Академический Документы

Профессиональный Документы

Культура Документы

Csa Hvteck Cable

Загружено:

rafa_4_everАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Csa Hvteck Cable

Загружено:

rafa_4_everАвторское право:

Доступные форматы

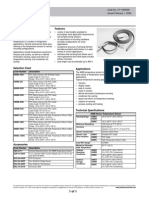

HVTECK SPECIFICATIONS

CSA HVTECK CU 3/C 90EPR TS PVC AIA PVC 5KV 100% 133%

PRODUCT HIGHLIGHTS

Southwire's 5kV HVTECK is a CSA approved armoured cable for Industrial and Commercial medium voltage applications. FT4, -40C, HL and 105C rated for use in harsh Canadian

environments. Rated for installation in cable trays, duct banks, direct burial, troughs, continuous rigid cable supports, and concrete encaseable.

CONSTRUCTION

Conductor:

Class B stranded copper

- compressed or compact

- in accordance with ASTM B3 and ASTM B8

Optional Class B compact stranded 8000 Series Aluminum ACM

Conductor Shield:

Extruded Semi-conducting thermosetting polymeric layer

Phase identification as per ICEA Method 3, using printed

circuit numbers

Meets requirement of ICEA, but built to CSA standards

Copper Tape Shield:

Helically wrapped 5 mil copper tape with 25% overlap

Grounding Conductor:

Class B compressed or compact stranded bare copper

Insulation:

- in accordance with ASTM B3 and B8

No-Lead EPR (ethylene propylene rubber)

Insulation Level: 100% / 133% - ungrounded system

SOUTHWIRE [symbol - lightning bolt] #P# CSA 3/C

Inner Jacket:

Black PVC

Thickness:

- No. 2 AWG to No. 1/0 AWG = 0.080" (2.0 mm)

- No. 2/0 AWG to 500 kcmil = 0.110" (2.8 mm)

- 750 kcmil = 0.145" (3.7 mm)

105C rated

Insulation Shield:

Extruded Semi-conducting thermosetting polymeric layer

CSA 68.10 - Shield removal/termination requirements are

printed on the surface

Overall Jacket:

Orange PVC (optional colours available)

Thickness:

- No. 2 AWG to 500 kcmil = 0.075" (1.9 mm)

- 750 kcmil = 0.085" (2.2 mm)

Print Legend:

Fillers:

Non-wicking, non-hygroscopic

Thickness: 0.090" (2.3 mm) - nominal

Armour:

Aluminum Interlocked Armour (AIA)

Optional Galvanized Steel Interlocked Armour (GSIA)

[AWG 2 to 750 kcmil] CPT CU 90EPR AIA 5KV

100% / 133% INS LEVEL 25%TS, SUN RES 105C FT4 HL

LTGG [-40C] RoHS YEAR (NESC) SEQUENTIAL

METER MARKS

TABLE 1 - WEIGHTS & MEASUREMENTS

Diameter Over

Insulation

Diameter Over

Ground

Insulation Shield Wire Size

inches

0.49

0.53

0.57

0.62

0.67

0.72

0.78

0.88

1.01

1.20

inches

0.55

0.59

0.63

0.68

0.73

0.78

0.84

0.94

1.09

1.28

mm

12.4

13.5

14.5

15.6

16.9

18.3

19.8

22.4

25.7

30.4

mm

13.9

15.0

16.1

17.1

18.4

19.9

21.3

23.9

27.7

32.5

AWG

6

4

4

4

3

3

3

2

1

1/0

Inner Jacket

Diameter

inches

1.42

1.51

1.60

1.75

1.86

1.98

2.31

2.33

2.65

3.13

mm

36.0

38.5

40.6

44.5

47.3

50.4

58.5

59.1

67.3

79.4

Armour

Diameter

inches

1.73

1.81

1.95

2.10

2.21

2.33

2.46

2.68

3.00

3.48

mm

43.8

46.0

49.5

53.4

56.2

59.3

62.4

68.0

76.2

88.3

Approx. Overall

Diameter

inches

1.85

1.93

2.08

2.22

2.33

2.47

2.61

2.83

3.15

3.65

mm

46.9

49.1

52.8

56.5

59.3

62.8

66.2

71.8

80.0

92.6

Approx. Weight Max. Reel Weight

Max. Reel

of Cable

(reel and cable)**

Diameter**

lbs/

1000ft kg/km

lbs

kg

inches

m

1898

2825

9147

4149

108

2.74

2210

3288 10393 4714

108

2.74

2572

3828 11200 5080

108

2.74

3052

4542 12238 5551

108

2.74

3547

5278 13081 5933

108

2.74

4175

6214 11993 5440

108

2.74

4688

6977 13275 6022

108

2.74

5959

8869 16453 7463

108

2.74

7891 11744 13392 6074

108

2.74

11164 16615 15510 7035

108

2.74

NOTE: These are minimum dimensions as per CSA Standards.

* Other conductor sizes and outer jacket colours are available upon request. (#s in brackets represent # of strands / conductor)

** These are maximum reel sizes and cable lengths. Standard sizes and lengths will be supplied. Reel sizes are not guaranteed. The factory reserves the right to make changes as necessary to optimize manufacturing requirements.

2014 Southwire Company, LLC. All Rights Reserved.

Max. Reel

Width**

inches

70.5

70.5

70.5

70.5

70.5

70.5

70.5

70.5

70.5

70.5

m

1.79

1.79

1.79

1.79

1.79

1.79

1.79

1.79

1.79

1.79

Max. Length

of Cable on Reel**

feet

4000

4000

3750

3500

3250

2500

2500

2500

1500

1250

m

1219.2

1219.2

1143.0

1066.8

990.6

762.0

762.0

762.0

457.2

381.0

SPS_A70_INDUSTRIAL-E(14-04)

HVTECK

Product Code

CU305A70-002

CU305A70-001

CU305A70-010

CU305A70-020

CU305A70-030

CU305A70-040

CU305A70-250

CU305A70-350

CU305A70-500

CU305A70-750

Conductor

Conductor

Size*

Diameter

AWG

or Kcmil inches

mm

2 (7)

0.28

7.2

1 (19)

0.32

8.2

1/0 (19)

0.36

9.2

2/0 (19)

0.41

10.3

3/0 (19)

0.46

11.6

4/0 (19)

0.51

13.0

250 (37)

0.56

14.2

350 (37)

0.66

16.8

500 (37)

0.79

20.1

750 (61)

0.97

24.6

HVTECK SPECIFICATIONS

CSA HVTECK CU 3/C 90EPR TS PVC AIA PVC 5KV 100% 133%

DESIGN

Qualication Standards:

CSA C68.10 - Shielded Power Cables for Commercial and

Industrial Applications - 5 to 46 kV

CSA C68.3 - Shielded & Concentric Neutral Power Cable 5 to 46 kV

CSA C22.2 No. 174 - Cables in Hazardous Locations

ICEA S-93-639 (NEMA WC 74) 5 to 46 kV - Shielded Power Cable

AEIC CS-8 - Qualification Testing Requirements

Flame Test Ratings:

FT1 - Flame Test (1,706 BTU/Hr nominal - Vertical Wire

Flame Test)

FT4 - Flame Test (70,000 BTU/Hr - Vertical Tray Flame Test)

IEEE 1202 - Flame Test (70,000 BTU/Hr - Vertical Tray Test)

IEEE 383 - Flame Test (70,000 BTU/Hr)

ICEA T-29-520 - Vertical Cable Tray Flame Test (210,000 BTU/Hr)

Product Ratings:

CSA C22.2 No. 2556 & No. 0.3. - Wire and Cable Test Methods

CSA LTGG [-40C] - as per C68.10 - for Cold Bend and

Impact rating

CSA HL - for Hazardous Locations rating

CSA FT4 - for Flame Retardancy rating

CSA SUN RES - for Sunlight Resistant rating

COPPER CONDUCTOR

Operating Temperatures:

-40C - CSA Cold Bend and Impact Temperature

-25C - Min. Installation Temperature

105C - Max. Continuous Operating Temperature

140C for Emergency Overload Temperature

250C for Short Circuit Temperature

INSULATION

CONDUCTOR SHIELD

INSULATION SHIELD

COPPER TAPE SHIELD

GROUND CONDUCTOR

INNER PVC JACKET

FILLER

ALUMINUM INTERLOCK ARMOUR

End View

OVERALL PVC JACKET

Conductor

Size*

HVTECK

Product Code

CU305A70-002

CU305A70-001

CU305A70-010

CU305A70-020

CU305A70-030

CU305A70-040

CU305A70-250

CU305A70-350

CU305A70-500

CU305A70-750

AWG

or Kcmil

2 (7)

1 (19)

1/0 (19)

2/0 (19)

3/0 (19)

4/0 (19)

250 (37)

350 (37)

500 (37)

750 (61)

Minimum

Bend Radius

inches

12.9

13.5

14.6

15.6

16.3

17.3

18.2

19.8

22.1

25.5

mm

441

469

484

487

517

544

571

613

672

724

Maximum

Pulling Tension

AC Resistance Rac

DC Resistance Rdc Ratios @ 90C & 60Hz

@ 25C

(each conductor)

/

lbs Newtons 1000ft

1593

7084

0.1620

2009

8935

0.1290

2534 11274 0.1020

3194 14209 0.0810

4027 17914 0.0642

5078 22590 0.0510

6000 26689 0.0431

8400 37365 0.0308

12000 53379 0.0216

18000 80068 0.0144

/

km

0.5315

0.4232

0.3347

0.2658

0.2106

0.1673

0.1414

0.1011

0.0709

0.0472

/

1000ft

0.2180

0.1730

0.1340

0.1070

0.0850

0.0680

0.0570

0.0410

0.0290

0.0200

/

km

0.7153

0.5676

0.4397

0.3511

0.2789

0.2231

0.1870

0.1345

0.0951

0.0656

* Other conductor sizes and outer jacket colours are available upon request. (#s in brackets represent # of strands / conductor)

Ampacities are based on Table 2 of the 2012 Canadian Electrical Code Part I (30C Ambient Temperature)

Ampacities are based on Table D12A and Detail 1 of Diagram B4-3 of the 2012 Canadian Electrical Code Part I

2014 Southwire Company, LLC. All Rights Reserved.

Inductance

L

mH/

1000ft

0.0920

0.0882

0.0855

0.0830

0.0807

0.0785

0.0778

0.0751

0.0725

0.0706

mH/

km

0.3018

0.2893

0.2804

0.2724

0.2647

0.2576

0.2554

0.2463

0.2380

0.2315

Capacitance (each

phase conductor)

C

F/

1000ft

0.0871

0.0979

0.1074

0.1176

0.1297

0.1430

0.1479

0.1711

0.2000

0.2305

F/

km

0.2858

0.3212

0.3525

0.3860

0.4257

0.4692

0.4852

0.5613

0.6564

0.7564

Inductive Reactance Capacitive Reactance Short Circuit

(each phase

(each phase

Current (each

conductor)

conductor)

conductor)

XL

XC

@60Hz

/

1000ft

0.0347

0.0332

0.0322

0.0313

0.0304

0.0296

0.0293

0.0283

0.0273

0.0266

/

km

0.114

0.109

0.106

0.103

0.100

0.097

0.096

0.093

0.090

0.087

M

1000ft

0.0305

0.0271

0.0247

0.0225

0.0204

0.0186

0.0179

0.0155

0.0133

0.0115

M

km

0.0999

0.0889

0.0810

0.0740

0.0671

0.0609

0.0589

0.0509

0.0435

0.0378

kAmps

5

6

7

10

13

14

17

25

35

51

Allowable

Ampacities in

Raceway or

Cable

Allowable

Ampacities

Directly Buried

in Earth

Amps

130

145

170

195

225

260

290

350

430

535

Amps

~

~

243

274

311

360

383

470

548

667

SPS_A70_INDUSTRIAL-E(14-04)

SLS_15KV PRIMARY

UD_ENERGY-E(12-09)

TABLE 2 - ENGINEERING SPECIFICATIONS

Вам также может понравиться

- Epr 25KV 133%Документ2 страницыEpr 25KV 133%ssimental710% (1)

- EPR 5KV 100% y 133%Документ2 страницыEPR 5KV 100% y 133%ssimental71Оценок пока нет

- 2000V EPR Mining CableДокумент1 страница2000V EPR Mining CableJulio MontalvoОценок пока нет

- Unishield - Uniblend 5kvДокумент2 страницыUnishield - Uniblend 5kvfmillan5018Оценок пока нет

- CIR CatalogДокумент12 страницCIR Catalogchaupha1Оценок пока нет

- Energy Cable Accessories Epp1984 EngДокумент156 страницEnergy Cable Accessories Epp1984 EngSathiyanathan ManiОценок пока нет

- Spec 46311Документ2 страницыSpec 46311DI Vlad Peña PrietoОценок пока нет

- 15kv Phelps DodgeДокумент4 страницы15kv Phelps DodgeJuan E Torres M100% (1)

- 33kV ABC Technical SpecificationДокумент7 страниц33kV ABC Technical SpecificationBijuОценок пока нет

- Control Bus CablesДокумент2 страницыControl Bus CablesVeronica Jeldes PonceОценок пока нет

- XLPE/XL-CPE, Instrumentation, Shielded 300 V, UL Type PLTC, Overall Shielded Pairs/TriadsДокумент1 страницаXLPE/XL-CPE, Instrumentation, Shielded 300 V, UL Type PLTC, Overall Shielded Pairs/TriadsRey AbarientosОценок пока нет

- Bussman Fuse HoldersДокумент12 страницBussman Fuse HoldersH33DОценок пока нет

- En Erg ExДокумент16 страницEn Erg ExAhmed H. HassanОценок пока нет

- High Voltage 2xs FL 2y A2xs FL 2y 110kv Power Cable 1Документ3 страницыHigh Voltage 2xs FL 2y A2xs FL 2y 110kv Power Cable 1SanalicaОценок пока нет

- Fire Resistant CableДокумент2 страницыFire Resistant Cablemetal_dung2Оценок пока нет

- B Span 330m Silec Technical Offer Ref 5890636827terДокумент9 страницB Span 330m Silec Technical Offer Ref 5890636827terUdriste DanielОценок пока нет

- Qse 93af600 DataДокумент9 страницQse 93af600 DataPutraAdityaОценок пока нет

- FIER RESISTANT 2-Hour Fire Rated Cables PDFДокумент4 страницыFIER RESISTANT 2-Hour Fire Rated Cables PDFJairo WilchesОценок пока нет

- Our Mission: The Coax LeaderДокумент3 страницыOur Mission: The Coax LeaderArindam BanerjeeОценок пока нет

- DF PDFДокумент8 страницDF PDFAtif JaveadОценок пока нет

- Type ST-C Cables: DescriptionДокумент51 страницаType ST-C Cables: DescriptiongilmarquijanoОценок пока нет

- A Span 200mtechnical Offer Ref 65285 200m Tub MeplДокумент10 страницA Span 200mtechnical Offer Ref 65285 200m Tub MeplUdriste DanielОценок пока нет

- Calculation Notes HV & MV CablesДокумент49 страницCalculation Notes HV & MV Cablesharrysaputra24Оценок пока нет

- Single Conductor 15KV, Shielded, MV-105Документ2 страницыSingle Conductor 15KV, Shielded, MV-105henry hernandezОценок пока нет

- Thermocouple Extension Cable: Application StandardsДокумент2 страницыThermocouple Extension Cable: Application StandardsTahir KhanОценок пока нет

- 2.4 KV GENERAL CABLE PDFДокумент2 страницы2.4 KV GENERAL CABLE PDFjhernandezelОценок пока нет

- MS 02 316Документ12 страницMS 02 316gazwang478Оценок пока нет

- ZX0 Gas-Insulated Medium Voltage SwitchgearДокумент9 страницZX0 Gas-Insulated Medium Voltage SwitchgearSai KiranОценок пока нет

- B.04. Cable XHHW-2 - General CableДокумент1 страницаB.04. Cable XHHW-2 - General CableBenjamín Benzaquen SalazarОценок пока нет

- Cleat WiringДокумент8 страницCleat WiringHaseeb NawazОценок пока нет

- Cabaccat2012k RITZДокумент28 страницCabaccat2012k RITZKosong SudahanОценок пока нет

- High Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YДокумент3 страницыHigh Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YNeven Ahmed HassanОценок пока нет

- Cables Catalogue 2Документ6 страницCables Catalogue 2fikih padliОценок пока нет

- A99bb-200c Sensor de TemperaturaДокумент1 страницаA99bb-200c Sensor de TemperaturanilopmОценок пока нет

- 3c Cu Xlpe PVC 12.7 (22) KV Heavy Duty Cws ArmouredДокумент2 страницы3c Cu Xlpe PVC 12.7 (22) KV Heavy Duty Cws Armouredgari_monsantoОценок пока нет

- Miniature Circuit Breakers-ABLДокумент21 страницаMiniature Circuit Breakers-ABLrasheed313Оценок пока нет

- Cable Selection Guide Gtc020212Документ4 страницыCable Selection Guide Gtc020212MEGA_ONEОценок пока нет

- CABLE GLANDS HAZARDOUS AREA FLAMEPROOF EXD INCREASED SAFETY EXEДокумент1 страницаCABLE GLANDS HAZARDOUS AREA FLAMEPROOF EXD INCREASED SAFETY EXEschmal1975Оценок пока нет

- E 2209 AcdcДокумент2 страницыE 2209 AcdcLuis Alejandro Gonzalez SantanaОценок пока нет

- En PyrotenaxSystem2000 DS H57049 Tcm432 26219Документ5 страницEn PyrotenaxSystem2000 DS H57049 Tcm432 26219thanna9783Оценок пока нет

- Raychem Spec 44Документ8 страницRaychem Spec 44zakariiОценок пока нет

- Simotec Langstab EngДокумент8 страницSimotec Langstab EngHillary Mcgowan0% (1)

- 3c Cu Xlpe PVC 3.8 (6.6) KV Light Duty CwsДокумент2 страницы3c Cu Xlpe PVC 3.8 (6.6) KV Light Duty Cwsgari_monsantoОценок пока нет

- Heavy Duty Power Cable for Distribution and TransmissionДокумент5 страницHeavy Duty Power Cable for Distribution and TransmissionSemar AngОценок пока нет

- Canalis KTA Characteristics GuideДокумент32 страницыCanalis KTA Characteristics Guideodin_auerОценок пока нет

- ASTM Conductor Spec SheetsДокумент27 страницASTM Conductor Spec Sheetsjavad4531Оценок пока нет

- Xlpe PVC 600v Sere3bfДокумент2 страницыXlpe PVC 600v Sere3bfFernando LoteroОценок пока нет

- NYBYДокумент5 страницNYBYEnnoAjeyОценок пока нет

- Cable Technical SpecificationДокумент66 страницCable Technical SpecificationKurama_MinatoОценок пока нет

- Data Sheet Kabel NA2XSEYДокумент5 страницData Sheet Kabel NA2XSEYGansar KharismawanОценок пока нет

- KAT0130-0004-E Cables For Reeling SystemsДокумент76 страницKAT0130-0004-E Cables For Reeling Systemsfranklinr68Оценок пока нет

- XLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeДокумент1 страницаXLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeLEMAGA GROUPОценок пока нет

- Medium-Extra High Voltage Power CablesДокумент56 страницMedium-Extra High Voltage Power CablesApichartj Jusuay100% (2)

- LG Bus Duct System Guide - Leader in Electrics & AutomationДокумент51 страницаLG Bus Duct System Guide - Leader in Electrics & AutomationRajneesh KatochОценок пока нет

- Tests According To IEC-En Standards (WAGO)Документ11 страницTests According To IEC-En Standards (WAGO)va3ttnОценок пока нет

- BS7870-4.10 33kv Single Core Un ArmouredДокумент3 страницыBS7870-4.10 33kv Single Core Un Armouredrudypl100% (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Forklift Truck Risk AssessmentДокумент2 страницыForklift Truck Risk AssessmentAshis Das100% (1)

- Palm Wine SpecificationДокумент10 страницPalm Wine SpecificationUday ChaudhariОценок пока нет

- Bill No. 1 - General Items PreliminariesДокумент24 страницыBill No. 1 - General Items PreliminariesNorazreen NorAzharОценок пока нет

- GSM Modernization Poster2Документ1 страницаGSM Modernization Poster2leonardomarinОценок пока нет

- Qand AДокумент5 страницQand AJoshua PascasioОценок пока нет

- Electrical Units of MeasureДокумент36 страницElectrical Units of MeasureHyung BaeОценок пока нет

- GT ĐỀ 04Документ39 страницGT ĐỀ 04Cao Đức HuyОценок пока нет

- BMW Mini COoper Installation InstructionsДокумент1 страницаBMW Mini COoper Installation InstructionsEdiJonОценок пока нет

- Speech for pecha kuchaДокумент6 страницSpeech for pecha kuchaaira mikaela ruazolОценок пока нет

- NASA Technical Mem Randum: E-Flutter N78Документ17 страницNASA Technical Mem Randum: E-Flutter N78gfsdg dfgОценок пока нет

- 2 - Alaska - WorksheetsДокумент7 страниц2 - Alaska - WorksheetsTamni MajmuniОценок пока нет

- LogiquidsДокумент2 страницыLogiquidsAloma FonsecaОценок пока нет

- IITG MA101 Endsem Question PaperДокумент12 страницIITG MA101 Endsem Question PaperNarravula Harshavardhan100% (2)

- Kingspan Spectrum™: Premium Organic Coating SystemДокумент4 страницыKingspan Spectrum™: Premium Organic Coating SystemNikolaОценок пока нет

- Flame Configurations in A Lean Premixed Dump Combustor With An Annular Swirling FlowДокумент8 страницFlame Configurations in A Lean Premixed Dump Combustor With An Annular Swirling Flowعبدالله عبدالعاطيОценок пока нет

- Three Bucket Method & Food ServiceДокумент4 страницыThree Bucket Method & Food Servicerose zandrea demasisОценок пока нет

- Ch3 XII SolutionsДокумент12 страницCh3 XII SolutionsSaish NaikОценок пока нет

- LIST Real Estate Contacts ListДокумент4 страницыLIST Real Estate Contacts ListChauhan Harshit100% (1)

- Understanding Earth's History Through Rock CharacteristicsДокумент1 страницаUnderstanding Earth's History Through Rock CharacteristicsSharmaine AcОценок пока нет

- Ninoy Aquino Parks and Wildlife CenterДокумент7 страницNinoy Aquino Parks and Wildlife CenterNinia Richelle Angela AgaОценок пока нет

- News Writing April 2019Документ39 страницNews Writing April 2019Primrose EmeryОценок пока нет

- 2021 - Tet Purchase Behavior Report - INFOCUSДокумент15 страниц2021 - Tet Purchase Behavior Report - INFOCUSGame AccountОценок пока нет

- National Gypsum Purple Book Fire Rated Assemblies in Commercial Construction 1189979Документ106 страницNational Gypsum Purple Book Fire Rated Assemblies in Commercial Construction 1189979alvychuОценок пока нет

- Thank You For Taking The Week 3: Assignment 3. Week 3: Assignment 3Документ3 страницыThank You For Taking The Week 3: Assignment 3. Week 3: Assignment 3DhivyaОценок пока нет

- Enviroclean 25 LTRДокумент1 страницаEnviroclean 25 LTRMaziyarОценок пока нет

- Earth and Life Science DLLДокумент6 страницEarth and Life Science DLLGsoon Sibulan100% (3)

- Weber Grills - FinalДокумент12 страницWeber Grills - FinalDIVYANSHU SHEKHARОценок пока нет

- BELL B40C - 872071-01 Section 2 EngineДокумент38 страницBELL B40C - 872071-01 Section 2 EngineALI AKBAR100% (1)

- NarendraVani KallubaluVKV 2010-11Документ144 страницыNarendraVani KallubaluVKV 2010-11Vivekananda Kendra100% (1)

- Instruction Manual: E2M40 and E2M80 Rotary Vacuum PumpsДокумент46 страницInstruction Manual: E2M40 and E2M80 Rotary Vacuum PumpsVicki NugrohoОценок пока нет