Академический Документы

Профессиональный Документы

Культура Документы

Is 3812 2 2003

Загружено:

VijayKatariaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Is 3812 2 2003

Загружено:

VijayKatariaАвторское право:

Доступные форматы

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

1 +, 1 +

01 ' 5

The Right to Information, The Right to Live

Step Out From the Old to the New

Mazdoor Kisan Shakti Sangathan

Jawaharlal Nehru

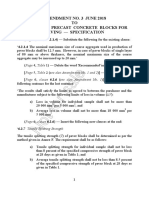

IS 3812-2 (2003): Specification for Pulverized Fuel Ash,

Part 2: For Use as Admixture in Cement Mortar and Concrete

[CED 2: Cement and Concrete]

! $ ' +-

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

! > 0 B

BharthariNtiatakam

Knowledge is such a treasure which cannot be stolen

w1712wma-r

(a-e-f?)

mk%khTRfma

3812 (Pat

2) :2003

mvd-Jrd$m

GYvF@m)

Indian Standard

PULVERIZED

FUEL ASH SPECIFICATION

PART 2 FOR USE AS ADMIXTURE

IN CEMENT

MORTAR

AND CONCRETE

(Second Revision )

ICS91.1OO.1O

G BIS 2003

BUREAU

MANAK

October 2003

OF

BHAVAN,

INDIAN

STANDARDS

9 BAHADUR

SHAH

NEW DELHI 110002

ZAFAR

MARG

Price Group 4

Cement and Concrete

Sectional Committee,

CED 2

FOREWORD

This Indian Standard (Part 2) (Second Revision) was adopted bythe Bureau of Indian Standards, after the draft

finalized by the Cement and Concrete Sectional Committee had been approved by the Civil Engineering Division

Council.

Pulverized fuel ash is a residue resulting from the combustion of ground or powdered or crushed bituminous coal

or sub-bituminous coal (lignite). About 80 percent of the total ash is finely divided and get out of boiler along

with flue gases and is collected by suitable technologies. This ash generally and in this standard is termed as fly

ash It is sometimes referred as chimney ash and hopper ash. The balance about 20 percent of ash gets collected

at the bottom of the boiler and is taken out by suitable technologies and is referred as bottom ash. Fly ash is

collected and stored in dry condition. When fly ash alone or alongwith bottom ash is carried to storage or

deposition lagoon or pond in the form of water slurry and deposited, it is termed as pond ash. Whereas if fly ash,

alone or alongwith bottom ash is carried to a storage or deposition site in dry form and deposited, it is termed as

mound ash.

Pulverized fuel ash is available in large quantities in the country as a waste product from a number of thermal

power stations and industrial piants using pulverized or crushed m ground coal or lignite as fuel for boilers. The

effect ive me of pulverized fuel ash as a pozzolana in the manufacture of and for part replacement of cement, as

an admixture in cement, cement mortar and concrete, lime pozzolana mixture and products such as fly ash lime

bricks, autoclave

aerated concrete blocks, etc, have been further established in the country in recent years.

f<ecent investigations of Indian pulverized fuel ashes have indicated greater scope for their utilization as a

construction material. Greater utilization of pulverized fuel ash will lead to not only saving of scarce construction

materials but also assist in solving the problem of disposal of this waste product. The recent investigations have

also indicated the necessity to provide proper collection methods for fly ash so as to yield fly ash of quality and

uniformity which are prime requirements of fly ash for use as a construction material.

This standard was first published in 1966 in three parts to cater to the requirements of fly ash for three specific

USCS:Part I covering use of-fly ash as a pozzolana, Part 2 covering use of fly ash as an admixture for concrete,

and Part 3 covering use of fly ash as fine aggregate for mortar and concrete. The Sectional Committee responsible

for the formulation of this standard subsequently felt that the performance of fly ash as a pozzolana or an admixture

or a fine aggregate, was complementary

and not separable and hence requirements of fly ash for these uses

should be covered by a single standard. This standard was, therefore, revised in 1981 by combining the three

parts into a single standard, also incorporating the modifications found necessary based on the experience gained

with the use of earlier standards. This revision classified fly ash in two grades, Grade 1 for incorporation in

cetnent, mortar and concrete and in lime pozzolana mixture, and for manufacture of Portland pozzolana cement,

and Grade 2 for incorporation in cement, mortar and concrete and in lime pozzolana mixture.

1mprovements -have taken place over time in combustion technologies and ash collection technologies. These

technological developments have resulted in improvement in ash qualities; specially the fineness and loss of

ignition. Technologies have also been developed for a large number of utilizations of wide range of pulverized

fuel ash. Application of technologies in the collection, transportation anddeposition

of ash have also resulted in

availabi 1ity of pulverized fuel ash in four forms, namely, fly ash, bottom ash, pond ash and mound ash. Though

the last revision of the standard pertained only to fly ash, number of important applications of fly ash were left

uncovered. The Sectional Committee, therefore, felt necessary that a comprehensive

specification shouId be

brought out. Separate Indian Standards for fly ash for use in different end applications such as lime pozzolana

mixture applications, sintered applications, geotechnical applications and agricultural applications are also being

developed.

This revision intends to bring out the standard for pulverized

Part 1 For use as pozzolana

fuel ash in twoparts.

The other part is:

in cement, cement mortar and concrete.

(Continued

on third cover)

IS 3812 (Part 2): 2003

Indian Standard

PULVERIZED

PART 2

FUEL ASH SPECIFICATION

FOR USE AS ADMIXTURE

IN CEMENT

MORTAR

AND CONCRETE

(Second Revision )

carbonate (CaC03), based on the measured carbon dioxide (COJ

content and the fraction calculated as calcium sulphate (CaS04),

based on the measured aulphate (S03) content, disregarding the

1 SCOPE

1.1 This standard (Part 2) covers the extraction and

the physical and chemical requirements of pulverized

fuel ash for use as admixhtre in cement mortar and

concrete.

S03 taken up by alkalis.

3.5 Fly Ash Pulverized fuel ash extracted from flue

gases by any suitable process such as by cyclone

separator or electro-static precipitator.

1.2 Pulverized fuel ash to be used as admixture in

cement mortar and concrete in accordance with this

-standard may be fly ash, bottom ash, pond ash or

mound ash which may be either in as collected

condition or beneficiated, segregated or processed.

3.6 Bottom Ash Pulverized fiel ash collected from

the bottom of boilers by any suitable process.

3.7 Pand Ash Fly ash or bottom ash or both mixed

in any proporticrn and conveyed in the form of water

slurry and deposited in pond or lagoon.

2 REFERENCES

The standards given in Annex A contain provisions

which through reference

in this text, constitute

provisions of this standard. At the time of publication,

the editions indicated were valid. All standards are

subject to revision, and parties to agreements based

on this standard are encouraged to investigate the

possibility of applying the most recent editions of the

standards indicated in Annex A.

3.8 Mound Ash Fly ash or bottom ash or both mixed

in any proportion and conveyed or carried in dry form

and deposited dry.

4 EXTRACTION

OF PULVERIZED

FUEL ASH

4.1 Fly ash may be extracted from flue gases of ground

or pulverized or crushed coal or lignite fired boilers

by any suitable process; such as by cyclone separation

or electrostatic precipitation;

bottom ash from the

boilers shall not be added to the fly ash. Fly ash

collected at later stages of electrostatic precipitator are

finer than the fly ash collected at initial stages of

electrostatic precipitator.

3 TERMINOLOGY

3.0 For the purpose of this standard, the definitions

given below shall apply and for other terms definitions

given in IS 4305 shall apply.

3.1 Pulverized Fuel Ash Ash generated by burning

of ground or pulverized or crushed coal or lignite tired

boilers. It can be fly ash, bottom ash, pond ash or

mound ash.

4.2 Bottom ash may be extracted from the bottom of

ground or pulverized or crushed coal or lignite fired

boiler by any suitable process. It is generally in the

form of clinkers, which are ground or broken to smaller

size to facilitate extraction.

3.2 Siliceous Pulverized Fuel Ash Pulverized fuel

ash with reactive calcium oxide less than 10 percent,

by mass. Such fly ash are normally produced from

burning anthracite

or bituminous

coal and has

pozzolanic properties.

4.3 When fly ash and bottom ash are mixed and

transported in the form of water slurry to a lagoon or

pond for storage, it is called pond ash. Pond ash may

be extracted from the pond or lagoon by conventional

techniques.

3.3 Calcareous Pulverized Fuel Ash Pulverized

fuel ash with reactive calcium oxide not less than

10 percent, by mass. Such fly ash are normally

produced from lignite or sub-bituminous coal and have

both pozzolanic and hydraulic properties.

4.4 When fly ash and bottom ash are mixed and

transported in dry form to a storage or deposition site,

it is called mound ash. Mound ash may be extracted

from the mound

by conventional

excavation

techniques.

3.4 Reactive Calcium Oxide (CaO) That fraction

of the calcium oxide which under normal hardening

condition can form calcium silicate hydrates or calcium

aluminate hydrates.

5 BENEFICIATION,

SEGREGATION

AND

PROCESSING

OF PULVERIZED

FUEL ASH

5.1 Pulverized

fuel ash as collected,

if does not

conforms to the requirements

of this standard or if

NOTE To evaluate this fraction, the total calcium oxide

contents is to be reduced by the fraction calculated as calcium

IS 3812 (Part 2) :2003

6.2 Limits regarding

moisture content .of pulverized

fuel ash shall be as agreed to between the purchaser

and the supplier. All tests for the properties specified

in 6.1 shall, however, be carried out on oven dry

samples.

required

otherwise,

may be processed

and/or

beneficiated and/or segregated to modify its physical

or chemical characteristics.

5.2 Appropriate

technologies

may be applied for

ben.eficiation,

segregation

and processing

of

pulverized fuel ash to improve its properties, such

as, lime reactivity,

loss of ignition, particle size

distribution

and any of other physical

and/or

chemical properties. Some of the technologies that

may be used are burninglremoval

of unburned

carbon,

siev.inglgrading

of fineness,

grindingl

attrition for reducing particle size, thermal treatment

and blen-ding of fly ash of different qualities.

6 CHEMICAL

7 PHYSICAL

7.1 Pulverized t%el ash, when tested in accordance with

the methods of test specified in IS 1727, shall conform

to the physical requirements given in Table 2.

Table 2 Physical Requirements

(Clause

REQUIREMENTS

sl

i)

ii)

(Clause

S1

No.

Characteristic

(1)

(2)

i)

Silicon dioxide

(SiO~)

DhlS

aluminium

oxide (A]203)

plus iron oxide

(Fe?07)

in

percent

bv

mass, &fin

Silicon dioxide

(SiO~)

in

bv

Percent

mass, Misr

Magnesium

oxide

(MEO)

in Dercent bv

mass, A4ur

Total

sukshur

as

sulphur

trioxide (S03)

in ~ercent bv

mass, Mar

Available

alkalis

as

sodium

oxide

(NazO)

:

vercent

mass, Max

Total chlorides

in percent by

mass, MUX

Loss

on

imrition

uercent

;

mass, Max

It)

iii)

iv)

v)

vi)

vii)

Requirements

iii)

6.1)

Requirements

Siliceous

Pulverized

Fuel Ash

(3)

70

Calcareous

Pulverized

Fuel Ash

(4)

50

7.1)

Characteristic

Requirements

No.

6.1 Pulverized fuel ash, shall conform to the chemical

requirements given in Table 1.

Table 1 Chemical

REQUIREMENTS

Method

of Test,

Ref to

Fineness-specific surface in m2/kg by

Blaines permeability method, Min

) Particles retained on 45 micron IS

sieve (wet sieving) in percent, Max

Soundness

bv autoclave

test

ex~arssion of sc.ecimen in oereent.

Mm

200

50

0.8

1)Optional test.

7.2 Uniformity

(5)

Requirements

In tests on individual samples, the specific surface and

particles retained on 45 micron IS sieve (wet sieving)

value shall not vary more than 15 percent from the

average established from the tests onthe 10 preceding

samples or of all preceding samples if less than 10.

IS 1727

8 TESTS

35

25

IS 1727

8.1 The sample or samples of pulverized fuel ash for

test shall be taken as described 9 and shall be tested in

accordance with 6 and 7.

5.0

5.0

IS 1727

5.0

5.0

IS 1727

8.2 All tests for the properties of the pulverized fhel

ash shall be carried out as it is supplied. [n case the

pulverized fuel ash supplied is to be beneficiated or

segregated or processed, the tests shall be carried out

only after beneticiation, segregation or processing as

applicable.

1.5

1.5

IS 4032

0.05

0.05

IS 12423)

5.0

5.0

IS 1727

8.3 Independent

8.3.1 If the purchaser or his representative requires

independent test, the samples shall be taken before or

immediately

after delivery

at the option of the

purchaser or his representative, and the tests shall be

carried outiarranged by the purchaser in accordance

with this standard. The supplier shall make available,

free of charge, the pulverized fuel ash required for

testing.

8.3.2 After a re~resentative sanmle

has been drawn.

.

tests on the sample shall be carried out as expeditiously

as possible.

11 For the purpose of this test, wherever reference to WStWtN h=

been made; it my be read as pulverized

Testing

fuel ash,

IS 3812 (Part 2): 2003

The bags in a sample

(see IS 4905).

9 SAMPLING

shall be selected

at random

9.1 Samples for Testing and by Whom to be Taken

11.2.2 The number of bags in a sample showing a

minus error greater than 2 percent of the specified net

mass shall be not more than 5 percerit of the bags in

the sample. Also the minus error in none of such bags

in the sample shall exceed 4 percent of the specified

net mass of pulverized fuel ash in the bag.

A sample or samples for testing maybe taken by the

purchaser or his representative,

or by any person

appointed to superintend the work for purpose of which

the pulverized fuel ash is required or by the latters

representative.

9.2 In addition to the requirements of 9.1, the methods

and procedure of sampling shall be in accordance with

1S 6491.

9.3 Facilities for Sampling

NOTE The matter given in 11.2.1 and 11.2.2 are extracts

based on the Standards of Weights and Measures (Packaged

Commodities) Rules, 1977 to which reference shall be made for

full details. Any modification made in these Rules and other

related Acts and Rules would apply automatical Iy.

and Identifying

11.2.3 In case of a wagon or truck load of 5 to 25 tonne,

the overall tolerance on net mass of pulverized fuel

ash shall be O to + 0.5 percent.

The supplier shall afford every facility, and shall

provide all Iabour and materials for taking and packing

the samples for testing the pulverized fhel ash and for

subsequent

identification

of pulverized

fuel ash

sampled.

11.4 The consignment

Standard Mark.

may also be marked with the

10 STC)RAGE

12 MANUFACTURERS

Pulverized fuel ash may be stored in accordance with

the recommendation

given in IS 4082. Additionally,

during bulk storage, the fly ash should be suitably

covered to avoid getting airborne.

The manufacturer

shall satisfy himself that the

pulverized fuel ash conform to the requirements of this

standard, and if.requested, shall supply a certificate to

this effect to the purchaser or his representative.

11 DELIVERY

13 MARKING

11.1 Supplies of pulverized fuel ash may be made in

bulk in suitable quantities

mutually agreed upon

between the purchaser and the supplier. Where so

required by the purchaser, the pulverized fuel ash may

also be supplied in bags (jute, jute-laminated, multiple

_paper or polyethylene lined) bearing the net mass (may

be 15 kg, 30 kg, 300 kg, 600 kg as agreed to between

the purchaser and the supplier), suppliers name or

registered trade-mark, if any. The tolerance on the mass

of pulverized fuel ash in each bag or consignment shall

be as mutually agreed upon between the purchaser and

the supplier.

13.1 Each bag/consignment

be clearly and permanently

information:

11.2 Tolerance

Requirements

for the Mass

Pulverized Fuel Ash Packed in Bags

of

11.2.1 The average net mass of pulverized fuel ash

packed in bags at the plant in a sample shall be equal

to or more than 15 kg, 30 kg, 300 kg, 600 kg as

applicable. The number of bags in a sample shall be as

given below:

Batch Size

loo to 150

151 to280

281 to 500

501 to 1200

1201 to3 200

3201 and over

Sample

CERTIFICATE

of pulverized.fuel ash shall

marked with the following

a)

Identification

of the

pulverized fuel ash;

b)

Type of pulverized fuel ash that is siliceous

or calcareous as applicable;

c)

Form of pulverized fuel ash that is, fly ash,

bottom ash, pond ash or mound ash as

applicable;

d)

Batch/Control

e)

Net mass;

manufacturer

unit numbe~

f)

Month and year of packin~

g)

Any other identification

the purchaser.

13.2 BIS Certification

of

and

mark as required by

Marking

The pulverized fuel ash may also be marked with the

Standard Mark.

Size

13.2.1 The use of the Standard Mark is governed by

the provisions of the Bureau of Indian Standards Act,

1986 and the Rules and Regulations made thereunder.

The details of conditions under which a licence for the

use of the Standard

Mark may be granted

to

manufacturers or producers maybe obtained from the

Bureau of Indian Standards.

20

32

50

80

125

200

IS 3812 (Part 2) :2003

14 REJECTION

14.1 Pulverized fuel ash may be rejected if it does

not comply with any of the requirements

of this

standard.

14.2 Pulverized fiel ash in bulk storage for more than

6 months or in bags for more than-3 months after

completion of tests, may be re-tested before use and

may be rejected, if it fails to conform to any requirements of this standard.

ANNEX A

(Clause 2)

LIST OF REFERRED

IS No.

1727:1967

4032:1985

4082:1996

Title

Methods

of test for pozzolanic

material @rst revision)

Method of chemical analysis of

hydraulic cement @rst revision)

Recommendations

for stacking and

storage of construction

materials

and components

at site (second

INDIAN STANDARDS

ZS No.

Title

revision)

4305:1967

4905:1968

6491:1972

12423:1988

Glossary

pozzolana

Methods

Methods

Methods

hydraulic

of

terms

relating

to

for random sampling

for sampling fly ash

for colorimetic analysis of

cement

IS 3812 (Part 2) :2003

ANNEX B

(Foreword)

COMMITTEE

COMPOSITION

Cement and Concrete Sectional Committee,

CED 2

Representative(s)

Organization

In personal capacity ( Chandrika, at 15th Cross 63-64 Ea.rt Park

Road, Malleswaram, Bangalore-560 003)

DR H. C. WSVESVARAYA(Chairman)

B. G. Shirke Construction

SHtUG. R. BHARtTKAR

Builders Association

Building Materials

Technology

Limited, Pune

SECRSTARY

of India, Mumbai

and Technology

SHtU T. N. GUPTA

Promotion Council, New Delhi

SHRt J. K. PRASAD (Alternate)

Cement Corporation

SHRtMAHESH KUMAR

of India Limited, New Delhi

SHIU I. K. WATTAL (Alternate)

Central Board of Irrigation and Power, New Delhi

MEMSER SECRETARY

Central Building Research Institute, Rwrkee

DR C. L. VERMA

Central Public Works Department

CHIEF ENOINEER(DESIGN)

DIRECTOR(CWIL) (Alternate)

DR B. K. RAIJ (Alternate)

New Delhi

SUPERSNTSNOING

ENGINEER(S & S) (Alternate)

.Central Road Research Institute, New Delhi

HkAD

Central Soil and Materials

DUWTOR

Dmmmm (Alternate)

Research

Station, New Delhi

SHRt P. L. KASHYAP (Allernafe)

Central Water Commission,

(CMDD) (N & W)

DRECTOR

New Delhi

DEPUTY Dmwrort

Directorate

General of Supplies and Disposals,

Bangalore

SHRt R. P. .9NGH

Engineer-in-Chiefs

Branch, Army Headquarter,

(CMDD)

(NW & S) (Alternate)

SHRI V. BALSUBtIAMANIAN

MAJ-GSNYASH

New Delhi

(Alternate)

MALHGTRA

SHtU MAHENDSA PRASAD (A/(ernate)

Fly Ash Mission,

Department

of Science and

Technology,

New Delhi

DR VWL

KUMAR

SHRt MUKESH MATHUR (Alterrrale)

Gammon India Limited, Mumbai

SHat S. A. REDDi

Geological

.DR S. S. A~ETA

SHSU M. U. SHAH

Survey of India, Jaipur

DR D. K. RAI

Grasim Industries

(Alternate)

(Alternate)

SHEJA. K. JAIN

Limited, Mumbai

CGL SUDWR TAMHANEY(RETO)

Gujarat Ambuja Cements

Hospital Services Consultancy

Corporation

(Alternate)

SHtUJ. P. DESAI

(Alternate)

SHRIB. K. JAGETtA

Limited, Ahmedabad

(India) Ltd, Noida

SHRI J. SARUP

SHIU P. K. JAIPURtAR(Alternate)

Housing and Urban Development

Corporation

Limited, New Delhi

SHRI V. SURSSH

SHRt V. ARUL KUMAR (Alternate)

SHRt

Indian Concrete Institute, Mumbai

L. N. Arm

SHRt D. SRtNtVASAN(Alternate)

Indian Institute of Science, Bangalore

PROF T. S. NAOARU

Indian Institute of Technology, Roorkee

PROS A. K. JAIN

Indian Institute of Technology,

DR ASHOK KUMAR GHOSH

Indian Roads Congress,

Kharagpur

DR S. S. SEHRA

New Delhi

SHRt ARUL KUMAR SHARMA(Alternate)

Institute for Solid Waste Research and Ecological

Vishakhapatnam

Balance,

DR N. BHANUMATHIDAS

SHRtN. KALIDAS (Alterrra/e)

SHRIC. R. V. SUBRAMANIUM

Larsen and Toubro Limited, Mumbai

(Continued on page 6)

IS 3812 (Part 2) :2003

(C0n[iZ7uedfr0m page 5)

Representative(s)

Organization

SHtU S. CHOWDHURY(Alternate)

Madras Cements Ltd, Chennai

DR N. BHANUMATHIDAS

Ministry of Road Transport and Highways,

New Delhi

SHRI C. C. BHATJACHAR~A

SHRI I. K. PANDEY (Alternate)

National Council for Cement and Building Materials,

DR S. C. MAITI

DR S. LAxMt (Alternate)

Ballabgarh

National Test House, Kolkata

SHIG D. K, K,4NLJNG0

OCL India Limited, New Delhi

DR S. C. AHLUWALJA

Public Works Department,

SUPERINTENDING

ENGiNEER(DESIGN)

SHRI B. R. MEENA (Alternate)

Chennai

EXECUTWEENGINEER(Alternate)

Research,

Design and Standards Organization,

(Sin) (B & SjCB-11

Jonm DMLSCTOR

JOtNT DIRSCTOR(STD) (B & S)/CR-l (A!/erna@

Lucknow

Sardar Sarovar Narmada Nigam Limited, District Narmada

CHIEF ENOINEER(NAVGAM DAM)

Structural

SHRI S. GOPALAKRISHNAN

SOPESJNTENDING

ENGINEER(Alternaie)

Engineering

Research

Centre, Chennai

SHIU N. P. RAJAMANE(Ahernare)

The Associated

Cement Companies

Limited, Mumbai

SHRt T. N. TIWAIU

DR D. GHOSH (At/ernate)

The India Cements

Limited, Chennai

SHRJ S. GOPINATH

SHRJ R. ARUNACHALAM(Alternate)

The Indian Hume Pipe Company

.%tuP. R. C.

Limited, Mumbai

NAJR

SHRJ P. D. KELKAR (A/iernate)

The Institution of Engineers (India), Bangalore

DR H. C. VMVESVARAYA

In personal capacity,

SHP.I Y. R. TANEJA

SHRJ D. C. CHATURVEDI(Alternate)

BIS Directorate

(F-12, Naraina Vihar, New Deihl)

SHRJ S. K. JAIN, Director

General

[Representing

and Head (CED)

Director General (Ex-oficio)]

Member Secretaries

SHRi SANJAYPANT

Joint Director (CED), BIS

SHRt ALOK KESARJ

Deputy Director (CED), BIS

Cement, Pozzolana

and Cement Additives

Subcommittee,

[n personal capacity, ( Chandrika, at 15th Cross 63-64 East Park

Road, Malleswaram, Bangalore-560 003)

DR

All India Mini Cement Manufacturers

SHRI K. GOP1 PR4sA0

Association,

Hyderabad

CED 2:1

H. C. V]SVESVARAYA(Convener)

SHRJ K. MOHAN Uo

Bui Iding Materials and Technology

Cement Corporation

Promotion Council, New Delhi

(A//ernare)

SHIU J. K. PRASAD

of India Ltd, New Delhi

SHRJ L K. WATTAL

SHRIMATtSARASWATHIDEW (Alterna/e)

Cement Manufacturers

Association,

Kolkata

SHRI SOMNATHBANEILIEE

Central Building Research Institute, Roorkee

DR B. K. Wo

Central Electricity

SHRJ Y. K. SHASMA

DR MANJIT SINGH (Allernale)

Authority, New Delhi

SHRJ MOHAN KUMAR (Alternate)

Central Public Works Department,

New Delhi

CHIEF ENGiNEER(CDO)

SUPERINTENDING

ENGINEER(S & S) (Ahernate)

(Continued on page 7)

IS 3812 (Part 2) :2003

(Con/imedfrom

page 6)

Representative(s)

organization

Central Road Research

SHFUS. S. SEEHRA

Institute, New Delhi

SHRI SATANOERKUMAR(A/fernOIe)

Central Soil and Materials

DIRECTOR

Research Station, New Delhi

SHRt N. CHANDRASEIQIAN(Alternate)

Central Water Commission,

DIRECTOR(CMDD-11)

New Delhi

DEPUTY DWWmOR (CMDD-11) (A/rerna/e)

Dalmia Cement (Bharat) Limited, New Delhi

DR K. C. NARANG

Engineer-in-Chiefs

SHRI1-lUrA LAL

SHRIC. S. SHARMA(A/fernUfe)

Branch, Chandigarh

LT-COL DEVENDrLAKUMAR (Alrernare)

Fly Ash Mission, Department

of Science and Technology,

New Delhi

DR VIMAL KUMAR

SHRI MUXESM

MATHUR (Alternate)

Gammon India Limited, Mumbai

Grasim hrdustries Limited, Mumbai

SHiU S.A.

REDO1

SHR] A.K.

JAIN

COL SUDHIRTAMHANEY(RETD) (Alternate)

Gujarat Ambuja Cements

SHRI J. P. DESAI

Ltd, Ahmedabad

SHRI B. K. JAGETiA(Alternate)

Gujarat Engineering

DISECTOR

Research Institute, Vadodara

SHRI J. K. PATEL (Alternate)

DRC.

Indian Concrete Institute, Chennai

S. WSWANATHA

PROFM. S. SHETrY(A/fernOte)

Indian Institute of Science, Bangalore

PROFT. S. NAGARAJ

Indian Institute of Technology, iChamgpur

DR ASHOK KUMAN GHOSH

hrdorama Cement Limited, Mumbai

SHRI

K.K.

SHRIA.

TAPARIA

K. PiusmR(M/ernare)

Larsen and Toubro Limited, Mumbai

SHRIS. CHOWDHURY

Madras Cements

DRN.

Maharashtra

Ltd, Chennai

Engineering

BHANUMATHIOAS

DHUZCTOR

Research Institute, Nasik

RESEARCHOFFICER(Alierrrate)

Ministry of Commerce

SHIUP. K. JAIN

and Industry, New Delhi

SHRI SHAISHKUMAR (A/ternOte)

Ministry of Road Transport

and Highways,

SHRI V. VELAYOTHAM

New Delhi

SHFOI. K. PANDEY (A//ernate)

National Coimcil of Cement and Building Materials,

DRK.

Ballabgarh

MOHAN

DRSHRIMATI S. LAxrw(A/ternafe)

SHRt B.R.

National Test House (WR), Mumbai

MEENA

SHIU B. K. MANDAL (Alternate)

Orissa Cement Limited, New Delhi

DR S. C. AHLUWALIA

Public Works Department,

SUPERSNTENOING

ENGINEER(DESIGN)

Chennai

SENIORDEPUTY CHIEF ENGINEER(Akernate)

Research,

Design and Standards Organization,

DEPUTY DIRECTOR(B & F)

Lucknow

ASSISTANTDESIGN ENGINEER(B & F) (A//erna/e)

Tamil Nadu Minerals Limited, Chennai

SHRI K. SUMANTHBABU

The Associated

SHIU T. N. TIWAIU

Cement Company Ltd, Mumbai

DR D. GHOSH (Alternate)

The Hindustan

Construction

SHRI A. P. PHADKE

Company Limited, Mumbai

SHIU L). M. SAVUR (Alrernate)

(Continued

from second

cover)

This standard (Part 2) covers the extraction and the physical and chemical requirements of pulverized fuel ash

for use as admixture in cement mortar and concrete. The use of pulverized fuel ash as pozzolana is not covered

under this standard and the same is covered in IS 3812 (Part 1).

The significant

modifications

in this revision includes:

a)

.Instead of earlier designation of fly ash as Grade I and Grade II, this part will cover pulverized

for use as admixture in cement mortar and concrete.

b)

Four forms of pulverized

defined.

c)

A new clause on beneficiation,

d)

The chemical requirements

fuel ash.

e)

Requirements

f)

Additional requirement of particle retained on 45 micron IS Sieve (wet sieving) has been added under

physical reqtiirements as in optional test.

g)

Requirement

for drying shrinkage has been deleted.

h)

Requirement

for lime reactivity and compressive

j)

A clause on uniformity

fuel ash, namely fly ash, bottom ash, pond ash and mound ash have been

segregation

and processing

~f pulverized

fuel ash has been added.

has now been prescribed on the basis of siliceous and calcareous

pulverized

for total chlorides has been added.

requirement

strength have been deleted.

has also been added.

Considerable

assistance has been rendered by Fly Ash Mission,

Government of India in preparation of this standard.

The composition

fuel ash

of the Committee

responsible

for the formulation

Department

of Science

and Technology,

of this standard is given in Annex B.

For the purpose of deciding whether a particular requirement of this standard is complied witli, the final value,

observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance with

1S 2:1960 Rules for rounding off numerical values (revised). The number of significant places retained-in the

rounded off value should be the same as that of the specified value in this standard,

of Indian Standards

Bureau

BIS is a statutory institution

established

under the Bureau

harmonious

development

of the activities of standardization,

and attending to connected matters in the country.

of Indian

marking

Standards

Act,

and quality

1986

certification

to promote

of goods

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permission

in writing of BIS. This does not preclude the free use, in the course of

implementing

the standard, of necessary details, such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

,4mendments are issued to standards as the need arises on the basis

periodically; a standard along with amendments is reaffirmed when

needed; if the review indicates that changes are needed, it is taken

should ascertain that they are in possession of the latest amendments

BIS Catalogue and Standards: Monthly Additions.

This

Indian Standard has been developed

from DOC : No.

Amendments

Amend No.

of comments. Standards are also reviewed

such review indicates that no changes are

up for revision. Users of Indian Standards

or edition by referring to the latest issue of

CED 2 (7167).

Issued Since Publication

Date of Issue

Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002

Telephones :23230131,23233375,2323

9402

Regional Qffices :

Telephone

23237617

{ 23233841

Central

: Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern

: 1/14 C.I.T. Scheme VII M, V. I. P. Road, Kankurgachi

KOLKATA 700054

Northern

: SCO 335-336, Sector, 34-A, CHANDIGARH

Southern

: C.I.T. Campus, IV Cross Road, CHENNAI

Western

: Manakalaya, E9 MIDC, Marol, Andheri (East)

MUMBAI 400093

Bmnches

Telegrams : Manaksanstha

(Common to all offices)

160022

600113

23378499,23378561

{ 23378626,23379120

603843

{ 609285

2254-1216,22541442

{ 22542519,22542315

28329295,28327858

{ 28327891,28327892

: AHMEDABAD. BANGALORE. BHOPAL. BHUBANESHWAR.

COIMBATORE. FARIDABAD.

GHAZIABAD.

GUWAHAT1. HYDERABAD.

JAIPUR. KANPUR. LUCKNOW.

NAGPUR.

NAL.4GARH. PATNA. PUNE. RAJKOT. THIRUVANANTHAPURAM.

VISAKHAPATNAM.

Fnnted at Prabhat Offset Press, New Delhi-2

Вам также может понравиться

- 3812 1 PDFДокумент14 страниц3812 1 PDFइंजि कौस्तुभ पवारОценок пока нет

- 04a Physical PropertiesДокумент13 страниц04a Physical PropertiesGanesh.RajanОценок пока нет

- 455 2015 Portland Slag CementAMD1 Reff2020Документ14 страниц455 2015 Portland Slag CementAMD1 Reff2020Debabrata PalОценок пока нет

- Is 15388 (2003) - Specification For Silica FumeДокумент13 страницIs 15388 (2003) - Specification For Silica FumeN GANESAMOORTHYОценок пока нет

- IS 4031 - Part15Документ8 страницIS 4031 - Part15Nagaraju ChintaОценок пока нет

- Is 1661 1972 PDFДокумент33 страницыIs 1661 1972 PDFPrasanna S KulkarniОценок пока нет

- 2021 Annex C &DДокумент24 страницы2021 Annex C &DSaurav Kumar100% (1)

- IS 456 2016 Google SearchДокумент2 страницыIS 456 2016 Google Searchvasudeo_eeОценок пока нет

- Is 2250-1981 (Preparation and Use of Masonry Mortars)Документ36 страницIs 2250-1981 (Preparation and Use of Masonry Mortars)DharmeshОценок пока нет

- Is 383 (1970) Grading ZonesДокумент2 страницыIs 383 (1970) Grading ZonesAnonymous 2RduvkjgZОценок пока нет

- List of Referred Indian Standard Codes For Civil EngineersДокумент5 страницList of Referred Indian Standard Codes For Civil EngineersDarshan M MОценок пока нет

- Is 6452 High Alumina Cement For Structural Use-SpecificationДокумент10 страницIs 6452 High Alumina Cement For Structural Use-SpecificationRamarraju KalidindiОценок пока нет

- JSW Ggbs 1 2015 PDFДокумент1 страницаJSW Ggbs 1 2015 PDFMohammed Javeed ahmedОценок пока нет

- Test of Sand QualityДокумент4 страницыTest of Sand QualityJamaludin100% (1)

- Rubber Content of Crumb Rubber Modified Bitumen: Soxhlet MethodДокумент8 страницRubber Content of Crumb Rubber Modified Bitumen: Soxhlet MethodLa FoliakОценок пока нет

- Is 15388 2003 PDFДокумент13 страницIs 15388 2003 PDFrahulОценок пока нет

- .Methods of Physical Tests For Hydraulic Cement: Indian StandardДокумент8 страниц.Methods of Physical Tests For Hydraulic Cement: Indian StandardRS EngineeringОценок пока нет

- Is SP 23 1982 PDFДокумент151 страницаIs SP 23 1982 PDFMano MaddulaОценок пока нет

- Hdian Standard: Methods Off Test For Autoclaved Cellular Concrete ProductsДокумент10 страницHdian Standard: Methods Off Test For Autoclaved Cellular Concrete ProductsshailendraОценок пока нет

- Cellular Light Weight ConcreteДокумент35 страницCellular Light Weight ConcreteUTP gamingОценок пока нет

- Fly Ash ClasificationДокумент15 страницFly Ash ClasificationprabhuwbОценок пока нет

- Is 4020 PDFДокумент34 страницыIs 4020 PDFAnand Kumar100% (1)

- Not For Sale: Amendment No. 2 March 2010 TO Is 4032: 1985 Method of Chemical Analysis of Hydraulic CementДокумент5 страницNot For Sale: Amendment No. 2 March 2010 TO Is 4032: 1985 Method of Chemical Analysis of Hydraulic CementRaghu NagarОценок пока нет

- Is 1727 1967Документ55 страницIs 1727 1967VijayKataria0% (1)

- Preparation of Viscosity Blends For Hot Recycled Bituminous MaterialsДокумент3 страницыPreparation of Viscosity Blends For Hot Recycled Bituminous MaterialsSri RamyaОценок пока нет

- Admixtures For ShotcreteДокумент4 страницыAdmixtures For ShotcreteRam Kumar JaiswalОценок пока нет

- BS 1881-116-1983 - Testing Concrete Part 116 - Method For Determination of Compressive Strength of Concrete CubesДокумент10 страницBS 1881-116-1983 - Testing Concrete Part 116 - Method For Determination of Compressive Strength of Concrete CubesSarifОценок пока нет

- Use of Waste Plastic in Bituminous Concrete MixДокумент51 страницаUse of Waste Plastic in Bituminous Concrete MixRahul KumarОценок пока нет

- 5225 (Rain Gauge)Документ10 страниц5225 (Rain Gauge)Ajit P. SinghОценок пока нет

- C1582C1582M-Aditivos Inhibidores de CorrosionДокумент10 страницC1582C1582M-Aditivos Inhibidores de CorrosionAnthony López HuamanОценок пока нет

- IS 15658 - AmendedДокумент3 страницыIS 15658 - Amendedraviteja036Оценок пока нет

- IS 2542 - 1978 (Part-2-Sec1 of 12) Method of Test For Gypsum Plaster, Concrete & Product-Gypsum Product PDFДокумент27 страницIS 2542 - 1978 (Part-2-Sec1 of 12) Method of Test For Gypsum Plaster, Concrete & Product-Gypsum Product PDFAnilОценок пока нет

- EN 12350-11 (2010) Testing Fresh Concrete - Self-Compacting Concrete - Sieve Segregation TestДокумент14 страницEN 12350-11 (2010) Testing Fresh Concrete - Self-Compacting Concrete - Sieve Segregation TestmariannydanimartinezОценок пока нет

- Fly Ash Cement Replacement Tds PDFДокумент2 страницыFly Ash Cement Replacement Tds PDFabualamalОценок пока нет

- BS 812-117-1988 PDFДокумент14 страницBS 812-117-1988 PDFMohammad Twaha Jaumbocus0% (1)

- Mix Design FormatДокумент3 страницыMix Design FormatAkshay MitraОценок пока нет

- Is 12089 Specification For Granulated Slag For The ManufactuДокумент11 страницIs 12089 Specification For Granulated Slag For The ManufactuRamarraju Kalidindi100% (5)

- Irc SP 53 2010Документ30 страницIrc SP 53 2010pradeepputta92567% (3)

- 1489 2 PDFДокумент15 страниц1489 2 PDFshashikant gaurОценок пока нет

- CAC-Hyperfluid R150: Superplasticiser For High Performance Concrete Based On Poly-Carboxylic EtherДокумент2 страницыCAC-Hyperfluid R150: Superplasticiser For High Performance Concrete Based On Poly-Carboxylic Ethermohsin shaikh100% (1)

- BS 1881-5 Part 5 Methods of Testing Hardened Concrete For Other Than Strength PDFДокумент15 страницBS 1881-5 Part 5 Methods of Testing Hardened Concrete For Other Than Strength PDFjunqiangdong100% (1)

- Standard Astm D 2172 DETERMINATION OF BINDER CONTENT FOR ASPHALT MIXДокумент3 страницыStandard Astm D 2172 DETERMINATION OF BINDER CONTENT FOR ASPHALT MIXSAQAR ALGHAMDIОценок пока нет

- 03AggregatesRID-ENSTP 2016Документ95 страниц03AggregatesRID-ENSTP 2016Jimmy RostantОценок пока нет

- BS-1881-118 Concrete Flexural Strength PDFДокумент12 страницBS-1881-118 Concrete Flexural Strength PDFAshraf TomizehОценок пока нет

- DS - 645 - Pro Anticarb HB Elastomeric CoatingДокумент2 страницыDS - 645 - Pro Anticarb HB Elastomeric CoatingRay EngineeringОценок пока нет

- Polypropylene Fibre Reinforced ShotcreteДокумент11 страницPolypropylene Fibre Reinforced Shotcreteabhineet srivastava100% (2)

- D 2041 D 2041M 11Документ4 страницыD 2041 D 2041M 11gadОценок пока нет

- Elastic RecoveryДокумент4 страницыElastic RecoverypdbОценок пока нет

- Amendment No. 5 July 2019 TO Is 456: 2000 Plain and Reinforced Concrete - Code of PracticeДокумент7 страницAmendment No. 5 July 2019 TO Is 456: 2000 Plain and Reinforced Concrete - Code of PracticeRajan GuptaОценок пока нет

- IS 2185 (Part 1) 1979Документ27 страницIS 2185 (Part 1) 1979manishparetaОценок пока нет

- ISO TC 074 Cement and LimeДокумент5 страницISO TC 074 Cement and Limehrd_managerОценок пока нет

- M-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeДокумент3 страницыM-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeSai CharanОценок пока нет

- Is 4031 (Part-3) Method of Physical Tests For Hydraulic CemeДокумент6 страницIs 4031 (Part-3) Method of Physical Tests For Hydraulic CemeRamarraju KalidindiОценок пока нет

- Precast Concrete Kerbs, Channels, Edging, Quadrants and Other Associated Fittings - SpecificationДокумент22 страницыPrecast Concrete Kerbs, Channels, Edging, Quadrants and Other Associated Fittings - SpecificationChandra Sekhar Babu GanjiОценок пока нет

- Standard Method of Test For Resistance of Compacted Asphalt Mixtures To Moisture-Induced DamageДокумент8 страницStandard Method of Test For Resistance of Compacted Asphalt Mixtures To Moisture-Induced Damagemehdi zalnezhadОценок пока нет

- Is 3812 1 2003Документ17 страницIs 3812 1 2003VijayKatariaОценок пока нет

- Is 3812 2 2013Документ16 страницIs 3812 2 2013VijayKataria100% (1)

- Pulverized Fuel Ash Is A Residue Resulting From The Combustion of Ground or Powdered orДокумент11 страницPulverized Fuel Ash Is A Residue Resulting From The Combustion of Ground or Powdered orvempadareddyОценок пока нет

- Foreword: Bureau of Indian Standards Draft For Comments OnlyДокумент12 страницForeword: Bureau of Indian Standards Draft For Comments OnlyGovind RaoОценок пока нет

- Final Report Siliceous Byproducts For Use in Concrete 1988Документ12 страницFinal Report Siliceous Byproducts For Use in Concrete 1988engenharia.skfОценок пока нет

- Ijciet 07 03 002Документ11 страницIjciet 07 03 002VijayKatariaОценок пока нет

- Is 8112 1989Документ17 страницIs 8112 1989biswashree10Оценок пока нет

- ECBC User Guide v-0.2 (Public)Документ176 страницECBC User Guide v-0.2 (Public)pal_stephenОценок пока нет

- Oil Well CementДокумент41 страницаOil Well CementadarshkalladayilОценок пока нет

- Is - 08112 - 2013Документ14 страницIs - 08112 - 2013sangitaghaisasОценок пока нет

- Disclosure To Promote The Right To InformationДокумент15 страницDisclosure To Promote The Right To InformationVijayKatariaОценок пока нет

- Disclosure To Promote The Right To InformationДокумент13 страницDisclosure To Promote The Right To InformationVijayKatariaОценок пока нет

- Is 8125 1976Документ13 страницIs 8125 1976VijayKatariaОценок пока нет

- Is 7861 1 1975Документ26 страницIs 7861 1 1975VijayKatariaОценок пока нет

- Is.7861.2.1981 Extreme Weather ConcretingДокумент29 страницIs.7861.2.1981 Extreme Weather ConcretingSangita SangamОценок пока нет

- Is 8041 1990Документ16 страницIs 8041 1990VijayKatariaОценок пока нет

- Is 8042 1989Документ18 страницIs 8042 1989VijayKatariaОценок пока нет

- Code For Slump TestДокумент14 страницCode For Slump Testanku4frenzОценок пока нет

- Is 7325 1974Документ15 страницIs 7325 1974VijayKatariaОценок пока нет

- Disclosure To Promote The Right To InformationДокумент29 страницDisclosure To Promote The Right To InformationVijayKatariaОценок пока нет

- Is 6461 11 1973Документ16 страницIs 6461 11 1973VijayKatariaОценок пока нет

- Is 6909 1990Документ17 страницIs 6909 1990VijayKatariaОценок пока нет

- Is 7246 1974Документ13 страницIs 7246 1974VijayKatariaОценок пока нет

- Is 6925 1973Документ13 страницIs 6925 1973VijayKatariaОценок пока нет

- Is 6491 1972Документ14 страницIs 6491 1972VijayKatariaОценок пока нет

- Disclosure To Promote The Right To InformationДокумент35 страницDisclosure To Promote The Right To InformationVijayKatariaОценок пока нет

- Is 6461 10 1973Документ17 страницIs 6461 10 1973VijayKatariaОценок пока нет

- Is 6461 9 1973Документ28 страницIs 6461 9 1973VijayKatariaОценок пока нет

- Is 6461 6 1972Документ20 страницIs 6461 6 1972VijayKatariaОценок пока нет

- Is 6461 3 1972Документ19 страницIs 6461 3 1972VijayKatariaОценок пока нет

- Is 6461 8 1973Документ16 страницIs 6461 8 1973VijayKatariaОценок пока нет

- Is 6461 4 1972Документ19 страницIs 6461 4 1972VijayKatariaОценок пока нет

- Is 6461 5 1972Документ32 страницыIs 6461 5 1972VijayKatariaОценок пока нет

- Is 6461 2 1972Документ13 страницIs 6461 2 1972VijayKatariaОценок пока нет

- Is 6461 1 1972Документ17 страницIs 6461 1 1972VijayKatariaОценок пока нет

- Research Paper Endorsement and Approval: CE 521G FORM-1Документ52 страницыResearch Paper Endorsement and Approval: CE 521G FORM-1Maria EdillonОценок пока нет

- Coal-Fired Electricity Emissions Literature ReviewДокумент187 страницCoal-Fired Electricity Emissions Literature Reviewoliver olang'Оценок пока нет

- Fyp2 184573Документ107 страницFyp2 184573shamsukarim2009Оценок пока нет

- ASTM C150 Aashto M 85Документ5 страницASTM C150 Aashto M 85J O M A RОценок пока нет

- Pca RCC PCA Dam PDFДокумент4 страницыPca RCC PCA Dam PDFtonykebbeОценок пока нет

- 01 Flyash Brick1Документ142 страницы01 Flyash Brick1Jigar M. Upadhyay100% (2)

- Highway Network System ReportДокумент36 страницHighway Network System ReportGaurav Jain100% (1)

- Green Building MaterialsДокумент102 страницыGreen Building MaterialsMartyОценок пока нет

- Precast Box CulvertДокумент4 страницыPrecast Box CulvertHermann PankowОценок пока нет

- Autoclaved Aerated ConcreteДокумент4 страницыAutoclaved Aerated ConcreteArunima DineshОценок пока нет

- Training and Development Final Copy AccДокумент76 страницTraining and Development Final Copy Accahmedezaz2Оценок пока нет

- Building Technology 3Документ25 страницBuilding Technology 3Melaine A. FranciscoОценок пока нет

- Fapohundaetal 2017Документ19 страницFapohundaetal 2017haziqОценок пока нет

- Aci523 - ImportanteДокумент5 страницAci523 - ImportanteCledson2Оценок пока нет

- En 14679-2003Документ98 страницEn 14679-2003Ivan ArapovОценок пока нет

- Bendable Concrete PDFДокумент14 страницBendable Concrete PDFKunal Bathija100% (24)

- Concrete Mix Proportioning: Essential ApparatusДокумент10 страницConcrete Mix Proportioning: Essential ApparatusVinot ValliОценок пока нет

- BrochureДокумент4 страницыBrochureMahesh Kumar AgrawalОценок пока нет

- Cube Compressive Strength Study-Lab ReportДокумент20 страницCube Compressive Strength Study-Lab ReportsyksamОценок пока нет

- Characteristics and Applications of Sugar Cane Bagasse Ash Waste in Cementitious MaterialsДокумент19 страницCharacteristics and Applications of Sugar Cane Bagasse Ash Waste in Cementitious MaterialsCuenta TelefonoОценок пока нет

- Comparison Study of Common Brick With S+WPSA Brick: June 2012Документ7 страницComparison Study of Common Brick With S+WPSA Brick: June 2012Hadi Iz'aanОценок пока нет

- Zuari Cement, YerraguntlaДокумент26 страницZuari Cement, YerraguntlaKvnaveen KvnОценок пока нет

- Shear Strength Fly Ash Geopolymer RC BeamsДокумент12 страницShear Strength Fly Ash Geopolymer RC BeamsJhon CardenasОценок пока нет

- A Review On Effects of Stabilizing AgentsДокумент7 страницA Review On Effects of Stabilizing AgentsGabriel SalgadoОценок пока нет

- ILC Plan - STH 19 FINLДокумент7 страницILC Plan - STH 19 FINLShreya Test HouseОценок пока нет

- 2 PDFДокумент4 страницы2 PDFSarwarОценок пока нет

- Fly Ash Handling Challenges and SolutionsДокумент10 страницFly Ash Handling Challenges and SolutionsalvarikokexОценок пока нет

- AKASHPARWAДокумент31 страницаAKASHPARWAshweta kakadeОценок пока нет

- Clay Brick MakingДокумент9 страницClay Brick MakingapihanasОценок пока нет

- 1 3Документ18 страниц1 3kkkОценок пока нет