Академический Документы

Профессиональный Документы

Культура Документы

Jaw Coupling PDF

Загружено:

hibhavuИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Jaw Coupling PDF

Загружено:

hibhavuАвторское право:

Доступные форматы

SNAP WRAP COUPLINGS

INDIA

... the coupling that pays for itself

Type L Coupling

Type SW Coupling

Type RRS Spacer Coupling

6 ways the "Snap Wrap"

ith its unique wrap around

coupling can help pay

for itself:

Nitrile rubber connecting element, the

Snap Wrap coupling eliminates the need

for dismantling the connected equipment

1. Prebored hubs

Hubs bored and keyed to

standard IEC motor shaft sizes

at no extra cost.

2. Snap Wrap

element

Ease of inspection and

replacement within 5 minutes.

amounts.

3. Modular hub

design

Both Models , SW & RRS

use the same hubs.

Combined with a range of prebored

4. Spacer coupling

RRS spacer model is available

for pump applications.

5. Fully machined

hubs

Balance, ease of alignment

and smooth contact surface

for elements are assured.

6. Any environment

Water, oil, greases & dust do not

affect performance.

while inspecting or replacing the

element - a major benefit when downtime on machinery can run into huge

hubs, a modular hub design and a

spacer option, the Snap Wrap coupling is

unsurpassed for quality, flexibility, speed

of installation and maintenance.

1

TECHNICAL

DATA

JAW - FLEX COUPLINGS

INDIA

SELECTION PROCEDURE

EXAMPLE

(a)

A coupling is required to transmit 65 kW from an electric

motor which runs at 1500 rpm to a centrifugal pump for

12 hours a day. The motor shaft diameter is 60 mm. and

the pump shaft diameter is 55 mm.

Service Factor

Determine appropriate SERVICE FACTOR from table A.

(b) Design Power

Multiply running power of driven machinery by the service

factor. This gives DESIGN POWER which is used as a

basis for coupling selection.

(c)

(a) Service Factor

From Table A the service factor is 1.0

(b) Design Power

Coupling Size

Design Power 65 x 1.0 = 65 kW

(c) Coupling Size

Read from 1500 rpm in the speed column of

'TECHNICAL DATA' table. The first power to

exceed the DESIGN POWER of 65 kW is 84 kW.

The size of the coupling specified in the first column

corresponding to 84 kW is SW-276.

(d) Bore Size

Max. Bore for coupling size SW-276 is 75 mm.

This shows that both the shaft diameters are within

the range.

Refer respective table for your required coupling type and

read from the appropriate speed column until a power

equal to or greater than the DESIGN POWER is found.

(d) Bore Size

Refer respective coupling 'TECHNICAL DATA' table to

check that the required bores can be accommodated.

A : SERVICE FACTORS

Type of Driving Unit

SPECIAL CLASSES

For applications where substantial shock, vibration and torque fluctuations

occur and for reciprocating machines e.g. internal combustion engines,

piston pumps and compressors, refer to Lovejoy with full machine details

Driven Machine Class

Electric Motors

Internal Combustion Engines

Steam Engines

Water Turbines

Hours per day duty

Hours per day duty

8

and

under

over 8

to 16

inclusive

over

16

8

and

under

over 8

to 16

inclusive

over

16

1.00

1.00

1.00

1.00

1.10

1.10

1.10

1.10

1.20

1.20

1.25

1.25

1.25

1.40

1.60

1.60

1.80

2.00

UNIFORM

Agitators, Brewing machinery, Centrifugal Blowers, Conveyors, Centrifugal

Fans and Pumps, Generators, Sewage disposal Equipments.Evaporators,

Feeders, Textile machines, Wood working machines.

MODERATE SHOCK*

Clay working machinery, Crane Hoists, Laundry machinery, Machine Tools,

Rotary Mills, Paper Mill machinery, Non-uniformly loaded centrifugal pumps,

Rotary Screens, Centrifugal Compressors.Shredders, Printing presses, Oil

industry, Mixers, Food industry, Beaters, Bucket elevators, Gear pumps,

Wood working machinery, Textile machinery

HEAVY SHOCK*

Reciprocating Conveyors, Crushers, Shakers, Metal Mills, Rubber machinery

(Banbury Mixers and Mills) Reciprocating Compressors, Welding Sets,

Freight & passenger elevators, Cooling tower fans, Hammer mills,

Reciprocating pumps, Vibrating screens, Winches, Wire drawing machines.

* It is recommended that keys with top clearance are fitted for applications where load fluctuation is expected.

MISALIGNMENT CAPABILITY

PARALLEL 0.4 mm

ANGULAR - 1

TYPE

L/SW/RRS

JAW - FLEX COUPLINGS

INDIA

G

D

G

T

S = STD. SPACER LENGTH

100,140,180 mm.

TYPE L

TYPE SW

TYPE RRS

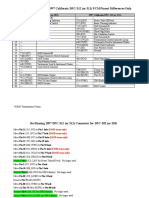

TECHNICAL DATA

kW Capacity

Coupling

Type

Bore

Rated

1500

3000

Nm

rpm

rpm

rpm

030

0.38

0.004

0.06

0.12

10

16

6.5

16

21

050

2.80

0.03

0.45

0.90

16

27

15

27

42

070

4.90

0.05

0.75

1.50

20

36

19

36

51

075

9.80

0.10

1.50

3.00

22

44.5

21

44.5

55

075

9.80

0.10

1.50

3.00

22

44.5

21

39

13

55

095

21.1

0.22

3.30

6.60

10

28

65

54

25

49

19

13

63

099

35.1

0.37

5.55

11.10

10

30

78

65

27

51

27

19

72

100

46.4

0.49

7.35

14.70

10

38

78

65

35

65

27

88

100A

46.4

0.49

7.35

14.70

10

35

78

65

35

57

27

22

88

110

89.0

0.93

13.95

27.90

15

42

96

85

43

76

35

30

108

150

141

1.49

22.35

44.70

15

48

111

96

45

80

35

30

115

190

190

2.01

30.15

60.30

15

60

129

115

54

102

45

35

133

225

265

2.76

41.40

82.80

15

65

142

127

64

111

45

45

153

226

327

3.43

51.45

102.90

25

70

153

137

70

119

51

54

178

276

532

5.60

84.00

168.00

25

75

173

157

80

127

60

61

200

280

782

8.20 123.00 246.00*

30

80

208

192

80

140

70

61

200

295

1279

13.4 201.00

30

95

253

237

95

162

80

70

238

SW

2955

2132

22.4 336.00

30

105

253

237

108

180

80

83

264

300

3047

31.9 478.50

30

105

272

254

115

180

100

90

283

350

4308

45.0 675.00

30

115

323

305

128

200

115

103

309

SW

RRS

Max.

SW

/RRS

All dimensions are in mm.

Above ratings are based on shore 800 elements.

Shore 920 elements are recommended for low rpm applications.

For power rating of elements with shore 800 & 920, refer table B on page 4.

For RRS/SW maintain gap G at the time of assembly.

Maximum bores can be increased in case of steel hubs. Consult manufacturer

thru

Overall

100

Min.

Gap

Torque

Size

Length

Bore D

Length

T (SW/L)

* Dynamic balancing preferred at this speed

.Material : Sintered iron for sizes 030 to 075

Aluminum for sizes 050 to 110 & for all RRS spacers.

Cast Iron for sizes 075 to 350.

075 -- Aluminium/Cast Iron

075 -- Sintered Iron

# For RRS, T = S + 2D

TYPE

TL/TSW

JAW - FLEX COUPLINGS

INDIA

A : DIMENSIONAL DATA

Bush n

Size

TL/TSW

099

100/100A

110

150

190

225

226

276

280

295

2955

300

350

350

Size

l Max. Bore

mm

Inch

1008

1108

1210

1210

1610

2012

2012

2517

2517

3020

3020

3020

3525

3535

25

28

32

32

42

50

50

60

60

75

75

75

100

90

1

1 1/8

1 1/4

1 1/4

1 5/8

2

2

2 1/2

2 1/2

3

3

3

4

3 1/2

TL

65

65

85

96

115

127

137

157

192

237

237

254

305

305

TSW

78

78

96

111

129

142

153

173

208

253

253

272

323

323

55

60

83

92

102

115

115

124

124

159

159

180

200

200

27

27

35

35

45

45

51

60

70

80

80

100

115

115

34

44

48

55

63

63

70

78

78

98

98

103

103

103

18

18

22

25

25

25

38

40

40

48

48

53

53

53

15.5

10.5

13.5

11.5

7.5

14.5

17.5

27.5

27.5

27.5

27.5

27.5

41.5

64.0

23.5

23.5

26.5

26.5

26.5

33.5

33.5

46.5

46.5

52.5

52.5

52.5

66.5

89.0

29

29

38

38

38

42

42

48

48

55

55

55

67

67

65

65

75

78

78

92

105

133

133

153

153

158

186

231

B : TECHNICAL DATA

kW capacity

Size

TL/TSW

100 rpm

80

099

100/100A

110

150

190

225

226

276

280

295

2955

300

350

350

0.37

0.49

0.93

1.49

2.01

2.76

3.43

5.60

8.20

13.4

22.4

31.9

45.0

45.0

92

1500 rpm

0

0.79

1.05

2.10

3.35

4.19

6.28

6.86

11.20

16.40

26.80

44.80

63.80

90.20

90.20

80

3000 rpm

92

5.55

11.89

7.35

15.75

13.95

31.50

22.35

50.25

30.15

62.85

41.40

94.20

51.45 102.90

84.00 168.00

123.00 246.00

201.00 402.00

336.00 672.00

478.50 957.00

675.00 1353.00

675.00 1353.00

80

11.1

14.70

27.90

44.70

60.30

82.80

102.90

168.00

*246.00

------

92

23.79

31.50

63.00

100.50

125.70

188.40

205.80

336.00

*492.00

------

Weight

per coupling

kg

1.24

1.26

2.46

3.30

4.71

5.80

8.48

13.75

18.00

34.15

32.70

39.10

63.30

73.60

Moment of Inertia

(WR2)per coupling

kg.m2

0.00064

0.00066

0.0020

0.0036

0.0076

0.0112

0.0184

0.0380

0.0720

0.2140

0.2040

0.3000

0.6500

0.6800

Dynamic tor.

Stiffness

Nm/ Deg.

12

12

30

37

61

80

122

222

393

894

1491

2206

3205

3205

Shore 92 spiders are recommended for low rpm applications.

l All dimensions are in mm unless otherwise specified.

* Dynamic Balancing preferred at these speeds.

l For detailed information about Taper Bush bore, please refer Taper Bush catalogue.

J is the wrench clearance

required for tightening

and loosening the bush

on the shaft. The use of

shortened key will allow

this dimension to be

reduced. Couplings can

be supplied with F/F or

H/H or F/H flange as

required.

Weight is for flange

without Bore.

n Lovejoy couplings are

supplied with taper bore

suitable to the bush size

specified in this column.

TL couplings are supplied

with spider.

TSW couplings are

supplied with snap-wrap.

In view of our constant endeavour to improve quality of our products, we reserve the right to alter or change specifications without prior notice.

This document is the intellectual property of Rathi Transpower Pvt. Ltd. and subject to copyright.

Rathi Transpower Pvt Ltd

UKAS

ISO 9001

QUALITY

MANAGEMENT

008

Distributor

Rathi Chambers, 7, Deccan College Road,

Pune 411 006.(INDIA)

Phone : 91-20-6696820, 6694826, 6697032

Fax : 91-20-6695655

E-mail : info@rathigroup.com

Website : www.rathitranspower.com

4

R-J-01/0-4/02

Вам также может понравиться

- Catalogo Giunti Samiflex - GB PDFДокумент8 страницCatalogo Giunti Samiflex - GB PDFDANE80Оценок пока нет

- PSK GET 9th v2Документ827 страницPSK GET 9th v2Luis PozoОценок пока нет

- VTL 30 DetailsДокумент4 страницыVTL 30 DetailspranaybinaykeОценок пока нет

- Remedial Tools HandbookДокумент250 страницRemedial Tools Handbookjdmacbook100% (5)

- Curve Jaw Type Coupling LOVEJOY PDFДокумент17 страницCurve Jaw Type Coupling LOVEJOY PDFRafo Vega GuerovichОценок пока нет

- Air Mite CatalogДокумент56 страницAir Mite Catalogtemoc128Оценок пока нет

- Catálogo de Camisas MELLINGДокумент24 страницыCatálogo de Camisas MELLINGricassterОценок пока нет

- Fits & TolerancesДокумент6 страницFits & Tolerancessuperman92makОценок пока нет

- Group Crushers Cone GCДокумент8 страницGroup Crushers Cone GCOrlando MelipillanОценок пока нет

- Industrial Tools For Fabrication and MaintenanceДокумент216 страницIndustrial Tools For Fabrication and MaintenanceMohammedОценок пока нет

- RaiseBoringUsersManual PDFДокумент40 страницRaiseBoringUsersManual PDFJhonatanLiCuadradoОценок пока нет

- T101 Drilling MachineДокумент4 страницыT101 Drilling MachineRemmy Torres VegaОценок пока нет

- Tyre Coupling CatalogДокумент9 страницTyre Coupling CatalogKariem R NoweerОценок пока нет

- CopperalloybrakeДокумент4 страницыCopperalloybrakeReinaldo Side JuniorОценок пока нет

- Driven Tool Holders - MazakДокумент54 страницыDriven Tool Holders - MazakLuvuyo ZithoОценок пока нет

- Ci NLДокумент12 страницCi NLanuraeОценок пока нет

- Max Air PDFДокумент8 страницMax Air PDFKNIGHTHAGENОценок пока нет

- Sepro Equipment BrochuresДокумент26 страницSepro Equipment BrochuresIvan Zurita100% (1)

- WP Cross ReferenceДокумент12 страницWP Cross ReferenceCentral HydraulicsОценок пока нет

- Gets InglesДокумент1 088 страницGets InglesKjatunMayu Gutierrez100% (6)

- DC MotorEnglishДокумент10 страницDC MotorEnglishVikaas JainОценок пока нет

- Thomson Super Metric Ball Bushing Bearings SpecsheetДокумент11 страницThomson Super Metric Ball Bushing Bearings SpecsheetElectromateОценок пока нет

- Jaw CrushersДокумент2 страницыJaw CrushersOrlando Melipillan0% (1)

- Final Idler and Roller CatalogДокумент6 страницFinal Idler and Roller CatalogShubham Khurana100% (1)

- Air Spring ManualДокумент11 страницAir Spring ManualPremchand BeuraОценок пока нет

- Haydon Kerk - Complete CatalogДокумент256 страницHaydon Kerk - Complete CatalogElectromateОценок пока нет

- Falk Coupling SGДокумент16 страницFalk Coupling SGJorge Ernesto PinzonОценок пока нет

- Pneumatic AutomationДокумент3 страницыPneumatic AutomationLuis MoreiraОценок пока нет

- Acople Falk-WrapflexДокумент16 страницAcople Falk-Wrapflexhenkis73Оценок пока нет

- Meraj Engineering - CatalogueДокумент29 страницMeraj Engineering - CatalogueMohammad Iqbal KhanОценок пока нет

- WD Cross ReferenceДокумент12 страницWD Cross ReferenceCentral HydraulicsОценок пока нет

- John Crane Acoplamientos Serie LДокумент8 страницJohn Crane Acoplamientos Serie LBenicio Joaquín Ferrero BrebesОценок пока нет

- Motor 13Документ5 страницMotor 13mctawardsОценок пока нет

- Spicer Wing Bearing Driveshafts CatalogueДокумент38 страницSpicer Wing Bearing Driveshafts CatalogueJose Israel Correa CortesОценок пока нет

- Coupling PDFДокумент7 страницCoupling PDFAnkur GaurОценок пока нет

- BIG Daishowa BIG-PLUS Tooling SystemДокумент0 страницBIG Daishowa BIG-PLUS Tooling Systemgeav25653855Оценок пока нет

- Elliot TurbineДокумент2 страницыElliot TurbinefjafarvandОценок пока нет

- Alignment Coupling Operation Manual Tyre-FlexДокумент37 страницAlignment Coupling Operation Manual Tyre-Flexer_sanjaypatelОценок пока нет

- T101 Drilling Machine BrochureДокумент4 страницыT101 Drilling Machine BrochureRicardo OrtegaОценок пока нет

- T101 Drilling MachineДокумент4 страницыT101 Drilling MachineFranklin Avendaño ArapaОценок пока нет

- IJ900 02 RedcutorДокумент19 страницIJ900 02 RedcutorJose Israel Correa CortesОценок пока нет

- Maintenance Arpex enДокумент39 страницMaintenance Arpex enPatrick BaridonОценок пока нет

- CADENAINGENIERIA Cat1Документ241 страницаCADENAINGENIERIA Cat1Armando Acosta100% (1)

- Catalogo Allied Locke PDFДокумент241 страницаCatalogo Allied Locke PDFGuillermo MendezОценок пока нет

- Jobber JR DetailsДокумент2 страницыJobber JR DetailsUrvish PatelОценок пока нет

- G2DT-21 2HP-230V-60HZ-1FДокумент8 страницG2DT-21 2HP-230V-60HZ-1FDaniel AbantoОценок пока нет

- VTP & VPC: Vertical Turbine Wet Pit and Double Casing Pumps Maintenance ChecklistДокумент2 страницыVTP & VPC: Vertical Turbine Wet Pit and Double Casing Pumps Maintenance Checklistsathiyam2kОценок пока нет

- CH 2500Документ20 страницCH 2500Ahmadreza Aminian100% (1)

- KF 006 Grid CouplingsДокумент30 страницKF 006 Grid CouplingsShravan VogulamОценок пока нет

- Okb Top SeriesДокумент4 страницыOkb Top SeriesIrma Pokvić-Ramulj100% (1)

- Acoplamiento DuraflexДокумент12 страницAcoplamiento DuraflexscribdviviОценок пока нет

- Veljan Hydraulic CatlogueДокумент20 страницVeljan Hydraulic CatlogueRaji SuriОценок пока нет

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyОт EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyРейтинг: 5 из 5 звезд5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.От EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Оценок пока нет

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreОт EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreРейтинг: 4.5 из 5 звезд4.5/5 (11)

- High-Performance GM LS-Series Cylinder Head GuideОт EverandHigh-Performance GM LS-Series Cylinder Head GuideРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Unit Operations Thumb RulesДокумент9 страницUnit Operations Thumb RuleshibhavuОценок пока нет

- Condensate Extracting PumpДокумент15 страницCondensate Extracting PumphibhavuОценок пока нет

- Eagle SealingДокумент30 страницEagle SealinghibhavuОценок пока нет

- GMM Operating ManualДокумент51 страницаGMM Operating Manualhibhavu100% (1)

- Kinney Vacuum Pump OilДокумент4 страницыKinney Vacuum Pump OilhibhavuОценок пока нет

- Dimensions Tables D and E BS 10 1962Документ1 страницаDimensions Tables D and E BS 10 1962gsantosh06Оценок пока нет

- Flange DimensionsДокумент30 страницFlange DimensionshibhavuОценок пока нет

- SKF Bearing BasicsДокумент28 страницSKF Bearing Basicshibhavu0% (1)

- Rim & Face MethodДокумент3 страницыRim & Face MethodhibhavuОценок пока нет

- How To Check Tightness of BeltДокумент1 страницаHow To Check Tightness of BelthibhavuОценок пока нет

- Site Maintenance Leader: DescriptionДокумент2 страницыSite Maintenance Leader: DescriptionhibhavuОценок пока нет

- Dimensions of Cut Ring GasketДокумент2 страницыDimensions of Cut Ring GaskethibhavuОценок пока нет

- Fit Between Impeller (With Key) and Pump ShaftДокумент3 страницыFit Between Impeller (With Key) and Pump ShafthibhavuОценок пока нет

- Hydra Cell PDFДокумент6 страницHydra Cell PDFhibhavuОценок пока нет

- Thermal Science and EngineeringДокумент91 страницаThermal Science and EngineeringRAMA RAJU PYDIОценок пока нет

- Belt DriveДокумент4 страницыBelt DrivehibhavuОценок пока нет

- Chicago Pneumatic HN2T 150180 NPДокумент37 страницChicago Pneumatic HN2T 150180 NPhibhavu100% (1)

- Fifth Wheel Parts Reference GuideДокумент40 страницFifth Wheel Parts Reference GuideMauricio Maldonado GutierrezОценок пока нет

- 06 - Coupling Fields-Torque PowerДокумент63 страницы06 - Coupling Fields-Torque PowerHùng Võ MạnhОценок пока нет

- Manual de Partes Del Motor Cat c9Документ127 страницManual de Partes Del Motor Cat c9jalb80% (5)

- Ag 180ao MMM 000Документ294 страницыAg 180ao MMM 000sergey62Оценок пока нет

- TD27Документ3 страницыTD27ETIENNEОценок пока нет

- w168 Wiring Diagram Starter and GeneratorДокумент2 страницыw168 Wiring Diagram Starter and GeneratorGjorgji TalevskiОценок пока нет

- BMW X6 2010 N63 4.4l - Torques de ApertoДокумент16 страницBMW X6 2010 N63 4.4l - Torques de ApertoBruno SantosОценок пока нет

- SG8R20 Shimano Hub ManualДокумент24 страницыSG8R20 Shimano Hub ManualarationalactorОценок пока нет

- Img 20230912 0001Документ3 страницыImg 20230912 0001Sadia Sultana 2025149660Оценок пока нет

- All Unit Important Question Without Answer - Kinematics of MachineryДокумент22 страницыAll Unit Important Question Without Answer - Kinematics of MachineryGanapathy TОценок пока нет

- The History of Small EngineДокумент12 страницThe History of Small EngineJastine Mico benedictoОценок пока нет

- Power V6 Quotation From Z-MaT (Yang) - 20210803Документ3 страницыPower V6 Quotation From Z-MaT (Yang) - 20210803Mohammed SakhibОценок пока нет

- Hydraulic Rock Drill HL 700, HL 710, HL 700 S, HL 710 S Lifting InstructionsДокумент75 страницHydraulic Rock Drill HL 700, HL 710, HL 700 S, HL 710 S Lifting Instructionsandrei_rh10100% (3)

- Description and Operation: Component Maintenance ManualДокумент12 страницDescription and Operation: Component Maintenance ManualserdoukОценок пока нет

- CLUTCH - 235DTR - 267DTR - 280DTR: Renault TrucksДокумент42 страницыCLUTCH - 235DTR - 267DTR - 280DTR: Renault TrucksMax SamОценок пока нет

- Ariel Corporation - Arielcorp - Com18Документ1 страницаAriel Corporation - Arielcorp - Com18Anwar SadatОценок пока нет

- Why Bearings FailДокумент22 страницыWhy Bearings Faildesaipt20039240100% (1)

- Land Rover Series III ManualДокумент368 страницLand Rover Series III ManualStephen Cooke100% (1)

- 1996 Vs 1997 Cali PCM Pinout Differences OnlyДокумент2 страницы1996 Vs 1997 Cali PCM Pinout Differences OnlyWilliam PeeleОценок пока нет

- Edrian Manzanares Resume NewДокумент3 страницыEdrian Manzanares Resume NewYcam ManzanaresОценок пока нет

- T574 T574NC, ST Operator Manual EN July 2020Документ191 страницаT574 T574NC, ST Operator Manual EN July 2020Nuno AlvesОценок пока нет

- MTM2014 Show PreviewДокумент24 страницыMTM2014 Show PreviewJulius CarballoОценок пока нет

- Stepper MotorДокумент14 страницStepper MotorJade Mark RamosОценок пока нет

- Manual de La Bop 3.06 15M PDFДокумент28 страницManual de La Bop 3.06 15M PDFJack FosterОценок пока нет

- Why Single Phase Induction Motor Is Not Self Starting - StudyElectrical - Online Electrical Engineering Study SiteДокумент6 страницWhy Single Phase Induction Motor Is Not Self Starting - StudyElectrical - Online Electrical Engineering Study Siteashish palОценок пока нет

- S50-32-135N-D09 Tech SpecsДокумент3 страницыS50-32-135N-D09 Tech SpecsNikhil RanaОценок пока нет

- Ammco 7000 - PL - 940941 - 00Документ10 страницAmmco 7000 - PL - 940941 - 00jmartinezmoОценок пока нет

- 107E 1 ShopManual PDFДокумент371 страница107E 1 ShopManual PDFGanda PrajaОценок пока нет

- 4AT Gears PDFДокумент8 страниц4AT Gears PDFNoah IstreОценок пока нет

- Trsm1500en-Us 0517Документ254 страницыTrsm1500en-Us 0517Keith McCann100% (1)