Академический Документы

Профессиональный Документы

Культура Документы

1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1

Загружено:

JithuJohnОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1

Загружено:

JithuJohnАвторское право:

Доступные форматы

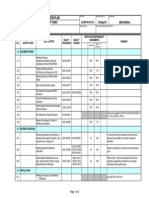

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

WELDING OF SPECIAL CORROSION RESISTANT MATERIALS (INCLUDING

DUPLEX SS)

PROJECT TITLE:

ITEM

NO.

PROJECT PHASE &

ACTIVITY CODE

1.0

DOCUMENT REVIEW

APPROVED DATE

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

SATIP-W-016-01

WBS/BI/JO/NO.

TASK / ACTIVITY

QUALITY

PROCEDURE

QUALITY

RECORD

25-May-05

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

SAUDI

ARAMCO

Welding Procedure

Specifications/Welding Procedure

Qualification Record (WPS/WPQR)

SAIC-W-2001

RH1

RH1

1.2

Welder & Welding Operator

Certifications (and Issuance of JCC)

SAIC-W-2035

RH1

R1

1.3

Method Statement & WPS for Weld

Repair, ie:

a) Crack/Rejectable discontinuities

b) Weld Mis-alignments

SAIC-W-2002

RH1

RH1

1.4

Parent Metal & Weld Joint Identification

System

SAIC-W-2008

RH1

RH1

1.5

Post Weld Heat Treatment (PWHT)

Procedure (If required)

SAIC-W-2003

RH1

RH1

1.6

Production Weld Hardness Testing

Procedure

SAIC-W-2012

RH1

RH1

1.7

Positive Material Identification

Procedure (Alloy Verification)

SAIC-L-2004

RH1

RH1

1.8

Non-Destructive Testing ProceduresLPT, UT & RT

1.9

Procedure for Control of Welding

Consumables

SAIC-W-2009

RH1

R1

1.10

Ferrite Content Testing Procedure for

SS Material

SAIC-W-2029

RH1

RH1

2.0

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

1.1

SATR-W-2004

DISCIPLINE:

REMARKS

Refer to SATIP-NDE-UT-01, LPT-01, RT-01)

MATERIAL RECEIVING

2.1

Receiving Inspection and Verification of

Welding Consumables-(Properties,

Type, approve source, storage, etc.)

SAIC-W-2010

SAIC-W-2010

H1

W2

S. Aramco shall verify and inspect the first batch of

delivered consumables, then random inspection

thereafter.

2.2

Welding Equipment Calibration

Verification

SAIC-W-2011

SAIC-W-2011

SATR-W-2009

SATR-W-2011

H1

W2

Random witnessing by S. Aramco at each calibration

cycle.

Page 1 of 4

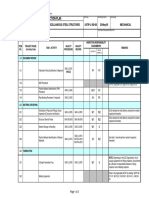

WELDING OF SPECIAL CORROSION RESISTANT MATERIALS (INCLUDING

DUPLEX SS)

PROJECT TITLE:

ITEM

NO.

PROJECT PHASE &

ACTIVITY CODE

2.3

3.0

3.1

3.2

APPROVED DATE

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

SATIP-W-016-01

WBS/BI/JO/NO.

QUALITY

PROCEDURE

QUALITY

RECORD

Positive Material Identification of

Stainless Steel Pipe and fitting

Materials.

SAIC-L-2010

Control of Welding ConsumablesStorage, Handling, Issuance &

Conditioning

SAIC-W-2032

TASK / ACTIVITY

25-May-05

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

SAUDI

ARAMCO

SAIC-L-2010

SATR-A-2012

SATR-A-2013

H1

W1

SAIC-W-2032

SATR-W-2010

W1

REMARKS

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

INSTALLATION

Buttering or Weld Build-Up of Joints

SAIC-W-2033

SAIC-W-2033

SATR-W-2006

H1

W1/H1

3.3

Pre-Welding Inspection

SAIC-W-2005

SAIC-W-2005

SATR-W-2006

H1

W2/H1

(See

remarks)

3.4

In-Process Weld Inspection

SAIC-W-2006

SAIC-W-2006

SATR-W-2007

W1

W2

3.5

Post-Welding Visual Inspection

SAIC-W-2007

SAIC-W-2007

H1

W1

3.6

Inspect Welding of Socket Joint and

Seal Welding Threaded Jts.

SAIC-W-2037

SAIC-W-2037

H1

W1

3.7

Repair of Weld Joints or Base Metal by

Welding (Prior to Weld Acceptance)

SAIC-W-2013

SAIC-W-2013

W1

3.8

DISCIPLINE:

Selection of Weld Joints for NDE

SAIC-W-2015

SAIC-W-2015

SATR-W-2007

Page 2 of 4

H1

W1/W2

Saudi Aramco inspection responsibility varies from H1 to

W1:

a) "W1" -for build-up thickness not exceeding 1/3 of

the metal thickness or 10mm whicever is less.

b) "H1" - for build-up thickness exceeding the above

and requiring CSD's approval.

S. Aramco's responsibilities varies as follows :

a) "W2" - for Welding on normal services at normal

conditions, refer to Note 1 of the General Notes.

b) "H1" - for critical welds, ie.; Tie-Ins, buttering, Hot

Taps, NDE-In-Lieu of Hydro & others as determined

by project requirements.

S. Aramco inspects and verifies Heat Input at random or

on routine basis on stainless steel welding.

For Saudi Aramco Responsibility:

a) "W1" -PID Inspectors shall participate in the

seletion of weld to be radiographed.

b) "W2" - will be in effect once the level of

confidence to the QC is established.

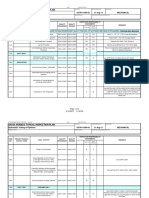

WELDING OF SPECIAL CORROSION RESISTANT MATERIALS (INCLUDING

DUPLEX SS)

PROJECT TITLE:

ITEM

NO.

PROJECT PHASE &

ACTIVITY CODE

APPROVED DATE

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

SATIP-W-016-01

WBS/BI/JO/NO.

TASK / ACTIVITY

QUALITY

PROCEDURE

QUALITY

RECORD

DISCIPLINE:

25-May-05

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

SAUDI

ARAMCO

REMARKS

3.9

Ferrite Content Testing (As-Welded

Condition)

SAIC-W-2030

SAIC-W-2030

SATR-W-2016

H1

W1

3.10

Post Weld Heat Treatment Inspection

(If Required)

SAIC-W-2004

SAIC-W-2004

SATR-W-2005

H1

W1/R1

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

3.11

Verification of Hardness Testing

Application and Results (If Required)

SAIC-W-2014

SAIC-W-2014

SATR-W-2012

H1

W1 & R1

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

3.12

Positive Material Identification (PMI) of

Deposited Weld for alloyed materials

within the scope of SAES-A-206.

SAIC-L-2010

SAIC-L-2010

SATR-A-2012

SATR-A-2013

H1

W1/ R1

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

W1/RH1

W1/R1

* Use the applicable SATIPS:

a) SATIP-D-100-01

b) SATIP-NDE-LPT-01

c) SATIP-NDE-MPT-01

d) SATIP-NDE-RT-01

e) SATIP-NDE-UT-01

**Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged or

random Witnessing shall be agreed upon.

H1

R1

H1

W1

H1

R1

3.13

Verification of Non-Destructive

Examination Method Application and

Evaluation of Results

See Remarks

3.14

Weekly reporting of the following:

a) Production Weld Status,

b) Welder & Project Repair Rate

c) Welder's Repair Assessment &

Tracer Welds

SAIC-W-2016

3.15

Liquid Penetrant Test on removal of

Temporary attachment welds

4.0

4.1

SAIC-W-2016

SATR-W-2013

SATR-W-2018

SATR-W-2019

SATR-NDE-2002 SATR-NDE-2002

S. Aramco reviews on weekly basis.

PRE-COMMISSIONING

Final Welding Documentation (Welding

Summary Report / Record & Weld Map)

SATR-W-2017

SATR-W-2008

SATR-W-2017

SATR-W-2008

Page 3 of 4

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged or

random Review shall be agreed upon.

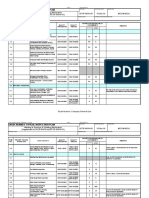

WELDING OF SPECIAL CORROSION RESISTANT MATERIALS (INCLUDING

DUPLEX SS)

PROJECT TITLE:

ITEM

NO.

APPROVED DATE

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

SATIP-W-016-01

WBS/BI/JO/NO.

PROJECT PHASE &

ACTIVITY CODE

QUALITY

PROCEDURE

TASK / ACTIVITY

QUALITY

RECORD

DISCIPLINE:

25-May-05

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

REMARKS

SAUDI

ARAMCO

GENERAL NOTES

1

The first three incidents of each Inspection or testing activity listed require 100 % participation by Saudi Aramco Site Inspection Personnel. After this period, Saudi Aramco Inspection may adjust the levels

of Saudi Aramco participation based upon the Contractors performance.

Surveillance: QA/QC organization to monitor work in progress without notice from Construction Organization

Witness:

QA/QC organization shall be notified of the timing of Inspection or test in advance. However, the inspection or test shall be performed as scheduled if the QA/QC organization representative is

not present.

Hold:

If the Main Contractor delegates the assigned responsibility to the Subcontractor, then the Main Contractor will have the same degree of responsibility as assigned to Saudi Aramco.

QA/QC organization shall be notified of the timing of inspection or test in advance. Inspection or test shall not be carried out without the QA/QC organization representative in attendance.

LEGEND

W1

100% Witness Inspection/Test

H2

Sample Hold Point for QC Inspection or Test

RH1 100% Review and Approval of Documents

RH2 Sample Review and Approval of Documents

W2

Sample Witness Inspection/Test

R1

100% Review of Documents

H1

100% Hold Point for QC Inspection or Test

R2

Sample Review of Documents

Page 4 of 4

Surveillance

Вам также может понравиться

- 1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1Документ3 страницы1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1JithuJohn100% (1)

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Документ4 страницы1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764Оценок пока нет

- SAIC-L-2136 Rev 0Документ3 страницыSAIC-L-2136 Rev 0philipyapОценок пока нет

- SATIP S 010 01 Sanitary SewerДокумент3 страницыSATIP S 010 01 Sanitary SewerMuhammad Farukh ManzoorОценок пока нет

- Satip W 014 01Документ12 страницSatip W 014 01spravin231Оценок пока нет

- Saudi Aramco Inspection ChecklistДокумент3 страницыSaudi Aramco Inspection ChecklistJoni Carino Suni100% (1)

- Satip D 001 01Документ11 страницSatip D 001 01Rijwan Mohammad0% (1)

- Materials System SpecificationДокумент13 страницMaterials System SpecificationJeck MaquitedОценок пока нет

- Saudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalДокумент11 страницSaudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalSasi Head OfficeОценок пока нет

- SATIP-N-001-02 Rev. 4Документ2 страницыSATIP-N-001-02 Rev. 4Anonymous 4e7GNjzGW100% (1)

- Saudi Aramco Inspection ChecklistДокумент3 страницыSaudi Aramco Inspection ChecklistAbdul HannanОценок пока нет

- SAIC-W-2084 Buttering or Build-Up of JointsДокумент1 страницаSAIC-W-2084 Buttering or Build-Up of Jointskarioke mohaОценок пока нет

- SAES-W-012 - Google Search3Документ1 страницаSAES-W-012 - Google Search3fayceal0% (1)

- 01-SAMSS-044 PDF Download - CRA Clad Pipe SpoolsДокумент4 страницы01-SAMSS-044 PDF Download - CRA Clad Pipe SpoolsZahidRafiqueОценок пока нет

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Документ2 страницыSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadОценок пока нет

- Saudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 WeldДокумент4 страницыSaudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 Weldhamidjoyia100% (1)

- 175 325100Документ2 страницы175 325100sridhar100% (1)

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18Документ8 страницSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18nadeem shaikhОценок пока нет

- Satr-W-2010Документ1 страницаSatr-W-2010Joni Carino SuniОценок пока нет

- Saes W 016 PDFДокумент10 страницSaes W 016 PDFRaj AryanОценок пока нет

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureДокумент2 страницыSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULОценок пока нет

- Satip e 007 01Документ2 страницыSatip e 007 01Anonymous 4e7GNjzGWОценок пока нет

- Saep 324 PDFДокумент13 страницSaep 324 PDFArvind ShakyaОценок пока нет

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldДокумент1 страницаSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387Оценок пока нет

- SAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Документ3 страницыSAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Anonymous S9qBDVkyОценок пока нет

- Saudi Aramco Typical Inspection Plan: Cement Lining of Pipes & Fittings SATIP-H-002-01 MechanicalДокумент1 страницаSaudi Aramco Typical Inspection Plan: Cement Lining of Pipes & Fittings SATIP-H-002-01 MechanicalSatheesh Rama SamyОценок пока нет

- Inspection ProcedureДокумент13 страницInspection ProcedureSantosh Kumar100% (1)

- 1 SATIP-D-109-01 Shop Fab Storage Tank PDFДокумент4 страницы1 SATIP-D-109-01 Shop Fab Storage Tank PDFJithuJohnОценок пока нет

- 00 Saip 12Документ8 страниц00 Saip 12aamirtec301Оценок пока нет

- Saudi Aramco Pre-Commissioning Form: Sf-6 Pad-Mounted SwitchgearДокумент2 страницыSaudi Aramco Pre-Commissioning Form: Sf-6 Pad-Mounted SwitchgearHaleem Ur Rashid BangashОценок пока нет

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Документ1 страницаSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganОценок пока нет

- SAIC-W-2085 Pre-Welding Inspection PDFДокумент4 страницыSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaОценок пока нет

- 175-026600 10312016Документ2 страницы175-026600 10312016Prasanna UmapathyОценок пока нет

- Saudi Aramco Typical Inspection PlanДокумент10 страницSaudi Aramco Typical Inspection Plankarthi51289Оценок пока нет

- Materials System SpecificationДокумент11 страницMaterials System SpecificationZubair RaoofОценок пока нет

- QP SPC L 0002 Rev 1 PDFДокумент80 страницQP SPC L 0002 Rev 1 PDFsouravrobinОценок пока нет

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGДокумент5 страницTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcОценок пока нет

- SATIP H 002 08 Rev 4.unlockedДокумент2 страницыSATIP H 002 08 Rev 4.unlockedMohamed Farhan B PositiveОценок пока нет

- 1 SATIP-L-350-08 Shop Fab - Piping and Steel Structures-Rev1Документ2 страницы1 SATIP-L-350-08 Shop Fab - Piping and Steel Structures-Rev1skychurch100% (2)

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Документ2 страницы1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyОценок пока нет

- Saudi Aramco Typical Inspection PlanДокумент3 страницыSaudi Aramco Typical Inspection PlanAnonymous S9qBDVkyОценок пока нет

- Saep 351Документ24 страницыSaep 351Raj KumarОценок пока нет

- SATIP B 019 01 (Revision 4)Документ2 страницыSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWОценок пока нет

- SAER1972Документ9 страницSAER1972zamil2008Оценок пока нет

- SATR-W-2006 Rev 6Документ1 страницаSATR-W-2006 Rev 6Manoj KumarОценок пока нет

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingДокумент5 страницSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiОценок пока нет

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsДокумент2 страницыSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyОценок пока нет

- Saes D 008Документ21 страницаSaes D 008Shajin Mohammed ShamsudhinОценок пока нет

- Materials System SpecificationДокумент7 страницMaterials System Specificationaanouar77Оценок пока нет

- Satip A 004 03Документ3 страницыSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingДокумент12 страницSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWОценок пока нет

- SAIC-L-2074 Rev 0Документ1 страницаSAIC-L-2074 Rev 0philipyapОценок пока нет

- SAIC-A-2009 Rev 2Документ5 страницSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுОценок пока нет

- Saudi Aramco Test ReportДокумент4 страницыSaudi Aramco Test Reportkarthi51289Оценок пока нет

- 175-Ir171300, (850146), 11.30.2015Документ2 страницы175-Ir171300, (850146), 11.30.2015Rami ELLOUMIОценок пока нет

- 1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDFДокумент4 страницы1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDFWIZKHALIFAОценок пока нет

- SAIC-W-2XXX-11 Control of Welding ConsumablesДокумент5 страницSAIC-W-2XXX-11 Control of Welding ConsumablesAnsuman KalidasОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент5 страницSaudi Aramco Inspection ChecklistMainuddin AliОценок пока нет

- Saudi Aramco Typical Inspection PlanДокумент4 страницыSaudi Aramco Typical Inspection PlanpravinОценок пока нет

- 1-3 Email Nurse - Role PlayДокумент2 страницы1-3 Email Nurse - Role PlayJithuJohnОценок пока нет

- 2015 Rev-Ect Feb 17 ListДокумент7 страниц2015 Rev-Ect Feb 17 ListJithuJohnОценок пока нет

- General Questions4Документ31 страницаGeneral Questions4JithuJohnОценок пока нет

- Material With Electrode SelectionДокумент2 страницыMaterial With Electrode SelectionJithuJohn100% (3)

- Pressure Vessel Exm QuestionsДокумент4 страницыPressure Vessel Exm QuestionsJithuJohn100% (1)

- General Questions4Документ31 страницаGeneral Questions4JithuJohnОценок пока нет

- General Questions4Документ31 страницаGeneral Questions4JithuJohnОценок пока нет

- Line Pipe API 5lДокумент3 страницыLine Pipe API 5lJithuJohnОценок пока нет

- Aramco QuestionДокумент72 страницыAramco QuestionZuberYousuf100% (1)

- General Questions4Документ31 страницаGeneral Questions4JithuJohnОценок пока нет

- PG Nursing Noti-APRIL - 2016Документ7 страницPG Nursing Noti-APRIL - 2016JithuJohnОценок пока нет

- OET Test 3 Listening Answers - Part A and BДокумент6 страницOET Test 3 Listening Answers - Part A and BJithuJohn100% (1)

- VT No: 1Документ12 страницVT No: 1JithuJohnОценок пока нет

- Subject Group of Materials Science and EngineeringДокумент2 страницыSubject Group of Materials Science and EngineeringJithuJohnОценок пока нет

- Rtliiim2: 20ci SourceДокумент1 страницаRtliiim2: 20ci SourceJithuJohnОценок пока нет

- Dpi QДокумент4 страницыDpi QJithuJohnОценок пока нет

- Agoura Hills DIVISION - 6. - NOISE - REGULATIONSДокумент4 страницыAgoura Hills DIVISION - 6. - NOISE - REGULATIONSKyle KimОценок пока нет

- PE Range Moulded Case Current Transformers: Energy DivisionДокумент7 страницPE Range Moulded Case Current Transformers: Energy DivisionUlfran MedinaОценок пока нет

- 3.13 Regional TransportationДокумент23 страницы3.13 Regional TransportationRonillo MapulaОценок пока нет

- Overcurrent CoordinationДокумент93 страницыOvercurrent CoordinationKumar100% (1)

- Science News Explores-June July 2023Документ36 страницScience News Explores-June July 2023Tobei AchimОценок пока нет

- CavinKare Karthika ShampooДокумент2 страницыCavinKare Karthika Shampoo20BCO602 ABINAYA MОценок пока нет

- SPC Abc Security Agrmnt PDFДокумент6 страницSPC Abc Security Agrmnt PDFChristian Comunity100% (3)

- Case Notes All Cases Family II TermДокумент20 страницCase Notes All Cases Family II TermRishi Aneja100% (1)

- Lec # 26 NustДокумент18 страницLec # 26 NustFor CheggОценок пока нет

- Scope: Provisional Method - 1994 © 1984 TAPPIДокумент3 страницыScope: Provisional Method - 1994 © 1984 TAPPIМаркус СилваОценок пока нет

- PHP IntroductionДокумент113 страницPHP Introductionds0909@gmailОценок пока нет

- Starkville Dispatch Eedition 12-9-18Документ28 страницStarkville Dispatch Eedition 12-9-18The DispatchОценок пока нет

- Application of ARIMAX ModelДокумент5 страницApplication of ARIMAX ModelAgus Setiansyah Idris ShalehОценок пока нет

- Canopy CountersuitДокумент12 страницCanopy CountersuitJohn ArchibaldОценок пока нет

- Dreamweaver Lure v. Heyne - ComplaintДокумент27 страницDreamweaver Lure v. Heyne - ComplaintSarah BursteinОценок пока нет

- UCAT SJT Cheat SheetДокумент3 страницыUCAT SJT Cheat Sheetmatthewgao78Оценок пока нет

- Fracture and FatigueДокумент15 страницFracture and FatigueZou JiaweiОценок пока нет

- Chapter 1: Investment Landscape: Financial GoalsДокумент8 страницChapter 1: Investment Landscape: Financial GoalsshubhamОценок пока нет

- Sangeetahealingtemples Com Tarot Card Reading Course in UsaДокумент3 страницыSangeetahealingtemples Com Tarot Card Reading Course in UsaSangeetahealing templesОценок пока нет

- IP Based Fingerprint Access Control & Time Attendance: FeatureДокумент2 страницыIP Based Fingerprint Access Control & Time Attendance: FeaturenammarisОценок пока нет

- Ethercombing Independent Security EvaluatorsДокумент12 страницEthercombing Independent Security EvaluatorsangelОценок пока нет

- Process Interactions PDFДокумент1 страницаProcess Interactions PDFXionОценок пока нет

- NIELIT Scientist B' Recruitment 2016 - Computer Science - GeeksforGeeksДокумент15 страницNIELIT Scientist B' Recruitment 2016 - Computer Science - GeeksforGeeksChristopher HerringОценок пока нет

- Mpi Model QuestionsДокумент4 страницыMpi Model QuestionshemanthnagОценок пока нет

- Gravity Based Foundations For Offshore Wind FarmsДокумент121 страницаGravity Based Foundations For Offshore Wind FarmsBent1988Оценок пока нет

- Vice President Enrollment Management in Oklahoma City OK Resume David CurranДокумент2 страницыVice President Enrollment Management in Oklahoma City OK Resume David CurranDavidCurranОценок пока нет

- Practical GAD (1-32) Roll No.20IF227Документ97 страницPractical GAD (1-32) Roll No.20IF22720IF135 Anant PatilОценок пока нет

- Payment of GratuityДокумент5 страницPayment of Gratuitypawan2225Оценок пока нет

- Mounting BearingДокумент4 страницыMounting Bearingoka100% (1)

- Intelligent Smoke & Heat Detectors: Open, Digital Protocol Addressed by The Patented XPERT Card Electronics Free BaseДокумент4 страницыIntelligent Smoke & Heat Detectors: Open, Digital Protocol Addressed by The Patented XPERT Card Electronics Free BaseBabali MedОценок пока нет