Академический Документы

Профессиональный Документы

Культура Документы

3M (TM) Vetbond Tissue Adhesive / LIQUID BANDAID MSDS

Загружено:

Rick OshayОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

3M (TM) Vetbond Tissue Adhesive / LIQUID BANDAID MSDS

Загружено:

Rick OshayАвторское право:

Доступные форматы

3M MATERIAL SAFETY DATA SHEET 3M(TM) Vetbond Tissue Adhesive 1469

07/14/2004

Material Safety Data Sheet

Copyright, 2004, 3M Company. All rights reserved. Copying and/or downloading of this information for the purpose of properly

utilizing 3M products is allowed provided that: (1) the information is copied in full with no changes unless prior written agreement is

obtained from 3M, and (2) neither the copy nor the original is resold or otherwise distributed with the intention of earning a profit

thereon.

SECTION 1: PRODUCT AND COMPANY IDENTIFICATION

PRODUCT NAME: 3M(TM) Vetbond Tissue Adhesive 1469

MANUFACTURER: 3M

DIVISION: Medical Division

ADDRESS: 3M Center

St. Paul, MN 55144-1000

EMERGENCY PHONE: 1-800-364-3577 or (651) 737-6501 (24 hours)

Issue Date: 07/14/2004

Supercedes Date: 02/03/2004

Document Group: 10-2454-6

Product Use:

Specific Use:

Used on animals as a bandage.

SECTION 2: INGREDIENTS

Ingredient

C.A.S. No.

N-butyl cyanoacrylate

Hydroquinone

Blue dye

6606-65-1

123-31-9

32724-62-2

% by Wt

> 98

<1

0.01

SECTION 3: HAZARDS IDENTIFICATION

3.1 EMERGENCY OVERVIEW

Specific Physical Form: Thin slightly viscous liquid

Odor, Color, Grade: Clear blue liquid with sharp characteristic odor.

General Physical Form: Liquid

Immediate health, physical, and environmental hazards: Combustible liquid and vapor. Closed containers exposed to heat from

fire may build pressure and explode. Vapors may travel long distances along the ground or floor to an ignition source and flash back.

Cyanoacrylate ester is an eye irritant and bonds tissues together when polymerized. Vapors cause lacrimation.

May cause

target organ effects. May bond tissue rapidly.

3.2 POTENTIAL HEALTH EFFECTS

_________________________________________________________________________________________________

Page 1 of 7

3M MATERIAL SAFETY DATA SHEET 3M(TM) Vetbond Tissue Adhesive 1469

07/14/2004

Eye Contact:

Lacrimation: Signs/symptoms may include severe stinging of the eyes, redness and profuse tear discharge.

Moderate Eye Irritation: Signs/symptoms may include redness, swelling, pain, tearing, and blurred or hazy vision.

Bonds eyelids rapidly.

Skin Contact:

Moderate Skin Irritation: Signs/symptoms may include localized redness, swelling, itching, and dryness.

Bonds skin rapidly.

Inhalation:

Upper Respiratory Tract Irritation: Signs/symptoms may include cough, sneezing, nasal discharge, headache, hoarseness, and nose

and throat pain.

Ingestion:

May be harmful if swallowed.

Target Organ Effects:

Gastrointestinal Effects: Signs/symptoms may include stomach upset; nausea, vomiting and diarrhea.

SECTION 4: FIRST AID MEASURES

4.1 FIRST AID PROCEDURES

The following first aid recommendations are based on an assumption that appropriate personal and industrial hygiene practices are

followed.

Eye Contact: Immediately flush eyes with large amounts of water for at least 15 minutes. Get immediate medical attention.

NOT PEEL EYELIDS APART.

DO

Skin Contact: Remove contaminated clothing and shoes. Immediately flush skin with large amounts of cold water for at least 15

minutes. Get immediate medical attention. Wash contaminated clothing and clean shoes before reuse. Soak in warm, soapy water, if

necessary to remove cured product.

Inhalation: Remove person to fresh air.

If signs/symptoms develop, get medical attention.

If Swallowed:

Do not induce vomiting unless instructed to do so by medical personnel. Give victim two glasses of water. Never

give anything by mouth to an unconscious person. Get medical attention.

SECTION 5: FIRE FIGHTING MEASURES

5.1 FLAMMABLE PROPERTIES

Autoignition temperature

Flash Point

No Data Available

185 F [Test Method: Closed Cup]

_________________________________________________________________________________________________

Page 2 of 7

3M MATERIAL SAFETY DATA SHEET 3M(TM) Vetbond Tissue Adhesive 1469

07/14/2004

No Data Available

No Data Available

Flammable Limits - LEL

Flammable Limits - UEL

5.2 EXTINGUISHING MEDIA

DO NOT USE WATER Use fire extinguishers with class B extinguishing agents (e.g., dry chemical, carbon dioxide).

5.3 PROTECTION OF FIRE FIGHTERS

Special Fire Fighting Procedures:

(SCBA).

Wear full protective equipment (Bunker Gear) and a self-contained breathing apparatus

Unusual Fire and Explosion Hazards: Combustible liquid and vapor. Closed containers exposed to heat from fire may build

pressure and explode. Vapors may travel long distances along the ground or floor to an ignition source and flash back. Vapors

exceeeding the flash point will ignite when exposed to flame.

Note: See STABILITY AND REACTIVITY (SECTION 10) for hazardous combustion and thermal decomposition

information.

SECTION 6: ACCIDENTAL RELEASE MEASURES

Accidental Release Measures: Refer to other sections of this MSDS for information regarding physical and health hazards,

respiratory protection, ventilation, and personal protective equipment. Call 3M-HELPS line (1-800-364-3577) for more information

on handling and managing the spill. Ventilate the area with fresh air. Contain spill. For larger spills, cover drains and build dikes to

prevent entry into sewer systems or bodies of water. Avoid contact with water. Cover with absorbent material. Collect as much of

the spilled material as possible. Clean up residue with an appropriate solvent selected by a qualified and authorized person. Ventilate

the area with fresh air. Read and follow safety precautions on the solvent label and MSDS. Collect the resulting residue containing

solution. Place in a metal container approved for transportation by appropriate authorities. Seal the container. Dispose of collected

material as soon as possible.

In the event of a release of this material, the user should determine if the release qualifies as reportable according to

local, state, and federal regulations.

SECTION 7: HANDLING AND STORAGE

7.1 HANDLING

Avoid eye contact with vapors, mists, or spray. Avoid skin contact. A no-touch technique is recommended. If skin contact occurs,

wash skin with soap and water. Acrylates may penetrate commonly-used gloves. If product contacts glove, remove and discard glove,

wash hands immediately with soap and water and then re-glove. Avoid breathing of vapors, mists or spray. Do not ingest. Do not

eat, drink or smoke when using this product. Wash exposed areas thoroughly with soap and water. Keep away from heat, sparks, open

flame, pilot lights and other sources of ignition. Avoid contact with oxidizing agents.

7.2 STORAGE

Keep container tightly closed. Store away from areas where product may come into contact with food or pharmaceuticals. Store away

from acids. Store away from heat. Store out of direct sunlight. Store away from oxidizing agents.

SECTION 8: EXPOSURE CONTROLS/PERSONAL PROTECTION

8.1 ENGINEERING CONTROLS

Use in a well-ventilated area. Local exhaust is required for operations using large amounts of material.

_________________________________________________________________________________________________

Page 3 of 7

3M MATERIAL SAFETY DATA SHEET 3M(TM) Vetbond Tissue Adhesive 1469

07/14/2004

8.2 PERSONAL PROTECTIVE EQUIPMENT (PPE)

8.2.1 Eye/Face Protection

Avoid eye contact with vapors, mists, or spray.

The following eye protection(s) are recommended: Indirect Vented Goggles.

8.2.2 Skin Protection

Avoid skin contact. Product will polymerize with body fluids and mucous and may bond tissues together.

Select and use gloves and/or protective clothing to prevent skin contact based on the results of an exposure assessment. Consult with

your glove and/or protective clothing manufacturer for selection of appropriate compatible materials.

Gloves made from the following material(s) are recommended: Neoprene, Nitrile Rubber, Polyvinyl Chloride.

8.2.3 Respiratory Protection

Avoid breathing of vapors, mists or spray.

8.2.4 Prevention of Swallowing

Do not eat, drink or smoke when using this product. Wash exposed areas thoroughly with soap and water.

8.3 EXPOSURE GUIDELINES

Ingredient

Authority

Type

Limit

Additional Information

Hydroquinone

Hydroquinone

Hydroquinone

ACGIH

CMRG

OSHA

TWA

STEL

TWA

2 mg/m3

4 mg/m3

2 mg/m3

Table A3

Table Z-1

SOURCE OF EXPOSURE LIMIT DATA:

ACGIH: American Conference of Governmental Industrial Hygienists

CMRG: Chemical Manufacturer Recommended Guideline

OSHA: Occupational Safety and Health Administration

AIHA: American Industrial Hygiene Association Workplace Environmental Exposure Level (WEEL)

SECTION 9: PHYSICAL AND CHEMICAL PROPERTIES

Specific Physical Form:

Odor, Color, Grade:

General Physical Form:

Autoignition temperature

Flash Point

Flammable Limits - LEL

Flammable Limits - UEL

Boiling point

Density

Vapor Density

Thin slightly viscous liquid

Clear blue liquid with sharp characteristic odor.

Liquid

No Data Available

185 F [Test Method: Closed Cup]

No Data Available

No Data Available

>=300 F

1.09 g/ml

3 [Details: Air=1]

Vapor Pressure

<=0.2 mmHg [@ 20 C]

Specific Gravity

pH

1.09

Not Applicable

_________________________________________________________________________________________________

Page 4 of 7

3M MATERIAL SAFETY DATA SHEET 3M(TM) Vetbond Tissue Adhesive 1469

Solubility in Water

Evaporation rate

Volatile Organic Compounds

Percent volatile

VOC Less H2O & Exempt Solvents

Viscosity

07/14/2004

Negligible

No Data Available

No Data Available

No Data Available

No Data Available

4.3 centipoise

SECTION 10: STABILITY AND REACTIVITY

Stability: Stable.

Materials and Conditions to Avoid: AlcoholsPolymerized by contact with water, alcohols, amines, and alkalis Additional

Information: Water, moisture, mild exothermic reaction is possible.

Hazardous Polymerization: Hazardous polymerization will not occur.

Hazardous Decomposition or By-Products

Substance

Condition

Hydrocarbons

Heat

SECTION 11: TOXICOLOGICAL INFORMATION

Please contact the address listed on the first page of the MSDS for Toxicological Information on this material and/or its

components.

SECTION 12: ECOLOGICAL INFORMATION

ECOTOXICOLOGICAL INFORMATION

Not determined.

CHEMICAL FATE INFORMATION

Not determined.

SECTION 13: DISPOSAL CONSIDERATIONS

Waste Disposal Method: Dispose of waste product in a facility permitted to accept chemical waste. As a disposal alternative,

incinerate in an industrial or commercial facility in the presence of a combustible material.

EPA Hazardous Waste Number (RCRA): Not regulated

Since regulations vary, consult applicable regulations or authorities before disposal.

SECTION 14:TRANSPORT INFORMATION

_________________________________________________________________________________________________

Page 5 of 7

3M MATERIAL SAFETY DATA SHEET 3M(TM) Vetbond Tissue Adhesive 1469

07/14/2004

ID Number(s):

70-2007-2892-4, 70-2007-4252-9

Please contact the emergency numbers listed on the first page of the MSDS for Transportation Information for this

material.

SECTION 15: REGULATORY INFORMATION

US FEDERAL REGULATIONS

Contact 3M for more information.

311/312 Hazard Categories:

Fire Hazard - No Pressure Hazard - No

Reactivity Hazard - No

Immediate Hazard - Yes

Delayed Hazard - No

STATE REGULATIONS

Contact 3M for more information.

CHEMICAL INVENTORIES

This material contains one or more substances not listed on the TSCA Inventory. Commercial use of this material is regulated by the

FDA.

Contact 3M for more information.

INTERNATIONAL REGULATIONS

Contact 3M for more information.

This MSDS has been prepared to meet the U.S. OSHA Hazard Communication Standard, 29 CFR 1910.1200.

SECTION 16: OTHER INFORMATION

NFPA Hazard Classification

Health: 2 Flammability: 2

Reactivity: 2 Special Hazards: Reacts with Water

National Fire Protection Association (NFPA) hazard ratings are designed for use by emergency response personnel to address the hazards that are

_________________________________________________________________________________________________

Page 6 of 7

3M MATERIAL SAFETY DATA SHEET 3M(TM) Vetbond Tissue Adhesive 1469

07/14/2004

presented by short-term, acute exposure to a material under conditions of fire, spill, or similar emergencies. Hazard ratings are primarily based on the

inherent physical and toxic properties of the material but also include the toxic properties of combustion or decomposition products that are known to

be generated in significant quantities.

Revision Changes:

Section 16: NFPA hazard classification heading was modified.

Section 3: Other potential health effects heading was modified.

Section 1: Division name was modified.

Section 8: Exposure guidelines data source legend was modified.

Section 15: 311/312 hazard categories heading was modified.

Section 15: International regulations information was modified.

Section 15: State regulations information was modified.

Section 15: US federal regulations information was modified.

Section 10: Hazardous polymerization heading was modified.

Section 2: Ingredient table was modified.

Section 3: Other health effects information was modified.

Section 16: NFPA explanation was modified.

Section 15: Inventories information was modified.

Section 12: Ecotoxicological information heading was modified.

Section 12: Chemical fate information heading was modified.

Section 5: Flash point information was modified.

Section 16: NFPA hazard classification for special hazards was modified.

Section 9: Flash point information was modified.

Section 12: Ecotoxicological phrase was modified.

Section 12: Chemical Fate phrase was modified.

Section 2: Ingredient phrase was added.

Section 15: EPCRA 313 information was deleted.

Section 15: EPCRA 313 text was deleted.

DISCLAIMER: The information in this Material Safety Data Sheet (MSDS) is believed to be correct as of the date issued. 3M

MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR COURSE OF PERFORMANCE OR USAGE OF

TRADE. User is responsible for determining whether the 3M product is fit for a particular purpose and suitable for user's method of

use or application. Given the variety of factors that can affect the use and application of a 3M product, some of which are uniquely

within the user's knowledge and control, it is essential that the user evaluate the 3M product to determine whether it is fit for a

particular purpose and suitable for user's method of use or application.

3M provides information in electronic form as a service to its customers. Due to the remote possibility that electronic transfer may

have resulted in errors, omissions or alterations in this information, 3M makes no representations as to its completeness or accuracy.

In addition, information obtained from a database may not be as current as the information in the MSDS available directly from 3M.

3M MSDSs are available at www.3M.com

_________________________________________________________________________________________________

Page 7 of 7

Вам также может понравиться

- 3M Material Safety Data Sheet Cc-4 and Cc-55 (Cable Cleaner - Bulk Liquid)Документ7 страниц3M Material Safety Data Sheet Cc-4 and Cc-55 (Cable Cleaner - Bulk Liquid)ramlijavierОценок пока нет

- 3M 1099 MSDSДокумент8 страниц3M 1099 MSDSRavi Shankar M GОценок пока нет

- 1 - Identification of The Substance/preparation and Company/undertaking Molub-Alloy 412 SFДокумент4 страницы1 - Identification of The Substance/preparation and Company/undertaking Molub-Alloy 412 SFwillowwood666Оценок пока нет

- Scotchgard MSDSДокумент12 страницScotchgard MSDStsj9205Оценок пока нет

- MediawebserverДокумент10 страницMediawebserverGilang HendraОценок пока нет

- 1240 EnglishДокумент8 страниц1240 EnglishNikos StamopoulosОценок пока нет

- Aculon NanoProof 5.0X SDSДокумент9 страницAculon NanoProof 5.0X SDSAlan TanОценок пока нет

- 1107 Solvent No 1 1314174041Документ8 страниц1107 Solvent No 1 1314174041Renato AsОценок пока нет

- Tyrin 200Документ10 страницTyrin 200Nicol AlejandraОценок пока нет

- Lockstop Primer Adhesive SDS-GreenstreakДокумент11 страницLockstop Primer Adhesive SDS-Greenstreakrobox514Оценок пока нет

- MSDS Citrus Based Adhesive Remover 3MДокумент10 страницMSDS Citrus Based Adhesive Remover 3MBlanca AguilarОценок пока нет

- MSDS of AB GlueДокумент10 страницMSDS of AB GlueThanhnam PhanОценок пока нет

- Modified Starch MSDSДокумент5 страницModified Starch MSDSdewi.mizobataОценок пока нет

- Toray Silicon 780 MSDSДокумент8 страницToray Silicon 780 MSDSsurawutwijarnОценок пока нет

- SW Darth Vader Voice ChangerДокумент9 страницSW Darth Vader Voice ChangerjeanyoperОценок пока нет

- MediawebserverДокумент10 страницMediawebservergofourcrazyОценок пока нет

- Bio Kleen Diesel Fuel BiocideДокумент13 страницBio Kleen Diesel Fuel BiocideDavannendran ChandranОценок пока нет

- 209 Flexo Wash SDSДокумент8 страниц209 Flexo Wash SDSNabil NnОценок пока нет

- Safety Data Sheet: 3M™ Easy Clean Coating ECC-1000Документ10 страницSafety Data Sheet: 3M™ Easy Clean Coating ECC-1000ForeverОценок пока нет

- 0902770182ca660e PDFДокумент22 страницы0902770182ca660e PDFmaheshОценок пока нет

- Safety Data Sheet: Chevron Open Gear GreaseДокумент8 страницSafety Data Sheet: Chevron Open Gear GreaseWork ForceОценок пока нет

- Safety Data Sheet: 3M (TM) PPT Adhesion Promoter No. 86AДокумент10 страницSafety Data Sheet: 3M (TM) PPT Adhesion Promoter No. 86AAkrem LaamiriОценок пока нет

- MSDS SolarguardДокумент5 страницMSDS SolarguardKeyleen LinaresОценок пока нет

- 3M Novec 1230 MSDS - ENДокумент9 страниц3M Novec 1230 MSDS - ENWilson VillarroelОценок пока нет

- MediawebserverДокумент11 страницMediawebserverFloyd PriceОценок пока нет

- Valvoline ATF Dexron III MerconДокумент10 страницValvoline ATF Dexron III MerconNyamdavaa KhatanbaatarОценок пока нет

- Tridur ZN-BДокумент9 страницTridur ZN-BJohn AtkinsОценок пока нет

- Used Oil MsdsДокумент7 страницUsed Oil Msdspequenita34Оценок пока нет

- Syltherm 800 Silicone Heat Transfer Fluid MSDSДокумент8 страницSyltherm 800 Silicone Heat Transfer Fluid MSDSNasser AlshalwyОценок пока нет

- Material Safety Data Sheet: 1. Product and Company IdentificationДокумент7 страницMaterial Safety Data Sheet: 1. Product and Company Identificationoverlord5555Оценок пока нет

- Sikafast-3131S - Part A (Drum-Pail)Документ11 страницSikafast-3131S - Part A (Drum-Pail)robox514Оценок пока нет

- Dow Corning Corporation Material Safety Data SheetДокумент9 страницDow Corning Corporation Material Safety Data Sheetgazwang478Оценок пока нет

- Safety Data Sheet T-Butyl Mercaptan: 1 IdentificationДокумент9 страницSafety Data Sheet T-Butyl Mercaptan: 1 IdentificationJeremíasОценок пока нет

- 3M™ Scotch-Weld™ Instant Adhesive CA40H ClearДокумент9 страниц3M™ Scotch-Weld™ Instant Adhesive CA40H ClearTania NuñezОценок пока нет

- Thionyl Chloride 99 - 2X1KGДокумент7 страницThionyl Chloride 99 - 2X1KGMiwcoОценок пока нет

- Safety Data Sheet: Exxonmobil Lubricants & Specialties Europe, A Division of Exxonmobil Petroleum & Chemical, Bvba (Empc)Документ8 страницSafety Data Sheet: Exxonmobil Lubricants & Specialties Europe, A Division of Exxonmobil Petroleum & Chemical, Bvba (Empc)Ali YasinОценок пока нет

- Penetrox HT x-1552 A (GHS)Документ10 страницPenetrox HT x-1552 A (GHS)yesrtyОценок пока нет

- 3M - CC-3 Cable Cleaning Pads (Cable Cleaner)Документ8 страниц3M - CC-3 Cable Cleaning Pads (Cable Cleaner)jaredf@jfelectric.comОценок пока нет

- MSDS THPS 75Документ8 страницMSDS THPS 75DyaniОценок пока нет

- FISPQ Ambra PDF Hydrosystem 68 SdsДокумент12 страницFISPQ Ambra PDF Hydrosystem 68 SdsRafael CozerОценок пока нет

- A0020594 - MSDS - ATF D-3 Mobil 15700 CST at - 40Документ8 страницA0020594 - MSDS - ATF D-3 Mobil 15700 CST at - 40eng_hamada_4uОценок пока нет

- Material Safety Data Sheet: Coupling GreaseДокумент6 страницMaterial Safety Data Sheet: Coupling GreaserefeiОценок пока нет

- Safety Data Sheet: G96, Multi-Purpose Cleaner (24-165A) : G9624Документ10 страницSafety Data Sheet: G96, Multi-Purpose Cleaner (24-165A) : G9624JUAN GUTIERREZОценок пока нет

- S25423 PDFДокумент8 страницS25423 PDFGaurav BfgОценок пока нет

- MtBE SDSДокумент2 страницыMtBE SDSWand LopesОценок пока нет

- Amine SDS 2021 - 1332471032Документ9 страницAmine SDS 2021 - 1332471032kathygona1980Оценок пока нет

- MSDS - Castrol - Aircol - SW - 32Документ5 страницMSDS - Castrol - Aircol - SW - 32simranОценок пока нет

- Ece-3650 Sylgard Hvic MsdsДокумент9 страницEce-3650 Sylgard Hvic Msdskamal_khan85Оценок пока нет

- 638060-08994 32 AU EN safetyDataSheet Sds 8799831064580 0 1Документ21 страница638060-08994 32 AU EN safetyDataSheet Sds 8799831064580 0 1Jonatan BernalОценок пока нет

- Hempalin Enamel 5214000030 En-UsДокумент9 страницHempalin Enamel 5214000030 En-UszayzanОценок пока нет

- Material Safety Data Sheet: 1. Basic InformationДокумент3 страницыMaterial Safety Data Sheet: 1. Basic Informationtexwan_Оценок пока нет

- ATCC DMSO SDS 510 PercentДокумент7 страницATCC DMSO SDS 510 PercentchetanaОценок пока нет

- Material Safety Data Sheet: Meropa® 68, 100, 150, 220, 320, 460, 680, 1000, 1500Документ5 страницMaterial Safety Data Sheet: Meropa® 68, 100, 150, 220, 320, 460, 680, 1000, 1500khurramОценок пока нет

- Dow Corning Toray Silane SZ-1671Документ7 страницDow Corning Toray Silane SZ-1671Eugene PaiОценок пока нет

- Msds Pu FoamДокумент8 страницMsds Pu FoamNicole MeyerОценок пока нет

- MDEAДокумент8 страницMDEAGhifaris VashaОценок пока нет

- 3M 1000 NFДокумент6 страниц3M 1000 NFLe Tan HoaОценок пока нет

- Dowex Upcore Mono C-600 H Cation Exchange ResinДокумент9 страницDowex Upcore Mono C-600 H Cation Exchange Resinengineer.humgОценок пока нет

- Cat ELC (Extended Life Coolant) ExtenderДокумент8 страницCat ELC (Extended Life Coolant) Extenderharikrishnanpd3327Оценок пока нет

- The Health & Safety Guide for Film, TV & Theater, Second EditionОт EverandThe Health & Safety Guide for Film, TV & Theater, Second EditionРейтинг: 4 из 5 звезд4/5 (1)

- FISCAL NOTE: Effect On Local Government: No. Effect On The State: NoДокумент10 страницFISCAL NOTE: Effect On Local Government: No. Effect On The State: NoRick OshayОценок пока нет

- Oster Model 10 Heritage Series 76010-010Документ91 страницаOster Model 10 Heritage Series 76010-010Rick OshayОценок пока нет

- Arrma Parts Xref AДокумент13 страницArrma Parts Xref ARick OshayОценок пока нет

- Huhn Solutions Repair Kit, 2004 Toyota Camry Head Bolt FailureДокумент5 страницHuhn Solutions Repair Kit, 2004 Toyota Camry Head Bolt FailureRick OshayОценок пока нет

- Safety Data Sheet: Aramcodura ® 150Документ9 страницSafety Data Sheet: Aramcodura ® 150Sameh RadwanОценок пока нет

- HarmonicDrive SK1A SDSДокумент5 страницHarmonicDrive SK1A SDSdragon66 hateОценок пока нет

- F1-000728 MSDSДокумент7 страницF1-000728 MSDScolinyОценок пока нет

- MSDS SunTone Yellow 2232Документ4 страницыMSDS SunTone Yellow 2232Iridian Cano CeronОценок пока нет

- DMDM H MSDSДокумент5 страницDMDM H MSDSIndra syahputraОценок пока нет

- CELSTRAN® PP-GF50-02 - PP - Glass Reinforced: DescriptionДокумент3 страницыCELSTRAN® PP-GF50-02 - PP - Glass Reinforced: DescriptionabirОценок пока нет

- Product Data Enrichment and Classification Process SamplesДокумент11 страницProduct Data Enrichment and Classification Process SamplesindraОценок пока нет

- Material Safety Data Sheet Cypermethrin PDFДокумент7 страницMaterial Safety Data Sheet Cypermethrin PDFSaid Muchsin AlkaffОценок пока нет

- FM200 MSDSДокумент7 страницFM200 MSDSMohd A IshakОценок пока нет

- Safety Data Sheet (SDS) : Raynguard Protective Materials, IncДокумент10 страницSafety Data Sheet (SDS) : Raynguard Protective Materials, IncDannyОценок пока нет

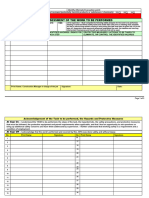

- Managing Hazardous Chemicals in Department of Education Workplaces Risk AssessmentДокумент10 страницManaging Hazardous Chemicals in Department of Education Workplaces Risk AssessmentNur E Alam NuruОценок пока нет

- SMC Material Safety Data Sheet MethanolДокумент9 страницSMC Material Safety Data Sheet Methanolanand.srajuОценок пока нет

- WebEx - PDF - en - 3518203 Iperico Material Safety Data SheetДокумент5 страницWebEx - PDF - en - 3518203 Iperico Material Safety Data SheetChirtop Ciprian FlorinОценок пока нет

- Arc Welding Basics LincolnДокумент61 страницаArc Welding Basics LincolngonzorsОценок пока нет

- MSDS R3 CB - 107Документ3 страницыMSDS R3 CB - 107Putri HagiaОценок пока нет

- JSTA - Job Safety Task AssessmentДокумент3 страницыJSTA - Job Safety Task AssessmentRyan GouwsОценок пока нет

- Technical Specification ForДокумент16 страницTechnical Specification Forvaishgoa56Оценок пока нет

- MSDS Sikabond NVДокумент8 страницMSDS Sikabond NVMoch Bagus Kurnianto PutroОценок пока нет

- En UsДокумент12 страницEn UsYudhi NapitupuluОценок пока нет

- JSA - Anti Termite Treatment WorkДокумент5 страницJSA - Anti Termite Treatment WorkRaju Khalifa67% (3)

- Msds Potassium Chloride: M S D SДокумент1 страницаMsds Potassium Chloride: M S D SQuality AssuranceОценок пока нет

- Distilled WaterДокумент6 страницDistilled WaterandriОценок пока нет

- Sodium Chromate Anhydrous PDFДокумент6 страницSodium Chromate Anhydrous PDFErika WidiariniОценок пока нет

- JotunДокумент5 страницJotunraza.slietОценок пока нет

- Kalium PermanganatДокумент5 страницKalium PermanganatMutia Nurul OctaviaОценок пока нет

- Fuel Stick MsdsДокумент3 страницыFuel Stick MsdsmehariiОценок пока нет

- Sika PDS - E - Sigunit L54 AF (Concentrate)Документ4 страницыSika PDS - E - Sigunit L54 AF (Concentrate)lwin_oo2435Оценок пока нет

- Ar 700-141 Hazmat PDFДокумент14 страницAr 700-141 Hazmat PDFjarrisonОценок пока нет

- Msds 1-ButeneДокумент12 страницMsds 1-ButeneakekuranОценок пока нет

- Packaged Rooftop Air Conditioners Precedent 3-10 Tons Cooling and Gas-ElectricДокумент74 страницыPackaged Rooftop Air Conditioners Precedent 3-10 Tons Cooling and Gas-ElectricjoseОценок пока нет