Академический Документы

Профессиональный Документы

Культура Документы

Severin Final

Загружено:

cristasocum_trans1758Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Severin Final

Загружено:

cristasocum_trans1758Авторское право:

Доступные форматы

Questionnaire for manufacturer qualification according to

Page 1 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 - EN ISO 3834-3

Application of the Manufacturer

Applicant

Name: SC ENERGOMONTAJ SA BUCHAREST

Branch DROBETA TURNU SEVERIN

Address: Village Halanga , District Mehedinti , zip code 227297

Plant / Department / Production Place: Village Halanga , District

Mehedinti

- Telephone No.: 0040 (0252) 32 11 44; 30 62 32; 0745-10 25 42

- Fax No.:0252/321144

- Internet:` www.saem.ro; www.saemdrobeta.go.ro

- E-mail: saemdrobeta@artelecom.net

Initial / Renewed / Supplementary Manufacturer Qualification according to

AD 2000-Merkblatt HP 0 / HP 100 R / TRD 201 / EN ISO 3834-2 / EN ISO 3834-3

EN 13480 EN 13445 EN 12952 EN 12953

Statements in the forms of this questionnaire are certified to be correct.

Date:07.06.2012

Stamp,

Signature of Corporate Management:

Note:

This questionnaire is valid for the qualification of pressure equipment manufacturers in accordance

with Pressure Equipment Directive (PED) in connection with AD 2000-Rules.

In case that other technical regulations or standards (e.g. EN 13445) instead of AD 2000 are used,

you should refer to their respective paragraphs.

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Questionnaire for manufacturer qualification according to

Page 2 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 -

EN ISO 3834-3

General firms data

Description

1.1

Responsible contact

person for TV

VOICA GHEORGHE-Quality Assurance Reprezentative

1.2

Responsible person of

Qualiy Assurance (QA)

Staff of QA

MURGILA SORIN - Quality Assurance

1.3

General manager

FIRUTI ION

TUCULANU CRISTIAN

Production manager

1.4

Organization

- please add an actual

organization chart

1.5

1.6

Organization chart is attached.

Number of employees

- Administration

31

- Production

159

Working area (approx.)

roofed / roofless

- for Manufacturing

2800 / 10.00 mp

- for Storage

450 / 2650 mp

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Evaluation /

Remarks

Questionnaire for manufacturer qualification according to

Page 3 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 -

EN ISO 3834-3

General firms data

Description

Evaluation /

Remarks

1.7

Total production scope

Manufacturing and erection for steam boilers, tanks, piping

(including non-PED items)

lines, hydromechanical equipment, welding steel

1.8

Production scope which

shall be examined

-

Steel structures according EN 1090-2

Metallic industrial piping according series of standards EN

13480

Water-tube boilers according series of standards EN 12952

Shell boilers according series of standards EN 12953

Unfired pressure vessel according series of standards EN 13445

1.9

Manufactured products in Product

the scope of Pressure

Equipment Directive

Boilers, vessels and pipes

97/237EC (PED),

Manufacturing acc. to

module

1.10

Parent metals

structures and other parts of above installation

Category Module

IV

1.1 ; 1.2 ; 1.3 ; 1.4 ; 2 ;3; 4 ; 5 ; 6 ; 7 ; 8 ; 9.1 ; 9.2 ; 9.3 ; 10

(Groups according to

CR ISO 15608)

1.11

Welding processes used

111 ; 135 ; 141 ; 141+111

(EN 24063)

1.12

Max. dimensions of the

products

Wall thickness (welded):100 mm

Diameter: 40.000 mm

Length:25 m

Weight: 60 t

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Questionnaire for manufacturer qualification according to

Page 4 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 2

EN ISO 3834-3

Quality requirements acc. to EN ISO 3834-2 / -3

Element

Par. of

Standards

Contract review

5.2

see also

PO

SAEM 01

Are procedures for

contract review

realized?

IO 001

What items /

requirements are

considered at contract

review?

Form 1 of

IO-001

Description

Evaluation/

Remarks

Operational procedure : Contract review

Operational instruction : Review of requirement and

Technical review

Checklist , includes the following :

Products standards ; manufactures ability to satisfy

requieements

E.g. to be clearly defined:

application standard / technical regulation

suplimentary specified requirements (structure, corrosion resistance, specification for the welding

process, non-destructive testing, heat treatment, type of recognized welding process and personnel,

involving of an independent inspection body)

measures against climate influences

How are the procedures for contract review documented?

Form 1 of

IO-001

L ist of applicable external documents , all technical

Form 2 of regulations and standards are available,

of IO-001

Are all necessary tech.

regulations/standards

available and known?

Are procedures for

handling changes and

updates defined?

Design review

Checklist

Form AC- Entire staff is trained on these requirements

F-01 :

5.3

Are procedures for

design review

realized?

IO - 003

Operational instruction : Control changes

PO

SAEM 02

Operational procedure : Design control

What aspects are

considered at design

review?

e.g:

Specifications for parent metals ; welding

consumables, welding procedure specification ;

procedure of termal treatments , welding growes and

sequence, accessibility of welds, quality and

acceptance criteria for welds

specifications for parent metals and welding consumables, welding sequence, accessibility of welds,

quality and acceptance criteria for welds (HP 5/1, EN ISO 5817)

How are the

procedures for design

review documented?

Form 1 of

PO

Checklist

SAEM 02

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Questionnaire for manufacturer qualification according to

Page 5 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 2

EN ISO 3834-3

Quality requirements acc. to EN ISO 3834-2 / -3

Element

Par. of

Standards

Sub-contracting

What measures are

taken to ensure, that

the sub-contractors

comply with the quality

requirements of this

standard?

see also

Description

PO

SAEM 06

Operational procedure : Evaluating suppliers

- selection of subcontractors (audit for suitability )

- is informed the manufacturer about all

requirements

- to be supplied with all relevant specifications /

standards/ codes

- are reviewed and approved sub-contractors

documents : Working procedures , Quality Plan

and

Inspection and testing plan ( ITP )

- setting ( in IPT ) Hold or Withnes point and

participation of inspection or test

- product audit

Evaluation/

Remarks

The sub-contractor has

- to be informed by the manufacturer about all requirements

- to be supplied with all relevant specifications / standards/ codes

- to be aidited and controlled by the manufacturer

- to document all activities and procedures

Welders and welding 7.2

operators

AD 2000HP 3

TRD 201,

encl. 2

EN 287

How is it ensured, that

only approved welders

are assigned for

welding production?

EN ISO

9606

EN 1418

VdTVMbl. 1164

Only responsible welding coordinator distributes

the welders

Check point in inspection and testing plan for

verification of certificates suitability and validity

List of welders (with explicit range of welding

suitability according calification certificate ) is at

Responsible work

See enclosure 1.

e.g. approval certificates available on site, list of welders

Welding

coordination

personnel

7.3

EN ISO

14731

See enclosure 2.

AD 2000HP3

for planning and

supervising the

welding production

The qualification (education in welding technology) of the welding coordination personnel has to be suitable for

the intended production scope.

Non-destructive

testing personnel

8.2

EN 473

See enclosure 3

AD 2000HP4

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Questionnaire for manufacturer qualification according to

Page 6 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 2

EN ISO 3834-3

Quality requirements acc. to EN ISO 3834-2 / -3

Element

Par. of

Standards

Personnel for quality 8.1

control and other

inspections

see also

PS SAEM01

Which personnel are

responsible for the

other inspections

(e.g. destructive and

visual inspections,

monitoring and

controlling of heat

treatment)?

Description of

manufacturing and

testing facilities

9.1

9.2

Suitability of

equipment

9.3

1 )Destructive test at

Destructive laborator laboratory of SC

Energomontaj SA Bucharest

2 ) Visual inspection

- Copaceanu Costel

- Moraru Iustinian

- Murgu Gheorghe

3 ) Monitoring and controlling welding process and

heat treatment

- Copaceanu Costel

- Murgila Sorin

IO - 002

Operational instruction : Production planning

IO 001

Check availability and adequacy ( at Contract review

and Technical review and Production planning) of

equipment and maintenance time before the strat of

production

There are record maintenance

9.4

What measures are

taken after installation

of new or refurbished

equipment?

PO - 07

F-07-07

(only applicable to

EN ISO 3834-2)

Maintenance

Operational procedure : Process control

See enclosure 4

What is taken to

ensure, that the

equipment is adequate

for the application

concerned?

New equipment

Description

Operational procedure : Maintenance of equipment

Testing for proper function according with Technical

manual of equipments

Form PO-07 ; Testing and commissioning equipment

9.5

Are there documented

plans for maintenance

of equipment for

production and

testing?

PO-07

F-07-05

Form PO-07 ; Plans for maintenance of

equipment

(only applicable to

EN ISO 3834-2)

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Evaluation/

Remarks

Questionnaire for manufacturer qualification according to

Page 7 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 2

EN ISO 3834-3

Quality requirements acc. to EN ISO 3834-2 / -3

Element

Par. of

Standards

see also

Calibration and

validation of

measuring,

surveillance and

testing equipment

16

DVSMbl.

0714,

IO 004

Which methods are

performed for calibration of equipment?

EN ISO

17662

EN

50504

(kind of equipment, calibration

authority, calibration intervals,

marking, documentation)

DVSMbl.

3009

EN ISO

3834-5

Production plan

10.1

Which criteria are

defined for production

planning?

Welding procedure

specification (WPS)

PC-TSxx

PCCVI

TS - xx

10.2

Are there WPS for the

welding production?

(applicable only for

EN ISO 3834-2;

or EN ISO 3834-3 in

conjunction with AD 2000HP2/1 /TRD)

EN ISO

15609-1

AD 2000HP 2/1

Description

Operational instruction : Calibration, verification and

validation equipment for welding and ancillary

activities

Essential parameters are tested / calibrated for

welding equipment ( current , voltage , wire speed ,

shielding gaz flow ) according techical manual of

echipment .

Calibration intervals : after repair and according

Mentenance plans ( at one year )

Each calibrated equipment is labeled

,, Calibrated , expire on ....

Calibration procces is recorded

Quality Plan Turnu Severin serial number

Inspection and Testing Plan - Turnu Severin

serial number

Specification for manufacturing and erection

Work procedures,

Equipment suitability

Inspection procedures

Yes

See enclosure 5.

TRD 201,

encl. 1

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Evaluation/

Remarks

Questionnaire for manufacturer qualification according to

Page 8 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 2

EN ISO 3834-3

Quality requirements acc. to EN ISO 3834-2 / -3

Element

Par. of

Standards

see also

Description

Welding procedure

approval

10.3

EN ISO

15610 15620

Welding procedures are approved / qualified

according following standards

Acc. to which part of

EN ISO 15610 to

16620 are the welding

procedures approved?

AD 2000HP 2/1

TRD 201,

Enclosure

1

- for the manufacture

acc. to AD 2000-HP0

/ TRD 201:

For mettalic construction

- EN ISO 15613 ;

- EN ISO 15612 ;

- EN ISO 15611 ;

- EN ISO 15610 ;

- for the manufacture

acc. to other rules:

Are other

manufacturing

procedures also

approved

(e.g. forming)?

No

If applicable, acc. to

which rules/standards?

Work instructions

See enclosure 5.

- EN ISO 15614-1

No

10.4

Are there also

additional work

instructions beside

WPS?

How is it ensured, that

these instructions

include all necessary

welding parameters

and are in accordance

with the WPS?

POS-01SAEM

Operational procedure :

The general procedure of welding

Operational instructions :

PL-01SAEM

PL-08SAEM

PL-14SAEM

Preheating and heat treatment procedure for welding

The procedure for storage, handling and distribution

of materials welding

The procedure for monitoring qualitative and semiquantitative analysis of metal

PL-21

Reconditioning of fusion welded joints

Additional instructions for WPS

Instruction are developed by Welding coordinator

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Evaluation/

Remarks

Questionnaire for manufacturer qualification according to

Page 9 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 2

EN ISO 3834-3

Quality requirements acc. to EN ISO 3834-2 / -3

Element

Par. of

Standards

Documentation

of the welding

procedures

10.5

Which procedures do

exist for quality

relevant documents?

Who is responsible for

establishment and

maintenance of

documents (e.g. WPS,

welding procedure,

approval records,

welders approval

certificates)?

Storage and

handling of filler

metals

see also

Description

PS SAEM

02

Quality system procedure : Control of documents

Chief of welding and substitute

Welding coordinator and substitute

11

Which documented

instructions exist for

storage, if applicable

for rebaking and

handling of filler

metals to avoid

damage?

PL-08

SAEM

The procedure for storage, handling and distribution

of materials welding

Yes , technical data shet or welding consumable

catalog ( handbook ) is consulted , also

Are the suppliers

recommendations for

processing available?

suppliers recomandation at package

Is batch testing of filler

metals performed?

(only applicable for

EN ISO 3834-2 and, if

stated, in the contract/

specification)

Only if required.

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Evaluation/

Remarks

Questionnaire for manufacturer qualification according to

Page 10 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 2

EN ISO 3834-3

Quality requirements acc. to EN ISO 3834-2 / -3

Element

Par. of

Standards

Storage of parent

metals

12

see also

Description

PO

Handling, storage, packaging, preservation

Evaluation/

Remarks

SAEM-05

Delivery

What measures are

taken to prevent

adversely effects (e.g.

damage, oxidation,

soiling, loss of

marking)?

PO

Identification and traceability.

SAEM-08

Periodic checking of the conditions of storage

IO-005

Post-weld heat

treatment

12

Which specifications

for performance of any

post-weld heat

treatment exist?

Which influential

variables are

considered?

ISO/TR

17663

PL 01

- SAEM

Preheating for welding procedure and heat

treatment.

The compatibility with parent metals, welded joints

and construction as well as the accordance with the

application standard / code is considered.

The compatibility with parent metals, welded joints and construction as well as the accordance with the

application standard / code have to be considered.

PL 01

How frequently / by

whom is the heat

treatment process

checked?

- SAEM

Form of

PL-01SAEM

AC F 52

How is the process of

heat treatment

documented?

Form of

POS-01SAEM

AC-F-13

According with the Procedure for preheat of

welding and heat treatment.

Report of preheating and / or thermal treatment

by flame

Weld card

Diagram

Re-traceability of the heat treatment process is necessary.

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Questionnaire for manufacturer qualification according to

Page 11 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 2

EN ISO 3834-3

Quality requirements acc. to EN ISO 3834-2 / -3

Element

Par. of

Standards

Welding related

inspection and

testing,

General

14.1

Welding related

inspection and

testing, before

welding

14.2

see also

Evaluation/

Remarks

Inspection and testing are scheduled based on the

project requirements and the applicable product

standards,type of inspection, extension, time and

location are specified in the inspection and testing

plan.

EN 287,

EN ISO

15609

WPS

POS-01SAEM

What kind of

inspections are

performed?

e.g.:

Description

- welders ( check if qualification certificate covers the

range of welding works )

- WPS , qualifications ( and approved if required ) ,

product standard requirements and other aplicable

rules

- shape preparation cleaninf and fit-up joint acc. WPS

- safety , health and working environment

- suitability of equipments and tools

suitability and validity of:

- welders and welding operators approval test certificates

- welding procedure approvals, if required

- welding procedure qualifications (WPS)

joint preparation

suitability of working conditions including evironment (air draught, temperature, special measures for

manufacturing of ferritic/austenitic steels etc.)

Welding related

inspection and

testing, during

welding

WPS

POS-1SAEM

14.3

PL 07SAEM

What kind of

inspections are

performed?

e.g.:

The general procedure of welding

Welding visual inspection procedure

- compliance parameters and requirements of WPS

- cleaning, shape or runs and lyers, back gouging

- correct use and handling of filler metals

- inspection (check of distortion, dimensions)

control and, if necessary, documentation of

- welding parameters and preheating / interpass temperature

- cleaning, shape or runs and lyers, back gouging

- correct use and handling of filler metals

- any intermediate inspection (check of distortion, dimensions)

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Questionnaire for manufacturer qualification according to

Page 12 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 2

EN ISO 3834-3

Quality requirements acc. to EN ISO 3834-2 / -3

Element

Par. of

Standards

Welding related

14.4

inspection and

testing, after welding

What kind of

inspections are

performed?

see also

Description

PL-06

PL-07

Procedures for:- visual inspection

PLL-02

PLL-05

PL-05

PLL-12

PLL-15

PL-100

PL-106

PL-125

Procedures for:- nondestructive tests:

Evaluation/

Remarks

Procedures for:- hardness control

PL-09

e.g.:

- visual inspection

- destructive and non-destructive tests,

- inspection of surface treatment (grinding, pickling etc.)

Inspection and test

status

PCCVI

14.5

Inspection and testing Plan

in signatures when the surgery is complete in

inspection and testing plan

How is the manufacturing and inspection

status of the product

indicated?

by use of routing card,

e.g.:

by use of routing card, production and inspection sequence plan with production related items

Non-conformities

15

and corrective action

Which measures for

control of non-conforming products are

defined?

(e.g. procedures for

separate storage,

repair and/or

rectification including

reinspection)

What measures are

assigned in order to

identify and eliminate

causes of nonconformities

(EN ISO 3834-2)

PS-SAEM Quality system procedure :

- 06

Control of non-compliant product

PL 21

SAEM

Operational instruction :

Reconditioning of fusion welded joints

PS SAEM 07

Quality system procedure :

Corective actions

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Questionnaire for manufacturer qualification according to

Page 13 of 13

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 2

EN ISO 3834-3

Quality requirements acc. to EN ISO 3834-2 / -3

Element

Par. of

Standards

see also

Identification and

traceability

throughout the manufacturing process

17

HP 0,

Para. 4

Operational procedure : Identification and traceability

PO SAEM -08

Which procedures are

defined for identification and traceability

of semifinished

products, welding

consumables, weld

seams (incl. repairs)

and products?

IO-005

Operational instruction : Identification and

traceability

Responsible personnel

for markshift of

materials

See enclosure 6.

AC F 013

Which documentation

for traceability of the

welding operations is

defined?

Quality records

Description

Quality system procedure :

18

Which records,

certificates, approvals

are defined?

According to the manual quality ,

PS

SAEM -02 quality control plan , inspection and testing plan

Who is responsible for

the establishment of

quality records?

Which procedures are

defined for cases of

non-conformities?

Form of POS- 01 SAEM : Weld card

Quality assurance responsible

PS Quality system procedure :

SAEM -06

Control of nonconforming product

What is the minimum

period of retaining the

quality records?

According to law and contractual provisions

- strike out not applicable parts

- please add supplementary description on a separate page, if the place in the question list is not sufficient

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Evaluation/

Remarks

Questionnaire for manufacturer qualification according to

Enclosure 1 Page 1 of 1

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 1

EN ISO 3834-3

Welder

1.1 Manual welders

(incl. welders for semimechanized welding processes, e.g. 131, 135, 136)

Total number:15

Examination group acc. EN 287-1 (steel)

Number of qualified / approved welders

1.1,1.2,1.4. ( 111 )

14

1.1,1.2,1.4. ( 135 )

11

1.1,1.2,1.3,1.4,2,3,4,5,6,7,8,9.1,11.(141)

1.1,1.2,1.3,1.4,2,3,4,5,6,7,8,9.1,11.(141+111)

8,9.29.3,10.(141+111)

4

See attashed table Encloseure 8

Examination group acc. EN ISO 9606-2 (Aluminium)

acc. to other standards:

Number of qualified / approved welders

Number of qualified / approved welders

1.2 Personnel for mechanized welding (with travelling carriage (e.g. 121), Orbit, Robot)

qualified in accordance with AD 2000-HP 2/1 - HP 5/2 - TRD 201 - EN 1418

Welding process

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

Parent metal

05.2004

Number of operators

Questionnaire for manufacturer qualification according to

Enclosure 2 Page 1 of 1

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 -

EN ISO 3834-3

Are welding and testing supervision performed by the same person?

Welding coordinator

yes , same person

(please indicate)

Name:Copceanu Costel

Education in welding technology as

(title): Welding Equipment and technology

at: Technical University of Timisoara

finished on (date):1994

EWE / IWE ASR CERTPERS SRL TIMISOARA

Experience in welding:17 years

employed at: SAEM Drobeta Turnu Severin as: Welding responsible from1995 till:present

Position: Welding coordinator

Range of responsability:According to EN ISO 14731

Substitute for the welding coordinator

Name:

Murgil Sorin

Education in welding technology

(title): Welding Equipment and technology

at:Technical University of Timisoara

finished on (date):1995

Experience in welding:16 years

employed at: SAEM Drobeta Turnu Severin Quality assurance and Quality control from: 1996 till: present

Range of responsability: According to EN ISO 14731

please enclose certificates about welding technology education

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Questionnaire for manufacturer qualification according to

Enclosure 3 Page 1 of 2

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 3

EN ISO 3834-3

Supervisor for NonDestructive Testing (NDT)

Name: Copaceanu Costel

Stamp and

Signature:

Education in NDT as (title/level):ISIM Timisoara

Certificate EN 473

issued by ISIM Timisoara

at:

finished on (date):2008

Level:2

Experience NDT:5 years

employed at: SAEM Drobeta Turnu Severin operator from:2002 till: present :

Range of responsibility: Responsible for the non-destructive examination

Substitute of the supervisor for NDT

Name:

MURGU PAVEL

Stamp and

Signature:

Education in NDT as (title):

Nondestructive flaw Center ISSUED training and specialization by: issued by:

professionals in the nuclear field during

at:31.01.1994-29.04.1994

finsihed on (date):

Experience in NDT: 17 years

employed at: SAEM Drobeta Turnu Severin operator from:1995 till: present :

Position: Substitute of NDT chief laboratory

Range of responsability: Responsible for the non-destructive examination

please enclose EN 473 certificates

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Questionnaire for manufacturer qualification according to

Enclosure 3 Page 2 of 2

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 4

EN ISO 3834-3

List of personnel for NDT

Testing process

Name

Level

acc. EN 473

Visual test

(VT)

Copaceanu Costel

Dye penetrant test

(PT)

Copaceanu Costel

Moraru Iustinian

Murgu Pavel

Neagoe Toma

Zaharia Ionel

Magnetic particle test

(MT)

Copaceanu Costel

Murgu Pavel

Neagoe Toma

Zaharia Ionel

Radiographic test

(RT)

Copaceanu Costel

Murgru Pavel

Neagoe Toma

Zaharia Ionel

Ultrasonic test

(UT)

Copaceanu Costel

Murgu Pavel

Neagoe Toma

Zaharia Ionel

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Questionnaire for manufacturer qualification according to

Enclosure 4 Page 1 of 7

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 1

Processing machines

1.1

Bending mills

EN ISO 3834-3

Quantity

3 pieces

Bending length

3000 mm

Kind of related heating equipment

-

Wall thickness range for rolling

(depending on diameter)

cold:

1.2

mm;

hot:

10

mm

Bending presses

Quantity

1 pieces

Force max.

200 daN

Kind of related heating equipment

-

Wall thickness range for pressing

cold:

1.3

mm;

hot:

Quantity

1 pieces

mm

Remarks

(1-8) mm

Equipment for surface treatment and finishing

Kind of treatment

(e.g. pickling, sand blasting, grinding, polishing)

Sand blasting

Grinding

1.5

20

Other equipment for forming

Kind

Bending presses

1.4

10

Quantity

2 pices

25 pieces

Plate shears

Quantity:3 pieces

Thickness range for cutting for ferritic steel:

1.6

Equipment for thermal cutting

Kind and quantity: CNC oxyfuel

for ferritic steel:

1.7

15 mm; austenitic steel: 10 mm

25 mm

1 pieces

for austenitic steel:15

Devices for handling

Rollers

1. Muffles

Positioners

Quantity

max. load capacity

Kind of drive

60 t

Quantity

max. load capacity

Kind of drive

Quantity

max. load capacity

Kind of drive

Other equipment:

Kind

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Questionnaire for manufacturer qualification according to

Enclosure 4 Page 2 of 7

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 -

EN ISO 3834-3

1. Traction device - high

20

2. Normal chain lifting device

15

6t

5

1

3

10 t

3. Pulley

4. Traveler

5. Erecting platform

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

3,2 t

20 t

0.6 t

Questionnaire for manufacturer qualification according to

Enclosure 4 Page 3 of 7

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 2

EN ISO 3834-3

Welding equipment

Kind

Generators

Quantity

2

max. Current

43 A at 230V

25 A at 400V

DC converters

23

250A

Transformers

---

---

TIG welding machines

250A

TIG pulse welding machines

MAG/MIG welding machines

Quantity

9 pieces

max. Current

450

MAG/MIG pulse welding machines

SAW welding machines

Oxy-fuel welding equipment

2 pieces

Further equipment

(e.g. for plasma arc welding*)

Manipulators for welding machines*)

*) please describe on separate page

3

Drying equipment for welding consumables

15 pieces

3.1

Drying / hot storing equipment for covered electrodes 2 pieces

Kind

max. Temperature (oC)

Calcined kiln and maintaining

400 oC

400 oC

100 oC

3.2

3.3

Quantity

2 piece for 30 kg.

1 piece for 50 kg

15 pieces for 5 kg.

Drying / hot storing equipment for flux-cored wires

Kind

max. Temperature (oC)

Quantity

Drying / hot storing equipment for flux

Kind

Quantity

max. Temperature (oC)

4 Heat treatment equipment (stationary and/or transportable)

examined acc. to AD 2000-Merkblatt HP 7 or equivalent code:

Kind and quantity of equipment *)

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Examination No.

Date

Questionnaire for manufacturer qualification according to

Enclosure 4 Page 4 of 7

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 -

EN ISO 3834-3

AEG Elotherm 120kW 1 pieces , for local heat treatment

by induction ( 2000 Hz ) , 0 1000 C ; temperature

registation

*)

please add a description of the equipment concerning: size / capacity / kind of heating / furnace atmosphere /

temperature range / kind of heat treatment / quantity of thermocouples for furnace temperature and

component temperature / subcontractor for heat treatment (name and address)

5 Transportation devices for the assembly and transport of individual parts and components as well as for hot

forming and heat treatment

Kind and quantity of transport. devices

1. Load lifting device, 4 hands = 1 piece

2. Auto crane = 1 pcs.

3. Auto crane = 1 pcs.

4. Crawler Crane = 2 pcs.

5. Tower crane = 1 pcs.

6. Gantry crane = 2 pcs.

7. Electric winch = 2 pcs.

8. Slide bridge = 4 pcs.

9. Truck = 1 pcs

1.

2.

3.

4.

5.

6.

7.

8.

9.

Load capacity

maximum load 26,5 t

maximum load 12,5 t

maximum load 25 t

maximum load 30 t

maximum load 1000 tm

maximum load 30 t

maximum load 12 t

maximum load 10 t

maximum load 20 t , 250x250x1600 cm

6 Particular other manufacturing device

1. Lathe = 4 pcs.

2. Finishing machine = 3 pcs.

3. Milling machine = 2 pcs.

4. Screwdriver = 4 pcs.

5. Rotary magnetic = 4 pcs.

6. Portable electric car plate chamfered = 2 pcs.

7. Band Saw = 2 pcs.

8. Chamfered pipe machines = 3 pcs

Material testing equipment

(e.g. tensile, bending, impact, hardness, pellini testing machines)

Quantity and type

Measuring range

Class acc. to

EN ISO 7500-1,

EN 10002-4

By whom and how

often are the machines

checked/ calibrated

(external, incompany)

(ref. DIN 51220)

Special equipment

(e.g. straingage,

elevated temp. and

low temp. tensile test

facilities)

Remarks

Measurement equipment (for simple devices only total number may be listed)

Quantity and type

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

Applicable range

(in general)

05.2004

By whom and how

often is this equipment

checked/calibrated

Remarks

Questionnaire for manufacturer qualification according to

Enclosure 4 Page 5 of 7

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 -

EN ISO 3834-3

SC METROREAL SRL

1. TR100 Surface Roughness Tester = 1

pcs.

1.c= 0 2,5 mm , U=0,2%

2. 0 1250 m , dry film thickness

2. Coating thickness gauge = 1 pcs.

3. 0 100 mm , 0,01 accuracy

3. Micrometers = 5 pcs.

4. 0 10 mm , 0,01accuracy

4. Comparator = 3pcs.

5. 0,01 accuracy

5. Nivel = 2 pcs.

6.( 2 0 + 520 ) C

6. Digital thermometer =2 pcs.

7. ( 0 + 1200 ) C

7. Temperature recorder = 2 pcs.

8. Device to measure hardness = 1 pcs.

8. 780 HLD

9 . Steel tapes = 35 pcs

9. 20 m ; 1mm/div

10 Caliper = 10 pcs

10. 800mm ; 0,05 mm/div

11 Theodolite = 1pcs

11. accuracy 20

12 Termohigrometer

12. ( -30 + 60 ) C ; 100RH

Devices for pressure test, leak test and burst test

Type and quantity

1. Pressure pump = 1 piece

Applicable range

Testmedium

max. test

pressure

Hidraulic Pressure

test

- metalic piping

- pressure vesel

- boilers

water

400 bar

Additional remarks:

*) manometers for the testing of pressure equipment shall be calibrated

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

By whom and how

often is this equipment

checked/calibrated

(e.g. manometer) *)

SC METROREAL SRL

Remarks

Questionnaire for manufacturer qualification according to

Enclosure 4 Page 6 of 7

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 -

EN ISO 3834-3

Equipment for metallographic examination (summary)

Type and Quantity (e.g. microscope)

Remarks

Equipment for chemical analysis

Type and Quantity

Manufacturer,

year of

construction

Elements to be

determined

Are the relevant

requirements

for the analysis

accuracy fulfilled? *)

Remarks

*) e.g. in acc. to German manual Handbuch fr das Eisenhttenlaboratorium

Remarks

Information about further testing equipment and testing procedures

(e.g. devices for identification check, corrosion tests)

Ultrasonic test equipment (UT)

Manufacturer and type

Quantity

1.USM 35 XS -KRAUTKRAMER

2.UT g-WM2 -KRAUTKRAMER

Remarks

(e.g. for calibration)

1

1

Kind of test probes / calibration blocks (summary)

Manufacturer and type

Remarks

CALIBRATION BLOCKS = A1; A2; A3;

MSEB 4 nr. 57462;B1S nr. 57744;MWB 45-2 nr. 56921;MWB70-2 nr 56923

MWB 60-4 nr. 56928;MWB 45-4 nr. 56927;MWB 70-4 nr.56929;B4S nr. 57746

MB2S nr. 57748

Radiographic test equipment (RT)

(z.B. X-ray tubes, isotope inspection equipment, linear accelerator)

Kind

Quantity

1. GAMARID 120M /120

Energy limit

Manufacturer and type

(EG)

or max. activity

80 Ci

2 pieces

Remarks

GAMMARID

URSS

Equipment for film examination

(e.g. densitimeter)

Kind

Quantity

1.Densitometer

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Manufacturer and type

Namicon HD-03

Remarks

Questionnaire for manufacturer qualification according to

Enclosure 4 Page 7 of 7

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 -

EN ISO 3834-3

Apparatures and devices for surface crack examination

Magnetic particle test equipment (MT)

Manufacturer and type

max. capacity

Remarks

(e.g. for calibration)

-Yoke magnetization

1 PIECE 4,1 kg.

- PARKER - MAGNETIC Jug DA 400 S 220V CA

- LABINO AB SWEDEN-LABINO PH 135

Test body-Berthold

1 PIECE

DC;AC

- Magnetic current

- Other methods

Devices and test probes for the control of tangential magnetic field intensity and indicator

liquid (e.g. Berhold-test probe)

Remarks

Dye penetrant test (PT)

Type (e.g. wet)

Manufacturer and type

U87; U88; U89 - HELLING GmbH

HELLING

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Remarks

Test body-P1

Questionnaire for manufacturer qualification according to

Enclosure 5 Page 1 of 1

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Reference/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 -

EN ISO 3834-3

Welding procedure approval tests performed

No.

Parent metals /

form

(material type /

tube, plate etc.)

Filler metals,

auxillary

materials

Welding

process

Welding Dimensional

position range

(thickness, )

mm

Heat

treatment

Operating

temperature

max./min. *)

C

Code

1.

Tube Gr 1

E42 4 B 42

H5 (EN499)

111

HL 045

3-24

PF

3-24

VP

704TUVRO

VP

705TUVRO

2.

Plate Gr 1

E42 4 B 42

H5 (EN499

111

3.

Plate Gr 1

G3Si1

135

PF

3-24

VP

706TUVRO

4.

Plate Gr 1

E46 5 Z B

32

111

PF

3-24

VP

707TUVRO

5.

Plate Gr 1

G42 4 M G

0 SG51

135

PF

3-24

VP

708TUVRO

6.

Plate Gr 1

E42 4 B 42

H5

111

PF

15-60

VP

709TUVRO

7.

Plate Gr 1

G3Si 1

135

PF

15-60

VP

710TUVRO

Additonal remarks:

See also Enclosure 7 for other Welding procedure aproval test performed

*) of welded items

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

03.2006

Remarks

Questionnaire for manufacturer qualification according to

Enclosure 6

- Pressure Equipment Directive 97/23/EC Annex I, Paragraph 4.3

in connection with AD 2000-Merkblatt HP 0 / TRD 201

Refernce/Inspection No.:

- EN 13480 EN 13445 EN 12952 EN 12953

- EN ISO 3834-2 -

EN ISO 3834-3

Responsible personnel for markshift

Name: MURGILA SORIN

Stamp and

Signature:

Education

as: Diplomat enginering

at: Technical University Timisoara

finsihed on (date):1995

Function: QA Responsible

Responsible personnel for markshift

Name: MURGU PAVEL

Stamp and

Signature:

Education

as: enginering

at: Technical College

finsihed on (date):2004

Function: QC Responsible

Responsible personnel for markshift

Name: CINCA VICTOR

Stamp and

Signature:

Education

as: mechanic locksmith

at: Tehnical school

finsihed on (date):1979

Function: QC Responsible

The consent for the transfer of marking was given by TV on (date) ..

3.06 -Questionnaire_AD_2000-HP0_ISO_3834_en

05.2004

Page 1 of 1

Вам также может понравиться

- STAINLESS Filler Selector Guide PDFДокумент1 страницаSTAINLESS Filler Selector Guide PDFArul Edwin VijayОценок пока нет

- What Says Doctors About Kangen WaterДокумент13 страницWhat Says Doctors About Kangen Waterapi-342751921100% (2)

- QW 406 Asme CodeДокумент3 страницыQW 406 Asme CodeMardeOpamenОценок пока нет

- Weldolet InfoДокумент4 страницыWeldolet InfoChoon Wei WongОценок пока нет

- Heavy-Walled (4 To 12-In. (114 To 305-mm) ) Steel Castings: Standard Reference Radiographs ForДокумент4 страницыHeavy-Walled (4 To 12-In. (114 To 305-mm) ) Steel Castings: Standard Reference Radiographs ForAvinash SilimkarОценок пока нет

- Problems With B16.5 and B16.47 Flange StandardsДокумент1 страницаProblems With B16.5 and B16.47 Flange StandardsManohar SeetharamОценок пока нет

- Participant Observation: Qualitative Research Methods: A Data Collector's Field GuideДокумент17 страницParticipant Observation: Qualitative Research Methods: A Data Collector's Field GuideMarta CabreraОценок пока нет

- ARAMCO QM Number ListДокумент3 страницыARAMCO QM Number ListMohamed Yousuf Syed MohamedОценок пока нет

- Building A Pentesting Lab For Wireless Networks - Sample ChapterДокумент29 страницBuilding A Pentesting Lab For Wireless Networks - Sample ChapterPackt PublishingОценок пока нет

- Ex ProtectionДокумент44 страницыEx ProtectionAnil MarkaleОценок пока нет

- Kirloskar Valves Technical Specification CatalogueДокумент24 страницыKirloskar Valves Technical Specification CatalogueAbhinay SuratkarОценок пока нет

- Tube-To-Tube Sheet Joint RequirementsДокумент2 страницыTube-To-Tube Sheet Joint RequirementsWaqas WaqasОценок пока нет

- En 50124 1 2001Документ62 страницыEn 50124 1 2001Vivek Kumar BhandariОценок пока нет

- EGE00B25Документ8 страницEGE00B25Jhonny Rafael Blanco CauraОценок пока нет

- Agenda Item: 650-2024: Coating Prior To Hydrostatic TestingДокумент4 страницыAgenda Item: 650-2024: Coating Prior To Hydrostatic Testinggigiphi1Оценок пока нет

- TDC 003 - SS Pipes - r0Документ1 страницаTDC 003 - SS Pipes - r0samkarthik47Оценок пока нет

- Itp Vessel PDFДокумент4 страницыItp Vessel PDFBUDAPESОценок пока нет

- Astm-A707 CS As LTS PDFДокумент5 страницAstm-A707 CS As LTS PDFGoutam Kumar DebОценок пока нет

- ASME Section 1 and Pressure Equipment DirectiveДокумент5 страницASME Section 1 and Pressure Equipment DirectivealextentwentyОценок пока нет

- ST 35.8 (Germany / DIN) : Material PropertiesДокумент3 страницыST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiОценок пока нет

- Welding Data BookДокумент152 страницыWelding Data Bookmetalgikanu100% (2)

- HAYAT - CLINIC BrandbookДокумент32 страницыHAYAT - CLINIC BrandbookBlankPointОценок пока нет

- Closure Data PEДокумент2 страницыClosure Data PEjowarОценок пока нет

- Anodes in Cooling Water Exchangers PDFДокумент12 страницAnodes in Cooling Water Exchangers PDFcbrittaivОценок пока нет

- Electric Vehicles PresentationДокумент10 страницElectric Vehicles PresentationVIBHU CHANDRANSH BHANOT100% (1)

- Dialog+ SW9xx - SM - Chapter 7 - 2-2013 - EN - Rinsing Bridge Version 5Документ1 страницаDialog+ SW9xx - SM - Chapter 7 - 2-2013 - EN - Rinsing Bridge Version 5Al ImranОценок пока нет

- List of Questions EN 13445 - 2014 PDFДокумент14 страницList of Questions EN 13445 - 2014 PDFwindsurferke007Оценок пока нет

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Документ6 страницRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriОценок пока нет

- Questionnaire Manufacturer AssessmentДокумент27 страницQuestionnaire Manufacturer AssessmentKrunoslav Duga100% (1)

- BS en 15085 - 2quality Requirements For ManufcturersДокумент48 страницBS en 15085 - 2quality Requirements For ManufcturersSubramanian R0% (1)

- Office: Printout Sample - ASME WPSДокумент2 страницыOffice: Printout Sample - ASME WPSDanem HalasОценок пока нет

- Questionnaire Manufacturer Assessment PDFДокумент27 страницQuestionnaire Manufacturer Assessment PDFulasОценок пока нет

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Документ15 страницFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaОценок пока нет

- UG-100 Pneumatic TestДокумент2 страницыUG-100 Pneumatic TestInaamОценок пока нет

- Asme VДокумент1 страницаAsme VMohd AnsariОценок пока нет

- Sa 263Документ8 страницSa 263Wagner Renato AraújoОценок пока нет

- Spectacle Blind FlangeДокумент3 страницыSpectacle Blind Flangel kishoreОценок пока нет

- Test Plan WorkshopДокумент24 страницыTest Plan WorkshopĐại NamОценок пока нет

- Oil Gas Construction Factory L.L.CДокумент2 страницыOil Gas Construction Factory L.L.CRenny DevassyОценок пока нет

- Astm A 234 A234m-15Документ9 страницAstm A 234 A234m-15Mohammed AliОценок пока нет

- WPS MCC 001 PDFДокумент1 страницаWPS MCC 001 PDFNuwan RanaweeraОценок пока нет

- 1.4301 Austenite Stainless SteelДокумент3 страницы1.4301 Austenite Stainless SteelSM Waqas ImamОценок пока нет

- G8s-5034-02-Bubble Leak TestДокумент4 страницыG8s-5034-02-Bubble Leak TestmaheshОценок пока нет

- Soft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesДокумент4 страницыSoft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesEduardoОценок пока нет

- Open Book Testing - API 653Документ9 страницOpen Book Testing - API 653EdisonCorderoОценок пока нет

- Nabakem Metal Surface Coating AgentДокумент6 страницNabakem Metal Surface Coating Agentsutrisno00Оценок пока нет

- Din en 10204Документ5 страницDin en 10204QA QCОценок пока нет

- Boq For AS BoilerДокумент1 страницаBoq For AS BoilerGayan ChathurangaОценок пока нет

- BS 1595 PDFДокумент9 страницBS 1595 PDFAdesina AlabiОценок пока нет

- BPVДокумент8 страницBPVendri2000Оценок пока нет

- SecVIII Div1 UW40Документ2 страницыSecVIII Div1 UW40arianaseriОценок пока нет

- Instruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Документ8 страницInstruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Ramon GarciaОценок пока нет

- P1 A C LHДокумент2 страницыP1 A C LHMohamed Reda HusseinОценок пока нет

- PSV DatasheetДокумент40 страницPSV DatasheetJonson Cao100% (1)

- 2019-5 TechPresentation BeachДокумент141 страница2019-5 TechPresentation Beachaneeshta100% (1)

- Pressure Test in Accordance With The Standard Din en 13445: Inspecta GroupДокумент14 страницPressure Test in Accordance With The Standard Din en 13445: Inspecta GroupNanang PhОценок пока нет

- Astm F436.04 PDFДокумент6 страницAstm F436.04 PDFWelington Volpatto MoraisОценок пока нет

- RT API 650 12th - 2013Документ1 страницаRT API 650 12th - 2013Đỗ Thị HuyềnОценок пока нет

- ASTM A182 - Standard Specification For Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings and Valves and Parts For High Temperature ServiceДокумент16 страницASTM A182 - Standard Specification For Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings and Valves and Parts For High Temperature ServiceKok WaiОценок пока нет

- Asme Boiler and Pressure Vessel Certificates of Authorization and Code Symbol StampsДокумент12 страницAsme Boiler and Pressure Vessel Certificates of Authorization and Code Symbol StampsNilesh PathareОценок пока нет

- ASME P-NumbersДокумент9 страницASME P-NumbersAamer MohammedОценок пока нет

- Astm A 450Документ10 страницAstm A 450Telmo VianaОценок пока нет

- Astm A179 PDFДокумент1 страницаAstm A179 PDFgaminОценок пока нет

- Form 167Документ239 страницForm 167Kumar Navneet SinghОценок пока нет

- Is 210Документ16 страницIs 210Debopriyo GhoshОценок пока нет

- Antrag 15085 Engl KoA RichtlinieДокумент9 страницAntrag 15085 Engl KoA RichtlinieCarlos Nombela PalaciosОценок пока нет

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- Power System Planning and OperationДокумент2 страницыPower System Planning and OperationDrGopikrishna Pasam100% (4)

- Lesson: The Averys Have Been Living in New York Since The Late NinetiesДокумент1 страницаLesson: The Averys Have Been Living in New York Since The Late NinetiesLinea SKDОценок пока нет

- CL RouterAndSwitches AE Kn1of3 AnswerДокумент19 страницCL RouterAndSwitches AE Kn1of3 Answereugene ngОценок пока нет

- Settlement Report - 14feb17Документ10 страницSettlement Report - 14feb17Abdul SalamОценок пока нет

- GTA IV Simple Native Trainer v6.5 Key Bindings For SingleplayerДокумент1 страницаGTA IV Simple Native Trainer v6.5 Key Bindings For SingleplayerThanuja DilshanОценок пока нет

- Specification Sheet: Case I Case Ii Operating ConditionsДокумент1 страницаSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarОценок пока нет

- Suspend and Resume Calls: Exit PlugДокумент4 страницыSuspend and Resume Calls: Exit PlugrajuОценок пока нет

- Homework 1Документ8 страницHomework 1Yooncheul JeungОценок пока нет

- War at Sea Clarifications Aug 10Документ4 страницыWar at Sea Clarifications Aug 10jdageeОценок пока нет

- Lec. 2Документ22 страницыLec. 2محمدОценок пока нет

- ISO - 21.060.10 - Bolts, Screws, Studs (List of Codes)Документ9 страницISO - 21.060.10 - Bolts, Screws, Studs (List of Codes)duraisingh.me6602Оценок пока нет

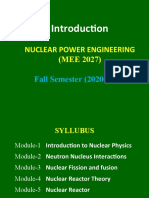

- Nuclear Power Engineering (MEE 2027) : Fall Semester (2020-2021)Документ13 страницNuclear Power Engineering (MEE 2027) : Fall Semester (2020-2021)AllОценок пока нет

- The BetterPhoto Guide To Creative Digital Photography by Jim Miotke and Kerry Drager - ExcerptДокумент19 страницThe BetterPhoto Guide To Creative Digital Photography by Jim Miotke and Kerry Drager - ExcerptCrown Publishing GroupОценок пока нет

- Code ExplanantionДокумент4 страницыCode ExplanantionVivek JadiyaОценок пока нет

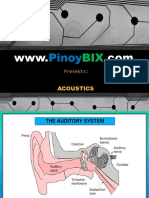

- AcousticsДокумент122 страницыAcousticsEclipse YuОценок пока нет

- International Patient Referral - Part 2 - Revised - 29-04-2010 - 2Документ2 страницыInternational Patient Referral - Part 2 - Revised - 29-04-2010 - 2Fatah AssadОценок пока нет

- How Can Literary Spaces Support Neurodivergent Readers and WritersДокумент2 страницыHow Can Literary Spaces Support Neurodivergent Readers and WritersRenato Jr Bernadas Nasilo-anОценок пока нет

- Research Paper On Air QualityДокумент4 страницыResearch Paper On Air Qualityluwahudujos3100% (1)

- Assignment Csi104Документ11 страницAssignment Csi104Minh Lê KhảiОценок пока нет

- The Minimum Means of Reprisal - China's S - Jeffrey G. LewisДокумент283 страницыThe Minimum Means of Reprisal - China's S - Jeffrey G. LewisrondfauxОценок пока нет

- Vernacular ArchitectureДокумент4 страницыVernacular ArchitectureSakthiPriya NacchinarkiniyanОценок пока нет

- Asus Test ReportДокумент4 страницыAsus Test ReportFerry RiantoОценок пока нет

- Personal Finance Kapoor 11th Edition Solutions ManualДокумент26 страницPersonal Finance Kapoor 11th Edition Solutions Manualsiennamurielhlhk100% (28)