Outlets Dimensions GuideДокумент1 страницаCimbria Conveyor In-Outlets Dimensions GuideChristian MavarezОценок пока нет

- Vat Rates enДокумент27 страницVat Rates enpacocastroОценок пока нет

- Gas Turbine Heat Rejection and Refrigeration Cycle CalculationsДокумент8 страницGas Turbine Heat Rejection and Refrigeration Cycle CalculationsRENE JOSHUA PECASOОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- PV connector technical specifications from JinkoSolarДокумент1 страницаPV connector technical specifications from JinkoSolarqiTОценок пока нет

- ME1130 Mechanism of SolidificationДокумент15 страницME1130 Mechanism of SolidificationShivam RajОценок пока нет

- Operation and Service Everfresh Controlled Atmosphere: 69Nt40-489-100 SeriesДокумент178 страницOperation and Service Everfresh Controlled Atmosphere: 69Nt40-489-100 SeriesHéctor AraujoОценок пока нет

- Pocket Mechanic Manual (Petrol Version)Документ177 страницPocket Mechanic Manual (Petrol Version)Bill jonesОценок пока нет

- PanasonicДокумент15 страницPanasonicMohd HaniffОценок пока нет

- Magnets Test 3rd GradeДокумент4 страницыMagnets Test 3rd Gradeapi-33371151667% (3)

- 301 Basic Mechanics Course DescriptionДокумент2 страницы301 Basic Mechanics Course DescriptionAnonymous q9eCZHMuSОценок пока нет

- Bel Ray BrochureДокумент20 страницBel Ray BrochureaditОценок пока нет

- Concrete CoolingДокумент19 страницConcrete CoolingAbdulrahman AlnagarОценок пока нет

- Catalogue Sensors For Engine Management Incl Oxygen Sensors 4 0Документ428 страницCatalogue Sensors For Engine Management Incl Oxygen Sensors 4 0Timon2005100% (1)

- Gujarat Technological UniversityДокумент2 страницыGujarat Technological UniversityPARMAR MAHENDRAОценок пока нет

- Fcu Pressure Drop PDFДокумент18 страницFcu Pressure Drop PDFvishalОценок пока нет

- Manta To Richmond SIMOPS Risk Matrix FINALДокумент1 страницаManta To Richmond SIMOPS Risk Matrix FINALDesmond Chang50% (2)

- Hvac-Question & AnswerДокумент4 страницыHvac-Question & AnswerKkrkollam KrishnaKumarОценок пока нет

- Reading Comprehension EnviromentДокумент5 страницReading Comprehension Enviromentandreapichoni100% (1)

- Chemistry Practice Paper SA1 Class 9 CBSEДокумент2 страницыChemistry Practice Paper SA1 Class 9 CBSEgurdeepsarora8738Оценок пока нет

- Seismic Acquisition and Processing BWДокумент33 страницыSeismic Acquisition and Processing BWghassen laouiniОценок пока нет

- Lifeboat Engine Operation Manual 380JДокумент29 страницLifeboat Engine Operation Manual 380JDuarte100% (2)

- CH-2 IS MATTER AROUND US PUREДокумент2 страницыCH-2 IS MATTER AROUND US PUREgurdeepsarora8738100% (1)

- Controls InstrumentationДокумент245 страницControls InstrumentationFreddy Yánez100% (1)

- Process AuxillariesДокумент58 страницProcess AuxillariesHarsh ParmarОценок пока нет

- Engine Fundamentals 1Документ3 страницыEngine Fundamentals 1anuradhaОценок пока нет

- Structure of SolidsДокумент22 страницыStructure of SolidsNicole Anne Borromeo100% (1)

- An Impedance Source Multi-Level Three Phase Inverter With Common Mode Voltage Elimination and Dead Time CompensationДокумент18 страницAn Impedance Source Multi-Level Three Phase Inverter With Common Mode Voltage Elimination and Dead Time CompensationRadu GodinaОценок пока нет

- PAUT Course Material PDFДокумент189 страницPAUT Course Material PDFYassine Koot100% (3)

- Quat KrugerДокумент52 страницыQuat Krugerruby0808Оценок пока нет

- Sungazing Protocol: How to Practice Hira Ratan Manek's Sun Energy MethodДокумент3 страницыSungazing Protocol: How to Practice Hira Ratan Manek's Sun Energy Methodparra7Оценок пока нет

- Bachelor of Engineering (Hons) Chemical Course OutlineДокумент2 страницыBachelor of Engineering (Hons) Chemical Course OutlineWan Mohammad Faris FahmiОценок пока нет

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaОт EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaОценок пока нет

- Sully: The Untold Story Behind the Miracle on the HudsonОт EverandSully: The Untold Story Behind the Miracle on the HudsonРейтинг: 4 из 5 звезд4/5 (103)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureОт EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureРейтинг: 5 из 5 звезд5/5 (124)

- Pale Blue Dot: A Vision of the Human Future in SpaceОт EverandPale Blue Dot: A Vision of the Human Future in SpaceРейтинг: 4.5 из 5 звезд4.5/5 (586)

- The Fabric of Civilization: How Textiles Made the WorldОт EverandThe Fabric of Civilization: How Textiles Made the WorldРейтинг: 4.5 из 5 звезд4.5/5 (57)

- A Place of My Own: The Architecture of DaydreamsОт EverandA Place of My Own: The Architecture of DaydreamsРейтинг: 4 из 5 звезд4/5 (241)