Академический Документы

Профессиональный Документы

Культура Документы

Procedure for Steam Blowing & Oil Flushing of F.O. System

Загружено:

srigirisetty208Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Procedure for Steam Blowing & Oil Flushing of F.O. System

Загружено:

srigirisetty208Авторское право:

Доступные форматы

PROCEDURE FOR STEAM BLOWING & OIL FLUSHING OF

F.O.SYSTEM

PROJECT:M/s RAMAGUNDAM

UNIT 7 (500 MW )

BHARAT HEAVY ELECTRICALS LIMITED

(A Government of India Undertaking)

Power Sector Southern Region

474, Anna Salai, Nandanam, Chennai 600 035.

PROJECT

M/s. RAMAGUNDAM UNIT 7, 500 MW

PROCEDURE

PROCEDURE FOR STEAM BLOWING & OIL

FLUSHING OF F.O.SYSTEM

PURPOSE OF

DOCUMENT

FOR EXECUTION / INFORMATION

DOCUMENT NO.

PS:TSX:174:00:03

COPY NO:

ISSUED TO:

00

Rev. No.

KJ

KPTM

KB

04.08.2003

Prepared by

Reviewed by

Approved by

Date

BHARAT HEAVY ELECTRICALS LIMITED

(A Government of India Undertaking)

Power Sector Southern Region

474, Anna Salai, Nandanam, Chennai 600 035.

Station: NTPC BHEL Ref No.PS-DC-202-500-0008

Sheet 1 of 7

Ramagundam

NTPC Ref no COS-COMM-RGM-Commg-PRO/008

Plant area: BOILER

PROCEDURE FOR STEAM BLOWING AND OIL FLUSHING OF FUEL OIL SYSTEM

SLNO

LIST OF CONTENTS

1.0

PLANT DETAILS

2.0

OBJECTIVE

3.0

PROPOSAL

4.0

SERVICES REQUIRED

5.0

SAFETY PERECAUTIONS

6.0

EMERGENCY PROCEDURE

7.0

STATE OF THE PLANT

8.0

METHOD

9.0

COMPLETION CRITERIA

10.0

APPENDICES

a) DRAWING

Station: NTPC BHEL Ref No.PS-DC-202-500-0008

Sheet 2 of 7

Ramagundam

NTPC Ref no COS-COMM-RGM-Commg-PRO/008

Plant area: BOILER

PROCEDURE FOR STEAM BLOWING AND OIL FLUSHING OF FUEL OIL SYSTEM

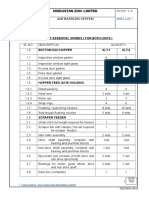

STATUS

SL.NO

1.0

PLANT DETAILS:

1.1

The Fuel oil plant consists of facilities for Unloading, Storage and

Supply of LDO and HFO.

Fuel Oil Pump House is located close to Fuel Storage Yard. The

Pump house houses:

a. LFO Pumps for Main Boiler

b. HFO Pumps for Main Boiler

c. HFO Heaters

d. HFO cooler in the return line

e. Drain Oil Tank & Drain Pump

f.

Electrical & control Panels for F.O.Pump House auxiliaries

1.2

Fuel Oil lines from Fuel Oil Pump House to Main Boiler are routed

through trestles with supports given suitably for thermal

expansion. Steam tracing lines run along the entire length of HFO

lines and are inside the same insulation.

2.0

OBJECTIVE

2.1

To remove debris, scales and weld splatters and clean the

internal surface of oil lines in the LDO / HFO system including

atomizing steam lines and steam tracing lines.

Signatures

NTPC

BHEL

Station: NTPC BHEL Ref No.PS-DC-202-500-0008

Sheet 3 of 7

Ramagundam

NTPC Ref no COS-COMM-RGM-Commg-PRO/008

Plant area: BOILER

PROCEDURE FOR STEAM BLOWING AND OIL FLUSHING OF FUEL OIL SYSTEM

STATUS

SL.NO

3.0

PROPOSAL:

3.1

All the lines shall be steam blown in sections.

3.2

Steam blowing shall be done by continuous blowing method.

3.3

Oil flushing of oil lines shall be taken up after completion of steam

blowing.

3.4

Since LDO system does not have provision of return line from

Boilers suitable temporary connections shall be made at Boiler

end and in storage tank area for oil flushing of LDO lines so that

closed loop flushing be carried out from LDO tank to Main Boiler

& back to LDO tank using HFO return line.

3.5

A temporary strainer shall be put in the return line near the LDO

Storage Tank. The mesh size of the strainer shall be same as that

envisaged for the suction strainers of the Pressurising Pumps.

Flushing of HFO lines shall be done using HFO.

3.6

SERVICES REQUIRED

4.0

Steam Blowing

4.1

4.1.1

Availability of Auxiliary Steam at required pressure and

temperature.

4.1.2

Availability of Permanent fire fighting system and sufficient

number of portable fire extinguishers at identified locations.

Availability of adequate manpower and communication facility.

4.1.3

4.1.4

Signatures

Availability of Public address system or siren to communicate the

commencement of steam blowing.

NTPC

BHEL

Station: NTPC BHEL Ref No.PS-DC-202-500-0008

Sheet 4 of 7

Ramagundam

NTPC Ref no COS-COMM-RGM-Commg-PRO/008

Plant area: BOILER

PROCEDURE FOR STEAM BLOWING AND OIL FLUSHING OF FUEL OIL SYSTEM

STATUS

SL.NO

4.2

Oil flushing

4.2.1

Availability of LT power supply for LDO / HFO Pumps.

4.2.2

Availability of sufficient quantity of LDO / HFO.

5.0

5.1

SAFETY PRECAUTIONS

First aid kit should be available in the test area.

5.2

Sufficient number of safety gears such as helmets, asbestos hand

gloves, ear mufflers etc should be available

5.3

Service water should be available near the activity area

5.4

The blowing area should be barricaded.

5.5

Required number of sign boards should be put at selected places to

indicate the ongoing process of steam blowing.

5.6

All permanent lines should be insulated prior to the commencement

of steam blowing.

5.7

All temporary lines which may come in contact with personnel should

be suitably insulated before steam blowing.

5.8

All the pipelines should have provision for free expansion.

5.9

Availability of Ambulance and Fire Tender in the Power Plant

premises.

6.0

EMERGENCY PROCEDURES

6.1

The persons involved in carrying out the cleaning activity should be

aware of the actions to be taken in the event of injury to personnel.

The group members should be aware of operating instructions of

6.2

portable fire extinguishers.

Signatures

NTPC

BHEL

Station: NTPC BHEL Ref No.PS-DC-202-500-0008

Sheet 5 of 7

Ramagundam

NTPC Ref no COS-COMM-RGM-Commg-PRO/008

Plant area: BOILER

PROCEDURE FOR STEAM BLOWING AND OIL FLUSHING OF FUEL OIL SYSTEM

STATUS

SL.NO

7.0

STATE OF THE PLANT

7.1

7.1.1

Steam Blowing

Suitable spool pieces are erected in places of Trip valves, control

valves and flow measuring elements.

7.1.2

Filter elements and NRV internals are removed wherever required. A

checklist is to be prepared which shall be used during restoration.

7.1.3

All vents and drains are properly routed and supported.

7.2

7.2.1

Oil Flushing

Steam blowing of the concerned lines is over.

7.2.2

LDO / HFO pumps are commissioned on recirculation.

7.2.3

Temporary lines (for LDO lines flushing) are suitably connected at

Boiler as well as storage tank ends.

7.2.4

A temporary strainer is provided in the return line before entry to the

Storage Tank. The mesh size of the strainer should be same as that

envisaged for the suction strainers of the Pressurising Pumps.

8.0

METHOD

8.1

8.1.1

Steam Blowing

The line to be blown is charged slowly with auxiliary steam and

warmed up keeping the drains open.

8.1.2

After proper charging blow is given for 20-30 minutes.

8.1.3

Steam at a pressure of 10-12 Kg/cm 2 and having a superheat of at

least 500 C at source is used for blowing.

8.1.4

The line is allowed to cool for two hours and then again blown.

Signatures

NTPC

BHEL

Station: NTPC BHEL Ref No.PS-DC-202-500-0008

Sheet 6 of 7

Ramagundam

NTPC Ref no COS-COMM-RGM-Commg-PRO/008

Plant area: BOILER

PROCEDURE FOR STEAM BLOWING AND OIL FLUSHING OF FUEL OIL SYSTEM

STATUS

SL.NO

8.1.2

Steam blowing is declared complete based on Completion criteria.

8.1.3

Blowing of drains, vents and instrument tapping points is done at

5 Kg/cm2 for 10 minutes each.

8.1.4

Blowing of LDO lines, Steam tracing lines and condensate lines is

done at 6 Kg/cm2 for 20-30 minute each.

8.1.5

Drains / vents of F.O.lines are kept open as required during steam

blowing and thereafter for draining of condensate.

8.1.6

After sufficient cooling the pipings are dried with compressed air.

8.1.7

After completion of steam blowing, all spool pieces are removed and

Trip valves, control valves, flow elements, filter elements and NRV

internals are restored / normalized. Pipe connections to LDO / HFO

pumps are normalized and pumps are commissioned.

NOTE: During the cooling period of one section of pipeline other

section, as per convenience, can be steam blown.

8.2

8.2.1

Oil Flushing of LDO Lines

LDO lines are lined up for flushing with LDO through HFO return line

from Boiler.

8.2.2

LDO Pump is started and the line flushed for minimum 24 hours.

Temporary filter in the return line and Pump suction filters are taken

out and cleaned as and when required. Frequency of strainer

cleaning is to be decided jointly by NTPC & BHEL at site.

8.2.3

Flushing is declared complete based on completion criteria.

8.2.4

LDO lines are subsequently normalized and released for regular

operation.

Signatures

NTPC

BHEL

Station: NTPC BHEL Ref No.PS-DC-202-500-0008

Sheet 7 of 7

Ramagundam

NTPC Ref no COS-COMM-RGM-Commg-PRO/008

Plant area: BOILER

PROCEDURE FOR STEAM BLOWING AND OIL FLUSHING OF FUEL OIL SYSTEM

STATUS

SL.NO

8.3

Oil flushing of HFO Lines

8.3.1

HFO lines are lined up for flushing with HFO through normal HFO

return line from Boiler.

8.3.2

Steam tracing line is kept charged.

8.3.4

HFO Pump is started and the line flushed for minimum 24 hours.

Pump suction and discharge filters (installed at outlet of heaters) are

taken out and cleaned as and when required. Frequency of strainer

cleaning is to be decided jointly by NTPC & BHEL at site.

8.3.5

Flushing is declared complete based on completion criteria.

9.0

COMPLETION CRITERIA

9.1

Steam Blowing

9.1.1

Steam blowing of the section of LDO / HFO lines is declared

complete after minimum five blows each having a blow duration of

20-30 minutes.

9.1.2

Blowing medium at exit of the pipe should be visually clean.

9.2

Oil Flushing

9.2.1

LDO flushing is declared complete after minimum 24 hours of

flushing and the filters remaining clean for 8 hours of continuous

flushing.

9.2.2

HFO flushing is declared complete after minimum 24 hrs of flushing

and the filters remaining clean for 8 hours of continuous flushing.

Signatures

NTPC

BHEL

Вам также может понравиться

- Procedure For Commissioning of Auxiliary Prds SystemДокумент14 страницProcedure For Commissioning of Auxiliary Prds SystemJackSparrow86100% (1)

- F O Flushing and Steam BlowingДокумент8 страницF O Flushing and Steam BlowingsprotkarОценок пока нет

- BFP TDДокумент22 страницыBFP TDJackSparrow8650% (2)

- Steam Turbine RevampДокумент38 страницSteam Turbine RevampVILLANUEVA_DANIEL2064100% (1)

- Cold Start Up Check ListДокумент6 страницCold Start Up Check ListSreekanthMylavarapuОценок пока нет

- Insp SOP's Revised With StatusДокумент2 страницыInsp SOP's Revised With StatushellmanyaОценок пока нет

- Boiler Constr DetailsДокумент21 страницаBoiler Constr DetailsAhemadОценок пока нет

- Procedure of vacuum leak detection in KWU steam turbines using steam pressurisationДокумент8 страницProcedure of vacuum leak detection in KWU steam turbines using steam pressurisationTamara Lee100% (1)

- Rolling turbine through IPT during generator dry outДокумент3 страницыRolling turbine through IPT during generator dry outAnudeep Chittluri100% (1)

- 1015t/h Subcritical Pressure Natural Circulation Boiler InstructionДокумент74 страницы1015t/h Subcritical Pressure Natural Circulation Boiler InstructioncynaiduОценок пока нет

- Steam Circulation SystemДокумент36 страницSteam Circulation Systemnavdeeplakhera100% (1)

- Boiler Efficiency, Losses and Performance Optimization: Boiler Shutdown, Emergencies, ProtectionsДокумент56 страницBoiler Efficiency, Losses and Performance Optimization: Boiler Shutdown, Emergencies, ProtectionsPranav Sai100% (1)

- Emergency Operations Training GuideДокумент62 страницыEmergency Operations Training Guideparveen164100% (1)

- Check Float Valve Settings Seal Oil Tank 500 MW GeneratorsДокумент3 страницыCheck Float Valve Settings Seal Oil Tank 500 MW GeneratorssprotkarОценок пока нет

- LP Bypass System OverviewДокумент43 страницыLP Bypass System Overviewamulya1981Оценок пока нет

- U4OHREPORT2008Документ88 страницU4OHREPORT2008Anonymous pKsr5vОценок пока нет

- Steam Turbine Combined Reheat Stop Description and Control ValvesДокумент2 страницыSteam Turbine Combined Reheat Stop Description and Control Valvesparthibanemails5779100% (1)

- Boiler EmergenciesДокумент15 страницBoiler EmergenciesAmit ChauhanОценок пока нет

- Turbine Condensate System in Thermal Power PlantДокумент35 страницTurbine Condensate System in Thermal Power PlantAshwani Dogra100% (1)

- A Research Paper On Design and Analysis of Shaftless Steam TurbineДокумент5 страницA Research Paper On Design and Analysis of Shaftless Steam TurbineEditor IJTSRDОценок пока нет

- Trouble Shooting Vibration in A Pulverized Coal Fired BoilerДокумент13 страницTrouble Shooting Vibration in A Pulverized Coal Fired Boilerparthi20065768100% (1)

- TH PP CH2 NewДокумент38 страницTH PP CH2 NewAnonymous I43VxQYvОценок пока нет

- 500MW Boiler Fans and ProtectionsДокумент5 страниц500MW Boiler Fans and Protectionsshashank100% (1)

- Precommissioning and startup activities for a boilerДокумент29 страницPrecommissioning and startup activities for a boilerSarah FrazierОценок пока нет

- CFBC DCPP at A Glance.Документ20 страницCFBC DCPP at A Glance.Sumit SuryavanshiОценок пока нет

- 03 APC ReductionДокумент55 страниц03 APC ReductionDevanshu SinghОценок пока нет

- Steam Blowing - Disturbance Factor Discusstion2 PDFДокумент5 страницSteam Blowing - Disturbance Factor Discusstion2 PDFchem_taОценок пока нет

- Turbine Operation GuideДокумент27 страницTurbine Operation GuidebhaskarОценок пока нет

- IR-CFBC Boiler Drive Start/Stop LogicДокумент6 страницIR-CFBC Boiler Drive Start/Stop Logicsambhu100% (1)

- Steam Circulation System DiagramДокумент36 страницSteam Circulation System DiagramAshwani Dogra100% (1)

- OnM Best Practices MPPGCLДокумент42 страницыOnM Best Practices MPPGCLJithinAbraham100% (1)

- TTPS Divisions GuideДокумент34 страницыTTPS Divisions GuideRamanand bharadwajОценок пока нет

- BasicsДокумент23 страницыBasicsSam100% (1)

- Control Valve Data SheetsДокумент150 страницControl Valve Data SheetsAnonymous ZnuMEWN1Оценок пока нет

- Boiler Ga, Specification & Line Up For Light Up: by Rahul R MungaleДокумент11 страницBoiler Ga, Specification & Line Up For Light Up: by Rahul R MungaleMukesh Kumar VaishnavОценок пока нет

- Turbine Lube Oil System ExplainedДокумент15 страницTurbine Lube Oil System ExplainedNitish Kumar100% (1)

- Boiler Maintenance Gyanendra Sharma NPTI DelhiДокумент38 страницBoiler Maintenance Gyanendra Sharma NPTI DelhiNPTI100% (1)

- Turbine Trip LogicДокумент2 страницыTurbine Trip Logicdilbagh_scribd50% (2)

- Hrsgs Behind FR 9E GTS: (123.4 MW Iso)Документ20 страницHrsgs Behind FR 9E GTS: (123.4 MW Iso)api-19986783100% (1)

- Cleaning NTPC's Seal Oil System PipingДокумент18 страницCleaning NTPC's Seal Oil System Pipingnetygen1Оценок пока нет

- Steam Turbine Maintenance: Ramagundam Super Thermal Power StationДокумент55 страницSteam Turbine Maintenance: Ramagundam Super Thermal Power StationMohamed Bin Ierous100% (1)

- Boiler OperationДокумент14 страницBoiler OperationjmayurrОценок пока нет

- 500MW-Boiler - Salient FeatureДокумент7 страниц500MW-Boiler - Salient FeatureAhemadОценок пока нет

- Power Plant Operation Turbine & Auxiliaries: 18 February 2013 PMI Revision 00 1Документ43 страницыPower Plant Operation Turbine & Auxiliaries: 18 February 2013 PMI Revision 00 1Alok Ranjan Tripathi100% (1)

- 600MW TurbineДокумент45 страниц600MW TurbineDharmaray Doddi100% (2)

- Introduction To Steam Seal System of 800Mw Kudgi TurbineДокумент10 страницIntroduction To Steam Seal System of 800Mw Kudgi TurbineSCEKUDGI 800Оценок пока нет

- Boiler LightupДокумент14 страницBoiler LightupRohtash GargОценок пока нет

- Turbine StartupДокумент16 страницTurbine StartupSakthi Murugan100% (1)

- Governing System, RSE & TG ExpansionsДокумент40 страницGoverning System, RSE & TG Expansionssaravan1891100% (2)

- CW Pumps Tripping On Over Load, 210 MW Unit, 02-03Документ5 страницCW Pumps Tripping On Over Load, 210 MW Unit, 02-03Charu ChhabraОценок пока нет

- Cold Startup Procedure 250 MWДокумент7 страницCold Startup Procedure 250 MWPrudhvi RajОценок пока нет

- Air PreheaterДокумент27 страницAir Preheatershantanu_scribdОценок пока нет

- F O Flushing and Steam Blowing PDFДокумент8 страницF O Flushing and Steam Blowing PDFSendal BodolОценок пока нет

- Clean Air Flow TestДокумент13 страницClean Air Flow Testsrigirisetty20880% (5)

- MDBFP Oil FlushingДокумент13 страницMDBFP Oil Flushingsrigirisetty208Оценок пока нет

- Aux Steam SystemДокумент14 страницAux Steam Systemsanjeevchhabra100% (1)

- Turbine Oil Flushing ProcedureДокумент25 страницTurbine Oil Flushing Proceduresrigirisetty208Оценок пока нет

- Testing Schedule For Commissioning of Condensate Extraction PumpsДокумент13 страницTesting Schedule For Commissioning of Condensate Extraction PumpsJackSparrow86100% (1)

- Aux Steam SystemДокумент14 страницAux Steam SystemDipti BhanjaОценок пока нет

- HP by Pass System-ModifiedДокумент21 страницаHP by Pass System-Modifiedsrigirisetty208100% (1)

- NB O&M Brochure 01sept2020Документ10 страницNB O&M Brochure 01sept2020srigirisetty208Оценок пока нет

- 5C1. Coal Ash Generation Process and Application FieldsДокумент2 страницы5C1. Coal Ash Generation Process and Application Fieldssrigirisetty208Оценок пока нет

- Arar 33kV Cable Sizing ReportДокумент9 страницArar 33kV Cable Sizing Reportsrigirisetty208Оценок пока нет

- 330MW Shrinagar Project Technical Data SheetДокумент4 страницы330MW Shrinagar Project Technical Data Sheetsrigirisetty208Оценок пока нет

- 330MW Shrinagar Hydroelectric Project Penstock Intake DataДокумент2 страницы330MW Shrinagar Hydroelectric Project Penstock Intake Datasrigirisetty208Оценок пока нет

- Fire Detection and Alarm System Design Basis DocumentДокумент12 страницFire Detection and Alarm System Design Basis Documentsrigirisetty208Оценок пока нет

- Boiler Tube Failures Due To Improper CommissioningДокумент21 страницаBoiler Tube Failures Due To Improper CommissioningDhandapani ManoharanОценок пока нет

- 4.2 - Dam and Spillway - Radial Gates and Hydraulic HoistДокумент3 страницы4.2 - Dam and Spillway - Radial Gates and Hydraulic Hoistsrigirisetty208Оценок пока нет

- Care and Maintenance of CFB Boilers Refractory FailureДокумент6 страницCare and Maintenance of CFB Boilers Refractory FailureAnonymous a19X9GHZОценок пока нет

- 4.19 - Instrumentation and ControlДокумент2 страницы4.19 - Instrumentation and Controlsrigirisetty208Оценок пока нет

- 330MW Shrinagar Project Technical Data SheetДокумент4 страницы330MW Shrinagar Project Technical Data Sheetsrigirisetty208Оценок пока нет

- 4.11 - Bypass Channel - Automatic GateДокумент1 страница4.11 - Bypass Channel - Automatic Gatesrigirisetty208Оценок пока нет

- HZL Crane EssentialsparesДокумент2 страницыHZL Crane Essentialsparessrigirisetty208Оценок пока нет

- 4.17 - Powerhouse - Powerhouse CraneДокумент3 страницы4.17 - Powerhouse - Powerhouse Cranesrigirisetty208Оценок пока нет

- 4.13 - Penstock Intake - Trashrack and Cleaning MachineДокумент2 страницы4.13 - Penstock Intake - Trashrack and Cleaning Machinesrigirisetty208Оценок пока нет

- Sch-3A 14-Perfor GuartДокумент5 страницSch-3A 14-Perfor Guartsrigirisetty208Оценок пока нет

- 4.2 - Dam and Spillway - Radial Gates and Hydraulic HoistДокумент3 страницы4.2 - Dam and Spillway - Radial Gates and Hydraulic Hoistsrigirisetty208Оценок пока нет

- 4.5 - Dam and Spillway - ElevatorДокумент2 страницы4.5 - Dam and Spillway - Elevatorsrigirisetty208Оценок пока нет

- Quality Assurance Plan for 2x150 MW Coal Power PlantДокумент1 страницаQuality Assurance Plan for 2x150 MW Coal Power Plantsrigirisetty208Оценок пока нет

- HZL Chs EssentialsparesДокумент6 страницHZL Chs Essentialsparessrigirisetty208Оценок пока нет

- SCH 3A.17 Q.a.assessmentДокумент1 страницаSCH 3A.17 Q.a.assessmentsrigirisetty208Оценок пока нет

- HZL Ahs EssentialsparesДокумент8 страницHZL Ahs Essentialsparessrigirisetty208Оценок пока нет

- 150 MW Coal Fired Power Plant Construction Equipment ListДокумент2 страницы150 MW Coal Fired Power Plant Construction Equipment Listsrigirisetty208Оценок пока нет

- BFP Drawings PDFДокумент42 страницыBFP Drawings PDFsrigirisetty208Оценок пока нет

- SCH 3A.9 Places of Mfg.Документ1 страницаSCH 3A.9 Places of Mfg.srigirisetty208Оценок пока нет

- BFP DrawingsДокумент42 страницыBFP Drawingssrigirisetty208Оценок пока нет

- SCH 3A.11 SparesДокумент3 страницыSCH 3A.11 Sparessrigirisetty208Оценок пока нет

- Equipment Supply by BidderДокумент6 страницEquipment Supply by Biddersrigirisetty208100% (2)

- SCH 3A.12 Special Tools &tacklesДокумент3 страницыSCH 3A.12 Special Tools &tacklessrigirisetty208Оценок пока нет

- Guaranteed DataДокумент2 страницыGuaranteed Datasrigirisetty208Оценок пока нет

- Schott Ky DiodesДокумент3 страницыSchott Ky DiodesAmarnath M DamodaranОценок пока нет

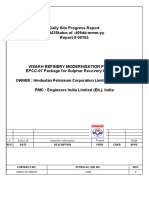

- Daily Site Progress Report 43443status of - 409dd-Mmm-Yy Report # 00105Документ8 страницDaily Site Progress Report 43443status of - 409dd-Mmm-Yy Report # 00105nemalipalli007Оценок пока нет

- Tiny House MovementДокумент51 страницаTiny House MovementAngelique Lucille PumanesОценок пока нет

- Adaptive Cruise Control: Current Flow DiagramДокумент5 страницAdaptive Cruise Control: Current Flow DiagramHany ElsehrawyОценок пока нет

- CalibrationДокумент7 страницCalibrationstolen mechieducОценок пока нет

- DRC800 Remote Control UserGuideДокумент2 страницыDRC800 Remote Control UserGuideLuis MurilloОценок пока нет

- Cisco SD-WAN Intro SOLRST-2006 PDFДокумент10 страницCisco SD-WAN Intro SOLRST-2006 PDFffusaroОценок пока нет

- Stampingjournal20130102 DLДокумент36 страницStampingjournal20130102 DLWaqar MansoorОценок пока нет

- A Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingДокумент10 страницA Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingJEORJEОценок пока нет

- Philips Chassis Lc7-1e La PDFДокумент91 страницаPhilips Chassis Lc7-1e La PDFcomphomeОценок пока нет

- Ult Studio Config 71Документ18 страницUlt Studio Config 71JoséGuedesОценок пока нет

- Emulsion BreakerДокумент19 страницEmulsion BreakerNovrie50% (2)

- Inventory Items DestinyДокумент11 страницInventory Items DestinyManish NautiyalОценок пока нет

- Satellite 2755dvdДокумент2 страницыSatellite 2755dvdeduinnОценок пока нет

- Sourav Roy - Loan IQ AnalystДокумент4 страницыSourav Roy - Loan IQ AnalystSourav RoyОценок пока нет

- Aluminium Pipe FittingsДокумент12 страницAluminium Pipe Fittingsrahult19Оценок пока нет

- Manual Cessna 188 PG 01-108Документ108 страницManual Cessna 188 PG 01-108Nilton César LimaОценок пока нет

- Smart is the most intelligent solution yet for urban drivingДокумент8 страницSmart is the most intelligent solution yet for urban drivingHenrique CorreiaОценок пока нет

- Ernest H Hill Ltd Equipment Catalogue SummaryДокумент17 страницErnest H Hill Ltd Equipment Catalogue SummaryhillpumpsОценок пока нет

- Viscosity and Normal Stress Differences in Molten PlasticsДокумент30 страницViscosity and Normal Stress Differences in Molten PlasticsAzizol WahabОценок пока нет

- FintechДокумент8 страницFintechArnab Das50% (4)

- High-Temperature Quad 2-Inputs OR Gate DatasheetДокумент6 страницHigh-Temperature Quad 2-Inputs OR Gate DatasheetSalim Abdul Rahman Sa'dyОценок пока нет

- SHG 25 3000 SeriesДокумент23 страницыSHG 25 3000 Seriesjpsingh75Оценок пока нет

- The Autolisp TutorialsДокумент285 страницThe Autolisp Tutorialsmynareshk100% (7)

- Oxygen USPДокумент2 страницыOxygen USPMartha Lucia Roa FonsecaОценок пока нет

- Bernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGДокумент1 страницаBernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGRhon Nem KhoОценок пока нет

- Ansys Fluent 14.0: Getting StartedДокумент26 страницAnsys Fluent 14.0: Getting StartedAoife FitzgeraldОценок пока нет

- TPF 5-165 Task 1 Final ReportДокумент112 страницTPF 5-165 Task 1 Final ReportLohith Kumar H PОценок пока нет

- Intelligent Traffic Manager - White PaperДокумент12 страницIntelligent Traffic Manager - White Paperharishv_scribdОценок пока нет

- Astm C109-16Документ10 страницAstm C109-16Travis TwaddellОценок пока нет