Академический Документы

Профессиональный Документы

Культура Документы

Plano de Transmision D6T

Загружено:

ronaldАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Plano de Transmision D6T

Загружено:

ronaldАвторское право:

Доступные форматы

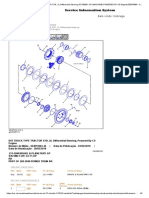

COMPONENT LIST

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

C-3

A-4

D-5

E-4

N/A

D-2

B-1

C-3

E-5

E-5

B-5

B-2

N/A

N/A

C-7

270-1763

235-5812

213-1308

263-9949

9G-5127

220-1418

238-1116

231-4166

220-1429

231-5969

231-5990

269-7635

241-5635

N/A

255-6934

Description

Power Train Oil Pump (3 Section)

Power Train Oil Filters

Brake Control Valve

Lube Dist. / TC Inlet Relief Manifold

Breather

Torque Converter Outlet Relief Valve

Oil Cooler

Pump Inlet Screen / Housing Gp.

Transmission Ar.

Left Drive / Brake Gp.

Right Drive / Brake Gp.

Torque Converter / Housing Gp.

Gage As. (NOT SHOWN)

Oil Fill Tube (NOT SHOWN)

Accumulator (Power Train)

BRAKES OFF

ACTUATING CONTROL:

NOTE

TEST LOCATION

ER1

UNITS

ENGINE

SPEED

TRANS. GEAR

P/T OIL TYPE

EU

BRAKES ON

BRAKES ON

FOOT CONTROL

PARKING

BRAKE

XL, XW, LGP, STD

800 +/- 10

---

NEUTRAL

NEUTRAL

NEUTRAL

3F STALL

NEUTRAL

WT.

SAE 30

SAE 30

SAE 30

SAE 30

SAE 30

80 +/- 5

80 +/- 5

80 +/- 5

80 +/- 5

80 +/- 5

2350 +/- 140

2550 +/- 140

2550 +/- 140

<70

<70

2585 +/- 105

2760 +/- 140

2760 +/- 140

2690 +/- 140

2585 +/- 105

TRANS. MAIN

RELIEF

T/C SUPPLY

PRESSURE

KPA

KPA

380 +/- 70

655 +/- 70

655 +/- 70

515 +/- 70

T/C OUTLET

PRESSURE

KPA

380 +/- 70

515 +/- 70

515+/- 70

415 +/- 70

L2

FLYWHEEL LUBE

PRESSURE

KPA

205 +/- 70

310 +/- 105

310 +/- 105

L1

TRANS. LUBE

PRESSURE

KPA

24 +/- 14

170 +/- 35

170 +/- 35

105 +/- 35

LB1

L BRAKE LUBE

PRESSURE

KPA

18 +18/-17

90 +/- 35

90 +/- 35

55 +/- 35

LB2

R BRAKE LUBE

PRESSURE

KPA

18 +18/-17

90 +/- 35

90 +/- 35

55 +/- 35

CL1

TRANS. CLUTCH 1

PRESSURE

KPA

CL2

TRANS. CLUTCH 2

PRESSURE

KPA

CL3

TRANS. CLUTCH 3

PRESSURE

KPA

CL4

TRANS. CLUTCH 4

PRESSURE

KPA

CL5

TRANS. CLUTCH 5

PRESSURE

KPA

The transmission charging section (G) of the power train

oil pump supplies approximately 54 L/min. (14.3 US

gal./min.) of oil to the transmission and brakes circuit.

G

F

I

E

Note C:

Note D:

Schematic

Location

AA

BB

B1

CL1

CL2

CL3

CL4

CL5

L1

L2

LB1

LB2

B-4

B-4

D-5

C-6

C-6

D-6

D-6

D-6

C-7

E-2

E-5

B-5

PTO Sampling Port (SOS)

PTO Pressure

Brake Pressure

Trans. Clutch 1 Pressure

Trans. Clutch 2 Pressure

Trans. Clutch 3 Pressure

Trans. Clutch 4 Pressure

Trans. Clutch 5 Pressure

Trans. Lube Pressure

Flywheel Lube Pressure

L Brake Lube Pressure

R Brake Lube Pressure

M

N

P

E-3

D-2

D-7

T/C Supply Pressure

T/C Ooutlet Pressure

Trans. Main Relief

10

LB1

D6T Track-Type Tractor

Power Train System

JHB1-UP

ZEB1-UP

SMC1-UP

JWD1-UP

LBD1-UP

LAE1-UP

DJG1-UP

WCG1-UP

CHECK VALVES

INFINITE POSITION

SHUTTLE

SPRING

LOADED

BASIC

SYMBOL

RETURN ABOVE FLUID LEVEL

PRESSURIZED

PRESSURE

PILOT

CONTROLLED

RETURN BELOW FLUID LEVEL

ROTATING SHAFTS

FLOW

TEMPERATURE

UNIDIRECTIONAL

BIDIRECTIONAL

COMBINATION CONTROLS

WFH1-UP

LKJ1-UP

KJL1-UP

SKL1-UP

GCT1-UP

RLW1-UP

LAY1-UP

PEZ1-UP

SOLENOID

or MANUAL

SOLENOID

SERVO

SOLENOID and

PILOT or MANUAL

SOLENOID

and PILOT

DETENT

THERMAL

MANUAL CONTROL SYMBOLS

PUSH-PULL LEVER

GENERAL MANUAL

MANUAL SHUTOFF

INTERNAL RETURN

SPRING LOADED

LINES CROSSING

GAS CHARGED

FIXED

DISPLACEMENT

FIXED

DISPLACEMENT

HYDRAULIC AND PNEUMATIC CYLINDERS

LINES JOINING

SINGLE ACTING

UNIDIRECTIONAL

BIDIRECTIONAL

BIDIRECTIONAL

DOUBLE ACTING

INTERNAL PASSAGEWAYS

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

INTERNAL

SUPPLY PRESSURE

COMPLETE

HYDRAULIC MOTORS

VARIABLE DISPLACEMENT

NON-COMPENSATED

SPRING

REMOTE SUPPLY PRESSURE

CROSSING AND JOINING LINES

HYDRAULIC PUMPS

Cooled oil from the power train oil cooler is directed to the

lube distribution manifold (L) through the hose on the left

(M). The smaller hose (P) is the line leading to the remote

pressure test port for torque converter inlet pressure

( M ). This remote pressure test port is located inside the

front compartment on the right fender

PEDAL

SIMPLIFIED

ACCUMULATORS

The torque converter inlet relief valve is installed in the

housing. Excess oil flows past the inlet relief valve into

the main sump through a port in the front of the case, and

behind the housing. Oil flow to the torque converter inlet

is through the hose on the right (N).

PUSH BUTTON

PILOT CONTROL SYMBOLS

RELEASED PRESSURE

EXTERNAL RETURN

PARALLEL

FLOW

FLOW IN ONE

DIRECTION

BB

AA

BB

TWO

POSITION

THREE

POSITION

INFINITE

POSITIONING

CROSS

FLOW

FLOW ALLOWED IN

EITHER DIRECTION

Printed in U.S.A.

2009 Caterpillar

All Rights Reserved

AA

Electrical Symbols Table

Hydraulic Symbols (Electrical)

Transmission Charge

Circuit Accumulator

Transmission Lube

Temperature Sensor

FOUR-WAY

THREE-WAY

MEASUREMENT

Power Train Oil Pump 1

Description

B1

TWO-WAY

THREE POSITION

P T

SHIFTED POSITION

VENTED

Transducer

(Fluid)

L1

CL1 CL2 CL3

CL4 CL5 P

L1

VALVE PORTS

FLUID STORAGE RESERVOIRS

The torque converter inlet relief valve (J) and the lube

distribution manifold (L) are both contained in one

housing. Oil from the torque converter charging section

of the power train oil pump is supplied to the torque

converter inlet relief valve through the upper hose (K).

Tap Locations

Tap

Number

The transmission and torque converter scavenge section

(H) of the power train oil pump draws approximately 125

L/min. (33 US gal./min.) from the torque divider case, and

the transmission case.

The scavenge oil is used for lubrication of the steering differential. The power train oil temperature sensor (I) provides main

sump oil temperature information to the Machine ECM. This is the temperature sensor that is considered when performing

power train calibrations, such as brake touch-ups and transmission clutch fill calibrations.

All flows are at rated engine speed of 1850 RPM with the transmission in neutral. All leakages

are max.

Oil Cleanliness must meet ISO Spec 18/15 at ship. ISO typical after 100hrs=16/13. Oil samples

should be taken at Oil Sampling Port.

ECPC Clutch Engagement Pressure calibration is not required. Transmission clutches 1-4

operate at Transmission Main. Relief (P) pressure when engaged. Transmission clutch 5

operates at 2240205 KPA when engaged.

Breather is located on the right-hand fender and connected to the vent hose.

Note B:

ATTACHMENT

LINE RESTRICTION

VARIABLE and PRESSURE

COMPENSATED

AB

P T

NORMAL POSITION

The power train oil pump draws oil for the torque

converter charging circuit and for the transmission

charging circuit from a screened suction manifold that

connects to the pump at the pump inlet (E).

P

Note A:

HYDRAULIC

PNEUMATIC

ENERGY TRIANGLES

CONTROL VALVES

1605 +/- 30

KPA

TWO POSITION

AB

1920+10/- 20

B1

PUMP: VARIABLE and

PRESSURE COMPENSATED

2-SECTION PUMP

VALVES

VALVE ENVELOPES

ONE POSITION

2010+10/-20

BRAKE

PRESSURE

LINE RESTRICTION

(FIXED)

RESTRICTION

PRESSURE

COMPENSATION

LINE RESTRICTION

(VARIABLE)

SPRING

(ADJUSTABLE)

VARIABILITY

CONTROL VALVES

SPRING

FLUID CONDITIONER

800 +/- 10

DEG C

PUMP or MOTOR

The torque converter inlet relief valve and the lube

distribution manifold are both incorporated into one

housing (D). These two components are mounted to the

left front of the main case, near the bottom.

RPM

PTO SUMP

OIL TEMP

NON EU

BASIC COMPONENT SYMBOLS

MAIN AUX.

The torque converter charging section (F) of the power

train oil pump supplies approximately 145 L/min. (38.3 US

gal./min.) of oil to the torque converter circuit for operation

of the torque converter and for lubrication purposes.

BRAKES OFF

FLUID POWER SYMBOLS

The three-section gear-type power train oil pump (B) is

mounted to the front of the main case, at the upper right.

The electronic brake valve (C) is located on top of the main

case, to the left of center.

MACHINE CONDITION

KENR5125-02

December 2009

The screened main suction manifold (A) for the power train

oil pump is located at the right front of the main case, near

the bottom.

Transducer

(Gas / Air)

Generator

Electric Motor

12

CL4

CL5

CL3

CL2

CL1

Pressure Switch

(Adjustable)

Pressure Switch

Electrical Wire

Temperature Switch

15

Electrical Symbols (Electrical)

T

L1

Pressure

Symbol

CL4

Temperature

Symbol

ECPC XMSN

Clutch Valves

CL5

Level

Symbol

Wire Number Identification Codes

CL3

Electrical Schematic Example

Hydraulic Schematic Example

Opening the top door of the forward compartment on the right fender gains access to the combination power train oil fill tube and dipstick (Q).

CL2

Current Standard

Current Standard

11

LB2

AA

Opening the front door of the forward compartment on the right fender gains access to the power train oil filter (S). This spin-on type canister

contains a replaceable 6-micron filter element. The filter base contains a filter bypass switch (R). This is a normally open switch that is held closed

by the filter bypass valve spool. The bypass valve opens, allowing the switch to open, when the difference in pressure between the filter inlet and

the filter outlet becomes great enough (approximately 50 psi). The switch is monitored by the Caterpillar Monitoring System and alerts the operator

to the filter bypass condition.

Transmission Lube

Temperature Sensor

CL1

Transmission Housing

13 14

Harness identification code

This example indicates

wire 135 in harness "AG".

B1

5 13 14

AA

Located at the rear of the machine, on top of the the transmission case are the following service points:

Also located in the forward compartment on the right fender and inboard from the power train oil filter canister are the following service points:

1. Transmission main relief pressure test port (P)

2. Transmission lube pressure test port (L1)

3. Transmission lube temperature sensor

(T). remote power train breather

(M). remote pressure test port for torque converter inlet pressure

(N). remote pressure test port for torque converter outlet pressure

Wire Color

325-AG135 PK-14

325-PK

Circuit Identification

Number

Wire Color

Wire Gauge

Previous Standard

Wire Color

Wire

Pressure test ports for each of the five transmission clutches remain on the transmission cover. These pressure test ports

are:

(CL1). Transmission clutch (reverse clutch)

(CL2). Transmission clutch (forward clutch)

(CL3). Transmission clutch (speed 3)

(CL5). Transmission clutch (speed 1)

(CL4). Transmission clutch (speed 2)

Wire

Circuit Number

Identification

The filter base also contains the power train oil sampling (AA) and a pressure test port (BB) for the transmission charging circuit. The pressure test

port is situated downstream from the filter. The power train oil sampling port is situated upstream, or before the filter.

CL1 CL2 CL3

CL4 CL5 P

L1

Flow

Symbol

325-PK-14

Power Train Oil Filter Group 2

B

Circuit Number

Identification

Wire Gauge

(EXAMPLE VALVE)

Clutch engagement pressure calibrations are no longer required, with the common top pressure strategy. Proper

adjustment of the transmission main relief valve will set the proper pressure for the operation of all five transmission

clutches and the brakes. It is still necessary to perform transmission clutch fill calibrations and to perform brake touch-up

calibrations.

Engine Oil Cooler

The transmission charge circuit accumulator is mounted

beneath the fuel tank and located above the transmission

case.

This accumulator is pre-charged to approximately 1725

kPa (250 psi). It is used to help maintain transmission

charge circuit pressure for short periods of time, such as

when transmission clutches are filling (shifts) or at other

times when the pressure in the transmission charging

circuit may become too low (cold oil, low idle, etc.).

Power Train

Oil Cooler

11 10

LB1 LB2

12

7

CL4

CL5

CL3

Right Side

CL2

Transmission Charge

Circuit Accumulator

Left Side

ECPC XMSN

Clutch Valves

Below and to the rear of the engine

oil cooler is the oil-to-water type

power train oil cooler.

CL1

Component and Tap Locations

Transmission Group 9

Power Train Oil Cooler 7

(Dimensions: 34 inches x 28 inches)

Part

Number

24 Page,

Schematic

Location

KENR5125-02

No.

L1

LB1

CLUTCH/BRAKES

LEFT BRAKE

PRESSURE PORT

10

9

CL4

CL5

CL3

CL1

CL2

4

BRAKE

LUBE

E

FLYWHEEL

HOUSING

L2

M

XMSN LUBE

TEMP - ECM

XMSN LUBE

MAIN

RELIEF

ENGINE

IMPLEMENT

PUMP

2ND

3RD

1ST

CL4

CL3

CL5

EB BRAKE VALVE

B1

ECPC XMSN

CLUTCH VALVES

PROPORTIONAL

VALVE

PROPORTIONAL

VALVE

D

DIFF STEER

BEVEL & TRANSFER

GEAR LUBE

P

PROPORTIONAL

VALVE

N

3

PROPORTIONAL

VALVE

24 Page, Color 2,

KENR5125-02

(Dimensions: 34 inches x 28 inches)

C9

XL, XW, LGP 240 NET HP,

STD 185 NET

TORQUE

CONVERTER

PROPORTIONAL

VALVE

PROPORTIONAL

VALVE

VENT LINE

ACCUMULATOR

PART: 255-6934

CL2

CL1

FWD

REV

ER1

PTO TEMP.

SENSOR

SUCTION SCREEN

L1

TRANS. LUBE

TEMP. SENSOR

DRIVESHAFT

SCREEN

SCAV

SCAVENGE OUTPUT AND

DIFF STEER LUBE

TRANSMISSION

CONTROL VALVE

TRANS

T/C

C

12

A: Transmission and Converter Scavenge

B: Transnission Charge

C: Torque Coverter Charge

POWERTRAIN

OIL COOLER

B

LINE PATTERNS

Pressure Line

BRAKE

LUBE

MACHINE CONDITION

BRAKES OFF

BRAKES OFF

ACTUATING CONTROL:

11

RIGHT BRAKE

PRESSURE PORT

AA

LB2

CLUTCH/BRAKES

BB

NOTE

TEST LOCATION

ER1

P/T OIL TYPE

ENGINE

SPEED

TRANS. GEAR

UNITS

EU

BRAKES ON

FOOT CONTROL

PARKING

BRAKE

2010+10/-20

1920+10/- 20

1605 +/- 30

800 +/- 10

---

NEUTRAL

NEUTRAL

NEUTRAL

3F STALL

NEUTRAL

WT.

SAE 30

SAE 30

SAE 30

SAE 30

SAE 30

80 +/- 5

80 +/- 5

80 +/- 5

80 +/- 5

80 +/- 5

2350 +/- 140

2550 +/- 140

2550 +/- 140

<70

<70

2585 +/- 105

2760 +/- 140

2760 +/- 140

2690 +/- 140

2585 +/- 105

B1

BRAKE

PRESSURE

KPA

TRANS. MAIN

RELIEF

T/C SUPPLY

PRESSURE

KPA

KPA

380 +/- 70

655 +/- 70

655 +/- 70

515 +/- 70

T/C OUTLET

PRESSURE

KPA

380 +/- 70

515 +/- 70

515+/- 70

415 +/- 70

L2

FLYWHEEL LUBE

PRESSURE

KPA

205 +/- 70

310 +/- 105

310 +/- 105

L1

TRANS. LUBE

PRESSURE

KPA

24 +/- 14

170 +/- 35

170 +/- 35

105 +/- 35

LB1

L BRAKE LUBE

PRESSURE

KPA

18 +18/-17

90 +/- 35

90 +/- 35

55 +/- 35

LB2

R BRAKE LUBE

PRESSURE

KPA

18 +18/-17

90 +/- 35

90 +/- 35

55 +/- 35

CL1

TRANS. CLUTCH 1

PRESSURE

KPA

CL2

TRANS. CLUTCH 2

PRESSURE

KPA

CL3

TRANS. CLUTCH 3

PRESSURE

KPA

CL4

TRANS. CLUTCH 4

PRESSURE

KPA

CL5

TRANS. CLUTCH 5

PRESSURE

KPA

Note A:

Note B:

Note C:

Note D:

Drain / Return Lines

Component Group

Attachment

800 +/- 10

DEG C

Pilot / Load Sensing Pressure

XL, XW, LGP, STD

RPM

PTO SUMP

OIL TEMP

NON EU

BRAKES ON

Air Line

CALLOUTS

YY

Taps (Pressure, Sampling,Sensor) by letter

52

Components by number

SECTIONS:

(A) TRANSMISSION AND CONVERTER SCAVENGE PUMP

(B) TRANSMISSION CHARGE PUMP

(C) TORQUE CONVERTER CHARGE PUMP

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

Brakes.

Supply Line.

Drain / Return Line.

Transmission Charge Pump.

Transmission and Torqueconverter Scavenge Pump

Torque Converter Charge Pump and Powertrain Oil Cooler

All flows are at rated engine speed of 1850 RPM with the transmission in neutral. All leakages

are max.

Oil Cleanliness must meet ISO Spec 18/15 at ship. ISO typical after 100hrs=16/13. Oil samples

should be taken at Oil Sampling Port.

ECPC Clutch Engagement Pressure calibration is not required. Transmission clutches 1-4

operate at Transmission Main. Relief (P) pressure when engaged. Transmission clutch 5

operates at 2240205 KPA when engaged.

Breather is located on the right-hand fender and connected to the vent hose.

THIS SCHEMATIC IS FOR THE D6T TRACK-TYPE TRACTOR

PARTNUMBER: 304-8567, CHANGE 01,

Components are shown installed on a fully operable machine.

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations

Вам также может понравиться

- D 8 TДокумент2 страницыD 8 TAlberjose Sanchez RuizОценок пока нет

- U340 441E DescriptionДокумент25 страницU340 441E Descriptionjo_cfo257388% (17)

- Elliott Yr SpecificationsДокумент8 страницElliott Yr SpecificationsOscar Barajas BОценок пока нет

- Tractor d6mДокумент2 страницыTractor d6mAnonymous KOtSfT6q100% (1)

- Control Valve D8R..Документ2 страницыControl Valve D8R..SyahdiОценок пока нет

- Diagrama Hidraulico de Power Train d8t InteractivoДокумент14 страницDiagrama Hidraulico de Power Train d8t InteractivoVeimar Gutierrez100% (1)

- Test de Presiones de Transmision 938g2Документ12 страницTest de Presiones de Transmision 938g2cristian chuquicondor torres100% (2)

- CAT993K Steering SystemДокумент11 страницCAT993K Steering SystemRafael RodriguezОценок пока нет

- D PWT D6riii PDFДокумент2 страницыD PWT D6riii PDFDennis Olaya100% (1)

- Cat 12H Motor Grader: Standard TypeДокумент22 страницыCat 12H Motor Grader: Standard Typestopaferreira80% (5)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Документ17 страницInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768wong waras100% (1)

- Retroexcavadora 416D B2DДокумент4 страницыRetroexcavadora 416D B2Denrique_13_14100% (7)

- 950g Hyd SysДокумент2 страницы950g Hyd SysLuis Enrique100% (1)

- 1 Test 924G, 1 General InformationДокумент12 страниц1 Test 924G, 1 General Informationmijael1393100% (1)

- d6n Elec Chem PDFДокумент4 страницыd6n Elec Chem PDFTeresa Marina PeraltaОценок пока нет

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Документ7 страницInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Albert Gafarov100% (1)

- D5M PDFДокумент42 страницыD5M PDFjvc251100% (1)

- Sensor Signal (PWM) - Test: TroubleshootingДокумент6 страницSensor Signal (PWM) - Test: Troubleshootingronald0% (1)

- Hydraulic ExcavatorsДокумент28 страницHydraulic Excavatorsиван ТрояновОценок пока нет

- D8T HidraulicoДокумент2 страницыD8T HidraulicoCristian Huarachi100% (1)

- D6R Series III Track Type Tractor Power Train SystemДокумент2 страницыD6R Series III Track Type Tractor Power Train SystemIH Medrano78% (9)

- Guia de Fallas de Transmision 416eДокумент4 страницыGuia de Fallas de Transmision 416eJosé GonzalezОценок пока нет

- Plano d7r Eléctrico PDFДокумент21 страницаPlano d7r Eléctrico PDFHarol Ariel Sanchez Meza100% (2)

- Plano Hyd d8tДокумент2 страницыPlano Hyd d8tMilton Frank Bobadilla100% (1)

- Den-Jet Ce20-500 - Master Mariner Manual - Dec 2017Документ40 страницDen-Jet Ce20-500 - Master Mariner Manual - Dec 2017First LastОценок пока нет

- 938H CatalougeДокумент24 страницы938H Catalougemootaz_ahmed46450% (2)

- D10TДокумент2 страницыD10TjoseluisyalicoОценок пока нет

- 938F 7SN Wheel Loader and It38f Integrated Toolcarrier Power TrainДокумент23 страницы938F 7SN Wheel Loader and It38f Integrated Toolcarrier Power Trainale aleОценок пока нет

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Документ24 страницыInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Eckard GuendelОценок пока нет

- Skid Steer Loaders: 216B2, 226B2, 232B2, 236B2, 242B2, 252B2 Electrical System Multi Terrain Loaders: 247B2, 257B2Документ4 страницыSkid Steer Loaders: 216B2, 226B2, 232B2, 236B2, 242B2, 252B2 Electrical System Multi Terrain Loaders: 247B2, 257B2lucas solon de souza costa100% (1)

- 007 - Cat-6060 - Travel SystemДокумент47 страниц007 - Cat-6060 - Travel SystemJorby CuadrosОценок пока нет

- Transmision d6mДокумент8 страницTransmision d6mTeresa Marina Peralta100% (5)

- Water Distribution Network PDFДокумент45 страницWater Distribution Network PDFVisal ChengОценок пока нет

- UENR0233 - 416E Backhoe Loader Hydraulic and Steering SystemДокумент11 страницUENR0233 - 416E Backhoe Loader Hydraulic and Steering Systemsanach0412Оценок пока нет

- Modulating Valve (Transmission Clutch) 966Документ3 страницыModulating Valve (Transmission Clutch) 966Ahmed Rezk100% (1)

- D5M/D6M Track-Type Tract ORSДокумент34 страницыD5M/D6M Track-Type Tract ORSELELCTRICAR SASОценок пока нет

- Transmission Pressures - Test - 084203Документ5 страницTransmission Pressures - Test - 084203Juan Lopez100% (1)

- Trans. de 140hДокумент4 страницыTrans. de 140hvictor franco gallegos100% (1)

- 924F Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsДокумент2 страницы924F Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsguayanecitroОценок пока нет

- Differential Steering System : SMCS Code: 4005 4010Документ18 страницDifferential Steering System : SMCS Code: 4005 4010Balikpapan City75% (4)

- 120H Caf Caterpillar TestДокумент4 страницы120H Caf Caterpillar TestMiguel Angel Garrido Cardenas100% (2)

- FireDETEC - Installation Manual CO2 - DHP - en - 0213 eДокумент12 страницFireDETEC - Installation Manual CO2 - DHP - en - 0213 ebmxmmxОценок пока нет

- Shutdown SIS Previous ScreenДокумент4 страницыShutdown SIS Previous ScreenEmanuel alvarado lopezОценок пока нет

- Liquid Level Switches Asme B31.1 ConstructionДокумент36 страницLiquid Level Switches Asme B31.1 Constructionsamer8saifОценок пока нет

- Cat - Dcs.sis - Controllerloader 924ghДокумент15 страницCat - Dcs.sis - Controllerloader 924ghmahmod alrousanОценок пока нет

- 938G Test and AdjustДокумент7 страниц938G Test and AdjustAntonio Mejicanos100% (4)

- Motoniveladora 120H Motor GraderДокумент19 страницMotoniveladora 120H Motor GraderLuis Ernesto Quintero Llano100% (2)

- Cat 12MДокумент28 страницCat 12MLeandro Sal100% (1)

- SENR6982 - Systems Operation PDFДокумент14 страницSENR6982 - Systems Operation PDFmetanirvanaОценок пока нет

- Plano Electrico 950 CaterpillarДокумент12 страницPlano Electrico 950 CaterpillarJulio CR100% (1)

- 950F Prueba y Ajuste Transmision Sistema ElectricoДокумент38 страниц950F Prueba y Ajuste Transmision Sistema Electricoale aleОценок пока нет

- Planos Hidráulicos Moto Cat 140MДокумент4 страницыPlanos Hidráulicos Moto Cat 140Mjuafe100% (2)

- Transmissao (Teste e Ajuste) - 120k CaterpillarДокумент7 страницTransmissao (Teste e Ajuste) - 120k CaterpillarKevin Lucas100% (1)

- Brall 2007Документ6 страницBrall 2007ronaldОценок пока нет

- PGS-29 - Directive Above-Ground Storage of Flammable Liquids in Vertical Cylindrical TanksДокумент81 страницаPGS-29 - Directive Above-Ground Storage of Flammable Liquids in Vertical Cylindrical Tanksbldp03100% (2)

- Systems Operation: D6R Series II Track-Type Tractor Hydraulic SystemДокумент56 страницSystems Operation: D6R Series II Track-Type Tractor Hydraulic SystemDe Javu100% (1)

- Track-Type Tractor: XL & LGPДокумент20 страницTrack-Type Tractor: XL & LGPRoussel Florez Zuloaga100% (3)

- Caterpillar Motoniveladora ManualДокумент102 страницыCaterpillar Motoniveladora ManualAndres Jarrin100% (3)

- 140H Cambios de MarchasДокумент12 страниц140H Cambios de MarchasJose Jaramillo100% (2)

- d6t Track-Type Tractor STD, XL Differential Steering Gct00001-Up (Machine) Powered by c9 Engine (Sebp4963 - 45) - Armação Dos Roletes Da EsteiraДокумент3 страницыd6t Track-Type Tractor STD, XL Differential Steering Gct00001-Up (Machine) Powered by c9 Engine (Sebp4963 - 45) - Armação Dos Roletes Da EsteiraDouglas FernandesОценок пока нет

- Esquema Electrico 324 DFMДокумент28 страницEsquema Electrico 324 DFMHeidi Cuevas Venegas100% (1)

- 120h PDFДокумент20 страниц120h PDFm.fadhlyaugustami fadhlyОценок пока нет

- Dokumen - Tips Using The 1u5470 Engine Pressure GroupДокумент11 страницDokumen - Tips Using The 1u5470 Engine Pressure Grouppedro sosaОценок пока нет

- Diagnostic Code List (Codigos de Averias) Caterpillar 938G IIДокумент4 страницыDiagnostic Code List (Codigos de Averias) Caterpillar 938G IIRolando Mancilla Flores50% (2)

- Valvula Relief Pruebas y Ajustes 325blДокумент9 страницValvula Relief Pruebas y Ajustes 325blcristian chuquicondor torresОценок пока нет

- Install A Plug at The Opening of Connector (D) To Prevent Pressure Leakage DuringДокумент2 страницыInstall A Plug at The Opening of Connector (D) To Prevent Pressure Leakage DuringalexanderОценок пока нет

- RENR8305RENR8305-04 - SIS 777f 1Документ4 страницыRENR8305RENR8305-04 - SIS 777f 1gadolineo100% (1)

- D10T Track-Type Tractor Power Train System: Rjg1-UpДокумент2 страницыD10T Track-Type Tractor Power Train System: Rjg1-UpJHOSMAR_22Оценок пока нет

- Diagrama Hidraulico 777FДокумент4 страницыDiagrama Hidraulico 777Ffabioalbor100% (1)

- Future Tense With "Going To" - What Is Sara Going To Do?Документ5 страницFuture Tense With "Going To" - What Is Sara Going To Do?ronaldОценок пока нет

- Sensor Signal (Analog, Active) - Test: TroubleshootingДокумент11 страницSensor Signal (Analog, Active) - Test: TroubleshootingronaldОценок пока нет

- General: Crude Oil - 219 Crude Oil - 219 1.117 82.6Документ1 страницаGeneral: Crude Oil - 219 Crude Oil - 219 1.117 82.6amirОценок пока нет

- Rockshox Tuning Guide 2001-2012Документ13 страницRockshox Tuning Guide 2001-2012Bhavin MistryОценок пока нет

- Modelling of A Pressure RegulatorДокумент11 страницModelling of A Pressure RegulatorErick Renzo Hidalgo OrtegaОценок пока нет

- Rev.090903 B.403.101Документ1 страницаRev.090903 B.403.101matiasgtxОценок пока нет

- Ec 160 Service ManualДокумент32 страницыEc 160 Service ManualNatalia MontañaОценок пока нет

- GRACO King 45-1 PartsДокумент10 страницGRACO King 45-1 Partssamgivp2869Оценок пока нет

- Tanques Hidroneumaticos Prosource EspecificacionesДокумент3 страницыTanques Hidroneumaticos Prosource EspecificacionesEduSizaОценок пока нет

- Instruction Manual FisherДокумент20 страницInstruction Manual FisherPrado_MoisesОценок пока нет

- Exp#6 Head Loss Due To Pipe FittingДокумент4 страницыExp#6 Head Loss Due To Pipe FittingSurenderan Logan0% (1)

- S220-Rankine Cycle Steam TurbineДокумент2 страницыS220-Rankine Cycle Steam TurbineIlyas EloufiriОценок пока нет

- Ball Valve: Navigation SearchДокумент33 страницыBall Valve: Navigation Searchrameshrao_2929Оценок пока нет

- Valvula Compuerta F607RWSFPДокумент1 страницаValvula Compuerta F607RWSFPDonny Quispe SilvetsreОценок пока нет

- Venturi Medium Sized (VMS) : ApplicationДокумент8 страницVenturi Medium Sized (VMS) : ApplicationChn TutkunОценок пока нет

- MS15054 - 00e MtuДокумент177 страницMS15054 - 00e MtuGioeОценок пока нет

- Mechanical Technician: G.Pon VijayДокумент4 страницыMechanical Technician: G.Pon Vijayjohn MОценок пока нет

- Operation Manual FOR SKT140 Series of Pneumatic Hydraulic Test-BedДокумент12 страницOperation Manual FOR SKT140 Series of Pneumatic Hydraulic Test-BedAlex RamirezОценок пока нет

- LPG and Propane Pumps LPG & PROPANE Piping and AccessoriesДокумент7 страницLPG and Propane Pumps LPG & PROPANE Piping and AccessoriesOmar WardehОценок пока нет

- 5-1. Steering SystemДокумент58 страниц5-1. Steering SystemSaidi JalelОценок пока нет

- Explosion Proof ActuatorsДокумент76 страницExplosion Proof Actuatorsgigel1980Оценок пока нет

- Core BarrelsДокумент20 страницCore BarrelsEmerson PasquarelliОценок пока нет