Академический Документы

Профессиональный Документы

Культура Документы

Testing of C - 2006 - Pull-Off PDF

Загружено:

Anonymous qjoKrp0oОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Testing of C - 2006 - Pull-Off PDF

Загружено:

Anonymous qjoKrp0oАвторское право:

Доступные форматы

Partially destructive strength tests 111

wide and although surface zone effects must be considered, the approach

appears to offer the most reliable available indication of in-situ strength

apart from cores. Although equipment costs are high, the damage, time and

cost of testing will be considerably less than for cores. Problems may arise

from the presence of reinforcement within the test zone, and bars must be

avoided, but the value of this test is considerable in situations where mix

details are not known.

4.2.2.4 Wood-screw method

A simple pull-out technique utilizing wood-screws has been described by

Jaegermann (121). This is intended for use to monitor strength development

in the 515 N/mm2 strength range for formwork stripping purposes in

industrialized buildings.

A nail is driven into the surface of the fresh concrete to push aside aggregate particles, and the screw with a plastic stabilizing ring attached at the

appropriate height is inserted until the ring touches the concrete surface. The

unthreaded upper part of the screw is painted to prevent bonding and tests

can be made at different depths by using screws of different lengths. A load

is applied to the screw head by means of a proving ring or hydraulic jacking

device. The principal assumption is that the force required to pull the screw

from the concrete is dominated by the fine mortar surrounding the screw

threads, and laboratory trials suggest good strength correlations with reasonable repeatability but further development is needed to facilitate field usage.

4.3 Pull-off methods

This approach has been developed to measure the in-situ tensile strength

of concrete by applying a direct tensile force. The method may also be

useful for measuring bonding of surface repairs (122) and a wide selection

of equipment is commercially available (123) with disk diameters typically 50 or 75 mm. Procedures are covered by BS 1881: Part 207 and it

should be noted that the fracture surface will be below the concrete surface

and will thus leave some surface damage that must be made good. ASTM

C1583 (124) also covers this test method for in-situ applications whilst BS

EN 1542 (125) uses the technique on laboratory specimens to assess the

bond properties of repair materials.

Pull-off tests have been described (120), which were developed initially

in the early 1970s for suspect high alumina concrete beams. A disk is glued

to the concrete surface with an epoxy resin and jacked off to measure the

force necessary to pull a piece of concrete away from the surface. The direct

tension failure is illustrated in Figure 4.24, and if surface carbonation or

skin effects are present these can be avoided by the use of partial coring to

an appropriate depth. Limpet loading equipment with a 10 kN capacity

112 Partially destructive strength tests

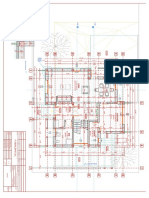

Figure 4.24 Pull-off method surface and partially cored.

is commercially available to apply a tensile force through a rod screwed

axially into a 50 mm diameter disk. This equipment (Figure 4.25) bears

on the concrete surface adjacent to the test zone and is operated manually

by steady turning of the handle, with the load presented digitally. Another

common type of loading system is by means of a tripod apparatus, with the

load applied mechanically (as in Figure 4.26) or hydraulically. Despite wide

variations in loading rates and reaction configurations between different

systems, the authors (126) have concluded that results are unlikely to be

affected provided there is adequate clearance between the disk and reaction

points. Considerable care is needed in surface preparation of the concrete

by sanding and degreasing to ensure good bonding of the adhesive, which

may need curing for between 1.5 and 24 hours according to material and

circumstances. Difficulties may possibly be encountered with damp surfaces.

BS 1881: Part 207 requires that the mean of six valid tests should be

used, and that these should be centred at least two disk diameters apart.

The stiffness of the disk has been shown to be an important parameter

and the limiting thickness/diameter ratio will depend upon the material

used (126). This is illustrated in Figure 4.27 from which it can be seen that

to ensure a uniform stress distribution, and hence maximum failure load,

steel disk thickness must be 40% of the diameter whilst for aluminium this

rises to 60%. These experimental findings have been supported by finite

element analyses.

A nominal tensile strength for the concrete is calculated on the basis

of the disk diameter, and this may be converted to compressive strength

using a calibration chart appropriate to the concrete. This calibration will

Partially destructive strength tests 113

Figure 4.25 Limpet equipment.

differ according to whether coring is used or not (119), with cored tests

generally requiring a lower pull-off force. Partial coring will transfer the

failure surface lower into the body of the concrete, but the depth of coring

may also be critical, as illustrated by Figure 4.28, and should always exceed

20 mm. Reinforcing steel clearly must be avoided when partial coring is

used. A test coefficient of variation of 7.9% with a range of predicted/actual

strength between 0.85 and 1.25 related to 150 mm Portland cement cubes

has been reported by Long and Murray (120) using the mean of three test

results. A typical calibration curve is illustrated in Figure 4.29, and it is

claimed that factors such as age, aggregate type and size, air entrainment,

compressive stress and curing have only marginal influences upon this.

Extensive field tests during the construction of a multistorey car park have

also been successfully undertaken (127).

BS 1881: Part 207 recommends that a strength correlation should be

established for the concrete under investigation and that site results from

one location are likely to yield a coefficient of variation of about 10%.

Accuracies of strength predictions under laboratory conditions of about

Figure 4.26 Hydrajaws tripod equipment.

Figure 4.27 Effects of disk type and thickness (based on ref. 126).

Partially destructive strength tests 115

Cube compressive strength (N/mm2)

Figure 4.28 Effects of partial coring (based on ref. 126).

specific mix with varying age

40

mean

30

20

lower 95%

confidence limit

10

1.0

2.0

3.0

4.0

2

Puff-off tensile strength (N/mm )

Figure 4.29 Typical pull-off/strength correlation for natural aggregate (based on

ref. 127).

15% (95% confidence limits) are likely. The authors (126) have also

demonstrated that separate correlations are required for different types of

lightweight aggregates, as illustrated in Figure 4.30, and that these are

different to those for natural aggregates due to different tensile/compressive

116 Partially destructive strength tests

Figure 4.30 Typical strength correlations for lightweight aggregates ( based on ref. 34).

strength relationships. It can be noted that pull-off values for lightweight

aggregates are higher than for natural aggregates at a given strength level.

This test is aimed primarily at unplanned in-situ strength determination.

The method is particularly suitable for small-section members, and longterm monitoring procedures could also be developed involving proof load

tests at intervals on a series of permanent probes. It is also particularly

suited, with the use of partial coring into the base material, for assessment

of bonding strength of repairs as indicated above.

This is an area receiving considerable industrial interest and many repair

specifications now require pull-off testing as part of quality control procedures (see reference to US and European Standards above). In such cases it

is usual to specify a minimum pull-off stress and it is thus vital that the test

procedures are carefully specified or standardized if this is to be meaningful.

A novel friction transfer device has recently been reported (128) in which

a partial core is physically gripped to avoid disk adhesion problems. A torsional load is then applied by torquemeter to cause a shear failure within

the core or at an interface between the substrate and an applied repair

material.

4.4 Break-off methods

4.4.1 Norwegian method

Johansen (108) has reported the use of a break-off technique developed in

Norway. This is intended primarily as a quality control test, and makes a

Вам также может понравиться

- GMW 14829 PDFДокумент3 страницыGMW 14829 PDFEd Ri100% (2)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- STT 330 ManuelДокумент183 страницыSTT 330 ManuelOzzyОценок пока нет

- C1583 101932-1TensileBondPullOffДокумент5 страницC1583 101932-1TensileBondPullOffcarsongbakerОценок пока нет

- Proper Use of The Rebound Hammer Updated To Reflect The Changes To ASTM C805Документ6 страницProper Use of The Rebound Hammer Updated To Reflect The Changes To ASTM C805Niroshan PereraОценок пока нет

- C 158 - 02 - Qze1oaДокумент9 страницC 158 - 02 - Qze1oaStuartОценок пока нет

- Reinforced High-Strength Concrete Beams in FlexureДокумент11 страницReinforced High-Strength Concrete Beams in FlexureAndrei IancuОценок пока нет

- Splitting Tensile Strength of Intact Rock Core Specimens: Standard Test Method ForДокумент4 страницыSplitting Tensile Strength of Intact Rock Core Specimens: Standard Test Method ForWalter German KrauseОценок пока нет

- C1150Документ4 страницыC1150jodapero13Оценок пока нет

- Flexural Strength of ConcreteДокумент3 страницыFlexural Strength of ConcretevikasОценок пока нет

- 2-11-1423831654-1. Civil - IJCSEIERD - INVESTIGATION ON ASTM C882 - Rashmi R Pattnaik PDFДокумент6 страниц2-11-1423831654-1. Civil - IJCSEIERD - INVESTIGATION ON ASTM C882 - Rashmi R Pattnaik PDFRush YoganathanОценок пока нет

- Wind Resistance of Concrete and Clay Roof Tiles (Mechanical Uplift Resistance Method)Документ6 страницWind Resistance of Concrete and Clay Roof Tiles (Mechanical Uplift Resistance Method)Ahmed Alzubaidi100% (1)

- Astm c633-79 - 1994 Leigh A Test C&RДокумент8 страницAstm c633-79 - 1994 Leigh A Test C&RastronotusОценок пока нет

- Properties of Anchor Grouts in A Confined State A D Barley Ice Conference London March 1997Документ10 страницProperties of Anchor Grouts in A Confined State A D Barley Ice Conference London March 1997Kenny CasillaОценок пока нет

- Asuncion, Rommel Rick C. AssignmentДокумент7 страницAsuncion, Rommel Rick C. AssignmentRommel Rick AsuncionОценок пока нет

- C 158 Â " 95 R00 QZE1OC1SRUQДокумент12 страницC 158 Â " 95 R00 QZE1OC1SRUQCesar PazОценок пока нет

- Fracture Strength: Lecture No. 5Документ9 страницFracture Strength: Lecture No. 5nayeemОценок пока нет

- TN 76Документ6 страницTN 76Hussein BeqaiОценок пока нет

- Fracture Toughness Testing - TwiДокумент5 страницFracture Toughness Testing - TwiSergio MunhosОценок пока нет

- Split Tensile Strength of ConcreteДокумент9 страницSplit Tensile Strength of Concreteabhineet srivastavaОценок пока нет

- 331-348 Materials For The Repair and Strengthening of Concrete Structures The Influence of Material Properties On Structural Perfor V V ImpДокумент16 страниц331-348 Materials For The Repair and Strengthening of Concrete Structures The Influence of Material Properties On Structural Perfor V V ImpMagdy BakryОценок пока нет

- Twi Tensile TestingДокумент10 страницTwi Tensile TestingchungndtОценок пока нет

- Mechanical TestingДокумент45 страницMechanical TestingshrikantajitОценок пока нет

- Astm C1161.21022 1Документ16 страницAstm C1161.21022 1raghav_goel1994100% (1)

- D 6916 - 03Документ6 страницD 6916 - 03luis-12Оценок пока нет

- Astm D 3164 - 03Документ4 страницыAstm D 3164 - 03phaindikaОценок пока нет

- Fracture ToughnessiДокумент49 страницFracture ToughnessiJithuJohnОценок пока нет

- CIP 16 - Flexural Strength of ConcreteДокумент2 страницыCIP 16 - Flexural Strength of ConcreteEkinawa AwanikeОценок пока нет

- Determining The Remaining Strength of Corroded Pipelines ASME B31G-1991Документ30 страницDetermining The Remaining Strength of Corroded Pipelines ASME B31G-1991ravi00098Оценок пока нет

- Viii Paper 07Документ17 страницViii Paper 07moonisqОценок пока нет

- Progress Towards Standardisation of Ball CrateringДокумент13 страницProgress Towards Standardisation of Ball CrateringLucas RaithsОценок пока нет

- Artigo - Control Tests For ConcreteДокумент24 страницыArtigo - Control Tests For ConcreteRonald Rolim de Moura100% (1)

- C633 617621-1 PDFДокумент8 страницC633 617621-1 PDFAmy BurnsОценок пока нет

- Ncma Tek: Segmental Retaining Wall Units TEK 2-4BДокумент4 страницыNcma Tek: Segmental Retaining Wall Units TEK 2-4BJorge Luis Arevalo LopezОценок пока нет

- CIP16 - Flexural Strength of ConcreteДокумент2 страницыCIP16 - Flexural Strength of ConcretePECMURUGANОценок пока нет

- Pressure Cycling 2010051Документ6 страницPressure Cycling 2010051Sharath KrishnanОценок пока нет

- Scad 2011 2 2 307 PDFДокумент13 страницScad 2011 2 2 307 PDFCarlos NievesОценок пока нет

- Saudi Aramco NDT Methods Application On Heat ExchangersДокумент30 страницSaudi Aramco NDT Methods Application On Heat Exchangersaasatti100% (1)

- Pull Out TestДокумент4 страницыPull Out TestAjoy Mc100% (1)

- Fracture Properties of Glass Fiber Composite Laminates and Size Effect EGYPTДокумент14 страницFracture Properties of Glass Fiber Composite Laminates and Size Effect EGYPTRajaneesh AnantharajuОценок пока нет

- Concrete Core TestДокумент5 страницConcrete Core Testtaruc jose royОценок пока нет

- Fatigue of Grouted Joint ConnectionsДокумент5 страницFatigue of Grouted Joint Connectionsscrane@Оценок пока нет

- Developments in Equipment and Standards For Testing Porosity in CoatingsДокумент11 страницDevelopments in Equipment and Standards For Testing Porosity in Coatingsmfazl33Оценок пока нет

- Flexural StrengthДокумент2 страницыFlexural StrengthMrcoke SeieОценок пока нет

- C 651Документ4 страницыC 651Asep TheaОценок пока нет

- F1160 1479757-1Документ8 страницF1160 1479757-1Thaweekarn ChangthongОценок пока нет

- 30 304NДокумент5 страниц30 304NJason SamuelОценок пока нет

- Sampling and Testing Concrete Masonry UnitsДокумент10 страницSampling and Testing Concrete Masonry UnitsRegenir Macedo AlvesОценок пока нет

- Concrete TestingДокумент32 страницыConcrete TestingAveesh singh100% (1)

- ASTM C633.617621 Norma Recubrimientos DurosДокумент7 страницASTM C633.617621 Norma Recubrimientos DurosJason MitchellОценок пока нет

- Tests On Aggregate: 1.crushing TestДокумент10 страницTests On Aggregate: 1.crushing TestzeeshanОценок пока нет

- Regression Modeling of Macrohardness ofДокумент5 страницRegression Modeling of Macrohardness ofabraham silva hernandezОценок пока нет

- Conducting Wet Sand/Rubber Wheel Abrasion Tests: Standard Test Method ForДокумент9 страницConducting Wet Sand/Rubber Wheel Abrasion Tests: Standard Test Method ForMiguel Angel B. VazquezОценок пока нет

- Compact Tension and J Integral Tests: Job KnowledgeДокумент4 страницыCompact Tension and J Integral Tests: Job KnowledgeSivaraman VisvanathanОценок пока нет

- ASTM D 1634-00 Standard Test Method For Compressive Strength of Soil-Cement Using Portions of Beams Broken in Flexure (Modified Cube Method)Документ3 страницыASTM D 1634-00 Standard Test Method For Compressive Strength of Soil-Cement Using Portions of Beams Broken in Flexure (Modified Cube Method)Pablo Antonio Valcárcel VargasОценок пока нет

- Rebound Number of Hardened Concrete: Standard Test Method ForДокумент3 страницыRebound Number of Hardened Concrete: Standard Test Method ForSNOWTOOSОценок пока нет

- Ipc2012 90690Документ12 страницIpc2012 90690Marcelo Varejão CasarinОценок пока нет

- BeamДокумент23 страницыBeamMohammad YusufОценок пока нет

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsОт EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerОценок пока нет

- 2.calaculul Imbinarii Cu Sudura Imbinare Guseu-Contravantuire: 2UPN 160Документ1 страница2.calaculul Imbinarii Cu Sudura Imbinare Guseu-Contravantuire: 2UPN 160Anonymous qjoKrp0oОценок пока нет

- E46 PDFДокумент2 страницыE46 PDFAnonymous qjoKrp0oОценок пока нет

- Lista Desene PDFДокумент2 страницыLista Desene PDFAnonymous qjoKrp0oОценок пока нет

- 2.calaculul Imbinarii Cu Sudura Imbinare Guseu-Contravantuire: 2UPN 160Документ2 страницы2.calaculul Imbinarii Cu Sudura Imbinare Guseu-Contravantuire: 2UPN 160Anonymous qjoKrp0oОценок пока нет

- SAMPLE-Building BoQ 01Документ86 страницSAMPLE-Building BoQ 01iGp2013Оценок пока нет

- Pile Cap DesignДокумент13 страницPile Cap DesignShabbir OsmaniОценок пока нет

- Bar Bending Schedule OF Box Culvert: Top Steel Bottom Steel DistributionДокумент1 страницаBar Bending Schedule OF Box Culvert: Top Steel Bottom Steel DistributionAnonymous qjoKrp0oОценок пока нет

- P128 CEmarking Versao AtualДокумент128 страницP128 CEmarking Versao AtualAnonymous qjoKrp0oОценок пока нет

- IncercariДокумент7 страницIncercariAnonymous qjoKrp0oОценок пока нет

- Radio Frequency Transmitter Type 1: System OperationДокумент2 страницыRadio Frequency Transmitter Type 1: System OperationAnonymous qjoKrp0oОценок пока нет

- Structural Steelwork Eurocodes: Development of A Trans-National ApproachДокумент23 страницыStructural Steelwork Eurocodes: Development of A Trans-National ApproachAnonymous qjoKrp0oОценок пока нет

- NoticeДокумент3 страницыNoticeDaniel David Ortiz CastroОценок пока нет

- Working Together in Allplan enДокумент25 страницWorking Together in Allplan enAnonymous qjoKrp0oОценок пока нет

- Steel Construction - CE MarkingДокумент20 страницSteel Construction - CE MarkingAnonymous qjoKrp0oОценок пока нет

- Ce Marking in Steel Construction: Luís Simões Da SilvaДокумент57 страницCe Marking in Steel Construction: Luís Simões Da SilvaAnonymous qjoKrp0oОценок пока нет

- CE Marking GuideДокумент26 страницCE Marking GuideAnonymous qjoKrp0oОценок пока нет

- CE Marking GuideДокумент26 страницCE Marking GuideAnonymous qjoKrp0oОценок пока нет

- Lecture 18 Worked ExampleДокумент4 страницыLecture 18 Worked ExampleAnonymous qjoKrp0oОценок пока нет

- Imbinare Heb 500 Cu Ipe 240Документ5 страницImbinare Heb 500 Cu Ipe 240Anonymous qjoKrp0oОценок пока нет

- Lecture 18Документ15 страницLecture 18Anonymous qjoKrp0oОценок пока нет

- Windows - Password For ArchiveДокумент1 страницаWindows - Password For ArchiveAnonymous qjoKrp0oОценок пока нет

- Research and Design Assisted by TestingДокумент16 страницResearch and Design Assisted by TestingAnonymous qjoKrp0oОценок пока нет

- Adina-Cladiri ETAJ-A2Документ1 страницаAdina-Cladiri ETAJ-A2Anonymous qjoKrp0oОценок пока нет

- Plan ParterДокумент1 страницаPlan ParterAnonymous qjoKrp0oОценок пока нет

- Mef Partea 2b NДокумент10 страницMef Partea 2b NAnonymous qjoKrp0oОценок пока нет

- Imbinare Continuitate StalpДокумент5 страницImbinare Continuitate StalpAnonymous qjoKrp0oОценок пока нет

- Adina Cladiri Fatada2 A2Документ1 страницаAdina Cladiri Fatada2 A2Anonymous qjoKrp0oОценок пока нет

- Adina Cladiri Fatada1 A2Документ1 страницаAdina Cladiri Fatada1 A2Anonymous qjoKrp0oОценок пока нет

- Plan Parter A.02Документ1 страницаPlan Parter A.02Anonymous qjoKrp0oОценок пока нет

- 안양외고 B차시 리딩Документ8 страниц안양외고 B차시 리딩yrz2ns4dfpОценок пока нет

- FDP ImpressionsДокумент113 страницFDP ImpressionsDeepak Kamalnathan100% (1)

- Berea Hardwoods Baron Roller Ball and Fountain Pen (Berea #0405R/-)Документ3 страницыBerea Hardwoods Baron Roller Ball and Fountain Pen (Berea #0405R/-)Doru GujbaОценок пока нет

- Wet Area Sunken - Method StatementДокумент5 страницWet Area Sunken - Method StatementbajrangОценок пока нет

- W1 D3 Handicraft Production Lesson 3 LO1Документ5 страницW1 D3 Handicraft Production Lesson 3 LO1Rochelle CatanОценок пока нет

- Dyuthi T0917Документ240 страницDyuthi T0917hung_105Оценок пока нет

- 4 Pipes 2015Документ134 страницы4 Pipes 2015kk Philips SmartОценок пока нет

- Archidply Products: Archidply Platinum PrimeДокумент9 страницArchidply Products: Archidply Platinum PrimekingshimbuОценок пока нет

- Smartcare Tile Adhesive For Tile On Tile ApplicationДокумент2 страницыSmartcare Tile Adhesive For Tile On Tile ApplicationDesign Group India IndiaОценок пока нет

- 2 1 8 P Ssa Trussdesign 1Документ12 страниц2 1 8 P Ssa Trussdesign 1api-345360665Оценок пока нет

- YukДокумент158 страницYukrezaОценок пока нет

- High Quality Equipment System SolutionsДокумент20 страницHigh Quality Equipment System SolutionsBurak YILMAZОценок пока нет

- 09 3000 Tiling SpecificationsДокумент5 страниц09 3000 Tiling SpecificationsمحمدОценок пока нет

- 3M - EU - Tech Bulletin - 480 - 2017 - 2Документ7 страниц3M - EU - Tech Bulletin - 480 - 2017 - 2ajmalakramОценок пока нет

- Araldite 2000Документ6 страницAraldite 2000Vong NgoОценок пока нет

- Deep Poly ChemДокумент4 страницыDeep Poly Chemplay bazaarОценок пока нет

- Chemicals For Substitution of Hazardous ChemicalsДокумент6 страницChemicals For Substitution of Hazardous ChemicalsFatima AnwarОценок пока нет

- David KaniosДокумент28 страницDavid KaniosJoko RinantoОценок пока нет

- Ocaldo & Wabbo Art Materials: Education Price ListДокумент5 страницOcaldo & Wabbo Art Materials: Education Price Listcer4396Оценок пока нет

- REMABOND Adhesive Systems: Our Complete Range of Adhesives & Rubber SolutionsДокумент11 страницREMABOND Adhesive Systems: Our Complete Range of Adhesives & Rubber SolutionsShaiju NarayananОценок пока нет

- Bai Yun-2Документ8 страницBai Yun-2Hamada Shoukry MohammedОценок пока нет

- 2P S7.1 VPI ESD Tile Test Process ResultsДокумент10 страниц2P S7.1 VPI ESD Tile Test Process ResultsJúlio AbraãoОценок пока нет

- PALOPAQUE - PVC Cladding BrochureДокумент24 страницыPALOPAQUE - PVC Cladding Brochureganpat_1Оценок пока нет

- Painting ProductsДокумент164 страницыPainting ProductsMiguel OliveiraОценок пока нет

- Multi Layer PackingДокумент48 страницMulti Layer PackingkeerthivarmaОценок пока нет

- AdhesiveДокумент24 страницыAdhesiveArpit Goel100% (1)

- Brochure - Electrical Insulating PapersДокумент28 страницBrochure - Electrical Insulating Papersbpd21Оценок пока нет

- Whalley, J. The Cast Ell Ani Diadem. 2005Документ2 страницыWhalley, J. The Cast Ell Ani Diadem. 2005Trinidad Pasíes Arqueología-ConservaciónОценок пока нет