Академический Документы

Профессиональный Документы

Культура Документы

1502 HOBAS PipeLine Railway Jacking

Загружено:

baby_osianaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1502 HOBAS PipeLine Railway Jacking

Загружено:

baby_osianaАвторское право:

Доступные форматы

Issue 2/2015

PipeLine

h Railway Jacking

1 | h CC-GRP Culverts DN 3000 Jacked Under Railway, Cikowice, PL

3 | h Jacking Pipes Installed under a Railroad, Ettelbruck, LU

4 | h Jacking Pipes Premiere in Hong Kong

5 | h Pipes Jacked at Port Cape Lambert, AUS

6 | XXL h GRP Jacking Pipes replace Concrete Railway Culvert, PL

7 | Interview with Kimberly Paggioli h GRP Pipe: Jack Of All Trains

8 | Trenchless Project on the Rails with h GRP Pipes, Budapest, HU

8 | Auger Boring Small Diameter h GRP Pipe Beneath Dutch Railway, NL

9 | Croatias Most Challenging Project Realized with h Pipes

10 | Russian Railways Authorize h Products

11 | h GRP Jacking Pipes Under Railway Track in Tinec, CZ

12 | Polish Railway Project on the Fast Track with h, Chiechanw, PL

h CC-GRP Culverts DN 3000

Jacked Under Railway

When a pipeline route crosses a railway embankment, jacking is usually the optimal installation method as it does not require disruptions in

rail traffic. In the village of Cikowice in Southern

Poland, four culverts with a diameter of 3000

mm and a length of 34 m each have been jacked

under a railway line for the sake of flood control.

HOBAS Poland supplied the required GRP pipes

for this challenging project.

In 2010, the Raba River overflowed its banks

and flooded Cikowice and its neighbouring villages. Unfortunately, Cikowice is bordered by a

railway embankment to the north, which acted

as a dam, causing an additional accumulation of

water. The water level on the village side was

almost a meter higher than that on the opposite

side, an area consisting largely of meadows.

In order to prevent such incidents in the future

and enable the outflow of excessive water, a

flood prevention project was initiated in 2014.

It was realized in the context of the modernisation of the railway line E30/C-E 30 and involved

the construction of four large culverts beneath

the railway embankment. If the water level rose

again, the culverts should allow for the water to

pass freely to the other side.

E Engineering GmbH | Pischeldorfer Str. 128 | 9020 Klagenfurt | Austria

T +43.463.48 24 24 | F +43.463.48 21 21 | info@hobas.com | www.hobas.com

h PipeLine | Issue 2/2015 | Page 02

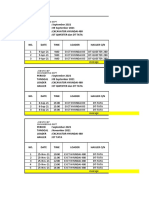

Year of construction

2014

Construction time

2 months

Total length of pipeline

136 m in total,

4 parallel lines of

34 m each

HOBAS Poland supplied the required pipes with an external diameter of 3000 mm for the

realization of the culverts. The pipes smooth inner surface ensures that flood water which

flows through them and usually contains various impurities does not lead to siltation.

HOBAS Pipes also made it much easier to resume jacking works after an installation

interruption due to heavy rain: The water causes the sandy soil to become slightly

compacted and adhesive, and the thrust force required to restart works after the interruption is usually quite high. Thanks to the smooth outer surface, the necessary

forces would be comparably lower and a restart quite easy.

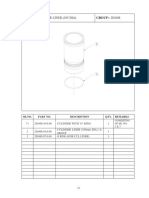

Diameter

De 3000

Pressure class

PN 1

Stiffness class

SN 40000, SN 64000

Application

Culvert beneath railway

for flood protection

Installation method

Trenchless installation /

pipe jacking

Before the start of the jacking works, the rail tracks were equipped with special

beams that transferred the load from the trains evenly to the rails in case of any

ground movements. The structure of the pipes, on the other hand, was strong

enough that even in the course of their installation the vibration induced by

passing trains was not felt inside. The jacking machinery was secured against

sliding on the sandy and slippery soil and positioned in a way to install the

pipes with a slight slope, so that the water would eventually flow in the right

direction. Once a culvert had been jacked through the embankment, its ends

were specially prepared: One side was bevelled from the top, while on the

uninhabited side of the embankment the culverts were equipped with special

flaps, which prevent the backflow of water to the village.

Client

PKP (Polskie Linie

Kolejowe) S.A.

The construction of culverts in Cikowice took around two months. The project is

in successful operation and the client satisfied with the HOBAS Solution.

(Polish rail infrastructure

company)

Contractor / Subcontractors

Intercor / PROI, PROI2

Advantages

Smooth inner and outer

wall surface, high

structural strength

Fmd: hobas.poland@hobas.com

h PipeLine | Issue 2/2015 | Page 03

On the Right Track with h

h Jacking Pipes Installed

under a Railroad, LU

Installing pipelines that run under railroad lines is always a difficult undertaking. While you can usually close roads for limited periods and divert

traffic, when it comes to trains construction poses far greater problems.

This is why engineers tend to opt for trenchless technology, particularly

in railroad projects. An added bonus is that very long pipelines can also be

jacked without visible construction sites at the surface.

Year of construction

2009

Construction time

3 days

Total length of pipeline

40 m

Diameter

Not only the installation method but also material selection calls for careful consideration. Electric rail systems create electromagnetic fields during

operation, which can lead to corrosion in materials such as steel or cast

iron. In addition, leakage current could flow to the metal components in

the pipes. Risks that have to be avoided at all costs.

De 1720

Wall Thickness 68 mm

Stiffness class

SN 64000

Application

Protection Pipe

A new pipeline running under railroad tracks was planned in Ettelbruck

in Luxembourg. Various networks were then to be installed in the pipeline. The planners initially selected a protective concrete pipe but soon

changed their minds when they heard about the unbeatable benefits

of HOBAS Jacking Pipes. Built up layer by layer, the GRP pipes do not

contain any metal components and are both corrosion resistant and nonconducting. Leakage current does therefore not affect HOBAS Pipelines.

Client

SIDEN

Contractors

Kuhn, K-Boringen

Special Features

Jacking under a railroad

line, fast installation,

low weight, small out-

In February 2009, HOBAS Pipes (De 1720) were jacked under the railroad

at a depth of 3 m. After installation, the pipeline was filled with a

25 cm thick layer of concrete to facilitate future maintenance work on the third party lines inside it. Once

construction had been completed, the client and

contractor alike were impressed by the rapid

installation rate and very pleased with the

pipes low weight and small outside

diameter, which meant that the jacking pits were much smaller than

anticipated. Quality from HOBAS

solutions for all situations!

Fmd:

hobas.france@hobas.com

side diameter

h PipeLine | Issue 2/2015 | Page 04

h Jacking Pipes Premiere in Hong

Kong Trenchless Installation of Protection

Pipes beneath Rail Tracks

Year of construction

2013

In December 2013, HOBAS Pipes De 1026 SN 320000 were jacked in the Chinese metropolis

Hong Kong underneath a railway track as protection for power lines.

Construction time

6 nights / 15 hours

Diameter

De 1026

Pressure class

PN 1

Stiffness class

SN 320000

Application

Protection pipes for

power lines

Client

MTR Corporation

Limited

Planner

Hong Kongs Mass Transit Railway (MTR) includes more than 200 km of rail. With an

average of 2.45 million passengers per day, it is one of the worlds most profitable rapid

transit railway systems. Its operating company, the MTR Corporation, is currently extending the network in the vicinity of Hung Hom railway station in the urban area

of Kowloon. Since the space around the existing rail track was very limited, the

construction company had to remove parts of the adjacent slope over a length of

400 m and relocate the existing power transmission lines. With the new planned

route crossing beneath the double-track, the project managers sought for the least

invasive and most sustainable solution. They found what they were looking for

in HOBAS Pipe Systems: HOBAS CC-GRP Pipes with an outer diameter of

De 1026 mm and a stiffness class of SN 320000 were jacked over a length of

12 meters in 2.3 m depth beneath the double-track as protection pipes for the

power lines. Thanks to the non-conductive material and high load capacity,

HOBAS Pipes are ideally suited for the given conditions.

Ove Arup & Partners

Hong Kong Limited

Constructor

Gammon Kaden SCL

1111 Joint Venture

Jacking Contractor

Victory Trenchless

Engineering Company

Limited

Advantages

The installation was challenging in several respects. Due to the limited working

space on the tracks ballast bed, the starting pit had to be kept quite narrow

(4 x 4.5 m) and the pipes could not be stored on site but had to be rolled to the

jacking pit one after the other on temporary tracks over 50 m distance. As the

railway track is in operation 19 hours a day from 5:30 to 00:30 a.m., the client allowed the jacking works to be conducted at nighttime between 1:30 and 4:00 a.m.

only. The contractor had to work very efficiently to achieve each nights installation

goal within these 2.5 hours. With their smooth outer surface and quick and easy

coupling system, HOBAS Pipes increased the installation efficiency significantly.

Non-conductive

features, high load

capacity, smooth outer

surface, easy coupling

system

Due to the restricted space on the other side of the

tracks, it was not possible to build a receiving pit.

Instead, the boring head was partly dismantled

inside the pipe after the installation and

withdrawn through the starting pit. After

6 nights and a jacking time of 15 hours,

the installation was successfully

completed.

Fmd: hobas.hongkong@hobas.com

h PipeLine | Issue 2/2015 | Page 05

h Jacking Pipes Down Under

h GRP Pipes Jacked at Port

Cape Lambert, AUS

The Pilbara Region in north-western Australia was first inhabited by the ancestors of todays Aboriginal people some 50,000 years ago. Since 2012, HOBAS Jacking Pipes De 2250 are playing an

important role as stormwater drainage lines for the emerging mining industry.

Year of construction

2012

Construction time

6 months

In the 1950s, it was discovered that the Pilbara area is home to one of the worlds largest iron ore

deposits. Since then it has been an integral contributor to the Australian economy with the help of

mining companies such as Rio Tinto. With most of the ore being exported today, a rail infrastructure and large ports have been built to accommodate the ore transportation. One of the largest

of these ports is Rio Tintos Cape Lambert. Trains travel in from Rio Tinto mines throughout the

region, carrying around 80 million tonnes of iron ore per year into Cape Lambert for processing

and ship loading.

Total length of pipeline

308 m

Pipe specifications

De 2250, PN 1, SN 32000

Client

Rio Tinto

Designer

Sinclair Knight Mertz

Cape Lambert is currently undergoing an upgrade, which will see its capacity more than double

by mid 2015. At the projects completion, an estimated 200 million tonnes of iron ore will be

exported per year from this port. An integral part of the upgrade project was the extension of

the Sams Creek drainage lines, which run under the existing rail lines allowing the release of

stormwater during the wet season. The rail lines needed to stay in constant operation throughout

the construction works in order to ensure the continual loading of ships. Stopping the productivity

was not an option, making trenchless installation the only choice.

The designer of the new drainage culvert Sinclair Knight Merz planned two rows of

2100 mm internal diameter pipes with approximately 100 meters length each.

HOBAS Jacking Pipes with an outside diameter of 2250 mm and a stiffness

of SN 32000 were specified for this purpose. With the soil being hard and

rocky, the initially calculated jacking force added up to 7850 kN. Thanks

to the smooth outer surface of HOBAS Jacking Pipes, the actually applied jacking forces were much lower than expected. The substantially

smaller outside diameter as compared to an alternative concrete

pipe had the additional benefit of allowing increased ground cover

beneath the rail line, reducing both risk and installation time. Furthermore, the lead-time for HOBAS was substantially shorter than that

of locally supplied concrete pipe, and given the tight timeframe for

the project, HOBAS proved to be the best solution.

The installation set a new record in terms of the largest diameter

HOBAS Jacking Pipe ever installed in Australia, and it paved the way for

similar projects in the ever-growing mining industry in Australia. The Rio

Tinto drainage system was also used as an opportunity for creating cultural

awareness: Local artists were invited to paint the HOBAS Pipes in the artistic

style of the traditional landowners. The imagery is supposed to bring good fortune to the land and HOBAS Pipes have become truly part of the local landscape.

Fmd: andy.holman@globalpipe.com.au

Contractor

NRW, Tunnel Boring

Australia

Advantages

Low jacking forces,

small inner/outer

diameter ratio

h PipeLine | Issue 2/2015 | Page 06

XXL h GRP Jacking Pipes replace

Concrete Railway Culvert

h Pipes De 3600 Jacked Beneath

Rails in Gdask, PL

Year of construction

2013

Construction time

2 months

Since the concrete culvert crossing beneath the railway line E65 Warsaw - Gdynia in the polish

city Gdask could no longer handle high water levels from the nearby stream, it was decided to

replace it. For this purpose, HOBAS Pipes with an external diameter of 3600 mm were jacked

beneath the railway embankment.

Diameter

De 3600

Pressure class

PN 1

Stiffness class

SN 40000

Application

Railway Culvert

Client

The 2 x 1.2 m concrete culvert could no longer handle the nearby Krlewski streams

elevated water levels during periods of heavy rain, which occasionally flooded the surrounding area. There was no doubt it had to be replaced. The first respective plan involved

two parallel 2 x 2 m square concrete culverts, laid in open trench. It soon became clear

however that the design was unsuitable for the given circumstances and that a different

approach was necessary. In 2013, a new rehabilitation project was initiated that involved

the construction of a single circular. It was decided to install the new culvert by means

of jacking and to use HOBAS GRP Pipes with a diameter of De 3600 for this purpose.

PKP Polskie Linie

Kolejowe

Contractor

Przedsibiorstwo Usug

Technicznych (PUT)

INTERCOR, PROI2

Advantages

No interruptions of the

The jacking works were carried out using a set of hydraulic jacks and a cutter head that

was specially designed for the project. Where the routes of the old and the new pipeline

intersected, the old culvert was demolished and removed. At the end of the installation

process, the annular space between the old and new structure was grouted with cement.

For safety reasons, the rail tracks had to be equipped with beams. In the case of any

ground movements caused by the jacking process, these beams would transfer the load

from the trains evenly to the rails.

rail traffic, non-conductive and highly durable

pipe material

The E65 is a main-line railway with trains passing every 3 minutes. Although the trains speed

was reduced to 30 km/h in this section because of the construction works, the trains could stay

in operation without interruptions thanks to trenchless installation. The contractors, PUT INTERCOR from Zawiercie and PROI2 from Katowice were highly satisfied with the

project result they have already installed HOBAS Pipe Systems several

times in the past and appreciate the products high quality.

Fmd: hobas.poland@hobas.com

Click on the picture or the below

link to watch a short video about

the installation in Gdask.

http://bit.ly/1GuANDU

h PipeLine | Issue 2/2015 | Page 07

h GRP Pipe: Jack Of All Trains

Interview with Kimberly Paggioli, Vice President of

Quality Control & Marketing at HOBAS Pipe USA

The American Railway Engineering and Maintenance-of-Way Association (AREMA) has recently added fiberglass pipes to the 2015 edition of

AREMAs Manual for Railway Engineering. This means that HOBAS Pipes

are covered in the new specifications and may expand the use of HOBAS

Pipes use in rail applications. Kimberly Paggioli, vice president of quality

control and marketing at HOBAS Pipe USA, talks about the usage of HOBAS Fiberglass Pipes for railway projects in the US and in general.

easier to specify and use HOBAS Pipes under

railways. In fact, every time that a pipeline track

crosses a rail, the engineer or the contractor

needs to submit a permit by the owner of the

rights-of-way. This process may be significantly

expedited when the product that is utilized is

already included in these standard specifications.

What are the special challenges when it comes to jacking projects

beneath railways?

KIM: In the vast majority of rail crossings, the tracks must remain in use

and undisturbed during the pipe installation. This means that trenchless

methods are usually be utilized at these locations. Whether it is a culvert

relining or in the case of jacking of new pipes, HOBAS Pipes meet the

specifications developed by AREMA.

The AREMA committees that evaluate products do a very thorough job and accept only the

highest performing products. The inclusion in

the Manual is therefore a great testimony to the

quality of our pipes.

Which requirements do pipes that can be specified for such projects

need to fulfill?

KIM: The pipe must be structurally capable of handling the live road imposed by the rail above. In addition, the non-metallic nature of the HOBAS

Pipes ensures that the pipes will not be affected by stray electrical currents

that may be present. For this reason, often HOBAS Pipes are found to be

preferable over steel for casing applications. Finally, as well as meeting the

long-term performance requirements, HOBAS Pipes can be manufactured

with the required axial capacity to meet the jacking forces foreseen by the

installer.

Any other advantages that make HOBAS Pipes particularly suitable

for railway jacking?

KIM: Generally our pipes under railroads are for sanitary sewers, so their

corrosion-resistance is another important benefit. The tight tolerance

gasket-sealed joints yield a fast assembly and a leak-free performance.

HOBAS Pipes also feature a smooth, constant, non-absorbing

outer surface, resulting in lower jacking loads as well as safer

and longer possible jacking drives.

How challenging is it to get enter the AREMA

Specifications, and what exactly does this

mean/change for HOBAS in the US?

KIM: Our pipes have already been widely used

under various rails across the country dating

back to the late 1980s. However, now

with the inclusion of fiberglass pipe in the

AREMA specifications, it will be even

How many railway projects have already

been successfully realized by HPUSA?

KIM: So many I cant even count them. And

there are definitely many more to come.

The Manual for Railway Engineering (MRE) is an

annual publication released every April and may

be purchased at www.arema.org/catalog.aspx

If you have any further questions regarding the

usage of HOBAS CC-GRP Pipes for railway applications, please send an e-mail to

KPaggioli@HobasPipe.com.

h PipeLine | Issue 2/2015 | Page 08

Trenchless Project on the Rails with

h GRP Pipes

h Jacking Pipes Installed Beneath

Streetcar Track in Hungary

For safety reasons, the Hungarian public railway company MV has special requirements for

structures to be installed beneath railways. The only traditional pipe solution and material used to be

double steel pipes with grouted annular space.

In 2002, HOBAS obtained the individual permit from MV for a jacking project in Aszf with 18

meters De 820 (SN 32000, PN 1) pipes. HOBAS Pipes convinced the railway company in terms

of the materials structural properties, its resistance to stray current corrosion, long lifetime

and easy installation. As a result of this successful first project and after thorough tests and

calculations, MV granted HOBAS a general permit for railway projects in 2010. Numerous

projects have been successfully implemented ever since.

Year of construction

2007

Total length of pipeline

30 m

Diameter

De 1720

Pressure class

The creek rdgrok, also known as Devils Ditch, leads rain water from the Buda

Moutains into the Danube in Budapest. While the creek flows freely in the upper part of

the mountains, it runs through a culvert midway down. In Hvsvlgyi street in Budapest,

this culvert passes underneath a streetcar track. When it needed to be replaced in 2007, the

contractor opted for trenchless installation with HOBAS Pipes to keep the impact on

the environment and traffic as low as possible and to benefit from the GRP materials excellent features. 30 meters of pipe De 1720, SN 32000 were jacked beneath

the rails the project was completed to the contractors utmost satisfaction.

PN 1

Stiffness class

SN 32000

Advantages

Low impact on environment and traffic, optimal

structural properties

Fmd: hobas.hungary@hobas.com

Year of construction

2011

Length of pipe

36 m

Diameter

De 220,

pipe wall thickness 20 mm

Installation method

Auger boring

Application

Protective pipe

Contractor

ProRail

Advantages

Quick installation due to

push-to-fit couplings, light

but sturdy material, flexibility in pipe design

Auger Boring of Small Diameter

h Pipe Under Dutch Railway

In 2010, due to the establishment of

new industrial plants in Rotterdams

harbor, a new 10,000 volt power

line became necessary for sufficient

power supply. Since the railway

networks safety measures demand

a protective pipe for all pressure lines

and cables running beneath the railway, ProRail, the company in charge

of the Dutch railway network, set

about seeking for an adequate small

diameter solution.

Quick installation was a crucial factor, so

that the usually employed GRE pipe which

has to be glued at the joints was ruled out.

ProRail turned to HOBAS Benelux: The

easy-to-handle, light weight HOBAS GRP

Pipes are quickly assembled due to their

push-to-fit couplings. HOBAS Benelux had been

an authorized supplier for pipelines undercrossing Dutch railways for a decade. Until then,

the smallest outside diameter for HOBAS GRP

listed by ProRail had been 427 mm. Thanks to

the flexibility in the design of HOBAS Pipes, the

required Jacking Pipes De 220 were produced

with a wall thickness of 20 mm to suit the

required maximal auger boring force of 148 kN

and to comply with all of the networks other

safety measures. The 36-meter host pipe was

installed in 4 meters depth within one day only.

The contractor was pleased with the result and

further small diameter auger boring and jacking

projects beneath the railway were implemented

with GRP, so that ProRail extended the listed

range of GRP diameters by DN 200.

Fmd: hobas.benelux@hobas.com

h PipeLine | Issue 2/2015 | Page 09

Jacking Beneath Railway and Street

Croatias Most Challenging Project

Realized with h Pipes

Year of construction

Slavonia is a region in eastern Croatia and known as the countrys breadbasket. To ensure a successful harvest, a reliable irrigation system is

necessary and this is why 513 m HOBAS Pipes De 2047 have been

jacked as part of a large-scale irrigation project.

2011

Construction time

3 months

Total length of pipeline

513 m

Croatias so far most challenging jacking project, realized with

HOBAS Pipes by the construction company and jacking expert Aquaterm,

passes beneath a highway and a railroad line. Three parallel sections were

drilled as planned in order to align the jacking pipes accurately. Heavy rain

and snowfall during the construction works posed a challenge to both

the workers and the equipment, but not to HOBAS Pipes, which can be

laid regardless of weather conditions. The project attracted strong interest from the entire Alps-Adriatic region: Experts in the fields of design,

construction, and finances from Croatia, Bosnia, Serbia, and Slovenia

visited the site and were introduced to jacking technologies.

Diameter

De 2047,

pipe wall thickness 65 mm

Pressure class

PN 1

Stiffness class

SN 32000

Application

Irrigation pipeline

Investor

Hrvatske Vode

The investor is more than satisfied with the unique characteristics of

HOBAS Products and the quick installation as a matter of fact, he used

HOBAS Pipes of the same diameter in a follow-up order for another irrigation project.

Designer

Institut IGD d.d.,

Krimir Gali d.i.g.

Contractor

Aquaterm d.o.o. Karlovac

Advantages

Fmd: hobas.croatia@hobas.com

Short installation time,

low weight, abrasion

resistance, low life cycle

costs

h PipeLine | Issue 2/2015 | Page 10

Russian Railways Authorize

h Products

GRP Pipes Jacked under Railway

Year of construction

2013

Construction time

4 months

Only few pipe producers offer a broad range of technical solutions and are authorized to install their products beneath Russian rail tracks. In order to receive approval, the products

need to comply with the requirements and standards of the Russian Railways (RD),

one of the three largest rail companies worldwide. Safety is absolutely essential.

Pipe length

137 m

Diameter

De 1414 and 1638

Pressure class

PN 1

Stiffness class

SN 32000 and 40000

Application

In summer 2012, RD granted HOBAS the permission to implement a pilot project

on the railway section between Surgut and Tobolsk in the Russian oblasts Samara

and Tjumen. A second rail track is under construction in this area, and the old

culvert running beneath it needed to be replaced, since the old corrugated steel

pipe showed heavy signs of corrosion that had affected its structural integrity.

In addition to this, the contractor asked for the installation of protective measures against flooding during the construction works and not to alter the natural

riverbeds. Disruptions to rail traffic should be avoided as well.

Culvert beneath rail

tracks

Installation method

Jacking,

open trench

Client

(Russian Railways RD)

Advantages

Given the circumstances, the contractor decided for HOBAS Pipes De 1434

which should be jacked directly next to the old pipe beneath the railway track

by means of auger boring. It was planned to first dispose of the spoil with an

auger transporting it through a steel casing. Once the boring head had made

its way through to the receiving pit, HOBAS GRP Pipes were connected to the

steel casing in the thrust pit and driven to the receiving pit. Subsequently,

HOBAS Pipes De 1638 were installed in open trench. For the duration of the

construction works on the rail around the site, trains were slowed to 40 km/h.

Thanks to trenchless installation, the train traffic could be maintained.

Corrosion and abrasion

resistance, high

structural integrity,

easy installation

HOBAS Products not only scored with their structural properties and corrosion

resistance (especially regarding stray currents) but also with a long service life and

easy installation. The construction works were completed in October 2012, after four

months only and to the complete satisfaction of everyone involved.

After this projects success, RD gave HOBAS Russia

the official authorization for using HOBAS Products

also in future projects that run beneath the

Russian railway.

Fmd: hobas.russia@hobas.com

h PipeLine | Issue 2/2015 | Page 11

Make Way for the Train with h

h GRP Pipes Jacked Under

Railway Track in Tinec, CZ

Pipelines crossing traffic routes, streams or buildings pose a big

challenge to contractors. Detours and the therefore required pipeline extension would in many cases increase costs considerably

so that they could sometimes not be implemented. A common

solution for this problem is therefore trenchless installation

with HOBAS Pipes such as was the case in Tinec, Czech

Republic, where HOBAS Pipes were jacked beneath a

railway track.

The construction of the 330 m long sewer line started in

November 2010, when winter set in with heavy snow falls

and freezing cold temperatures. These unfriendly conditions represented, however, no obstacle for HOBAS Pipes

which can be installed regardless of cold or hot temperatures. Jacking was conducted without difficulties in frostfree depth.

Several tracks intersect at the rail junction in Tinec. The soil is

very stony in this area. In order to protect the GRP pipes from being damaged by the hard soil conditions, the contractor opted for a

three-step jacking process: After the pilot drill, protective steel casings

were pushed through the soil before the GRP pipes were installed. Since

it was assumed that the steel would gradually corrode due to stray currents

from the railway tracks, the HOBAS Pipes De 427 were designed to provide

full, autonomous structural stability. GRP Pipes, on the contrary, are nonconductive and therefore insensitive to magnetic fields. In the end, the

remaining annulus was filled with a cement/fly-ash mixture.

Fmd: hobas.czech@hobas.com

Year of construction

Application

2010-2011

Sewer

Total length of pipeline

Client

330 m

Glasspol Krom

Diameter

Contractor

De 427

Michlovsk

Pressure class

protlaky a.s. Zln

PN 1

Advantages

Stiffness class

Temperature and cor-

SN 100000

rosion resistance, long-

Installation

term structural stability,

Jacking

leak-tightness

h PipeLine | Issue 2/2015 | Page 12

Polish Railway Project on the Fast Track

with h

Microtunneling GRP Culverts under the

E65 Railway Line

Year of construction

2010 - 2011

Total length of pipeline

94 m

Diameter

De 1720, De 2047

The construction of HOBAS Culverts beneath the railway line in the

area of Ciechanw was carried out as part of the nationwide project

Modernization of E65 Warsaw Gdynia Railway Line. The

main aims of this extensive project were to improve travel

comfort, increase safety and shorten the journey by

27 minutes on this 103-km-long section.

Pressure class

PN 1

Stiffness class

SN 64000

SN 100000

Application

Stormwater,

animal passageways

Installation method

Microtunneling

An initial idea was to construct the culverts under the

railway line near Ciechanw in open trench. In order

to save time and respect the given time schedule,

the method was, however, abandoned in favor of

microtunneling. HOBAS Pipes were jacked to establish

three culverts 16, 24 and 32 meters in length, with an

external diameter of 1720 mm and a nominal stiffness of

100000 kN/m. Another 22-meter section was implemented with HOBAS Pipes De 2047, SN 64000.

Client

PKP Polskie Linie

Kolejowe S.A.

Contractor

Przedsibiorstwo

Przewiertowe MOTYL

Advantages

Quick installation,

The client, the Polish State Railways (PKP Polskie Linie Kolejowe S.A.), was already

familiar with HOBAS Products, which are technically approved by the Road and Bridge Research Institute (IBDiM) and the Polish Railway Institute (IK). The first HOBAS GRP Railway

Culvert, a DN 1300 section, had been installed under the E20 railway at Mienia in 2003. One

year later, the second followed at Ostrw Wielkopolski using a pipe with an external diameter

of 2047 mm. In 2005, a line De 1229 to 1434 in diameter had been installed under the railway

between Misk Mazowiecki and Terespol. Numerous further projects followed.

corrosion resistance

The engineering team from HOBAS worked closely with the design office in order to determine

adequate stiffnesses for the pipes, and the load capacity was calculated on the basis of the finite

element method (FEM). Highly experienced in directional drilling and similar jobs, the Polish

contractor Przedsibiorstwo Przewiertowe MOTYL made sure that microtunneling ran smoothly

and was completed successfully. In order to streamline the installation process and save on time,

the company ordered angular cut pipes and equipped these with precast headwalls from HOBAS

Poland. This way, the works were completed in a couple of days only.

Constantly scrutinizing and double checking the performance of pipes to provide clients with

optimal solutions, HOBAS decided to monitor the performance of the employed De 2047 pipes. To

this end, external experts in strength analysis were assigned to measure the pipes before and after

they were installed. After two years of operation they will be measured once again for final results.

Fmd: hobas.poland@hobas.com

Вам также может понравиться

- Ashgate Practical Building Conservation Timber Contents PDFДокумент6 страницAshgate Practical Building Conservation Timber Contents PDFDaniel Alvarez33% (6)

- Civil Engineering for Underground Rail TransportОт EverandCivil Engineering for Underground Rail TransportJ. T. EdwardsРейтинг: 5 из 5 звезд5/5 (2)

- Heritage Architecture (Ivatan House)Документ45 страницHeritage Architecture (Ivatan House)Hazel Acidre100% (1)

- Velocity StringsДокумент2 страницыVelocity StringsCarlos LiscanoОценок пока нет

- Electrical Wiring PlanДокумент39 страницElectrical Wiring PlanniloОценок пока нет

- 1502 HOBAS-PipeLine Railway-Jacking PDFДокумент12 страниц1502 HOBAS-PipeLine Railway-Jacking PDFSaif AlkatbОценок пока нет

- Replacement of Existing Railway BridgeДокумент9 страницReplacement of Existing Railway BridgeIrwan JoeОценок пока нет

- Curve Jacking - Paper Bangkok T-1ThorenДокумент10 страницCurve Jacking - Paper Bangkok T-1ThorenCheng KimHuaОценок пока нет

- Prague Metro - Line C Extension: J. KunakДокумент6 страницPrague Metro - Line C Extension: J. KunakHarold TaylorОценок пока нет

- January 2009Документ52 страницыJanuary 2009gifanta100% (2)

- Millennium Bridge PDFДокумент8 страницMillennium Bridge PDFPetra IlijevicОценок пока нет

- Joep Tunnissen AbsДокумент23 страницыJoep Tunnissen AbsAnonymous IwqK1NlОценок пока нет

- Leighton LRДокумент12 страницLeighton LRKhuba Ni Kun Al100% (1)

- 07-International Experiences in Tunnelling - Budapest Metro Line-Nigel ButterfieldДокумент23 страницы07-International Experiences in Tunnelling - Budapest Metro Line-Nigel ButterfieldPrashant PatilОценок пока нет

- Cau My ThuanДокумент2 страницыCau My ThuanTrần Bé ThêuОценок пока нет

- Your Solution Network: Middle EastДокумент24 страницыYour Solution Network: Middle EastDrPadipat ChaemmangkangОценок пока нет

- Review of The Project With Regards On The TBM Specific Parts and ChallengesДокумент52 страницыReview of The Project With Regards On The TBM Specific Parts and Challenges2sangjun75Оценок пока нет

- Recent Major Arch BridgesДокумент20 страницRecent Major Arch Bridgesi love you babyyОценок пока нет

- Concrete Bridges in GermanyДокумент12 страницConcrete Bridges in GermanydelujaОценок пока нет

- Large Diameter Pipe Roof Box Excavation For Passenger Linkway TunnelДокумент14 страницLarge Diameter Pipe Roof Box Excavation For Passenger Linkway TunnelMH Enc Const TrdОценок пока нет

- Railway Over Bridge Training ReportДокумент50 страницRailway Over Bridge Training ReportMitulChopra100% (1)

- Project Reference Catalogue: Bridge Design ServicesДокумент19 страницProject Reference Catalogue: Bridge Design ServiceswpchengОценок пока нет

- A351Документ2 страницыA351Evonne LeeОценок пока нет

- Abdichtung Uetliberg TunnelДокумент12 страницAbdichtung Uetliberg Tunneljoje2010Оценок пока нет

- 02 Cable Stay Suspension Extradosed Bridges HДокумент16 страниц02 Cable Stay Suspension Extradosed Bridges HdziktadzikkОценок пока нет

- The HONG-KONG-ZHUHAI MACAO Bridge - The HONG-KONG Link RoadДокумент9 страницThe HONG-KONG-ZHUHAI MACAO Bridge - The HONG-KONG Link RoadFerga VanessaОценок пока нет

- I S S U E T W O 1 9 9 7: Mount Rushmore Parking Garage - USAДокумент16 страницI S S U E T W O 1 9 9 7: Mount Rushmore Parking Garage - USADrPadipat ChaemmangkangОценок пока нет

- Chenab Bridge DesignДокумент8 страницChenab Bridge DesignMahendra SuryavanshiОценок пока нет

- Pipe Jacked TunnelsДокумент10 страницPipe Jacked Tunnelsretk0801Оценок пока нет

- Design, Fabrication and Construction of Railway Bridge Over Södertälje CanalДокумент10 страницDesign, Fabrication and Construction of Railway Bridge Over Södertälje CanalOscarKonzultОценок пока нет

- Railways Tunnels and Airport Case StudyДокумент9 страницRailways Tunnels and Airport Case Study1DS20CV446 Sai Vinay GОценок пока нет

- 205 Paper 350 - Design of The SMART Project-AДокумент12 страниц205 Paper 350 - Design of The SMART Project-Aodri5Оценок пока нет

- Bappler - 2017 TBM APPLICATIONS FOR SHORT TUNNELSДокумент9 страницBappler - 2017 TBM APPLICATIONS FOR SHORT TUNNELSPaloma CortizoОценок пока нет

- Esveld - Recent Development of SlabtrackДокумент5 страницEsveld - Recent Development of SlabtrackIrwan JoeОценок пока нет

- Case Study Cable Stayed Bridge 5 PagДокумент5 страницCase Study Cable Stayed Bridge 5 PagBravo Paytano BryanОценок пока нет

- Major Reference PDFДокумент51 страницаMajor Reference PDFJacky LeongОценок пока нет

- FRP Bridges 2012 Dawlish Footbridge Paper Kendall Smith GoughДокумент14 страницFRP Bridges 2012 Dawlish Footbridge Paper Kendall Smith GoughDavid Kendall100% (1)

- Infrastructure Tunnel ConstructionДокумент24 страницыInfrastructure Tunnel ConstructionAntonio RamosОценок пока нет

- Bandra Worli Sea LinkДокумент18 страницBandra Worli Sea LinkEticala RohithОценок пока нет

- DPR CorrectedДокумент23 страницыDPR CorrectedVikhyat GoudОценок пока нет

- Viable TBM Applications For Short Tunnel Drives 900 MetersДокумент11 страницViable TBM Applications For Short Tunnel Drives 900 MetersPaloma CortizoОценок пока нет

- 10.3 Micropile Foundations - The Easy Way - Brandner PDFДокумент11 страниц10.3 Micropile Foundations - The Easy Way - Brandner PDFVandolph Quilab LozanoОценок пока нет

- Underground StructuresДокумент12 страницUnderground StructuresmctrtОценок пока нет

- Case Study For The Hong Kong Zhuhai Macau BridgeДокумент29 страницCase Study For The Hong Kong Zhuhai Macau BridgeAli ImranОценок пока нет

- Sutong BridgeДокумент8 страницSutong BridgeDhindeM100% (1)

- Immersed Tunnels: in The Permanent Stage Is Kept at AДокумент1 страницаImmersed Tunnels: in The Permanent Stage Is Kept at AmaherelabdОценок пока нет

- Innovative Shield Tunnel Constructions at The Betuweroute in The NetherlandsДокумент10 страницInnovative Shield Tunnel Constructions at The Betuweroute in The NetherlandsHarold TaylorОценок пока нет

- Pipa JackingДокумент8 страницPipa Jackingfikri ramadhanuОценок пока нет

- VSL News 1998 2Документ16 страницVSL News 1998 2DrPadipat ChaemmangkangОценок пока нет

- Design and Construction of Toorak Road Multi-spanRailBridge-FINALДокумент12 страницDesign and Construction of Toorak Road Multi-spanRailBridge-FINALKiRa LatentОценок пока нет

- 1.1 General: Chabahil Road in Kathmandu District, BagmatiДокумент25 страниц1.1 General: Chabahil Road in Kathmandu District, Bagmatienlacer009Оценок пока нет

- Tram Plan Calls For Bridge Variety: Steel SpotlightДокумент5 страницTram Plan Calls For Bridge Variety: Steel SpotlightMarshall BravestarОценок пока нет

- Rich Text Editor FileДокумент12 страницRich Text Editor FilesaritasohamОценок пока нет

- Vibratory Hammer PTC 4PHF Reinforcing Bridge Piers France PDFДокумент1 страницаVibratory Hammer PTC 4PHF Reinforcing Bridge Piers France PDFerkegroupОценок пока нет

- Slab Track NBU SystemДокумент8 страницSlab Track NBU SystemSima ViorelОценок пока нет

- Meier Et Al CFRP HangerДокумент11 страницMeier Et Al CFRP HangerKarthik SNОценок пока нет

- Immersed TunnelsДокумент3 страницыImmersed TunnelsAndrés García CaseroОценок пока нет

- CH116 PDFДокумент8 страницCH116 PDFMercedez BenzОценок пока нет

- Submerged Floating TunnelsДокумент15 страницSubmerged Floating TunnelsVijay PowarОценок пока нет

- A Guide to Some of the Equations used in Constructing a Suspension BridgeОт EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeОценок пока нет

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsОт EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsОценок пока нет

- Building Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksОт EverandBuilding Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksОценок пока нет

- Bi-Directional Load TestДокумент64 страницыBi-Directional Load TestAnonymous zpNy2blt100% (3)

- Devi Heating CalculationДокумент2 страницыDevi Heating CalculationJohn AriesОценок пока нет

- Kirloskar 6R1080TA 21-40Документ20 страницKirloskar 6R1080TA 21-40Niten GuptaОценок пока нет

- 3889-Article Text-8520-1-10-20180712Документ17 страниц3889-Article Text-8520-1-10-20180712JohnОценок пока нет

- Uji Petik DT Ob 022022Документ11 страницUji Petik DT Ob 022022RaynaldiSaputraОценок пока нет

- Elgaaly1997 PDFДокумент11 страницElgaaly1997 PDFAsr FlowerОценок пока нет

- LAboratory Evaluation CTB - TRRДокумент10 страницLAboratory Evaluation CTB - TRRVINEESHA CHUNDIОценок пока нет

- Troubleshooting The Positive Displacement RotaryДокумент4 страницыTroubleshooting The Positive Displacement Rotaryابو المعالي الهمامОценок пока нет

- LEVEL GAUGE DATASHEET-Rev.AДокумент8 страницLEVEL GAUGE DATASHEET-Rev.Asugeng wahyudiОценок пока нет

- Sewerage Sanitation PlanДокумент18 страницSewerage Sanitation PlanlengjavierОценок пока нет

- ARaymond Energies PowAR-Slot Datasheet EE-2019-0312-ENДокумент2 страницыARaymond Energies PowAR-Slot Datasheet EE-2019-0312-ENSivaОценок пока нет

- 00 AWWA StandardsДокумент3 страницы00 AWWA Standardsliviu_dovaОценок пока нет

- MBT Coupler BrochureДокумент8 страницMBT Coupler BrochureRay RamiloОценок пока нет

- Petronas STDДокумент64 страницыPetronas STDNad DiyaОценок пока нет

- NSDC - ADVANCE CERTIFICATE IN SAFETY HEALTH AND ENVIRONMENT MANAGEMENT SyllabusДокумент16 страницNSDC - ADVANCE CERTIFICATE IN SAFETY HEALTH AND ENVIRONMENT MANAGEMENT Syllabusbasant26Оценок пока нет

- Aermec FCX Technical Manual EngДокумент72 страницыAermec FCX Technical Manual Engzlobcek0% (1)

- Category Business Name Phone CityДокумент24 страницыCategory Business Name Phone CityMadhav PatilОценок пока нет

- Prestress ConcreteДокумент19 страницPrestress ConcreteAbdulrhman Abduelgassim OsmanОценок пока нет

- ElecticalSafety HighVoltageДокумент3 страницыElecticalSafety HighVoltagesiswoutОценок пока нет

- Earthen DamДокумент11 страницEarthen Dam20CE015 Swanand DeoleОценок пока нет

- KF Components VacotecДокумент13 страницKF Components Vacotecaldo2306Оценок пока нет

- Seepage Flow Net FDMДокумент68 страницSeepage Flow Net FDMRenalyn AndradeОценок пока нет

- Astm A572Документ4 страницыAstm A572udaykiranorange100% (2)

- Astm A761Документ8 страницAstm A761Carlos Andres Caballero ReyesОценок пока нет

- New Microsoft Office PowerPoint PresentationДокумент9 страницNew Microsoft Office PowerPoint PresentationRAMA MОценок пока нет

- BG153 Rev 1Документ1 страницаBG153 Rev 1SyОценок пока нет