Академический Документы

Профессиональный Документы

Культура Документы

View PDF

Загружено:

MaheshИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

View PDF

Загружено:

MaheshАвторское право:

Доступные форматы

2nd Post Combustion Capture Conference (PCCC2)

New Process simulation and improvement of CO2 removal system

using aqueous MEA in coal-fired power plant

Hongxia Gaoa, Teerawat Semaa, Zhiwu Lianga,b*, Paitoon Tontiwachwuthikula,b

a

Joint International Center for CO2 Capture and Storage (iCCS), College of Chemistry and Chemical Engineering,

Hunan University, Changsha, 410082, P.R. China

b

International Test Centre for CO2 Capture (ITC), Faculty of Engineering and Applied Science,

University of Regina, Regina, Saskatchewan, S4S 0A2, Canada

(Corresponding Authors Email: zwliang@hnu.edu.cn)

Keywords: CO2 capture; ProMax Simulation; re-boiler heat duty; Novel Process

ABSTRACT

By far, an amine-based CO2 capture technology is one of the most promising options for reducing CO2 emissions

from fossil fuel-fired power plant due to its commercially maturity, cost efficiency, and convenience to retrofit into

existing power plants. However, an energy consumption to break down the chemical link between CO2 and the

amine-type absorbent is relatively high. Owing to the advantages of monoethanolamine (MEA) such as high

absorption rate, low cost, MEA, which is the most well studied chemical solvent for CO2 capture, is considered to be

the state-of-the-art absorbent, and it is the type of solvent used in this study.

Thanks to the ever-accelerated pace of computer technology, computer-aided numerical simulation has enjoyed

great popularity in modeling process unit or optimizing process-configuration with the aims of quality improvement

and cost reduction. Over the past decades, many researchers have widely simulated the amine absorption CO2

capture process for process research and design in the area of CO2 removal by using commercial process simulators

(e.g., Aspen plus, Aspen HYSYS, ProMax). ProMax3.0 has simple specifier and simple solver options that specify

numerical relationship among necessary process variables and that is, thus, useful for controlling the process so that

it meets users requirements. For simulation re-boiler heat duty of stripper, the ProMax results have been found to be

closer to the results of pilot plant tests compared with others commercial process simulators (Tontiwachwuthikul P.

et al, 2011).

MEA-based CO2 capture process needs relatively higher re-boiler heat duty, thus giving rise to more efforts to

create advanced configurations to further reduce the heat requirement. Recent industrial work in industry has also

shown interest in the development of more complex configurations with higher efficiency. In recent years, lots of

advanced and promising process configurations have been proposed to lower heat consumption, such as a MEA split

draw process (Chang and Shih ,2005) and a multi-pressure stripper process configuration (Rochelle et al., 2006).

Moreover, there are many other alternative process configurations based on the modification of the baseline process,

such as AMPSSPIASP, ASSP, AIESP, AVSP. Although these reductions of heat duty are enormously encouraging,

they are far from enough. Heat pump distillation uses the latent heat of water and the heat output is three times

higher than the consumption of mechanical energy through the compressor, so this technology is a favorable

measurement of energy saving and consumption reduction. However, none of studies has considered the integration

of carbon capture system with heat pump distillation into coal-fired power plant.

In this study, the MEA-based capture process model of a 300 MW coal-fired power plant was established and

simulated using Promax3.0. A base case was defined in which the total inlet gas flow to the absorber was 40,000

kmol/hr containing 14.6 mol% CO2. Two innovative absorption/stripping process configurations for CO2 removal,

(namely, absorption split stripping process (ASSP) and heat pump distillation process with split flow (HPDP-ASSP),

as shown in Figure 1) were taken into consideration. Based on the principle of systemic heat integration and the

sensitivity analysis of simulation results that focus on the effects of a range of variables on the re-boiler duty, a

highly efficient heat-integration process configuration that can obviously decrease the regenerating heat was created

and successfully simulated. The influence of the CO2 lean loading on the re-boiler duty for the MEA-based CO2

capture process and the HPDP-ASSP is illustrated in Figure 2.By combining heat pump system process with

improved split flow, it leads to a very significant reduction of re-boiler duty by 37.7% when CO2 lean loading is

0.25, as compared to the conventional process.

Figure 1.Heat pump distillation process with Split flow

Figure 2 The effects of the CO2 lean loading on reboiler duty

Acknowledgment: The financial supports from National Natural Science Foundation of China (No. 21250110514

and No. 21276068) and Ministry of Science and Technology of China (No. 2012BAC26B01) are gratefully

acknowledged.

References

1. Idem R., Tontiwachwuthikul P., Gelowitz D.. Energy Procedia 4, 2011,1707-1712.

2. Chang, H., Shih, C.M.. Separation and Purification Technology, 2005,40 (4), 877-909.

3. Jassim, M.S., Rochelle, G.T.. Ind. Eng. Chem. Res. 2006 ,45, 2465-2472.

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

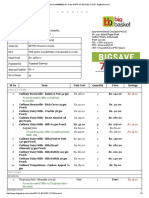

- Invoice #6006922 For Order # BPFVO-6012102-211215 - BigBasketДокумент2 страницыInvoice #6006922 For Order # BPFVO-6012102-211215 - BigBasketMahesh0% (1)

- Bendik Sen 1991Документ10 страницBendik Sen 1991MaheshОценок пока нет

- 1101.0969 2 PDFДокумент10 страниц1101.0969 2 PDFMaheshОценок пока нет

- PH Coagulant DosageДокумент6 страницPH Coagulant Dosageromdhan88Оценок пока нет

- REfrigeration CO2 GuidelinesДокумент7 страницREfrigeration CO2 GuidelinesMaheshОценок пока нет

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Документ33 страницыSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2MaheshОценок пока нет

- Strategic Investment Analysis - PINSДокумент10 страницStrategic Investment Analysis - PINSMaheshОценок пока нет

- AFT Fathom InstallationДокумент1 страницаAFT Fathom InstallationMaheshОценок пока нет

- Reid Vapour Pressure Methods in HYSYSДокумент3 страницыReid Vapour Pressure Methods in HYSYSMahesh100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- AutoRecovery 1 Save of Lab Report Template With Grading Rubric (1) .AsdДокумент5 страницAutoRecovery 1 Save of Lab Report Template With Grading Rubric (1) .AsdMohammed ElnaggarОценок пока нет

- Uv Vis SpectrophotometerДокумент8 страницUv Vis SpectrophotometerFath Bond100% (1)

- Behavior and Analysis of A Curved and Skewed I-Girder BridgeДокумент17 страницBehavior and Analysis of A Curved and Skewed I-Girder BridgeaapennsylvaniaОценок пока нет

- MA5630 Term Project ReportДокумент22 страницыMA5630 Term Project ReportvamshiОценок пока нет

- NCGD ProcedureДокумент2 страницыNCGD ProcedureAhmad ArifОценок пока нет

- Taylor Patterns For Discrete Arrays: Alfred T. VilleneuveДокумент5 страницTaylor Patterns For Discrete Arrays: Alfred T. VilleneuveKorbi SchramlОценок пока нет

- Art 1 Jeopardy Final ReviewДокумент53 страницыArt 1 Jeopardy Final Reviewapi-243273616Оценок пока нет

- Psabits WithanswersДокумент12 страницPsabits WithanswersChinnareddy KarriОценок пока нет

- Private - Lost Secrets of The Sacred Ark (16288949)Документ10 страницPrivate - Lost Secrets of The Sacred Ark (16288949)Gordon Scott TaylorОценок пока нет

- Chapt 6Документ15 страницChapt 6morphos777Оценок пока нет

- Nmat Physics Simulations (Mock 2) DIRECTIONS: Select The Best Answer To Each of TheДокумент4 страницыNmat Physics Simulations (Mock 2) DIRECTIONS: Select The Best Answer To Each of TheCin 0322Оценок пока нет

- Detonation N Pre-IgnitionДокумент9 страницDetonation N Pre-IgnitionSanthosh RamananОценок пока нет

- 00030316-Correlaciones PVT Crudo PesadoДокумент16 страниц00030316-Correlaciones PVT Crudo PesadoJohn Edinson Rodriguez FajardoОценок пока нет

- Mitutoyo - Czujniki Linear Gage - PRE1474 (2) - 2018 ENДокумент64 страницыMitutoyo - Czujniki Linear Gage - PRE1474 (2) - 2018 END.T.100% (1)

- HW 14 SolutionsДокумент8 страницHW 14 SolutionsSeleneblueОценок пока нет

- Calculus Cheat Sheet Derivatives ReducedДокумент2 страницыCalculus Cheat Sheet Derivatives ReducedsumitОценок пока нет

- Medium Voltage - CELLPACKДокумент12 страницMedium Voltage - CELLPACKfreddysh4330Оценок пока нет

- Romain - Lemoine - Final - Hydrodynamics, Mass Transfer and Modeling of The Toluene Oxidation ProcessДокумент399 страницRomain - Lemoine - Final - Hydrodynamics, Mass Transfer and Modeling of The Toluene Oxidation Processandrei12320003181Оценок пока нет

- DFT With Plane Waves, PseudopotentialsДокумент22 страницыDFT With Plane Waves, PseudopotentialsIsmael Antonio González RamirezОценок пока нет

- FluorosensДокумент14 страницFluorosensabdul wahidОценок пока нет

- Design Charts For Vertical Drains Considering Soil DisturbanceДокумент10 страницDesign Charts For Vertical Drains Considering Soil DisturbanceSABEASNОценок пока нет

- Review Article: Liposomes For Use in Gene DeliveryДокумент13 страницReview Article: Liposomes For Use in Gene DeliveryParagRoyОценок пока нет

- Hysteresis Modelling For A MR Damper: Rmm@itesm - MX (Ruben Morales-Menendez)Документ9 страницHysteresis Modelling For A MR Damper: Rmm@itesm - MX (Ruben Morales-Menendez)dvarsastryОценок пока нет

- Basics of Process SimulationДокумент36 страницBasics of Process SimulationArjun GujarОценок пока нет

- Structural Report BMU 13 Revere Place Brooklyn.Документ10 страницStructural Report BMU 13 Revere Place Brooklyn.Laura MajjulОценок пока нет

- Experimental Aerodynamic Analysis of Delta WingДокумент8 страницExperimental Aerodynamic Analysis of Delta WingShiva UОценок пока нет

- MCQ PhysicsДокумент19 страницMCQ PhysicsAshok KumarОценок пока нет

- New Insights Into The Removal of Calcium SulfateДокумент10 страницNew Insights Into The Removal of Calcium SulfatetsanshineОценок пока нет

- Earth Electrode Resistance PDFДокумент28 страницEarth Electrode Resistance PDFChathura PriyankaОценок пока нет

- Funteachtic Learning Center Bulalacao Bldg. P. Zamora ST., Batangas CityДокумент2 страницыFunteachtic Learning Center Bulalacao Bldg. P. Zamora ST., Batangas CityLorna HerillaОценок пока нет